Patents

Literature

75results about How to "Guaranteed to be installed in place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-functional intelligent well cover system

InactiveCN104420482AThe collection is less affected by the environmentImprove reading speedArtificial islandsUnderwater structuresRelevant informationCovering system

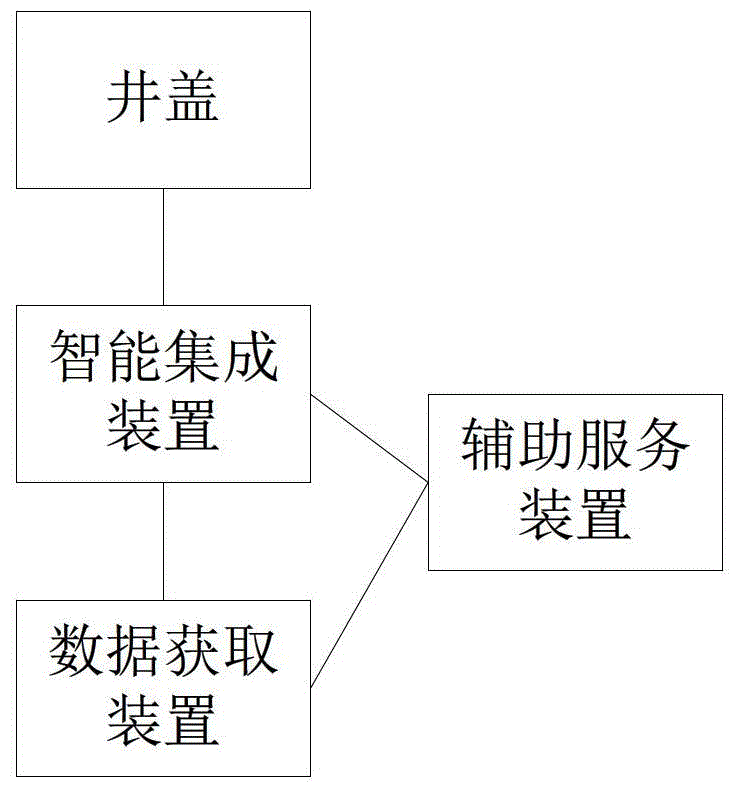

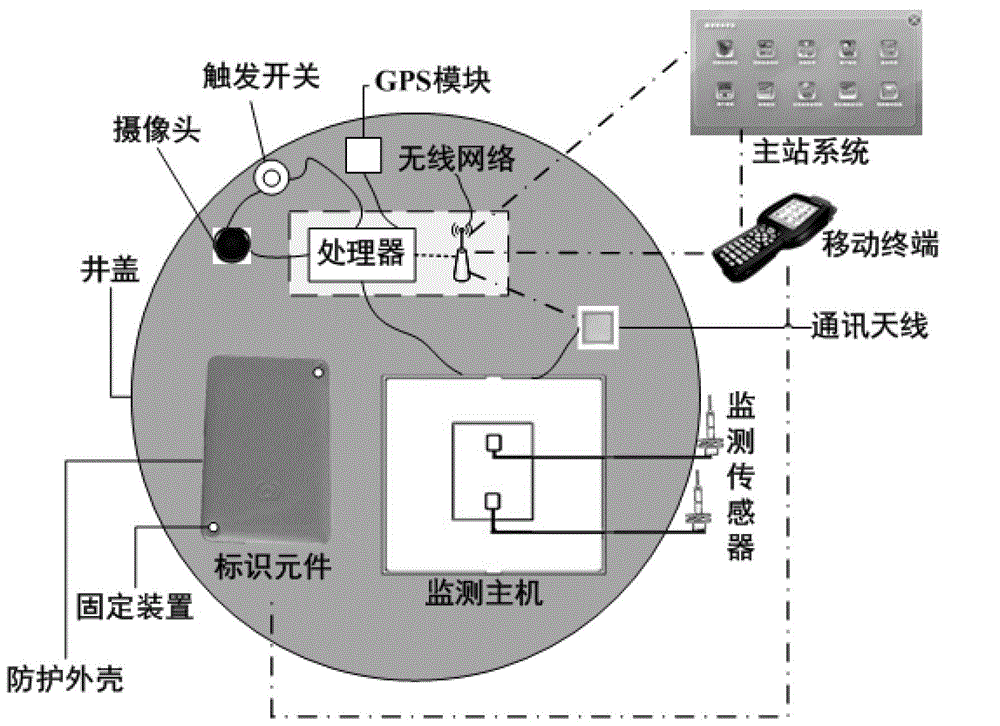

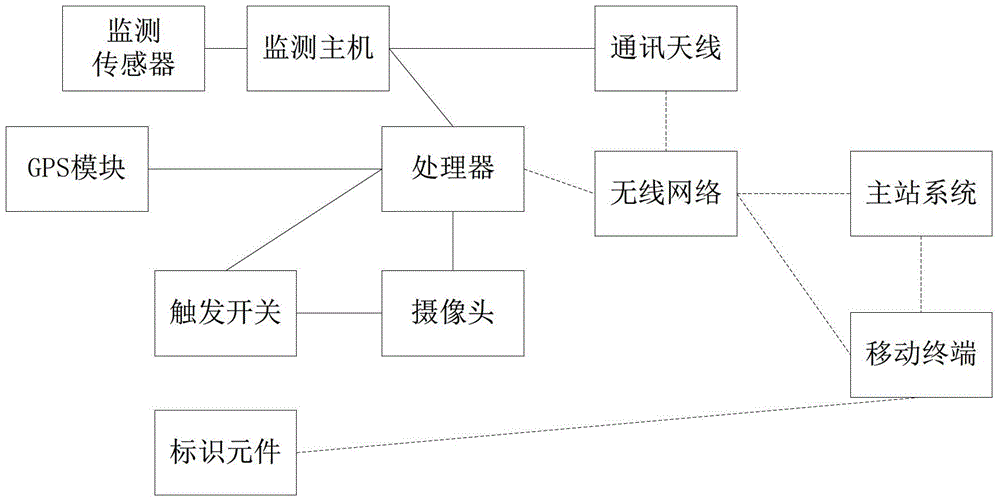

The invention discloses a multi-functional intelligent well cover system. The multi-functional intelligent well cover system is characterized by comprising a well cover, an intelligent integration device for performing intelligent processing on the well cover, an information acquisition device for obtaining relevant information of the well cover, and an auxiliary service device for providing application service to the intelligent integration device and the information acquisition device. The multi-functional intelligent well cover system can perform positioning, unique identification, alarm and monitoring on the well cover.

