A method for purifying and concentrating plutonium

A plutonium nitrate and extraction technology is applied in the field of purification and concentration of plutonium, which can solve the problems of serious solvent radiolysis effect, adverse effect of stripping effect, and reducing the plutonium stripping yield, and achieves short time consumption, small radiolysis effect, The effect of simplifying method steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

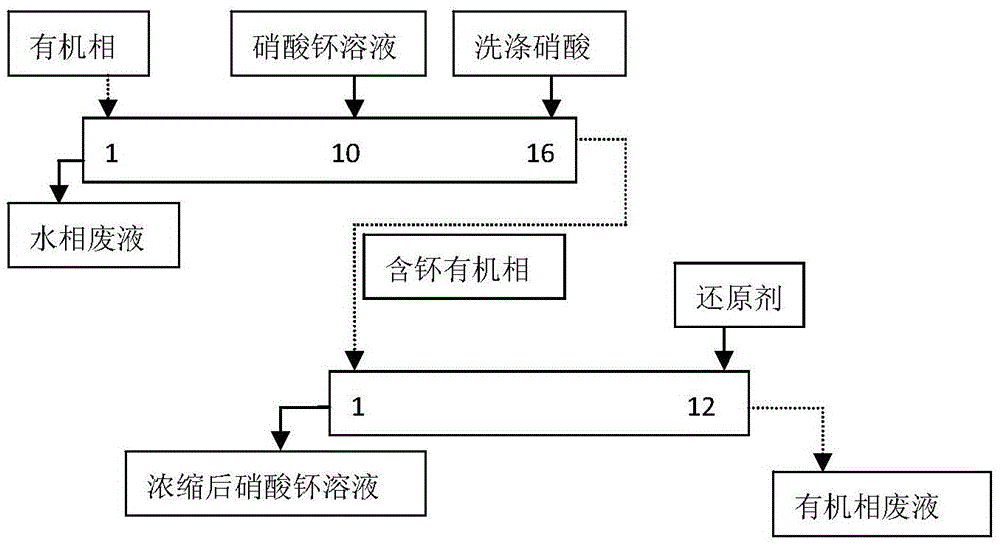

[0030] The purification and concentration of plutonium is carried out in a centrifugal extractor. This method includes two steps of extraction and stripping. The process flow of the method is as follows: figure 1 shown.

[0031] (1) Extraction

[0032] The Pu(IV) in the plutonium nitrate solution composed of 3.3g / L plutonium-3.5mol / L nitric acid is extracted into the organic phase 30% TBP-kerosene solution, and the Zr is further purified while the Pu(IV) is concentrated. , Ru and other splinter elements; the volume of 30% TBP-kerosene is 1 / 4 of the plutonium nitrate solution. The number of extraction stages is 10. Then wash with 1mol / L nitric acid, the number of washing stages is 6.

[0033] (2) Stripping

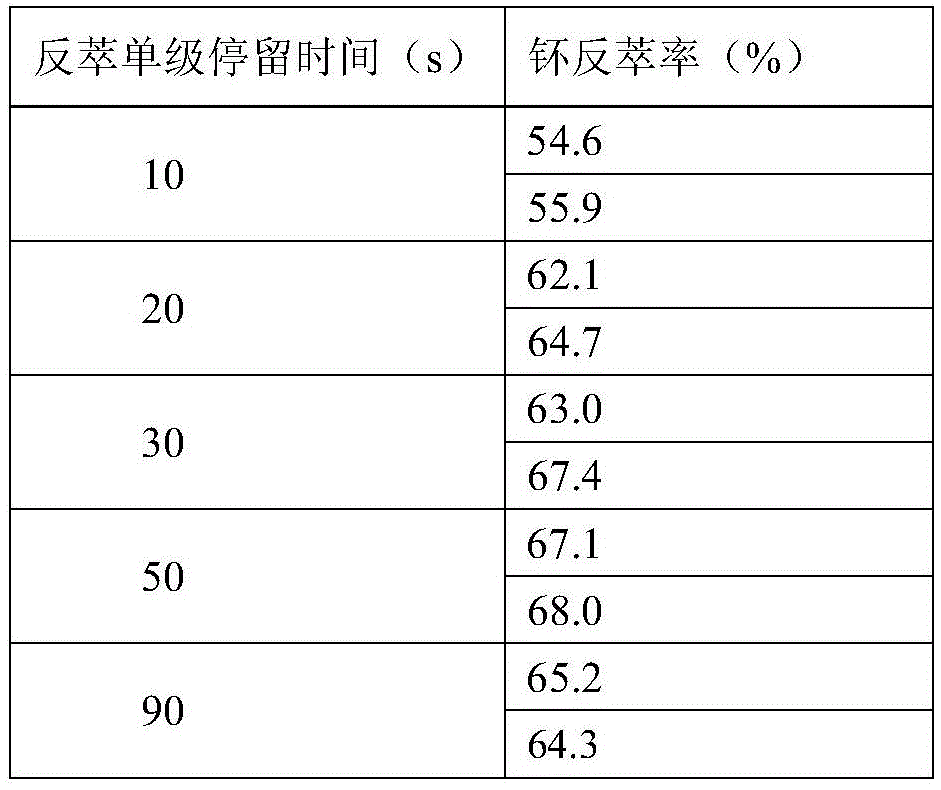

[0034] Pu(Ⅳ) in 30% TBP-kerosene solution was reduced to Pu(Ⅲ) by using nitric acid solution containing dimethylhydroxylamine as a reducing agent, and Pu(Ⅲ) was back-extracted into the water phase, so that the plutonium nitrate solution was purified and concentrated. W...

Embodiment 2

[0039] The same method and steps as in Example 1, except that the volume of 30% TBP-kerosene in step (1) is 1 / 3 of the plutonium nitrate solution, and the number of extraction stages is 11. Then wash with 1.5mol / L nitric acid, the number of washing stages is 7.

[0040] The volume of the nitric acid solution containing dimethylhydroxylamine in step (2) is 1 / 3 of the 30% TBP-kerosene solution. The number of stripping stages is 13, and the concentration of dimethyl hydroxylamine is 0.8mol / L.

[0041] The bench test results are: under the given process conditions, the plutonium extraction yield is 99.93%, the plutonium back-extraction yield is 99.98%, and the plutonium concentration in the concentrated plutonium nitrate solution is 30.5g / L.

Embodiment 3

[0043] The same method and steps as in Example 1, except that the volume of 30% TBP-kerosene in step (1) is 1 / 4 of the plutonium nitrate solution, and the number of extraction stages is 12. Then wash with 1.5mol / L nitric acid, the number of washing stages is 8.

[0044] The volume of the nitric acid solution containing dimethylhydroxylamine in step (2) is 1 / 3 of the 30% TBP-kerosene solution. The number of stripping stages is 14, and the concentration of dimethyl hydroxylamine is 1mol / L.

[0045] Bench test results are: under the given process conditions, the plutonium extraction yield is 99.91%, the plutonium stripping yield is 99.99%, and the plutonium concentration in the concentrated plutonium nitrate solution is 40.2g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com