Method of reducing optical fiber coloring unevenness and apparatus thereof

A technology of uneven coloring and optical fiber, applied in the field of optical fiber manufacturing, can solve the problems of poor air tightness of plastic tanks, uneven coloring, uneven coloring of optical fibers, etc., and achieve the effect of solving uneven coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

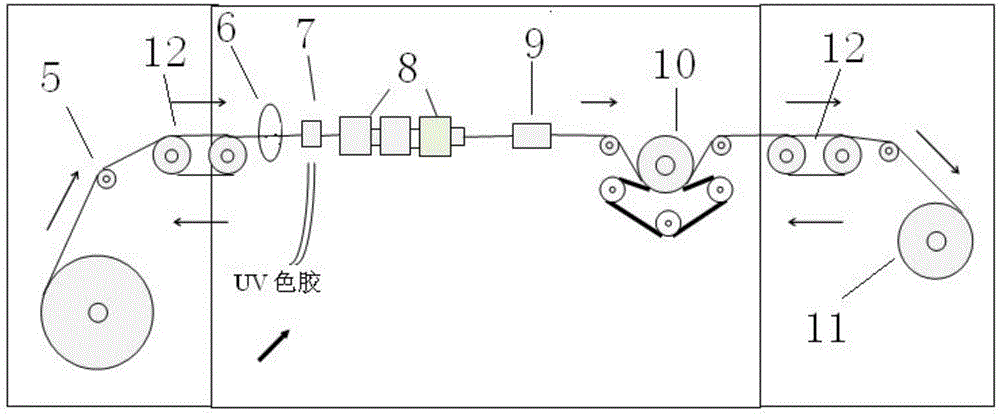

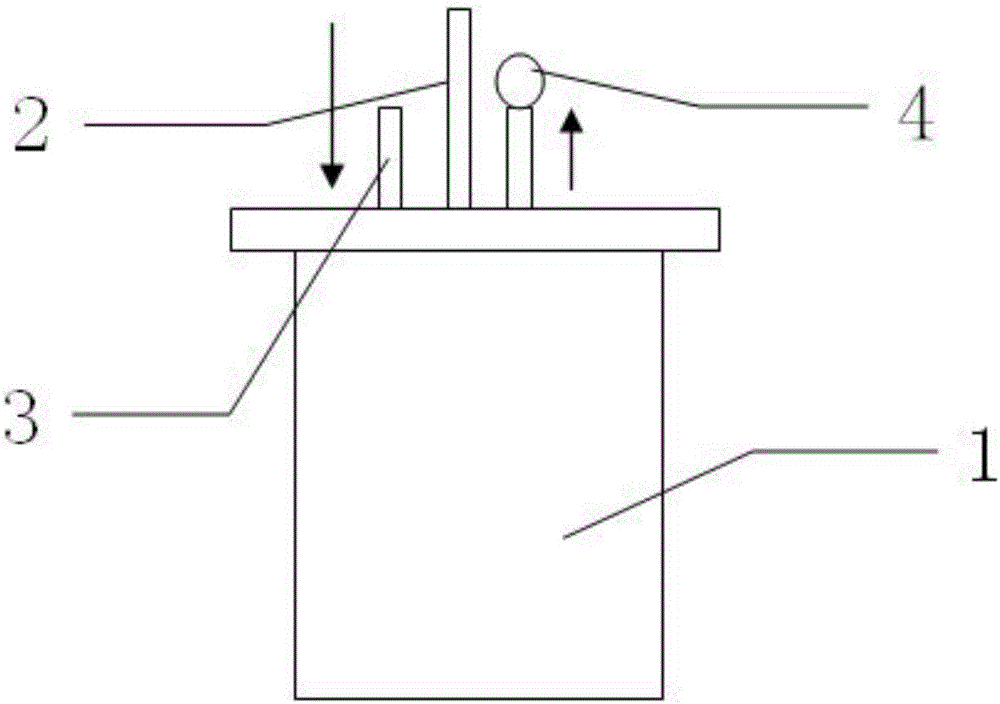

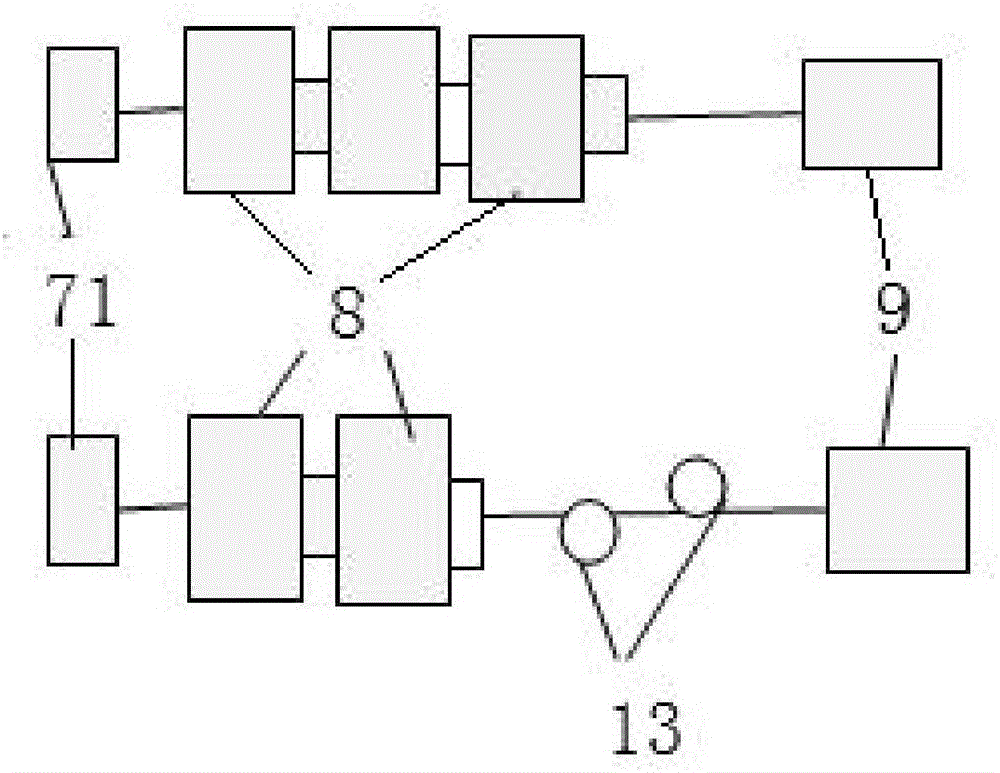

[0025] Such as figure 1 , the method for reducing the uneven coloring of the optical fiber of the present invention includes: the step of making the optical fiber coloring uniform by reducing the eccentricity of the optical fiber: before assembling the optical fiber, a laser is set between the pay-off reel and the eye mask mold base, and the laser is located Pre-set center line, and along the set center line to irradiate the eye mask mold hole, after installing the eye mask, record the light spot situation projected by the laser on the eye mask, when the distance between any two points on the light spot is within the set When it is within the value range of , it is considered that the concentricity of the eye mask installation is good, and the optical fiber can be assembled. The steps to make the optical fiber color uniform by reducing the jitter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com