Owner:北京清控人居环境研究院有限公司

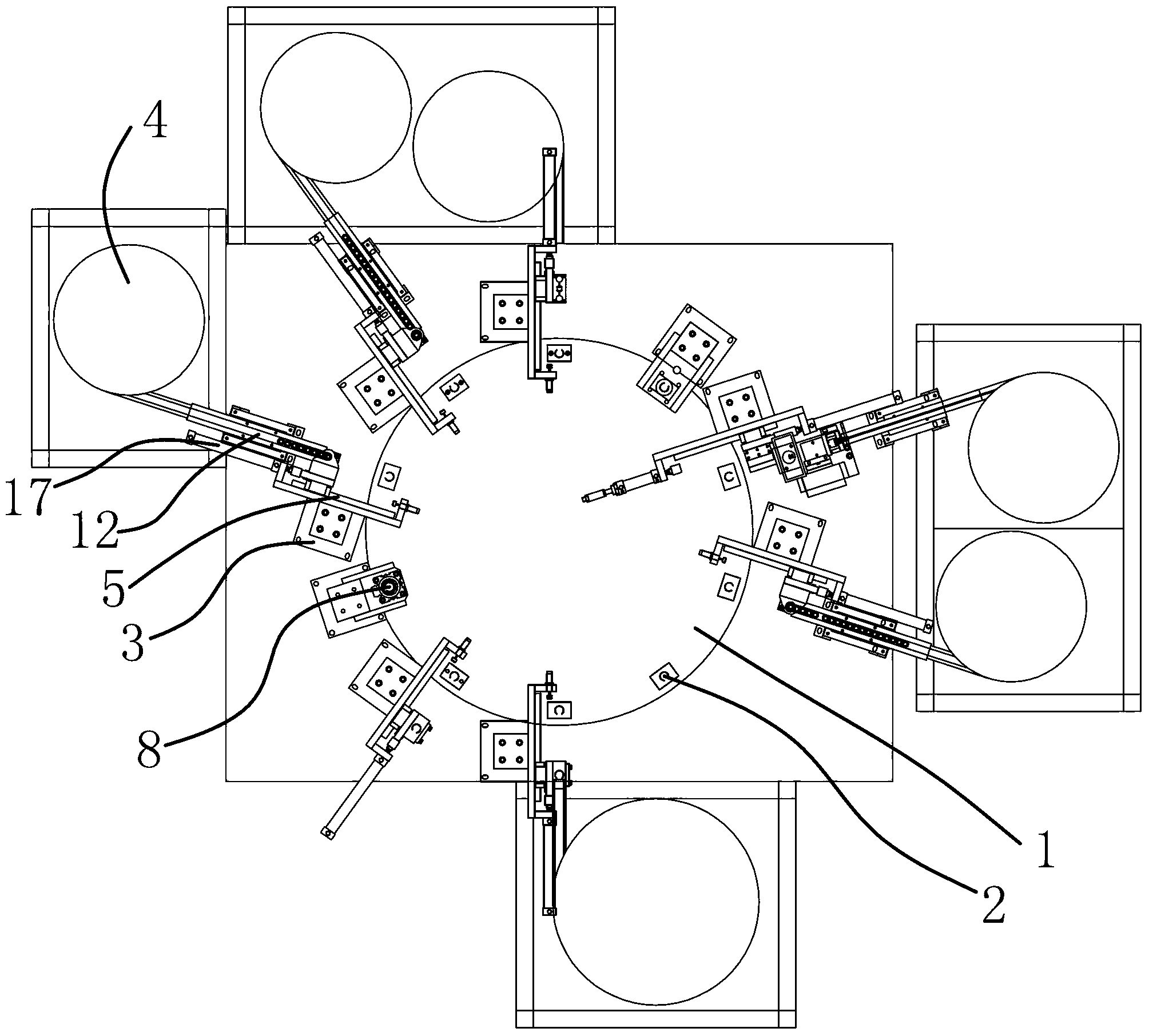

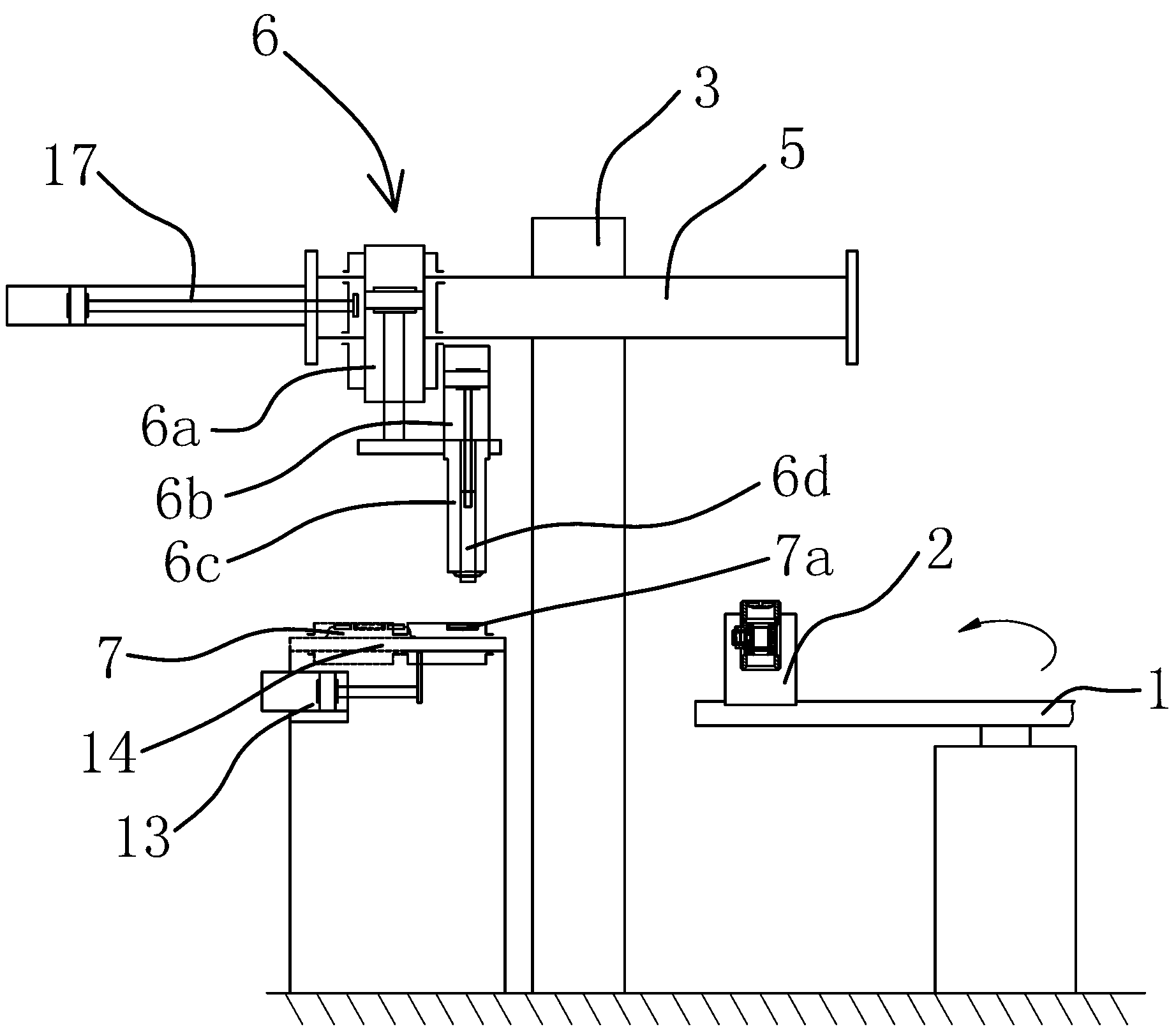

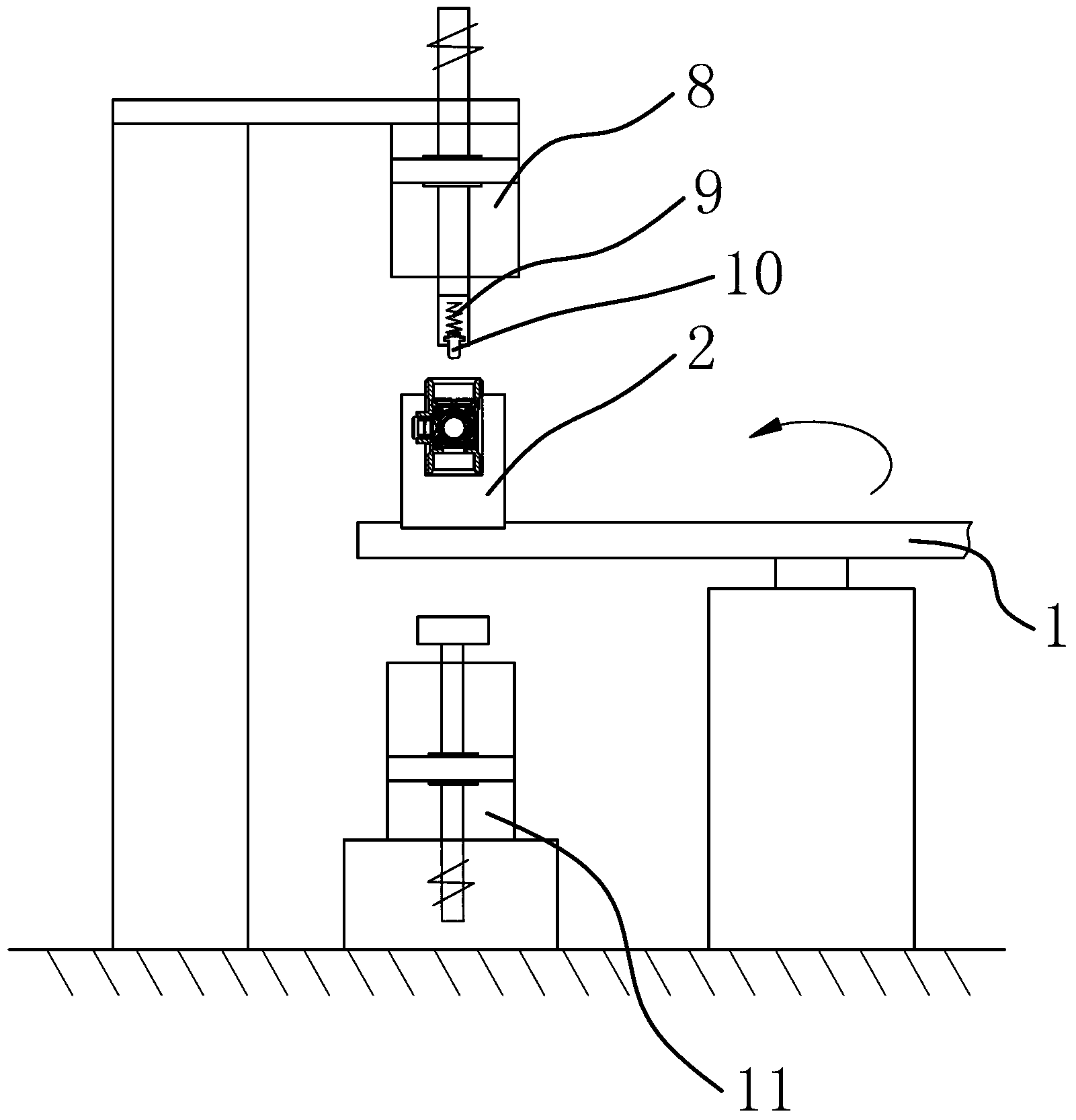

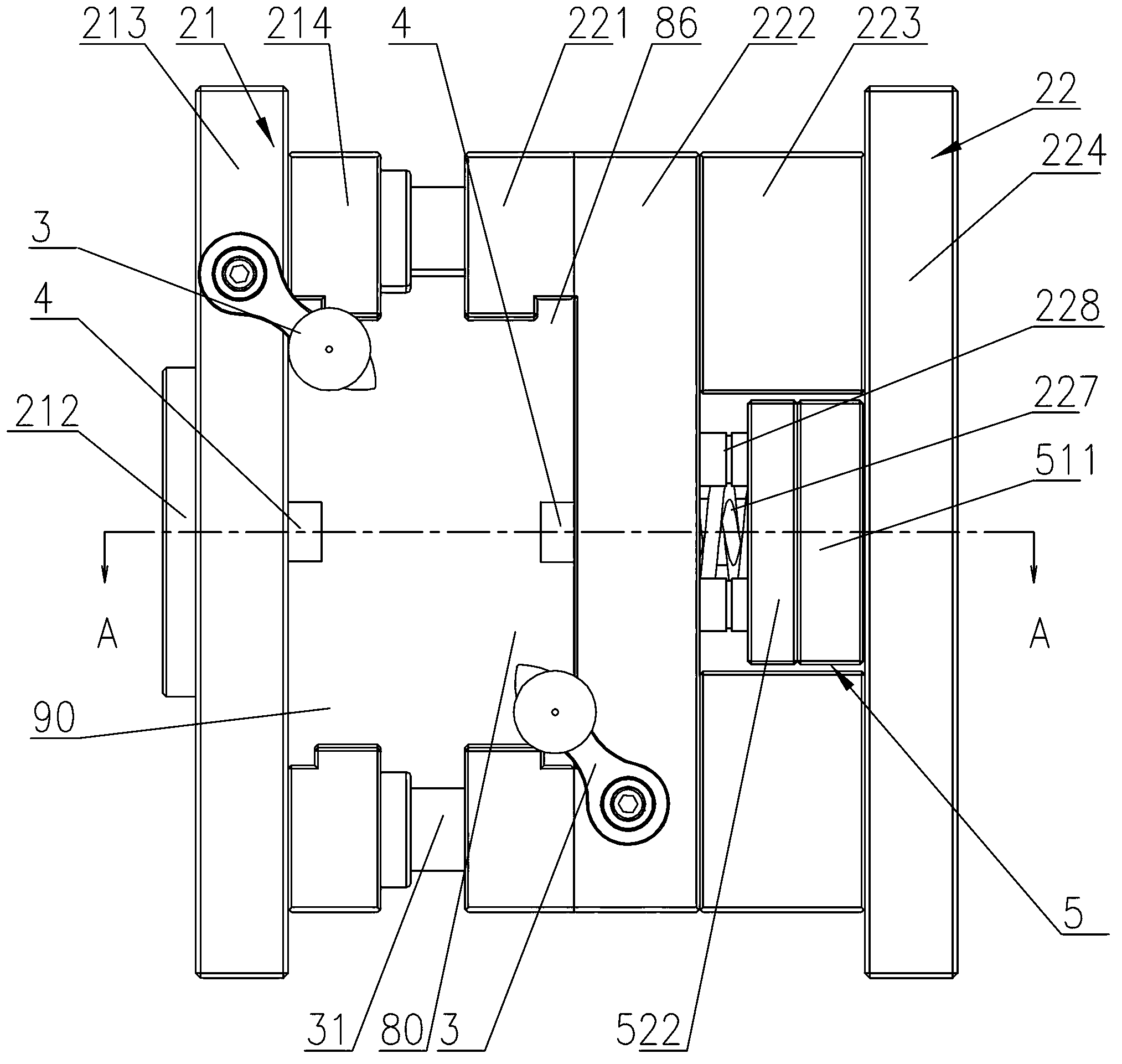

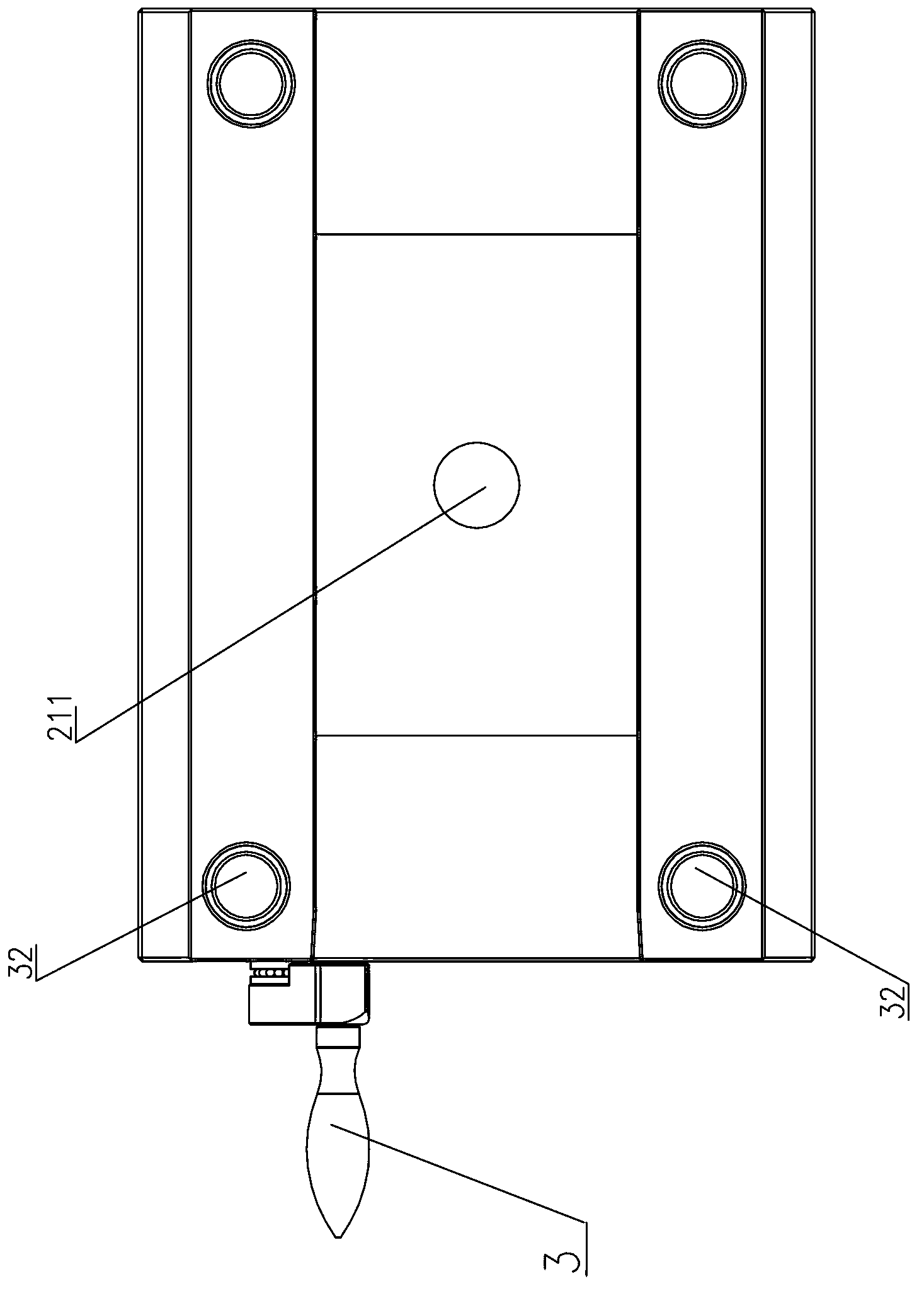

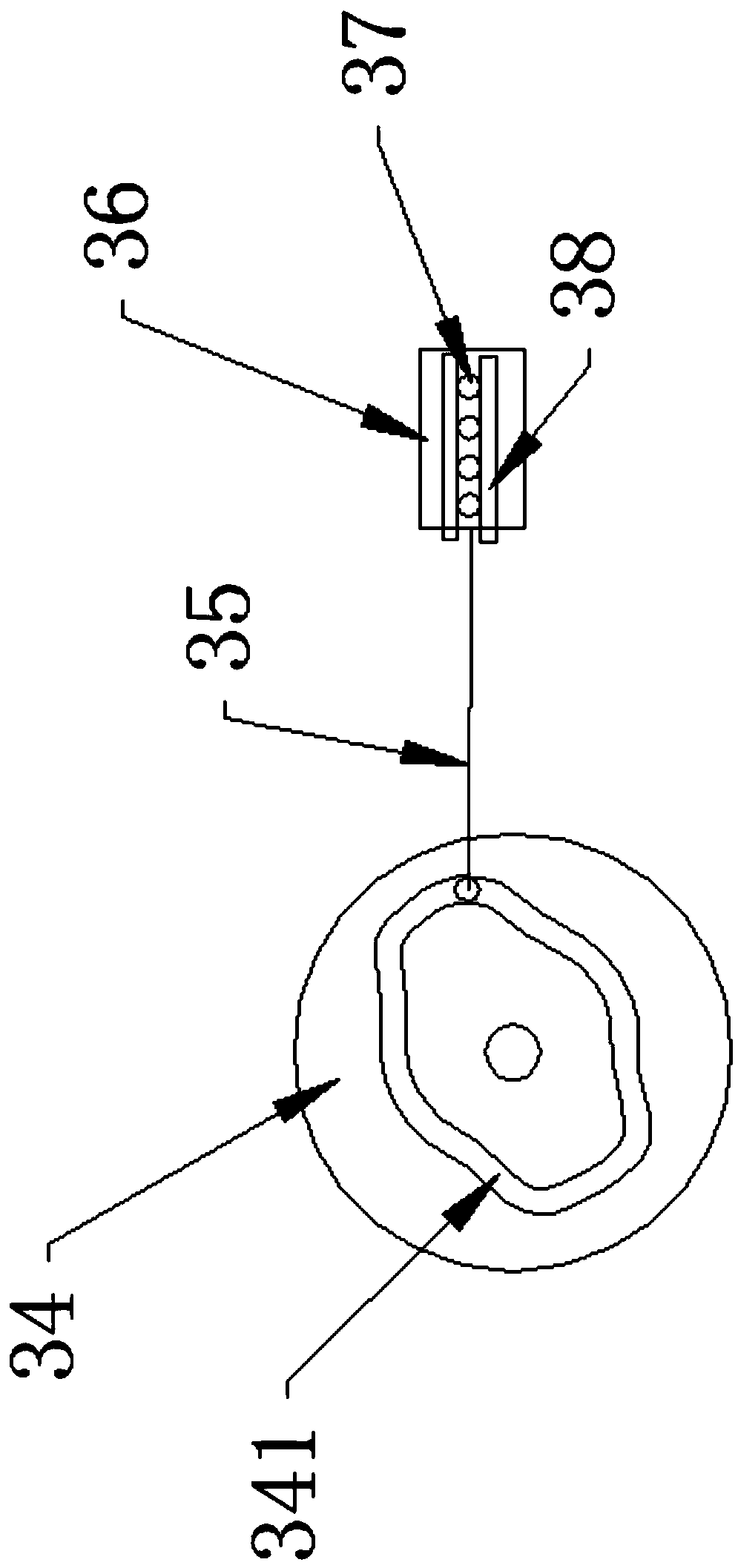

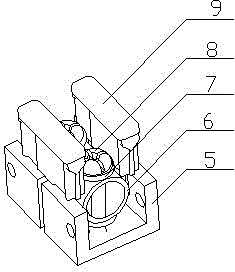

Clamping spring loading device of ball valve automatic assembling machine

ActiveCN103212985AHigh degree of automationImprove assembly efficiencyAssembly machinesMetal working apparatusBall valveManipulator

The invention provides a clamping spring loading device of a ball valve automatic assembling machine, belongs to the technical field of machinery, and aims to solve the problems that an existing ball valve is assembled manually, the assembling efficiency is low, and the labor cost is high and the like. According to the clamping spring loading device of the ball valve automatic assembling machine, the ball valve automatic assembling machine comprises an operating table which his fixedly connected with a mold seat, wherein the mold seat moves together with the operating table; and the clamping spring loading device is arranged at the side edge of the operating table, and comprises a rack, a vibration material disc and a driving mechanism, wherein the top of the rack is fixedly connected with a horizontal guide rail which is movably connected with a manipulator, a material outlet of the vibration material disc is provided with a slide block, the slide block is provided with a material receiving groove, the driving mechanism can drive the slide block to perform reciprocating motion between the material outlet of the vibration material disc and the manipulator, and the manipulator can convey a clamping spring in the material receiving groove into a valve body at the mold seat. The clamping spring loading device has the advantages of high automation degree, capability of improving the assembling efficiency of the ball valve and the like.

