Fixed-pressure rolling tool

A constant pressure and rolling technology, which is applied in the field of rolling tools, can solve the problems that the sealing strip cannot be installed in place and affects the installation quality, and achieves the effect of simple structure and satisfactory installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The object of the invention of the present invention will be further described in detail below in conjunction with specific embodiments, wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

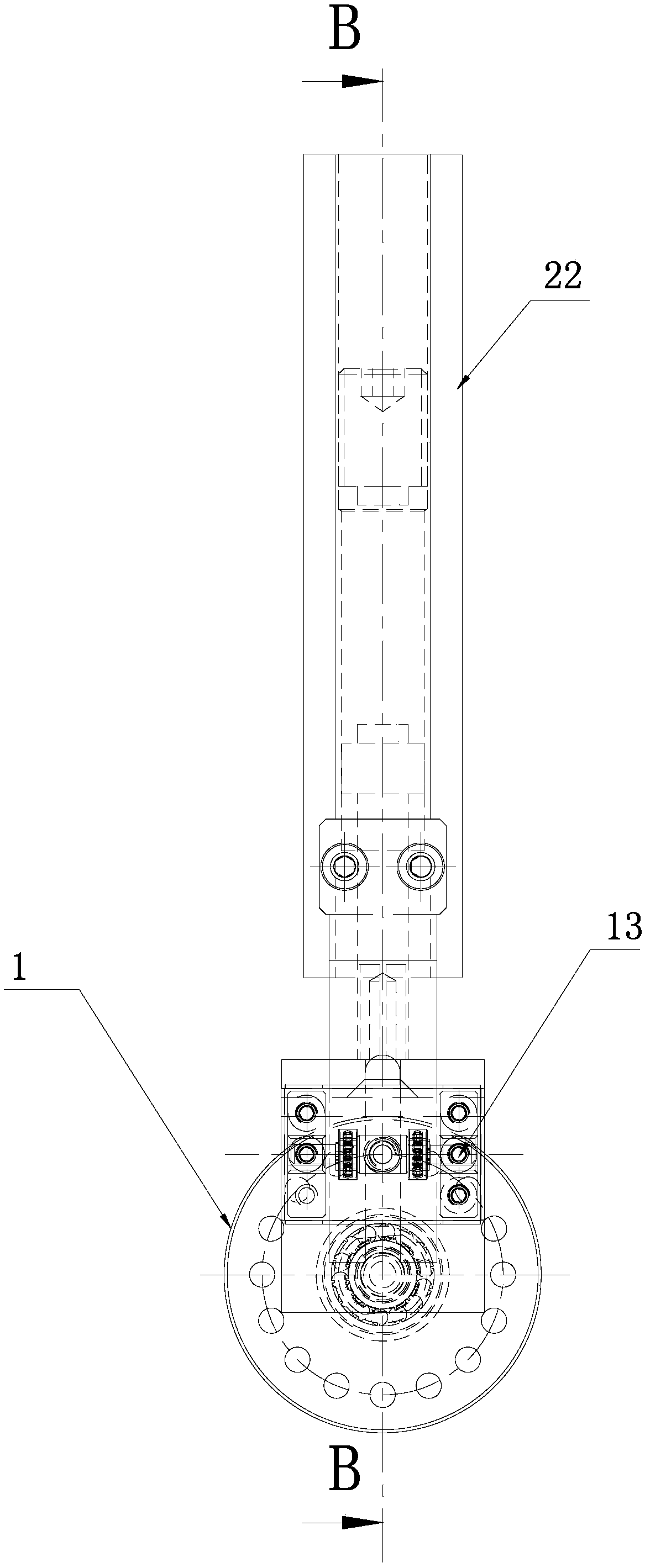

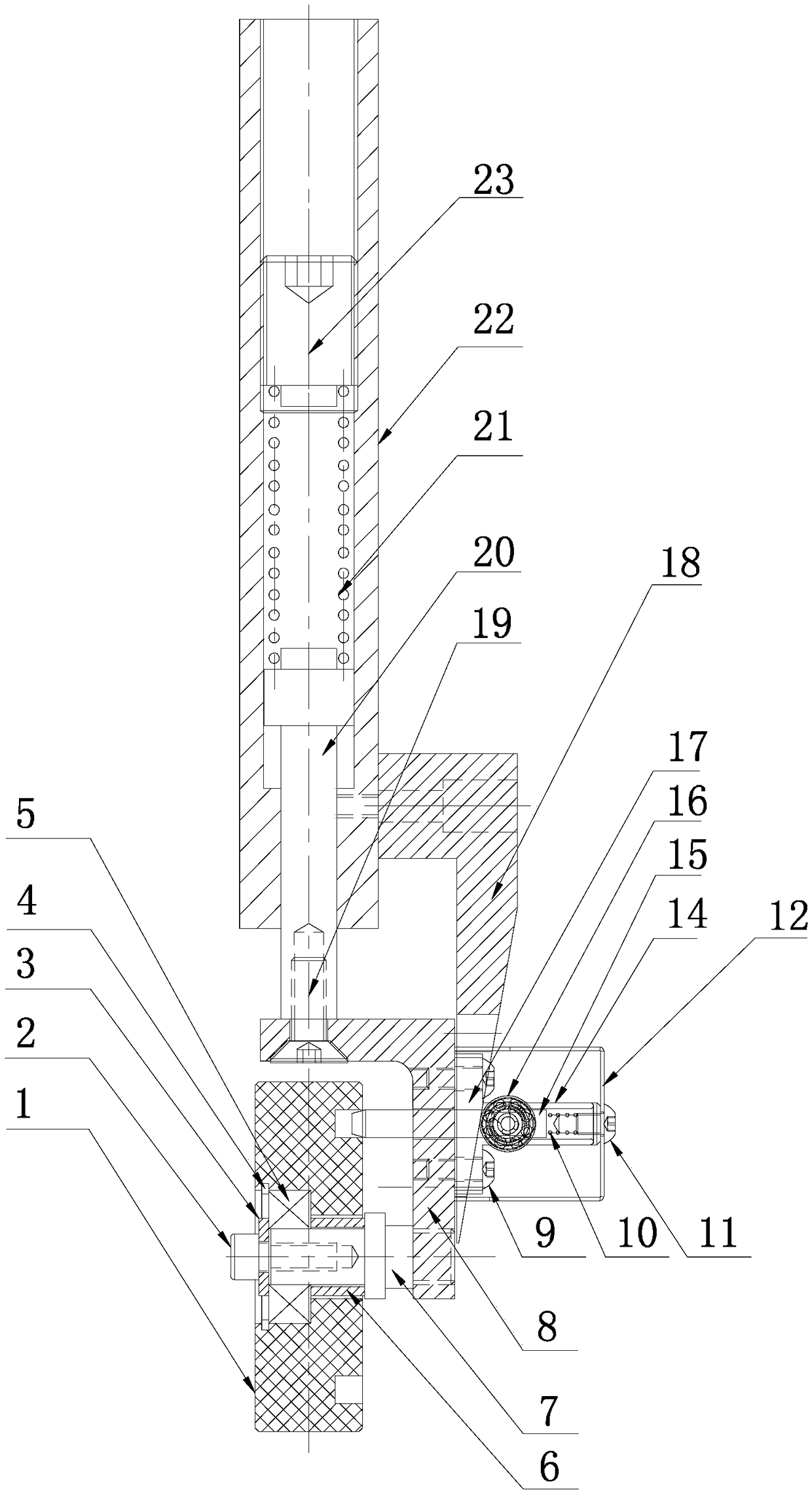

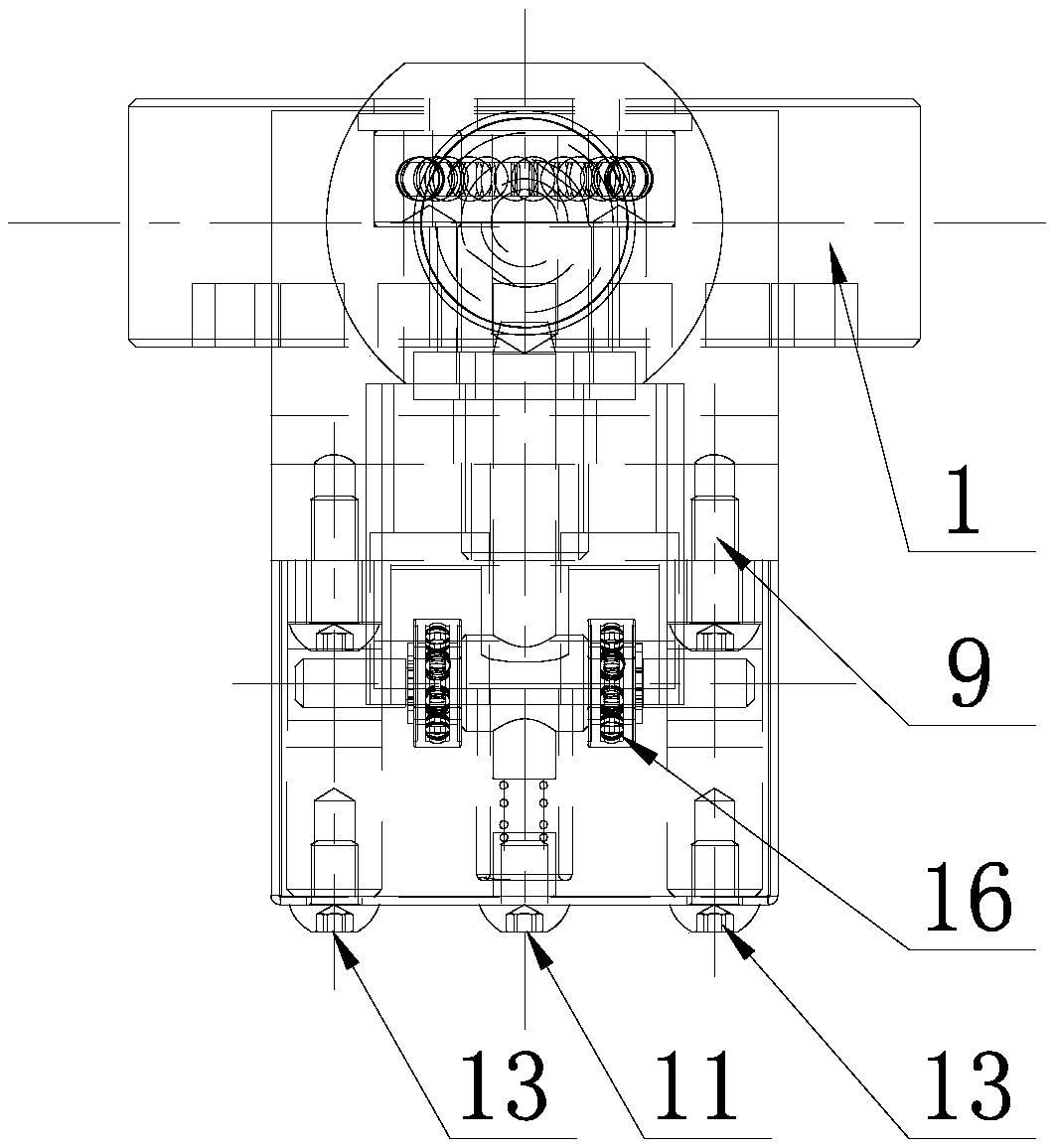

[0021] Such as Figure 1 to Figure 3 As shown, a constant pressure rolling tool includes a handle 22 provided with an axial center hole, a slide rod 20 slidably inserted in the center hole of the handle 22, and the slide rod 20 extends out of the handle 22 One end is connected with the roller mounting frame 8, and the other end of the slide bar 20 is connected with one end of the second spring 21 located in the center hole of the handle 22, and the other end of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com