Owner:ZHEJIANG VALOGIN TECH

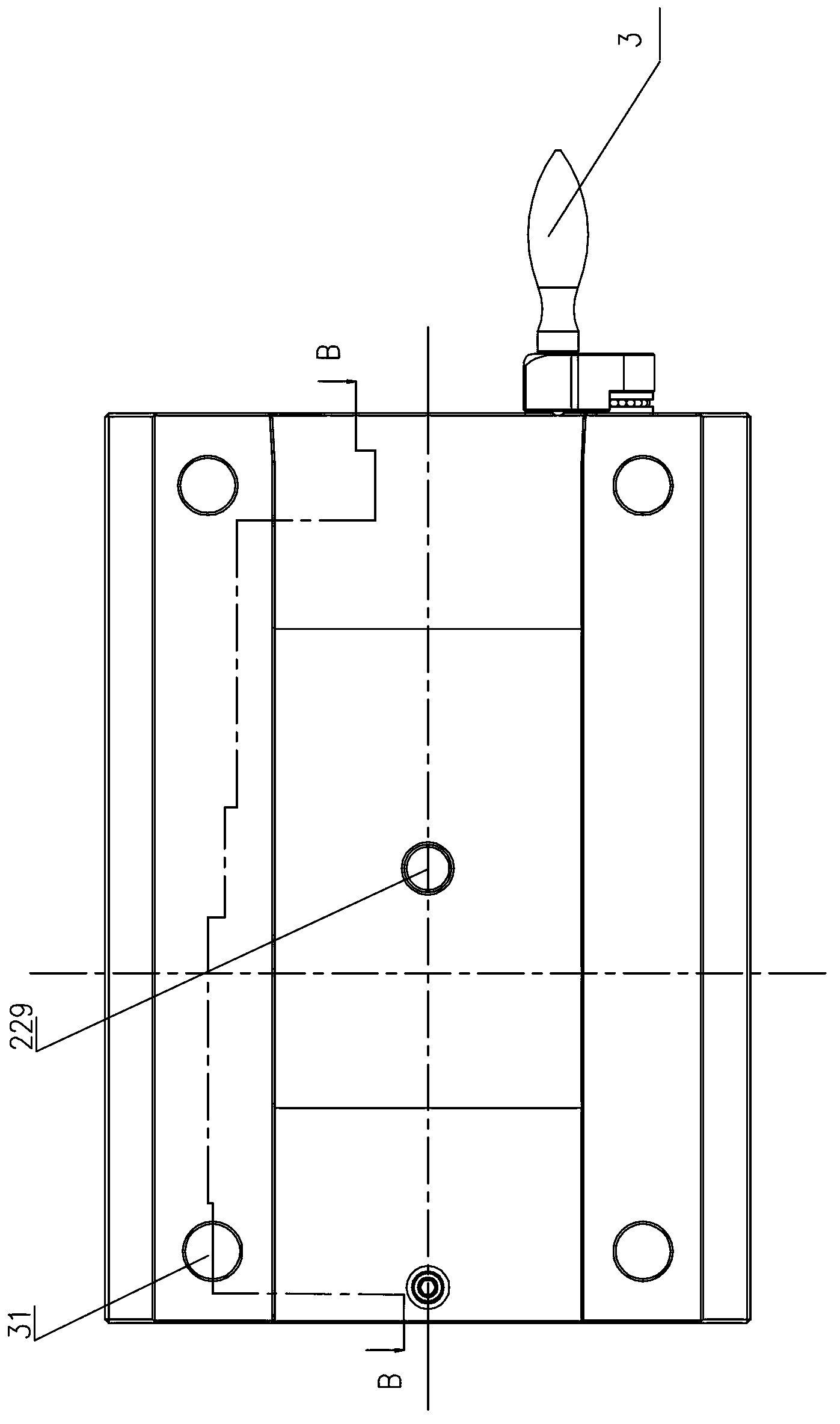

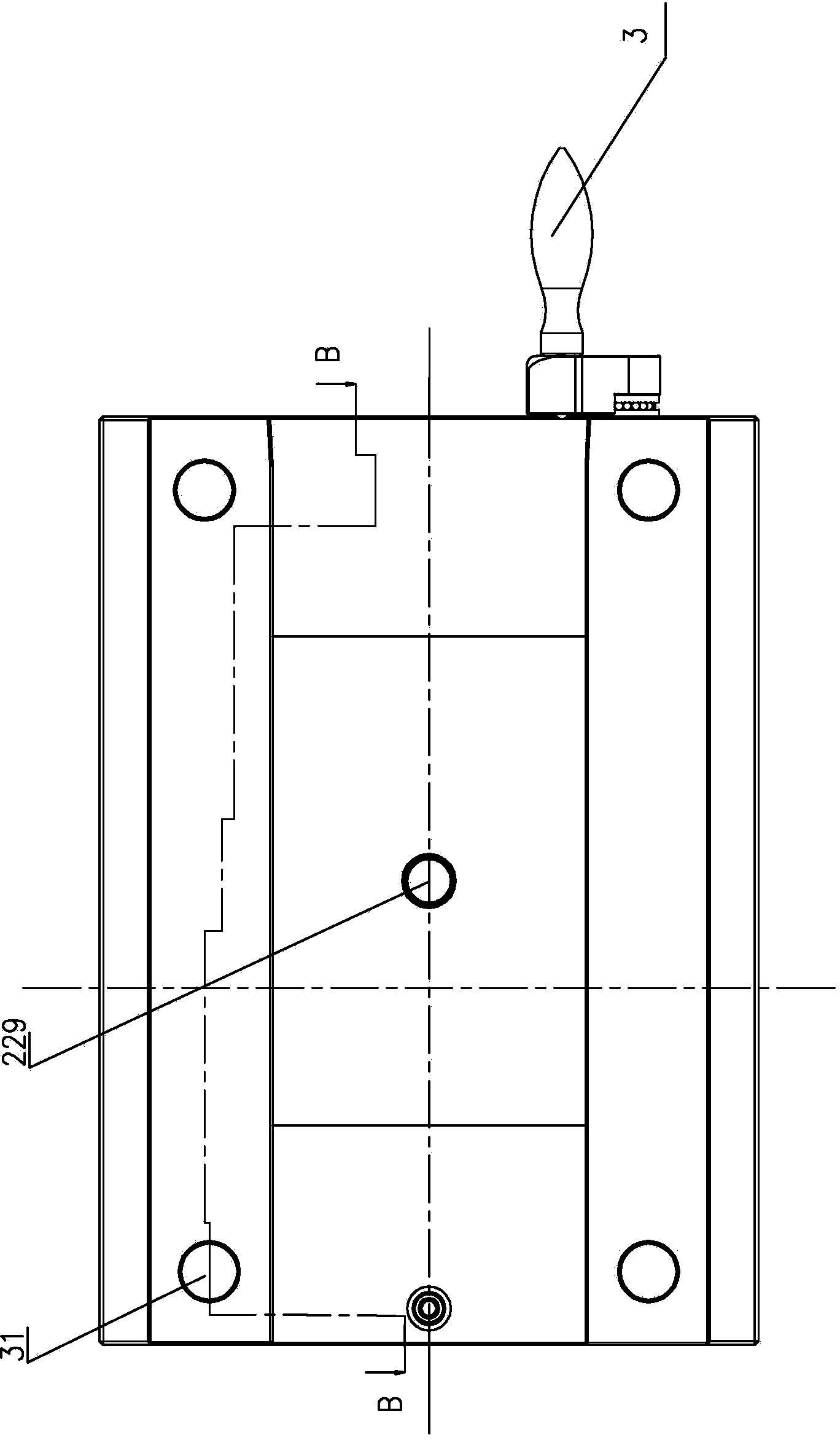

Injection mould with rapidly-replaced mould cores

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:广州现代塑料有限公司

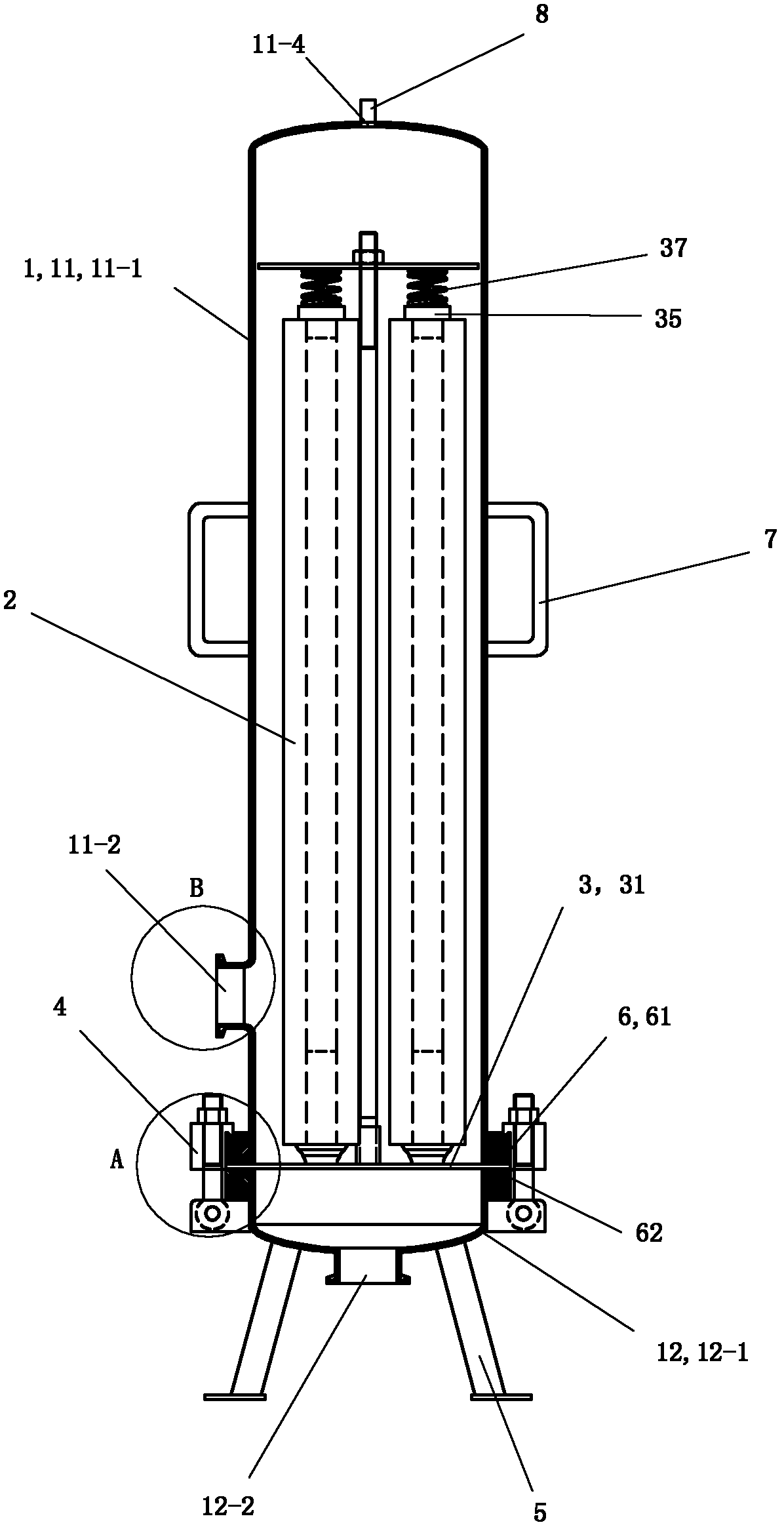

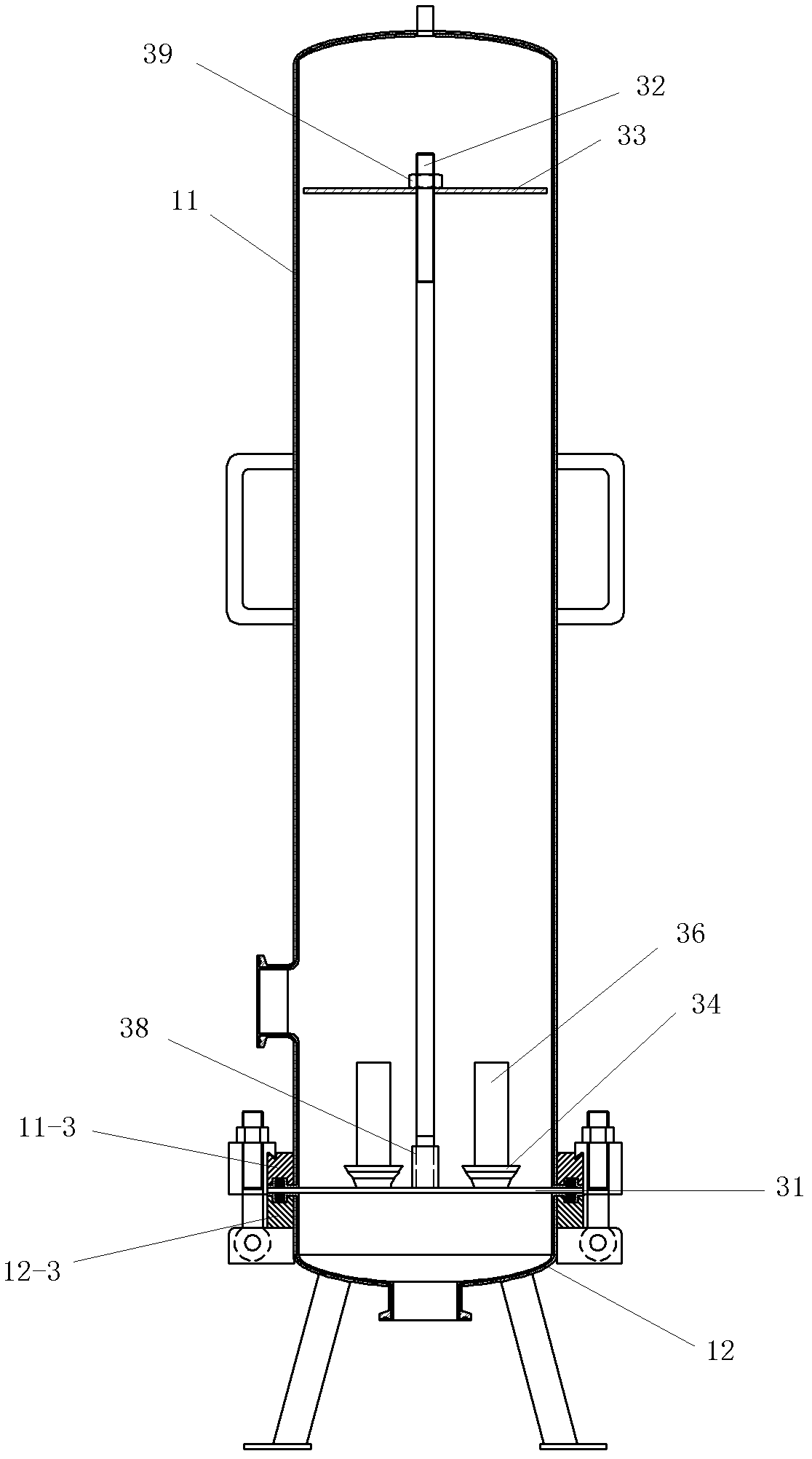

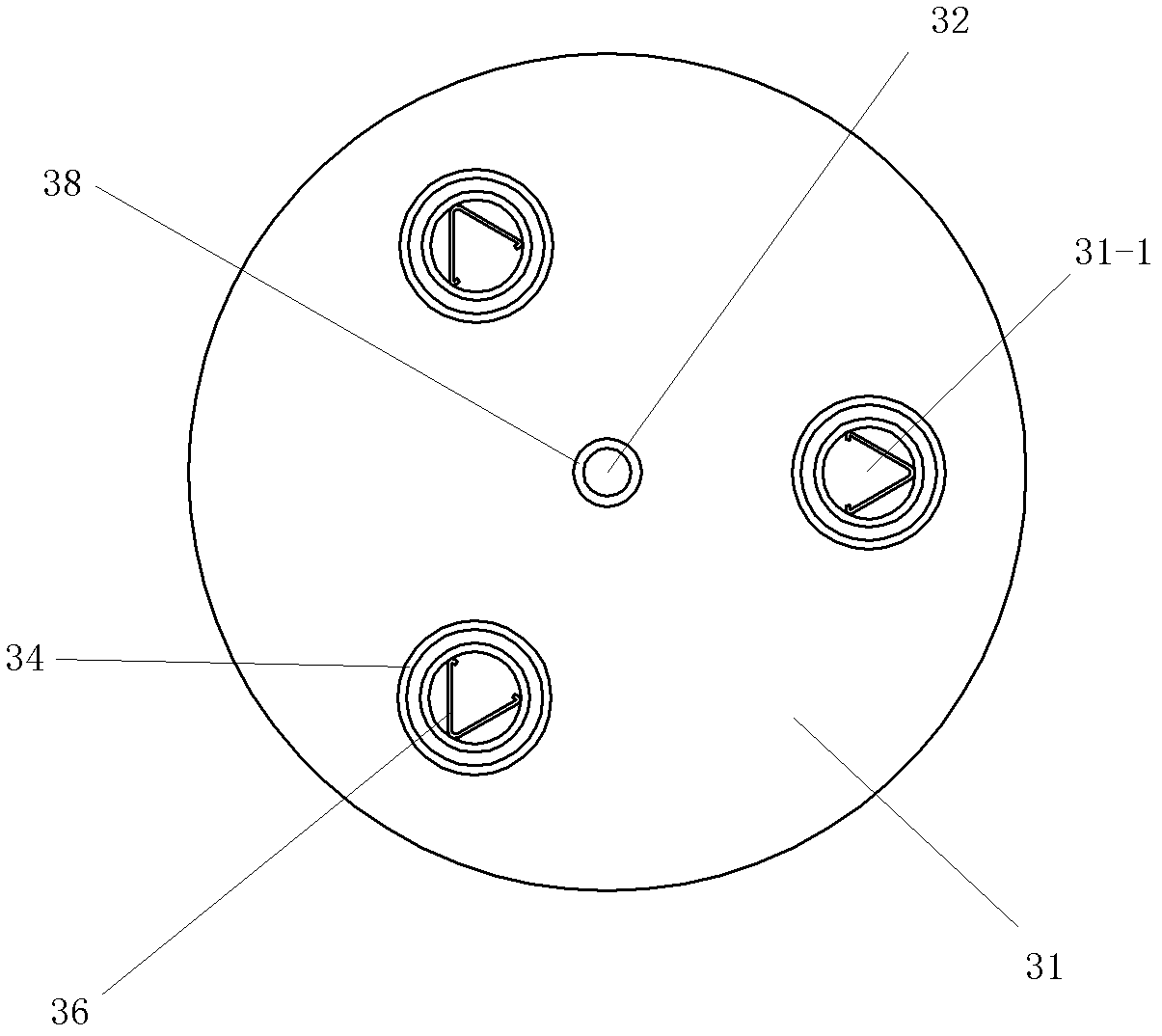

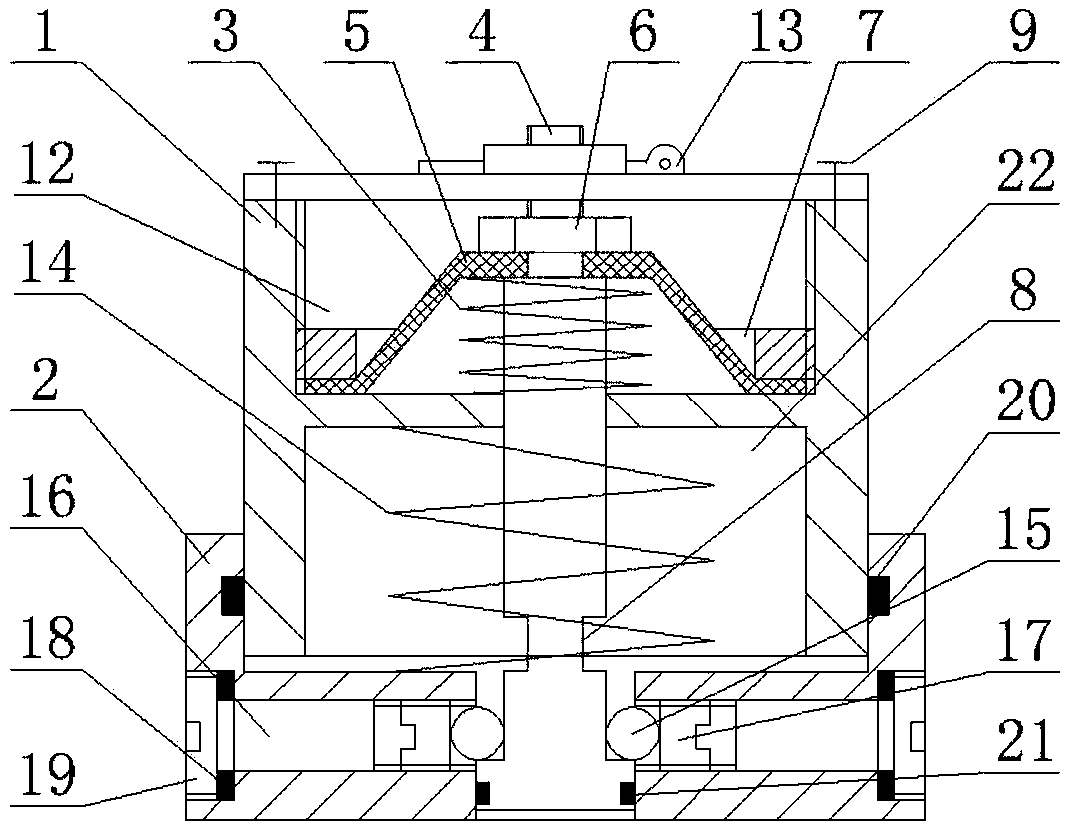

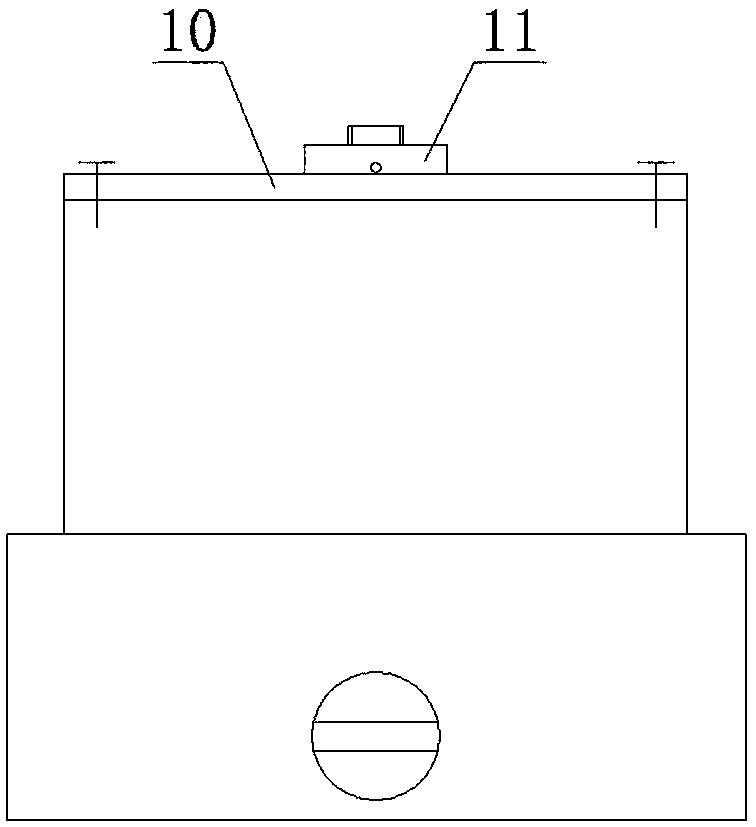

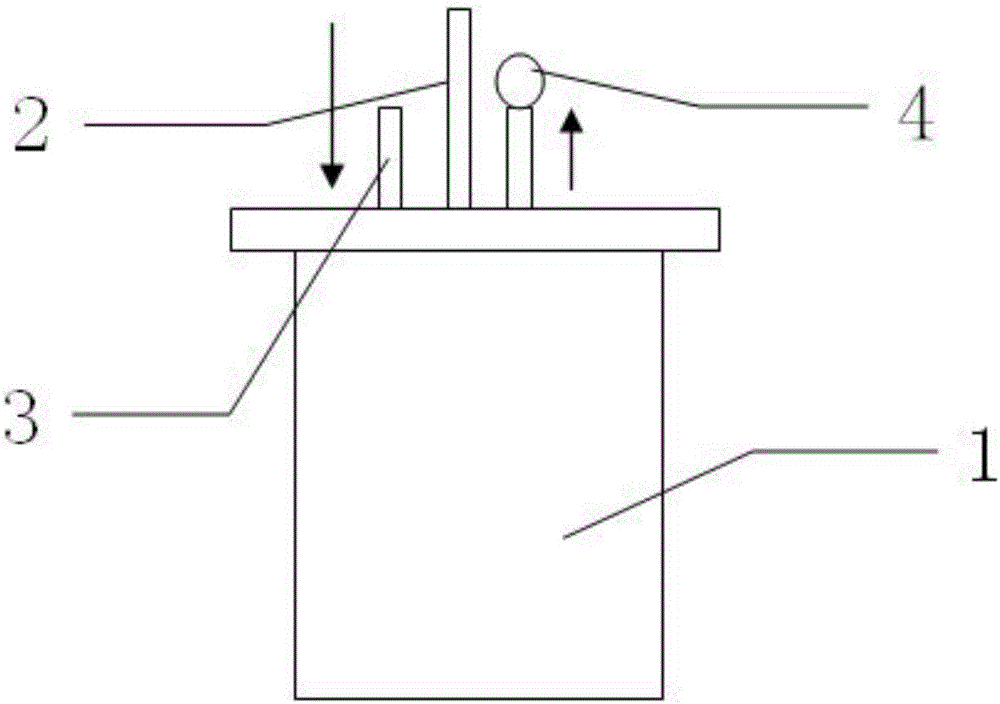

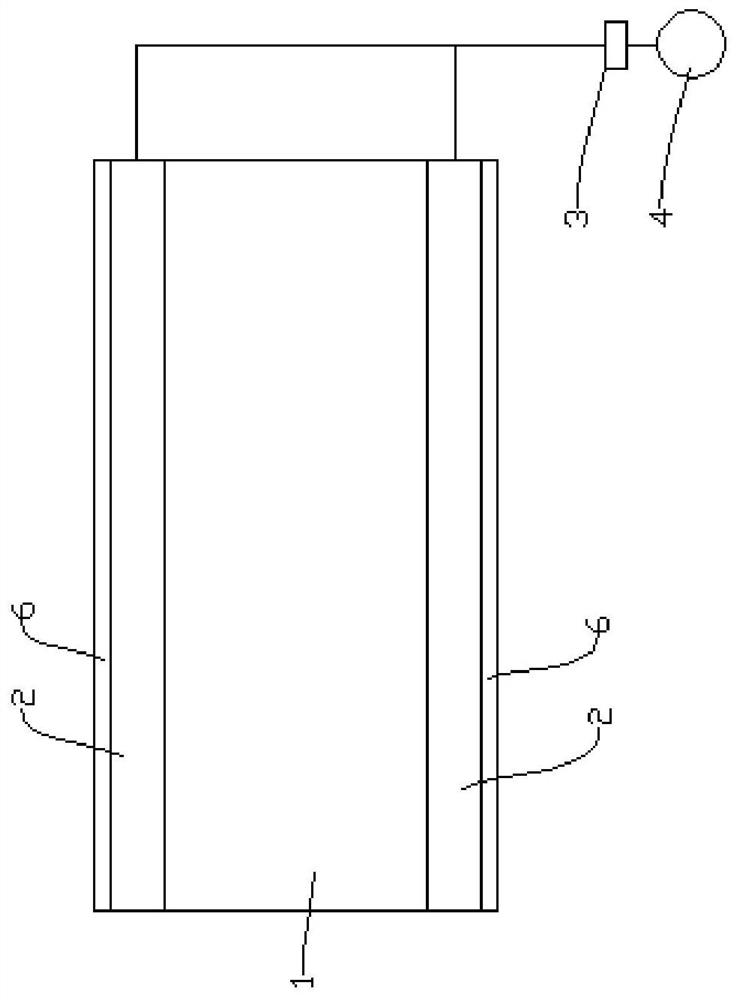

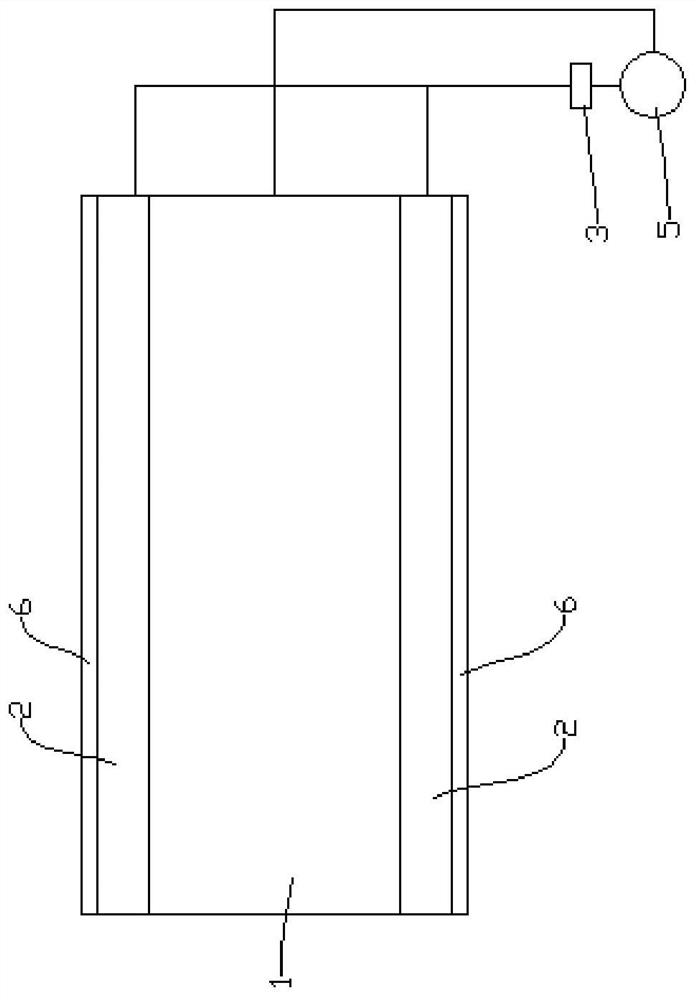

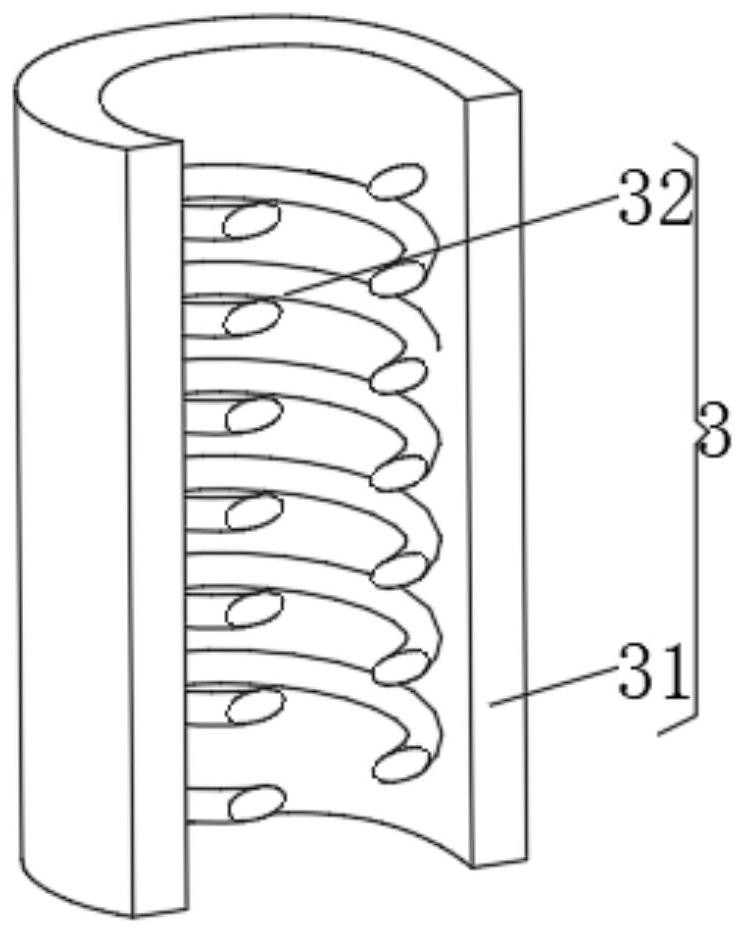

Precise filter

InactiveCN102430275ASimple structureEasy to installStationary filtering element filtersEngineeringMechanical engineering

The invention discloses a precise filter which comprises a cylinder, 2-8 filter elements, a filter element installing frame and connectors, wherein all the filter elements and the filter element installing frame are arranged in the cylinder, the filter element installing frame is fixedly connected with the cylinder, and all the filter elements are fixedly connected with the filter element installing frame. The precise filter is characterized in that the cylinder comprises a main cylinder at the upper part of the cylinder and a lower cylinder at the lower part of the cylinder, the filter element installing frame comprises a separator, a pull rod, a pressing plate, filter element lower seats, a filter element pressing seat, a compression spring and a gland nut, the end port of each filter element lower seat is respectively welded to a corresponding through hole of the separator hermetically so that the cavity of the filter element lower seat is communicated with a space at the lower side of the separator, each corresponding filter element, the filter element pressing seat and the compression spring are arranged between the filter element lower seats and the pressing plate in sequence from bottom to top, the edge part of the separator of the filter element installing frame is clamped between the lower end face of the main cylinder and the upper end face of the lower cylinder, and the separator of the filter element installing frame, the main cylinder and the lower cylinder are detachably, fixedly and hermetically connected into a whole through the connectors.

Owner:CHANGZHOU CONNECT MACHINERY EQUIP

Cam-driven delasting-lasting integrated machine

The invention provides a cam-driven delasting-lasting integrated machine, belonging to the shoemaking equipment field. The integrated machine comprises a fixed frame, wherein an inverted shoe tree isfixedly arranged on the fixed frame, a flat pressing assembly is arranged above the shoe tree, clamping assemblies are arranged on the left and right sides of the shoe tree; and a delasting assembly is arranged at the rear end of the shoe tree and comprises a raising cam, a raising driving rod and a lifting frame, the raising cam is rotatably connected to the fixed frame, a first driving slot is formed in the raising cam and is used for driving the lifting frame to move up and down through the raising driving rod, a translation cam, a translation driving rod and a delasting block are arrangedat the upper end of the lifting frame, the translation cam is horizontally arranged and is rotatably connected with the lifting frame, a second driving slot is formed in the translation cam and is used for driving the block to move leftwards and rightwards through the translation driving rod. The integrated machine is driven by a power supply, so that the operation of the whole structure is relatively stable and reliable, the failure rate is greatly decreased, the energy consumption is reduced, the energy source is saved, and the integrated machine is relatively environment-friendly.

Owner:JIHUA LAB

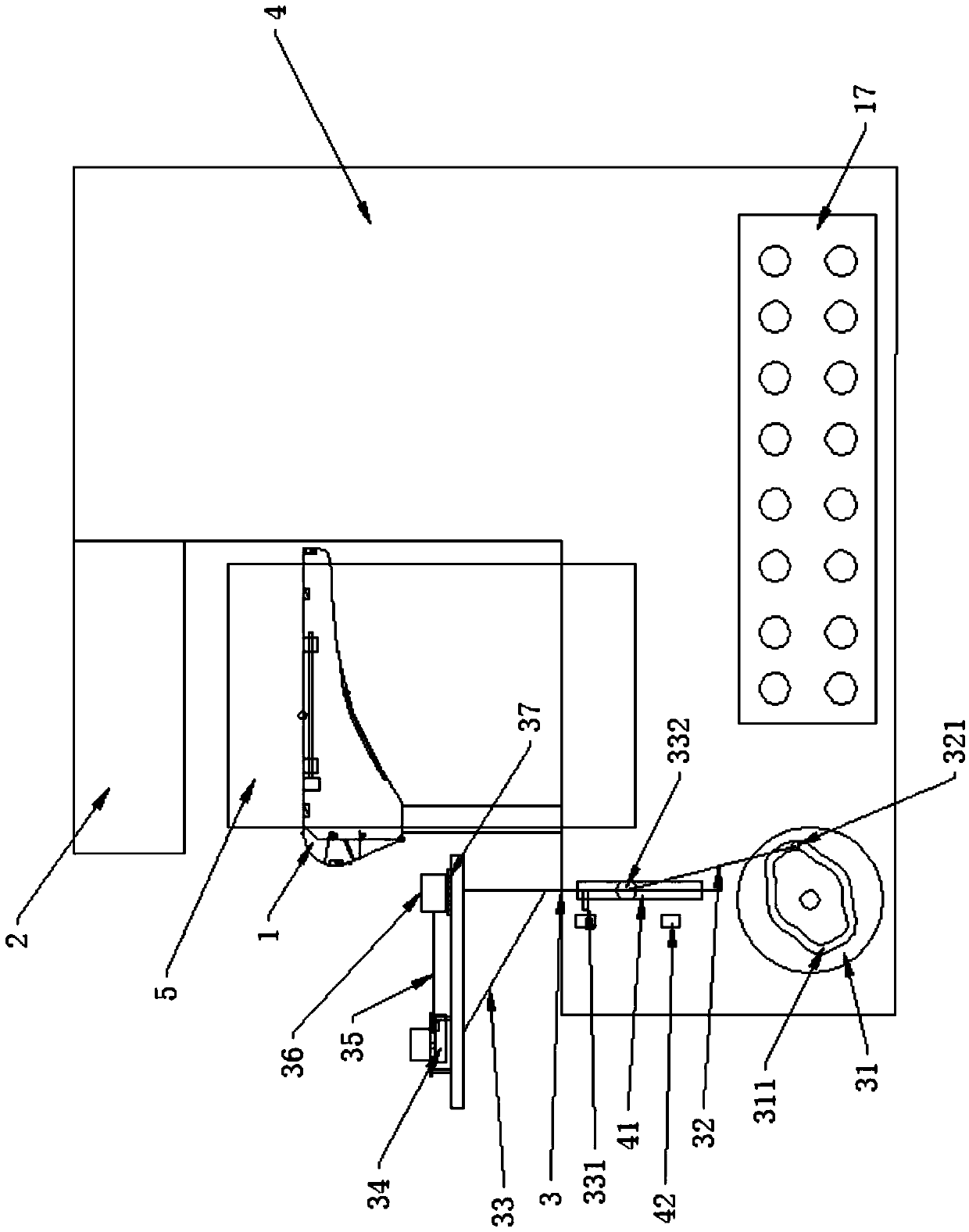

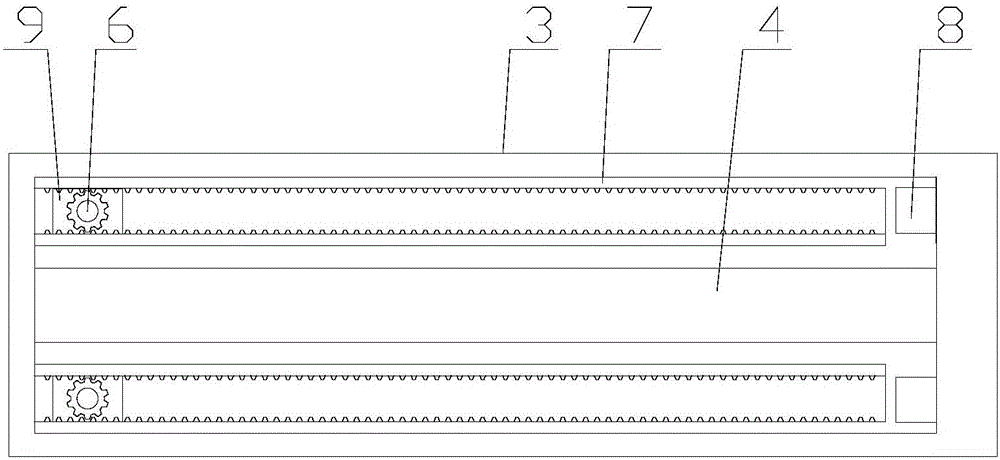

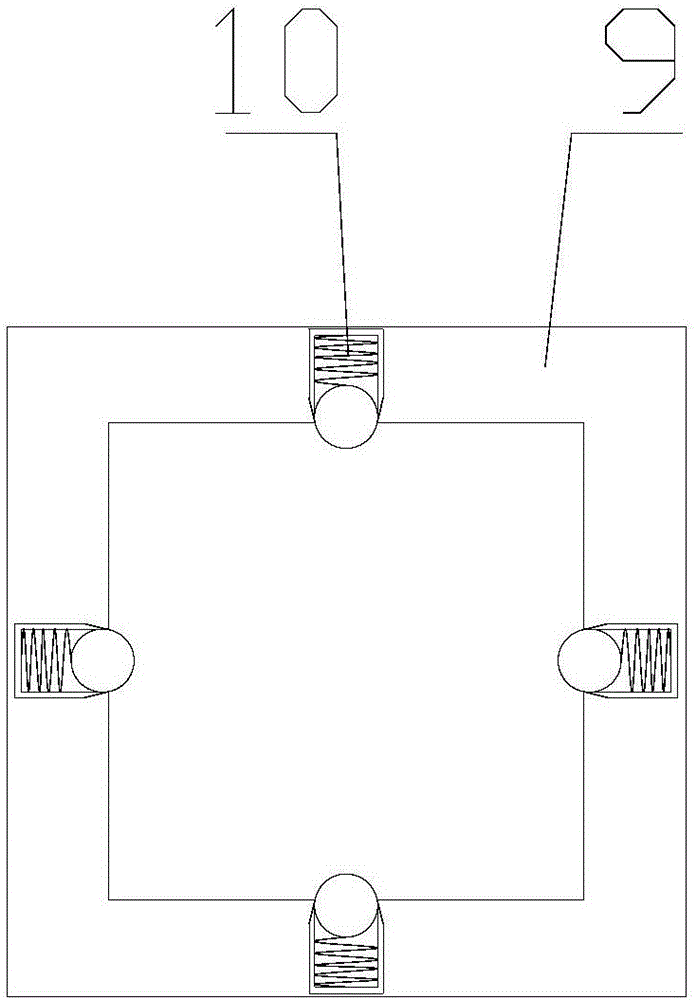

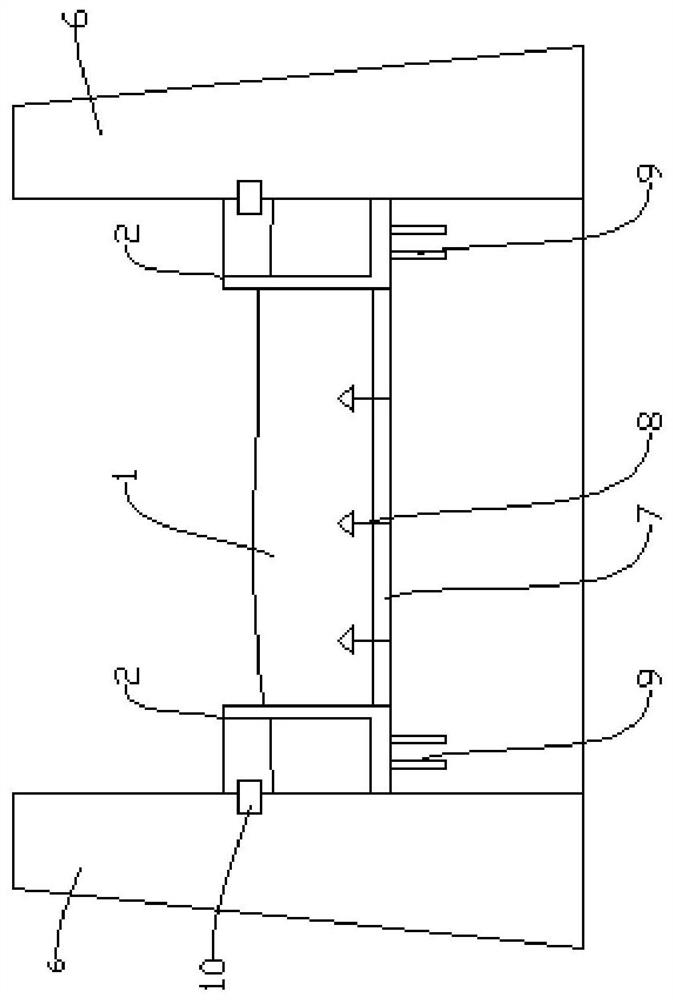

Communication mounting equipment based on Internet of things

ActiveCN106488338AGuaranteed to be installed in placeImprove reliabilityAc-dc conversionSelection arrangementsThe InternetDistance sensors

The invention relates to communication mounting equipment based on Internet of things. The communication mounting equipment comprises a cabinet body and a cabinet door, wherein a plurality of mounting grooves are formed in the cabinet body; four mounting mechanisms are arranged at four corners of the mounting grooves; mounting guide bars are arranged on two sides of the mounting grooves; and the mounting guide bars are positioned between two mounting mechanisms. In the communication mounting equipment based on the Internet of things, communication equipment is fixed through four mounting blocks, and driving gears are used for driving the communication equipment to move at the same time, so that the communication equipment can be mounted in place. Moreover, distance sensors are used for monitoring, so that the mounting reliability of the communication equipment is improved further, and the reliability of the communication mounting equipment is improved. In a working power circuit, a first diode is in a parallel connection with a second triode, so that current on the first diode is lowered; the output power of the power circuit is increased; and the reliability of the communication mounting equipment is improved.

Owner:上海聚奂信息科技有限公司

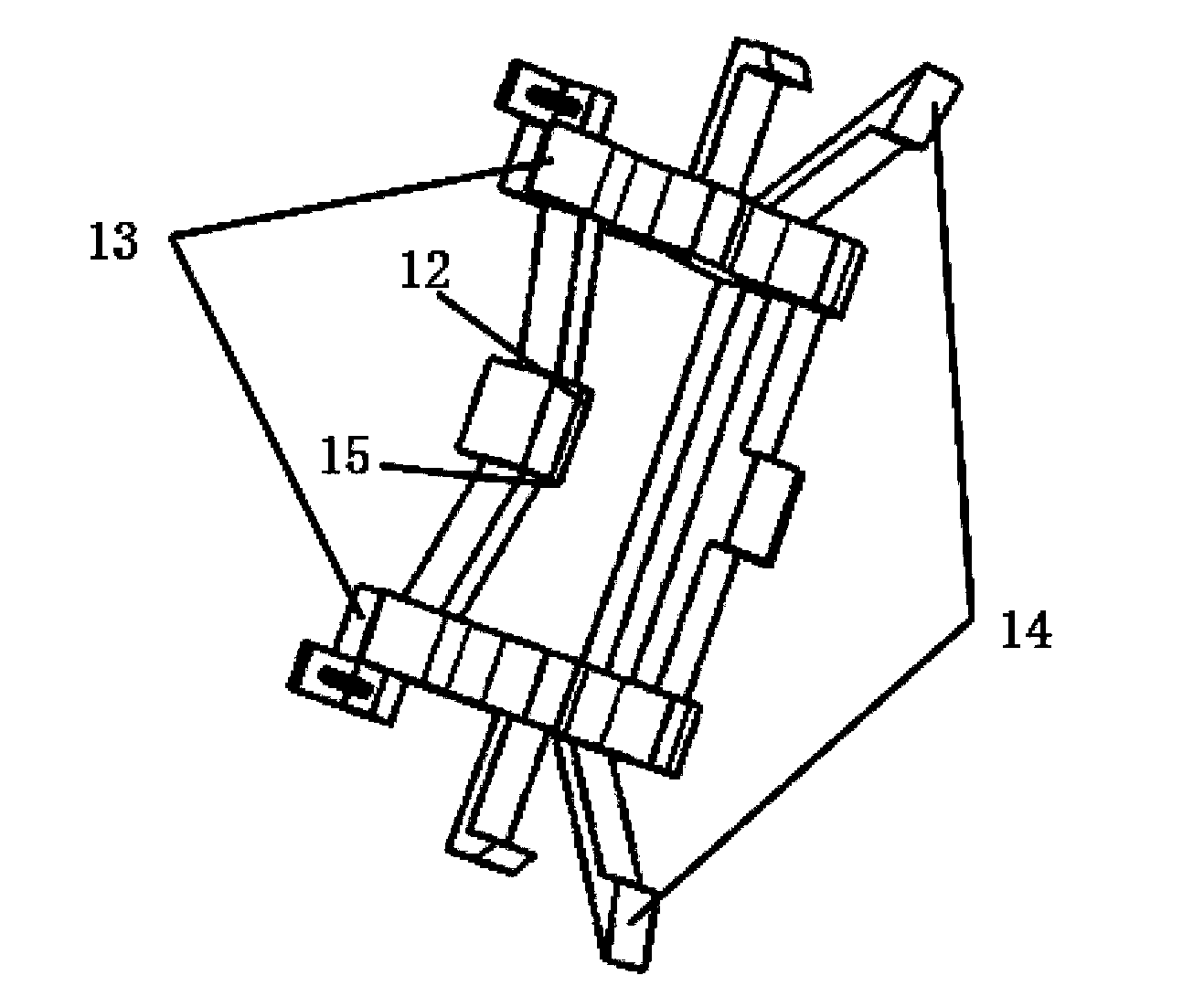

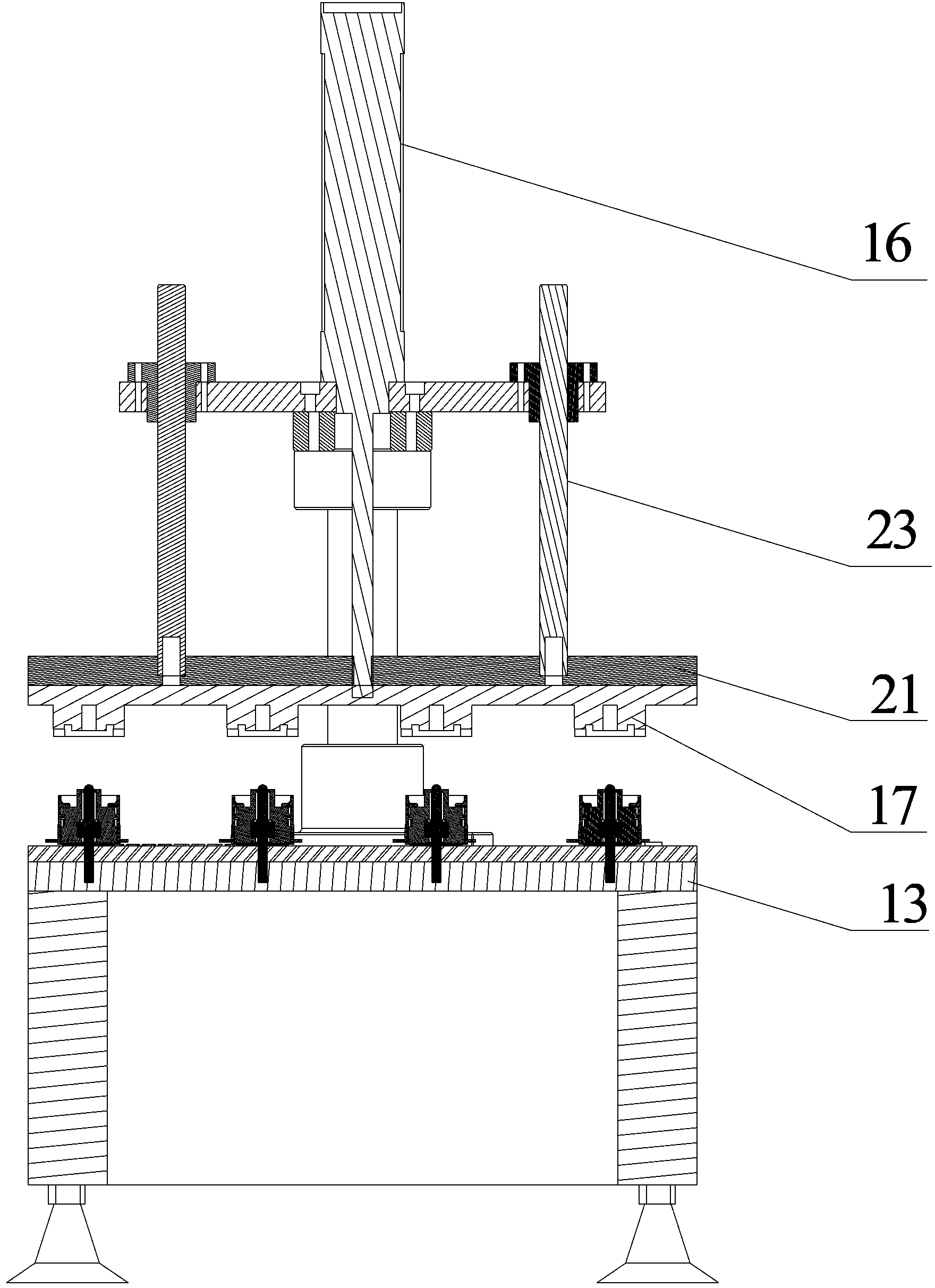

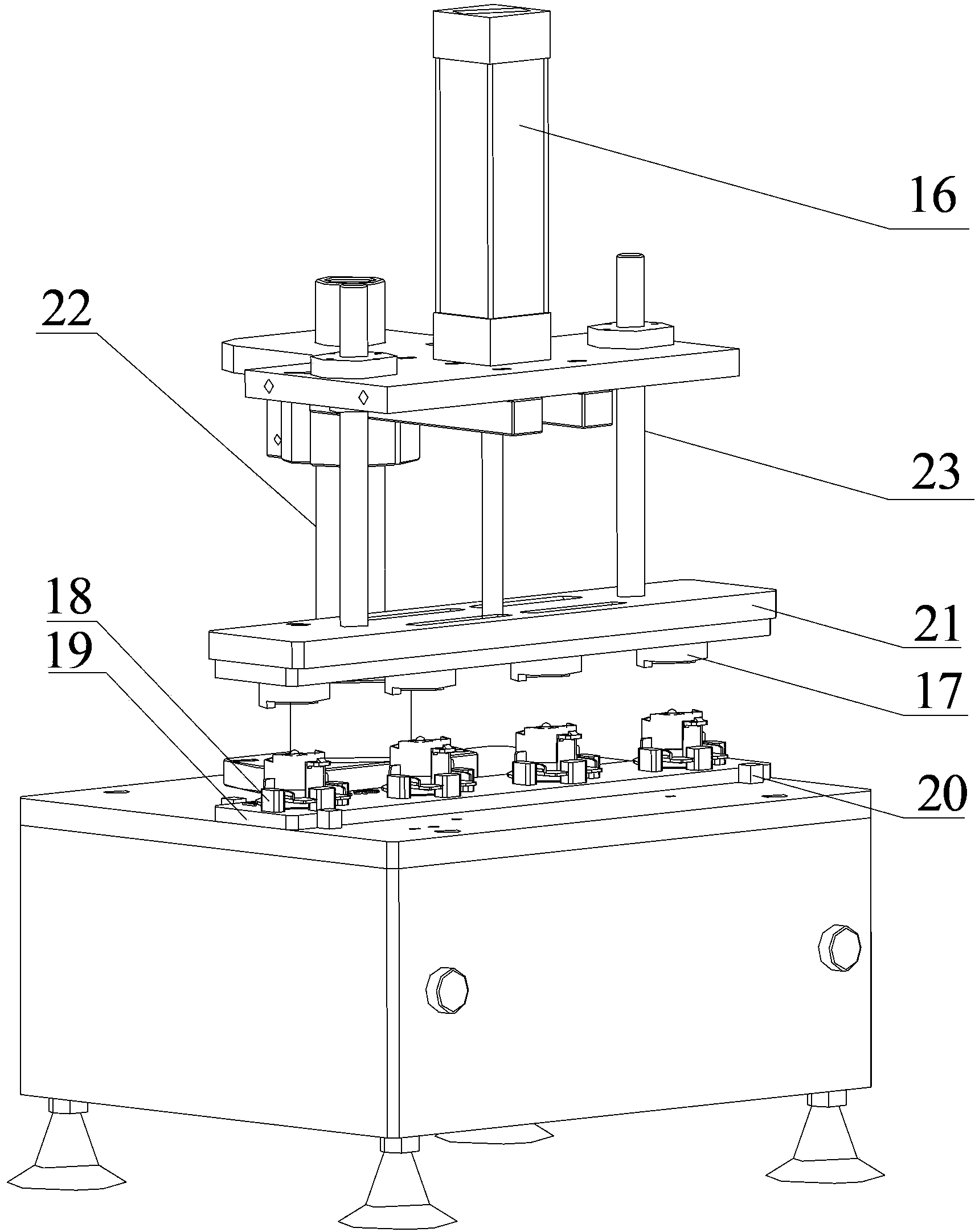

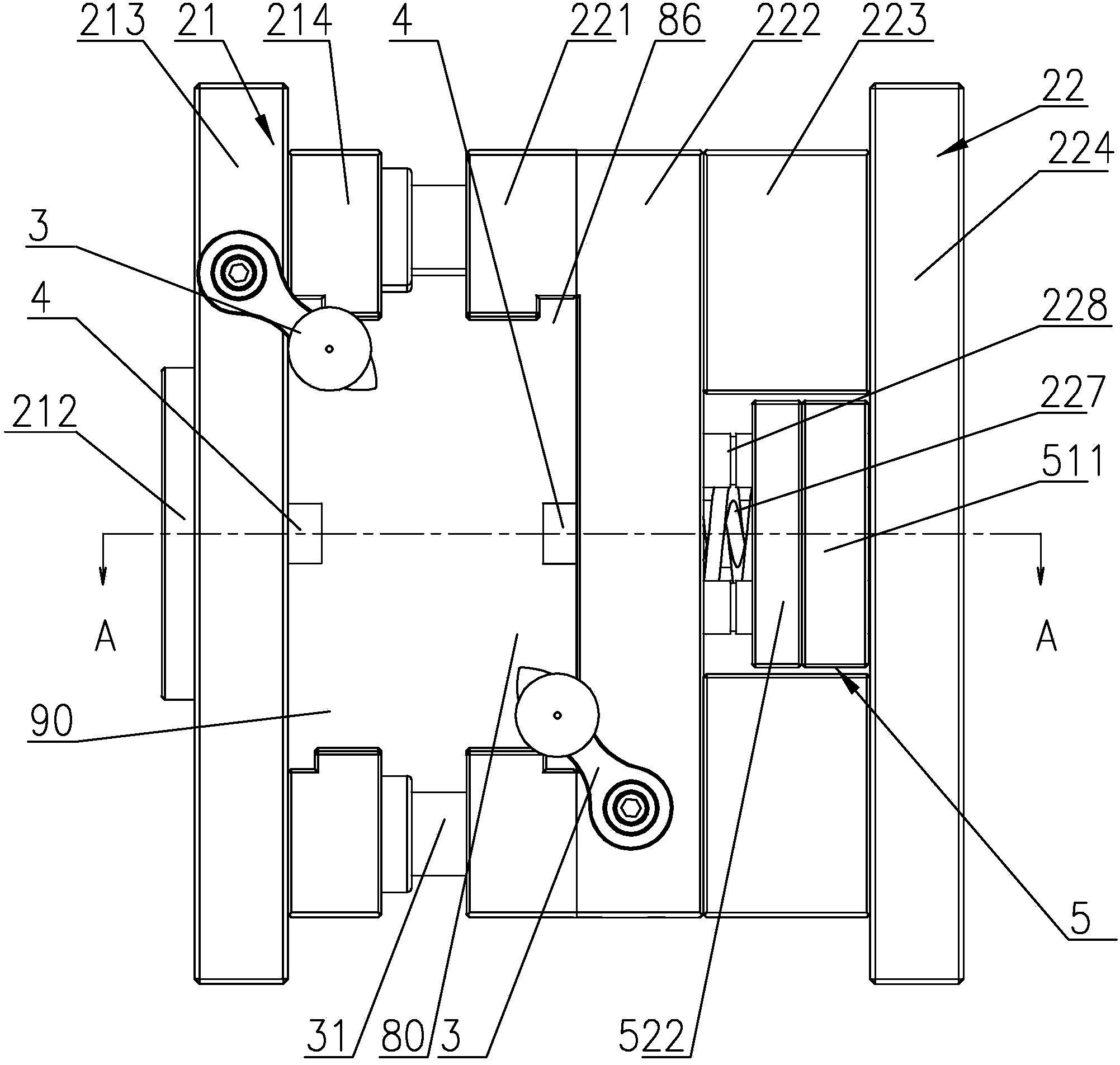

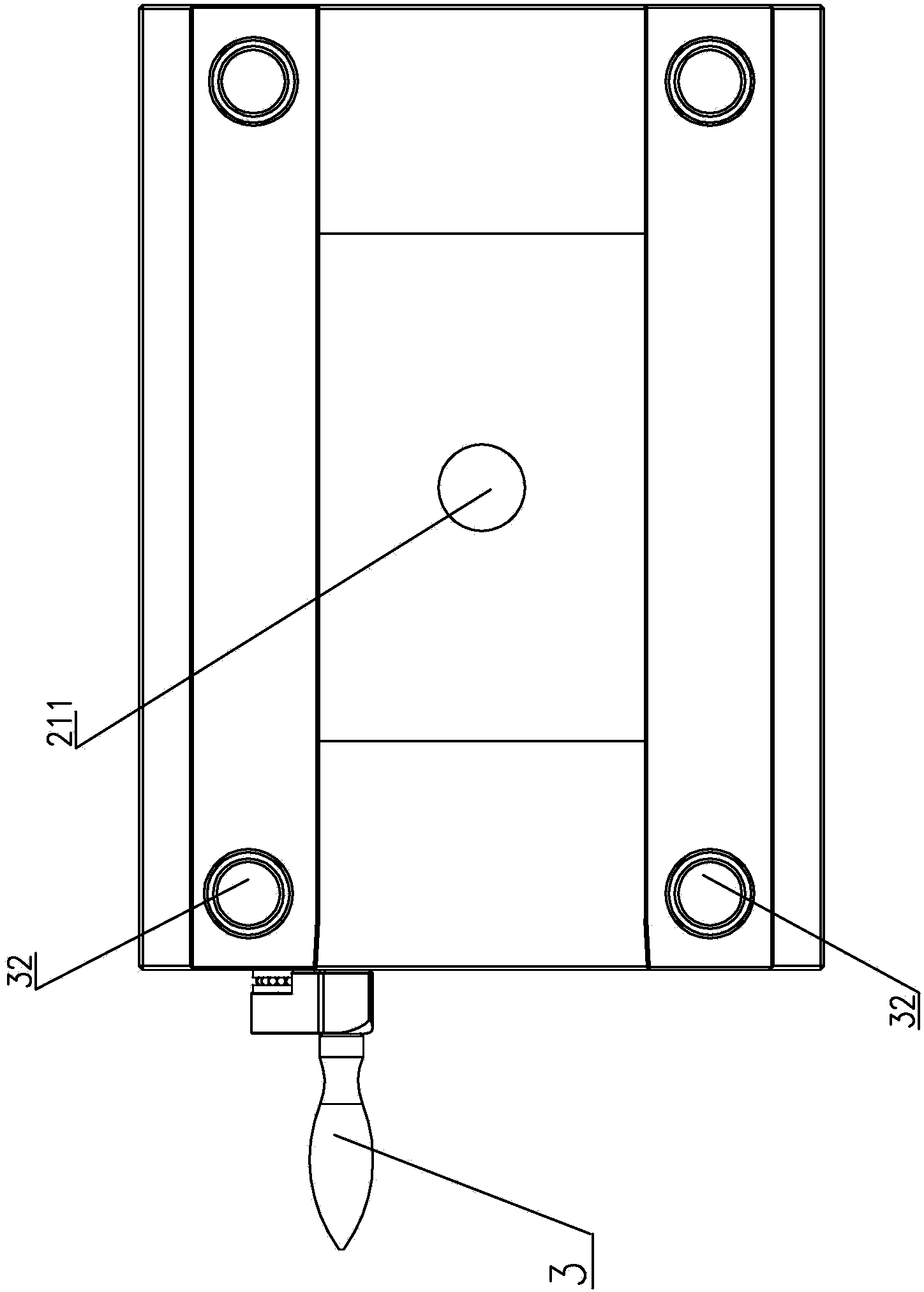

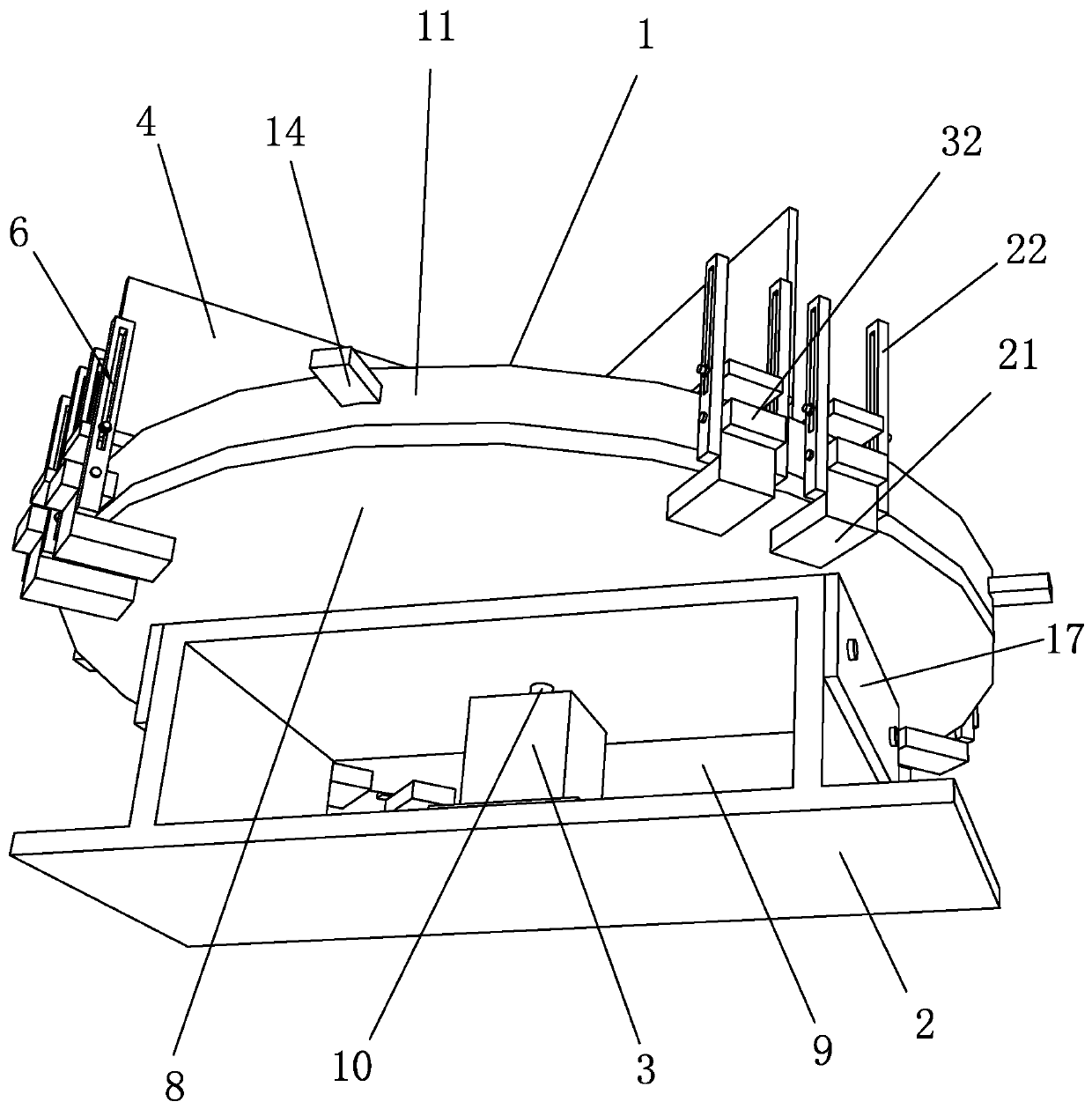

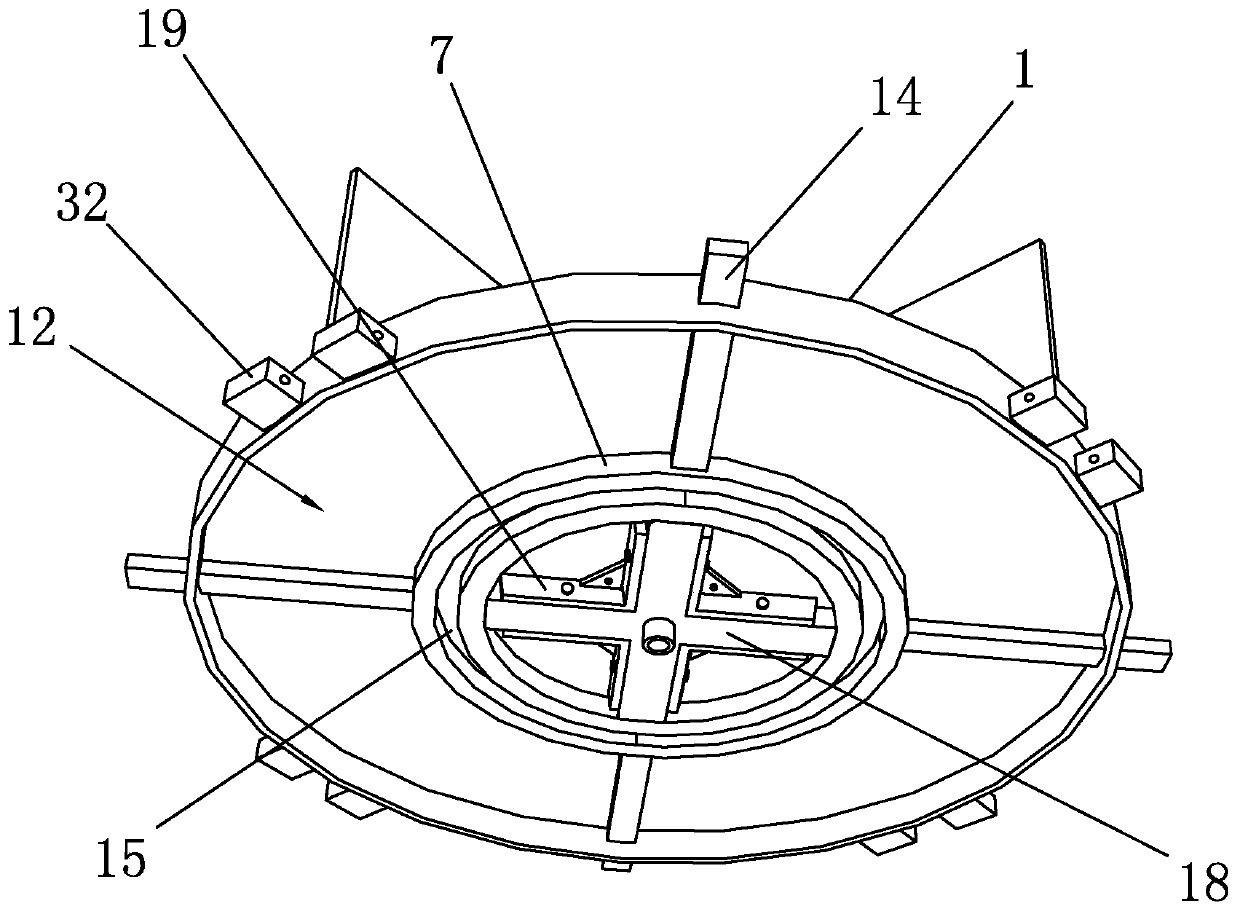

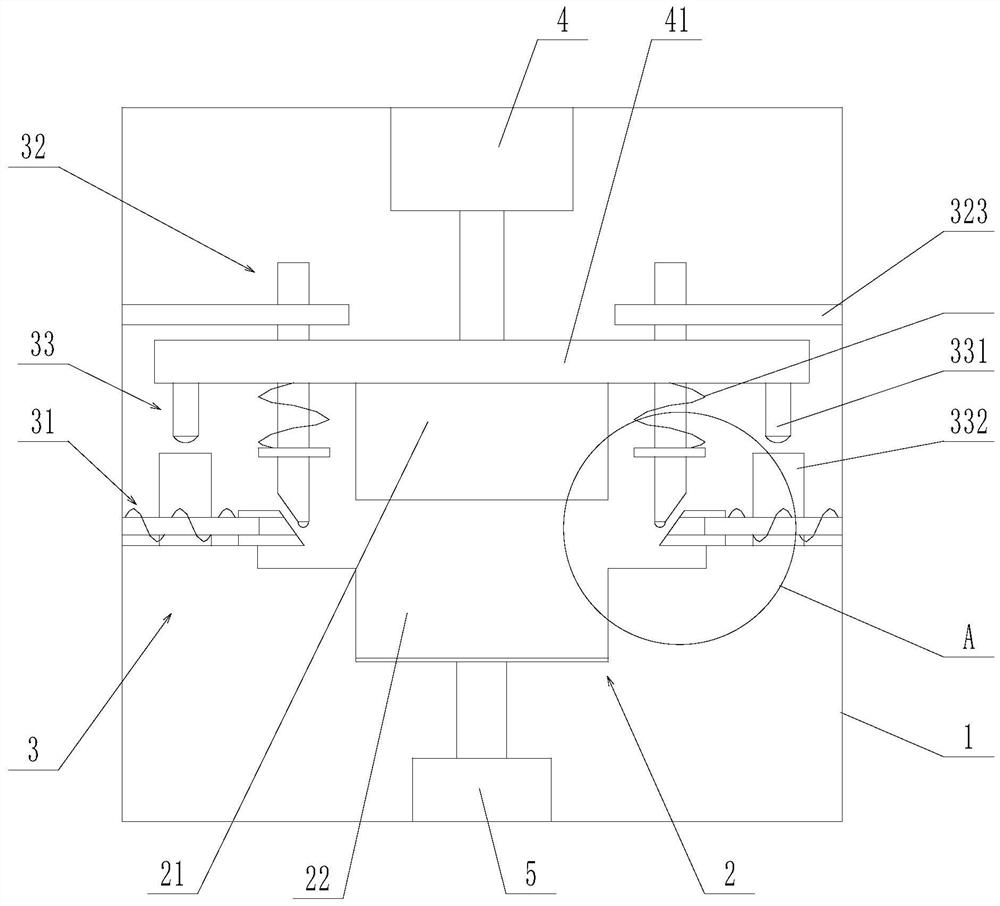

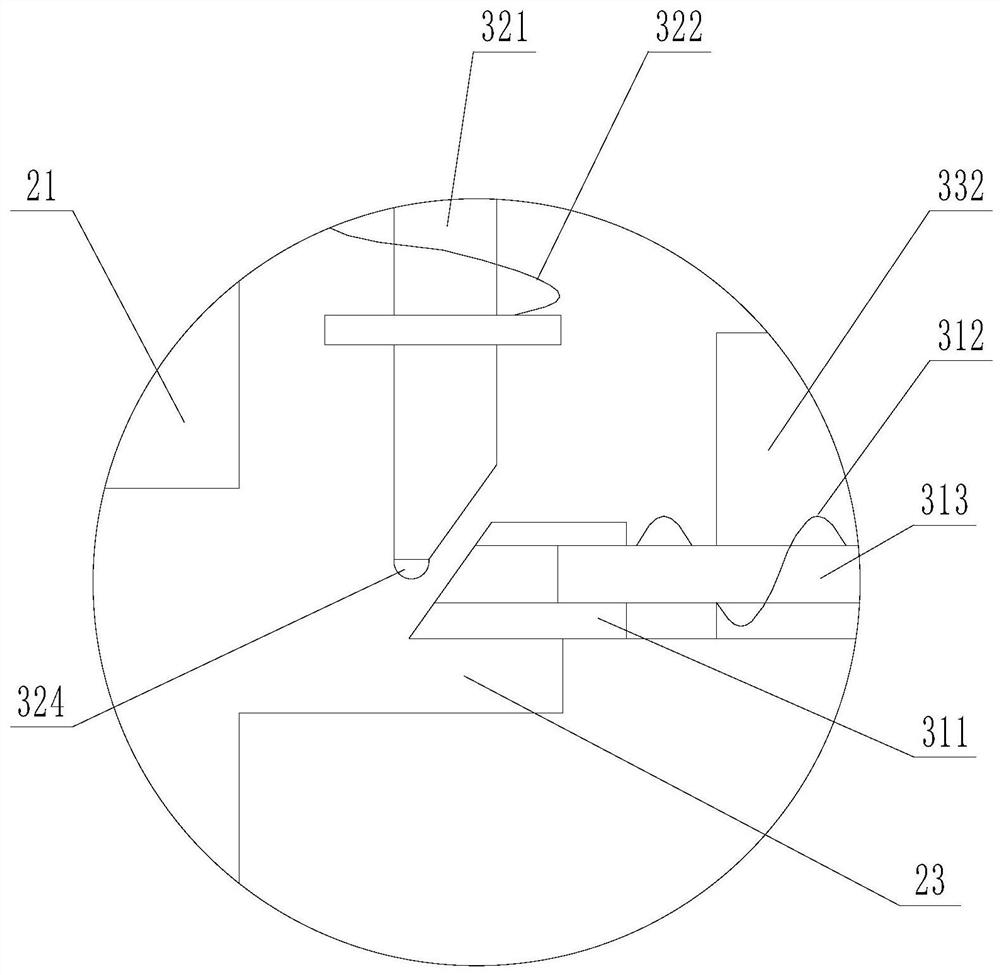

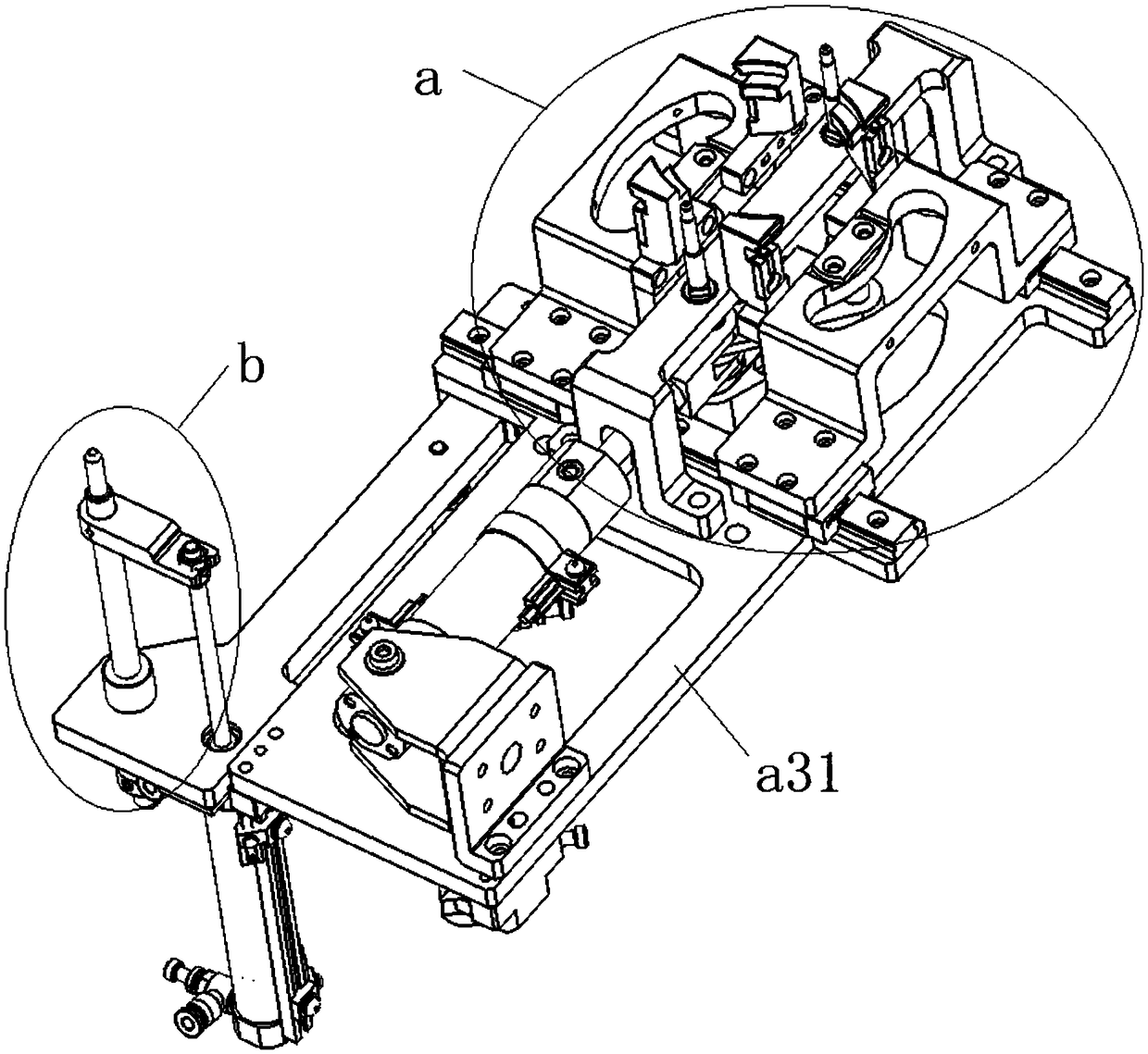

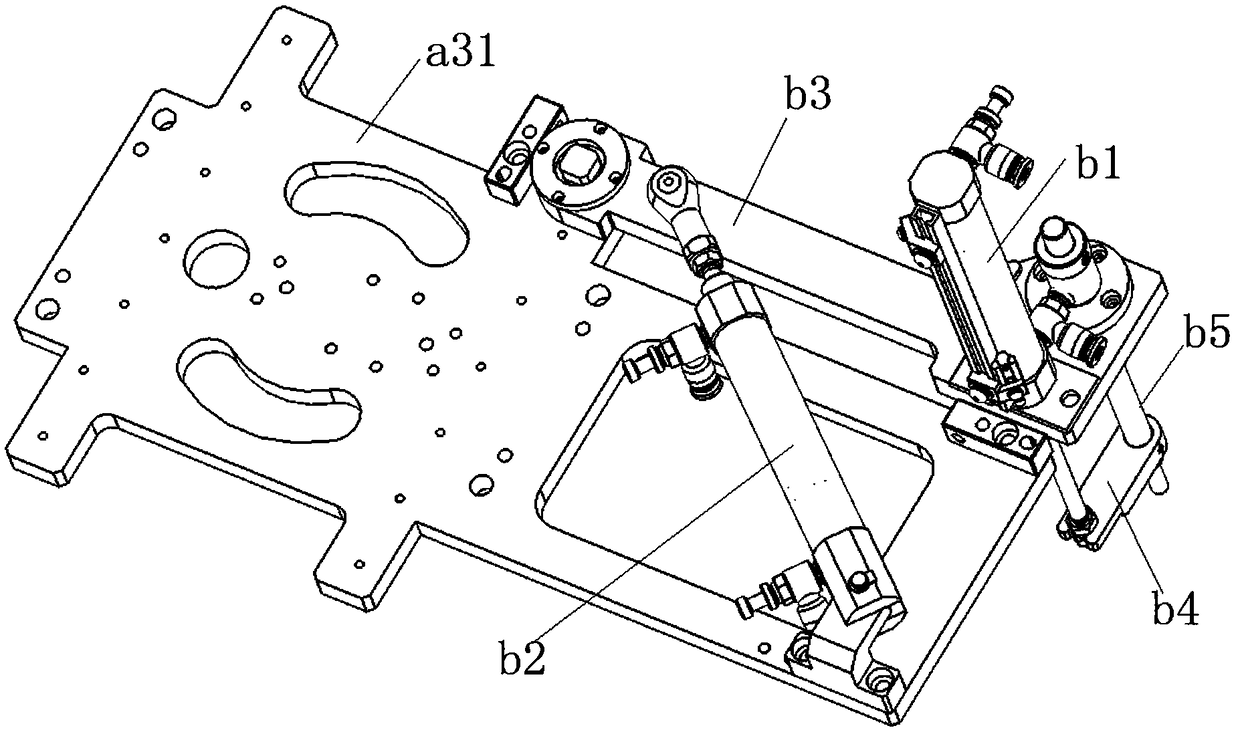

Assembling clamping device

InactiveCN103949999AGuaranteed to be installed in placeReduce labor intensityWork holdersEngineeringMechanical engineering

Owner:TIANJIN ZHONGHUAN SANFENG ELECTRONICS

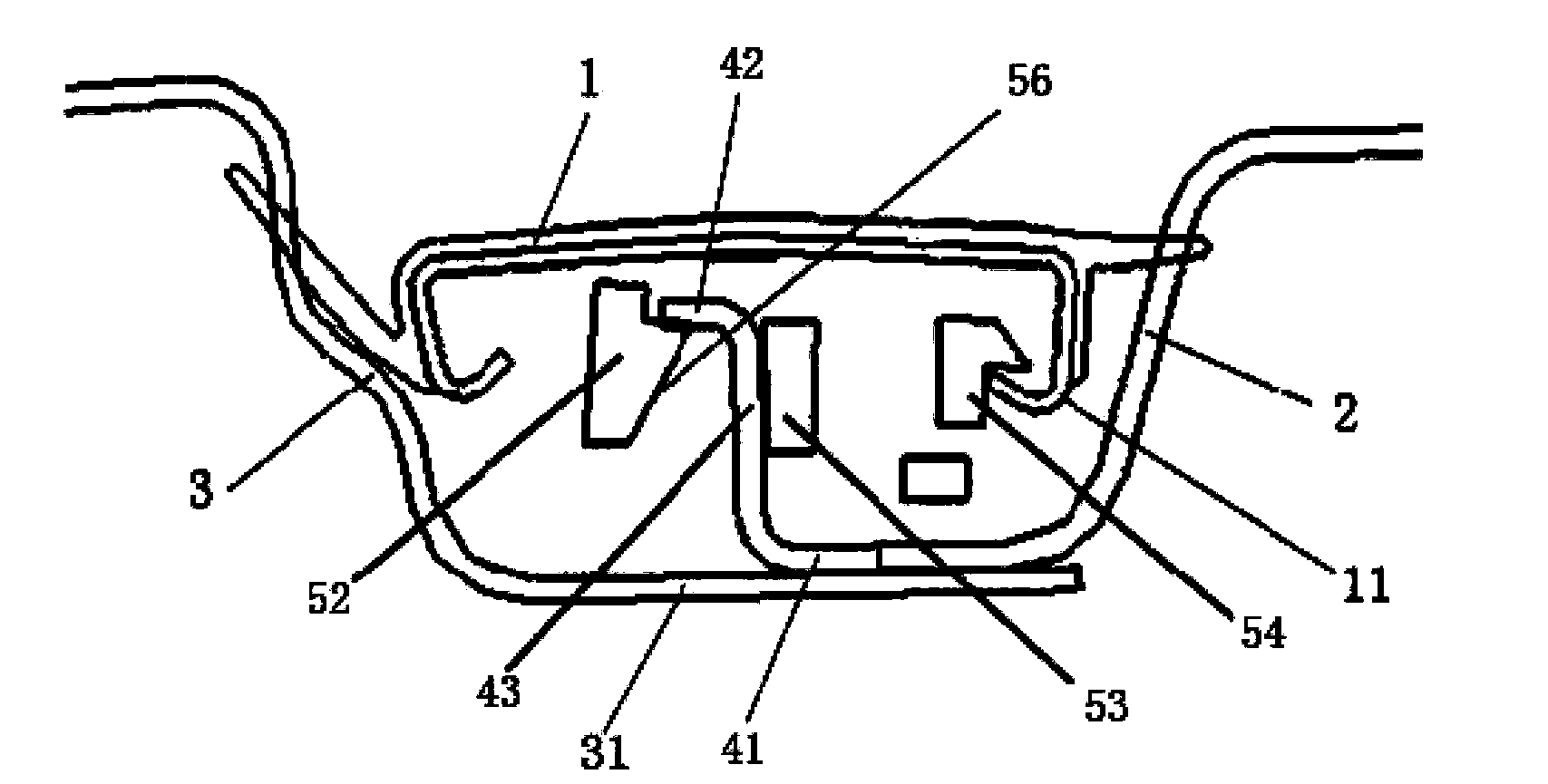

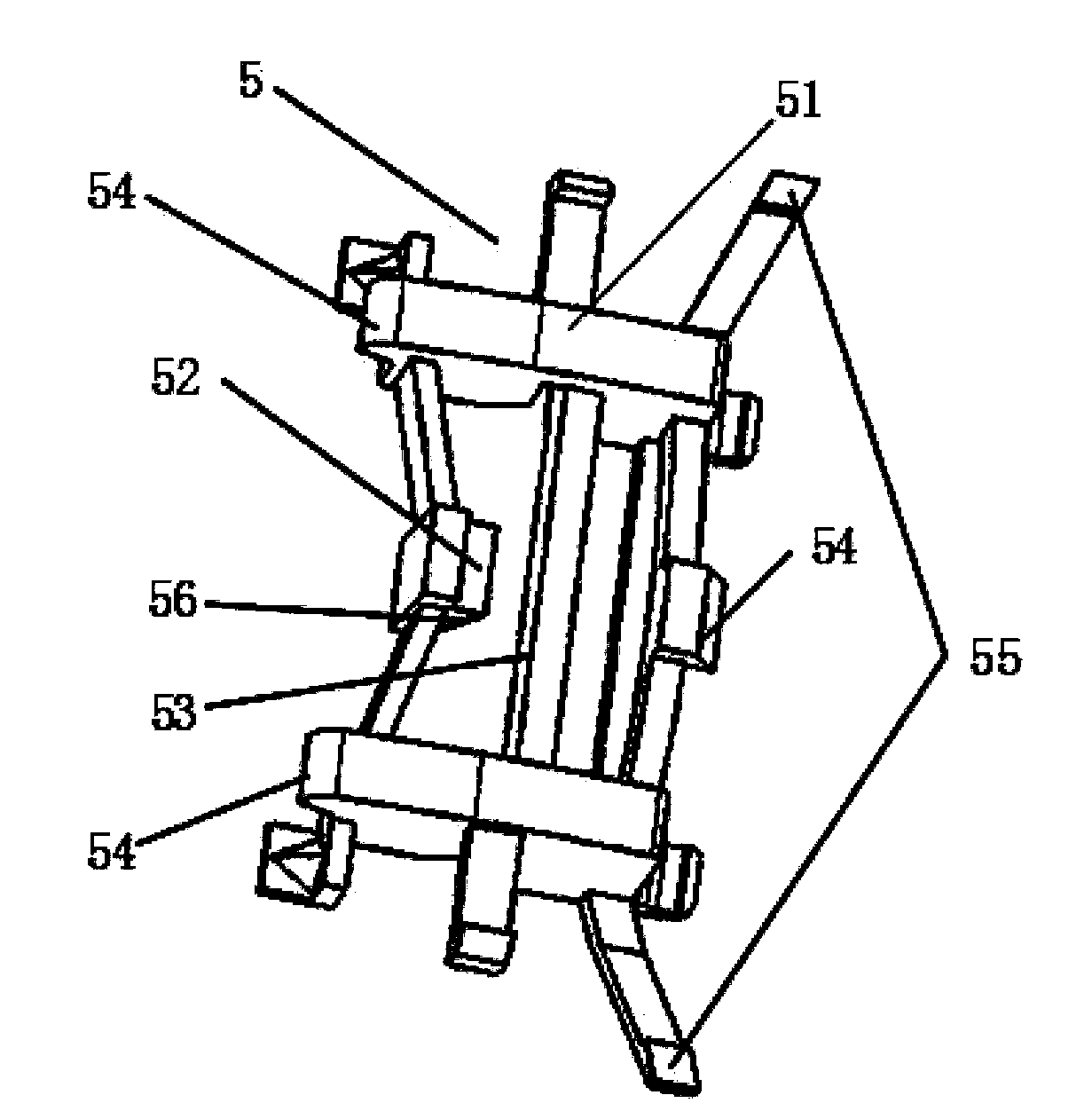

Automobile top cover decoration strip mounting structure

InactiveCN103770725ARealize the limit of Y directionGuaranteed to be installed in placeVehicle componentsWater leakageLap joint

The invention discloses an automobile top cover decoration strip mounting structure which comprises a top cover decoration strip, a top cover overturned edge with the cross section in a reverse L shape and a side wall overturned edge with the cross section in an L shape. The top cover overturned edge and the side wall overturned edge are in lap joint to form a groove, at least three connecting pieces are arranged in the groove, and every connecting piece is fixedly connected with the bottom surface of the groove. The automobile top cover decoration strip mounting structure further comprises at least three clamping components, the clamping components are matched with the connecting pieces, and the top cover decoration strip is respectively in matched connection with the top cover overturned edge, the side wall overturned edge and the clamping components. Every clamping component is of a frame structure and comprises a frame body and a baffle arranged on the frame body, tow ends of the left of the frame body are respectively provided with an inverted hook, the middle of the left of the frame body is provided with a clamp, the middle of the right of the frame body is further provided with an inverted hook, and two ends of the right of the frame body are respectively provided with a supporting foot. The automobile top cover decoration strip mounting structure has the advantages that looseness of the top cover decoration strip is avoided, the appearance is smoother and more attractive after the top cover decoration strip is installed, and water leakage can be avoided simultaneously.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

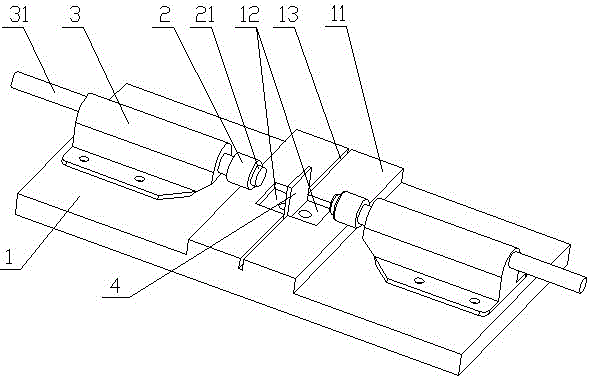

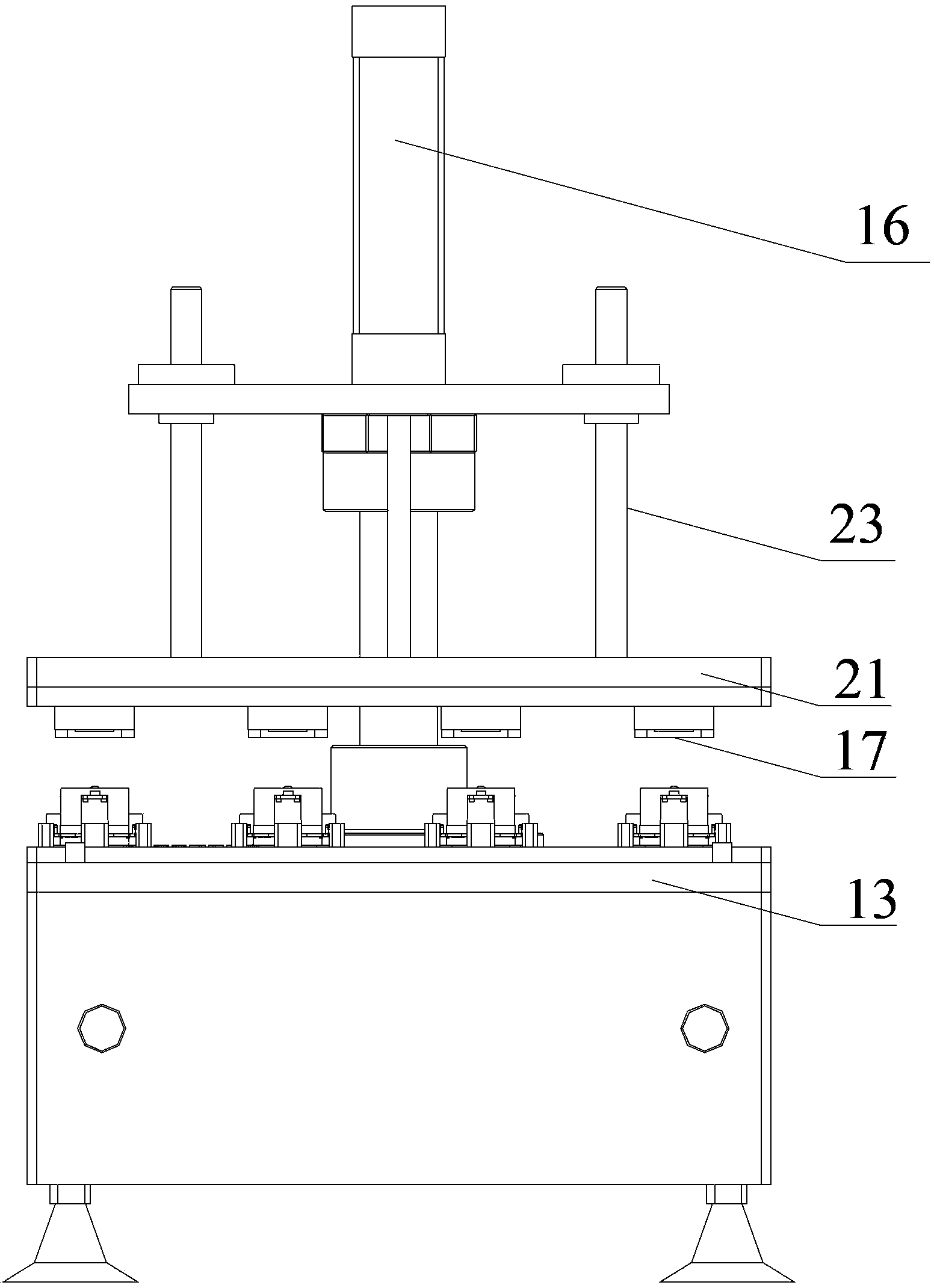

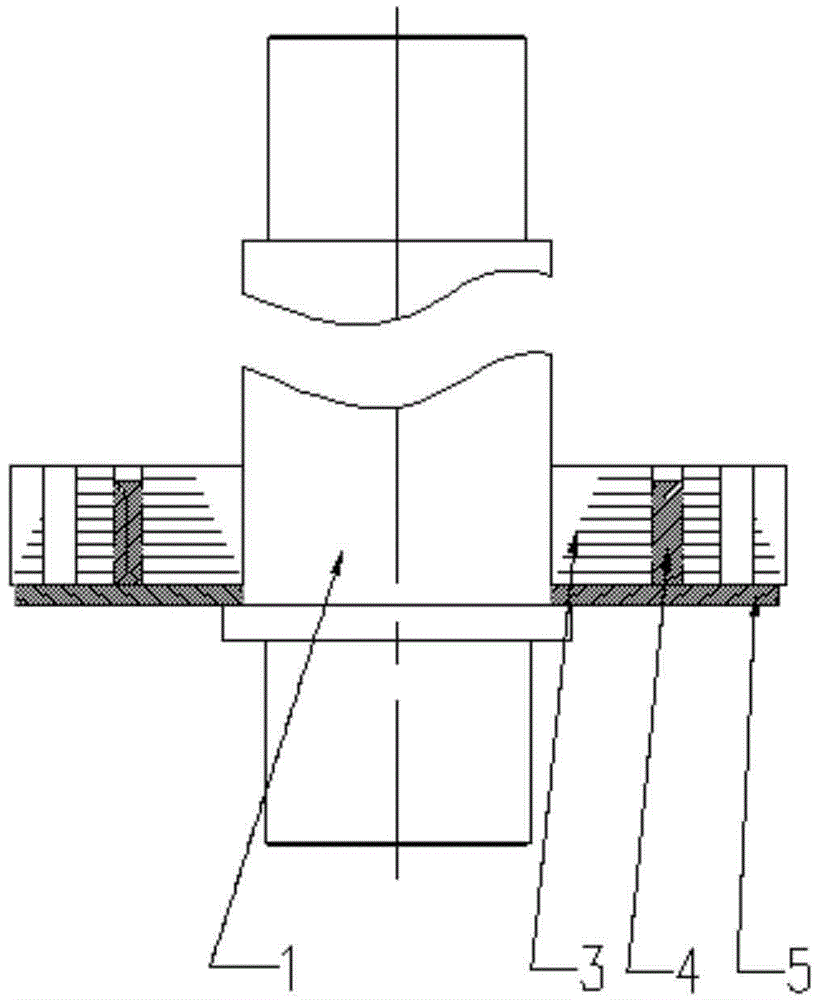

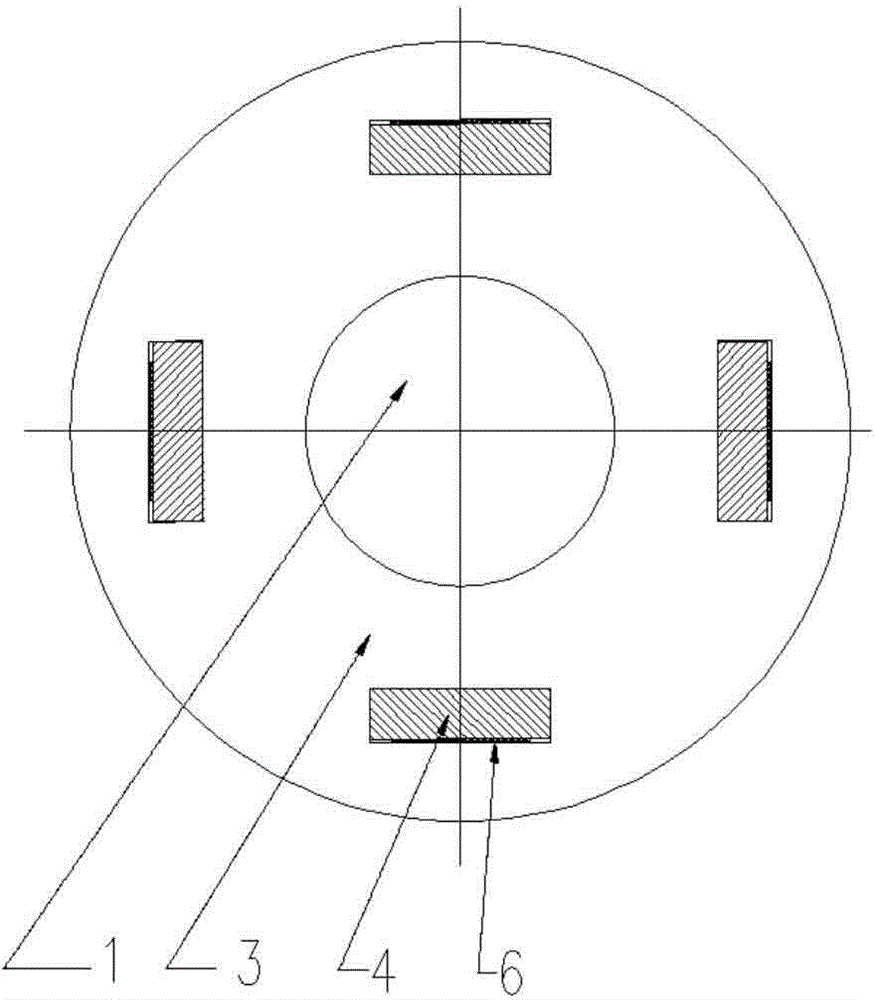

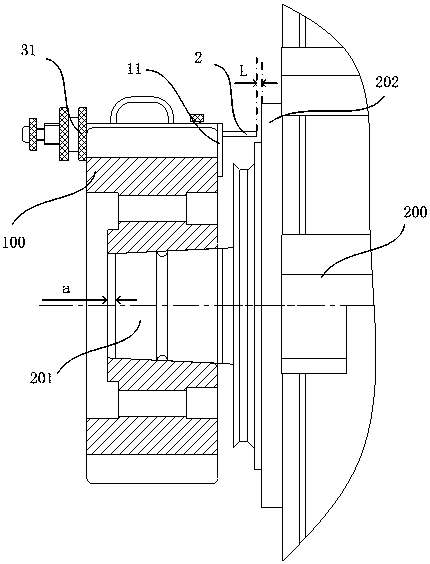

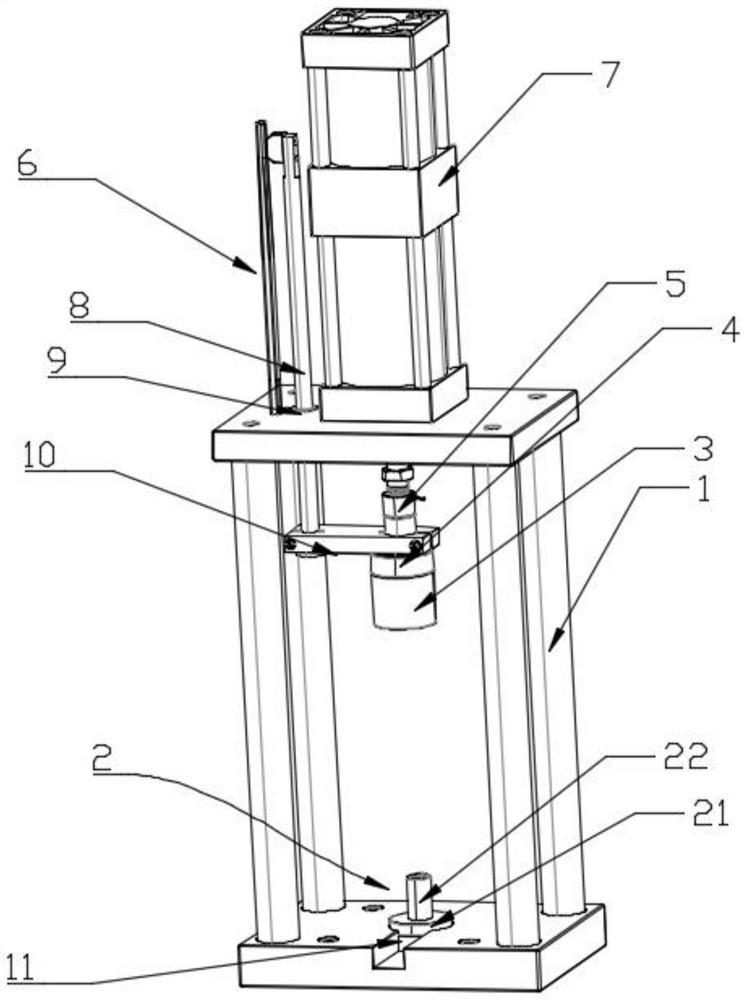

Tool for assembling bearing rubber gasket assembly and bearing rubber gasket seat

InactiveCN104339143AGuaranteed to be installed in placeReduce manual labor intensityMetal working apparatusEngineeringStandard position

The invention discloses a tool for assembling a bearing rubber gasket assembly and a bearing rubber gasket seat. The tool comprises a workbench, a positioning device for fixing the bearing rubber gasket assembly, a pad padded below the bearing rubber gasket assembly, a pressing component for axially pressing the bearing rubber gasket seat, and a driving device for driving the pressing component, wherein the pad is positioned within a projection area on the workbench in the axial direction of the bearing rubber gasket seat. By adopting the structure, the tool for assembling the bearing rubber gasket assembly and the bearing rubber gasket seat can ensure that the bearing rubber gasket assembly is assembled at a standard position inside the bearing rubber gasket seat, and can effectively reduce the labor intensity.

Owner:GREE ELECTRIC APPLIANCES INC

Injection mould capable of being easily de-molded

The invention discloses an injection mould capable of being easily de-molded. The injection mould is formed by a movable mould and a fixed mould, which are used as the injection mould, wherein each one of the movable mould and the fixed mould comprises a molding part, a pushing-out mechanism, a mould guide part and a pouring system; a mould cavity is arranged in the mould; the mould cavity is arranged on the mould closing face of the single injection mould, namely, the mould cavity is arranged on the mould closing face of the movable mould or the mould closing face of the fixed mould; the mould closing face of the other injection mould has no mould cavity and is a plane; the movable mould and the fixed mould are closed to form the complete injection mould cavity. According to the injection mould disclosed by the invention, the structure of only arranging the mould cavity on the single injection mould is applicable to injection of a standard test sample strip or an injection piece with the similar shape. The injection mould has the beneficial effects of being beneficial to simplification of the structure of the mould, improving the manufacturability of the mould and reducing the cost of the mould.

Owner:广州现代塑料有限公司

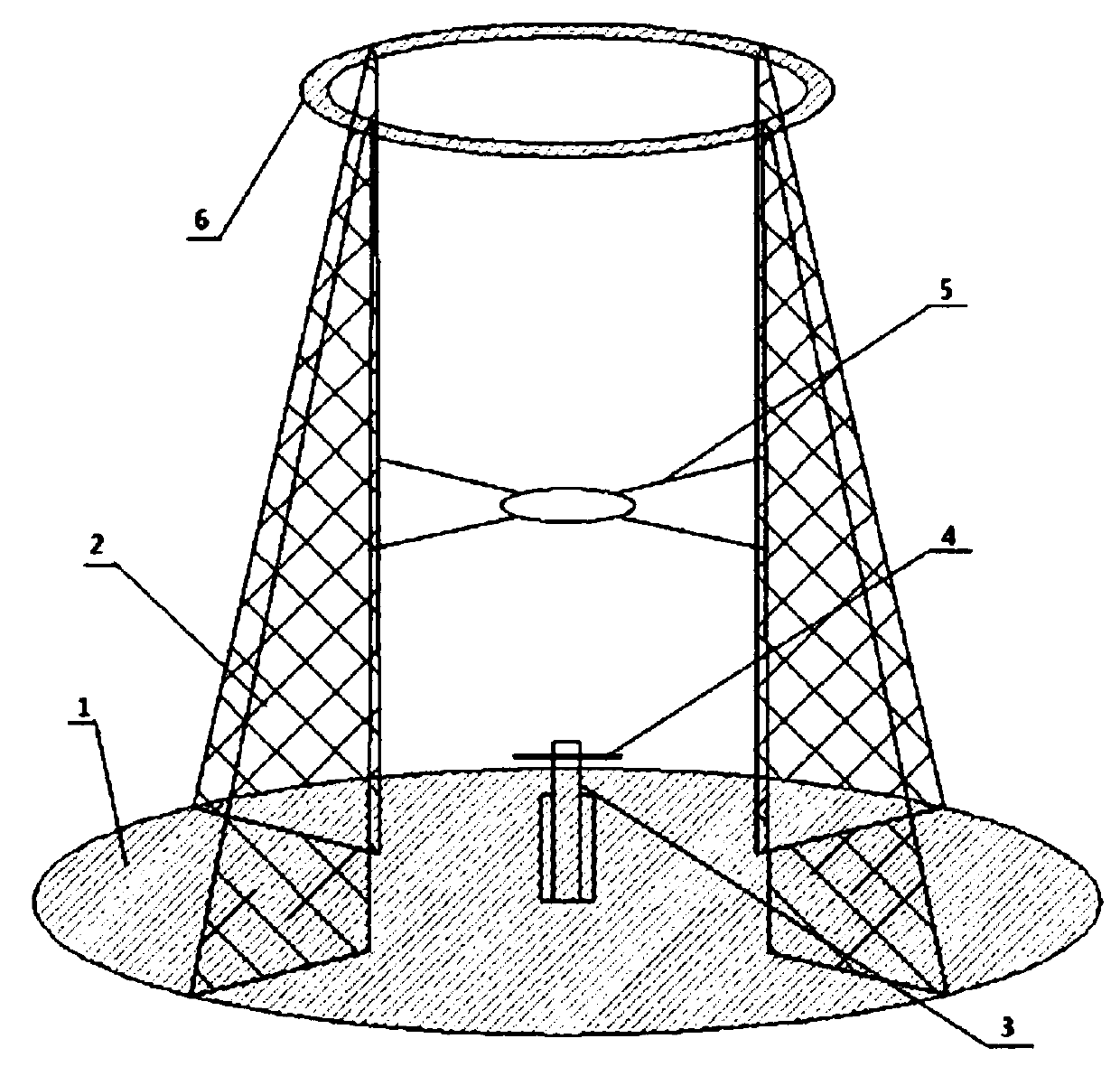

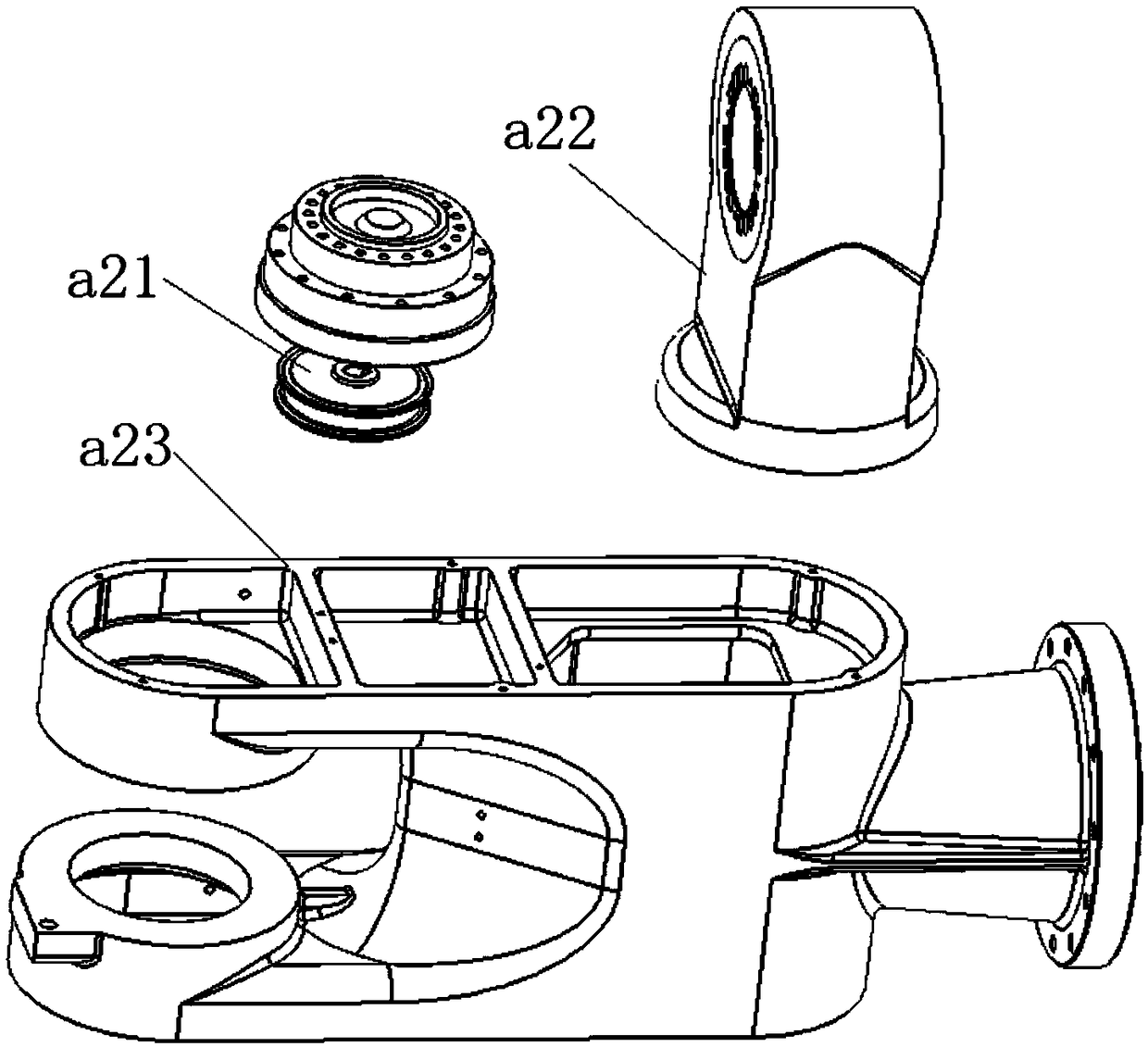

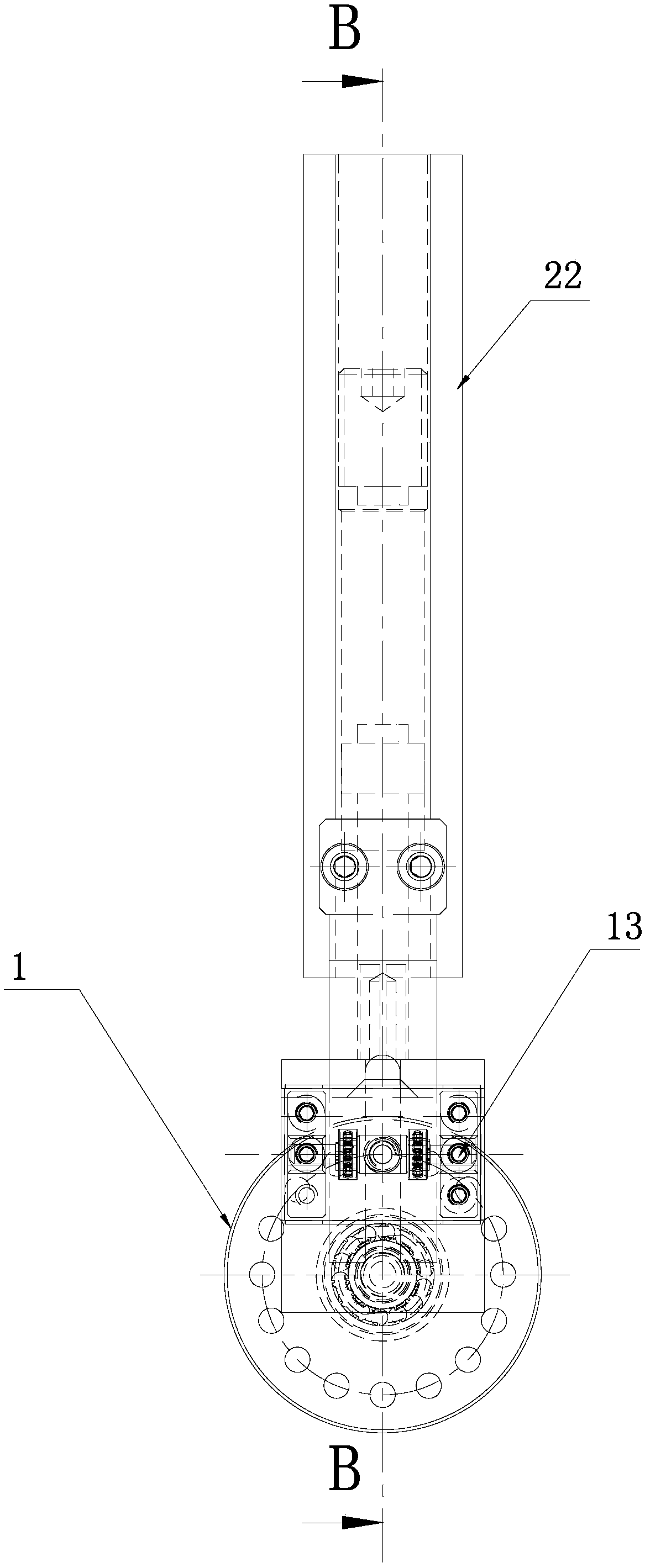

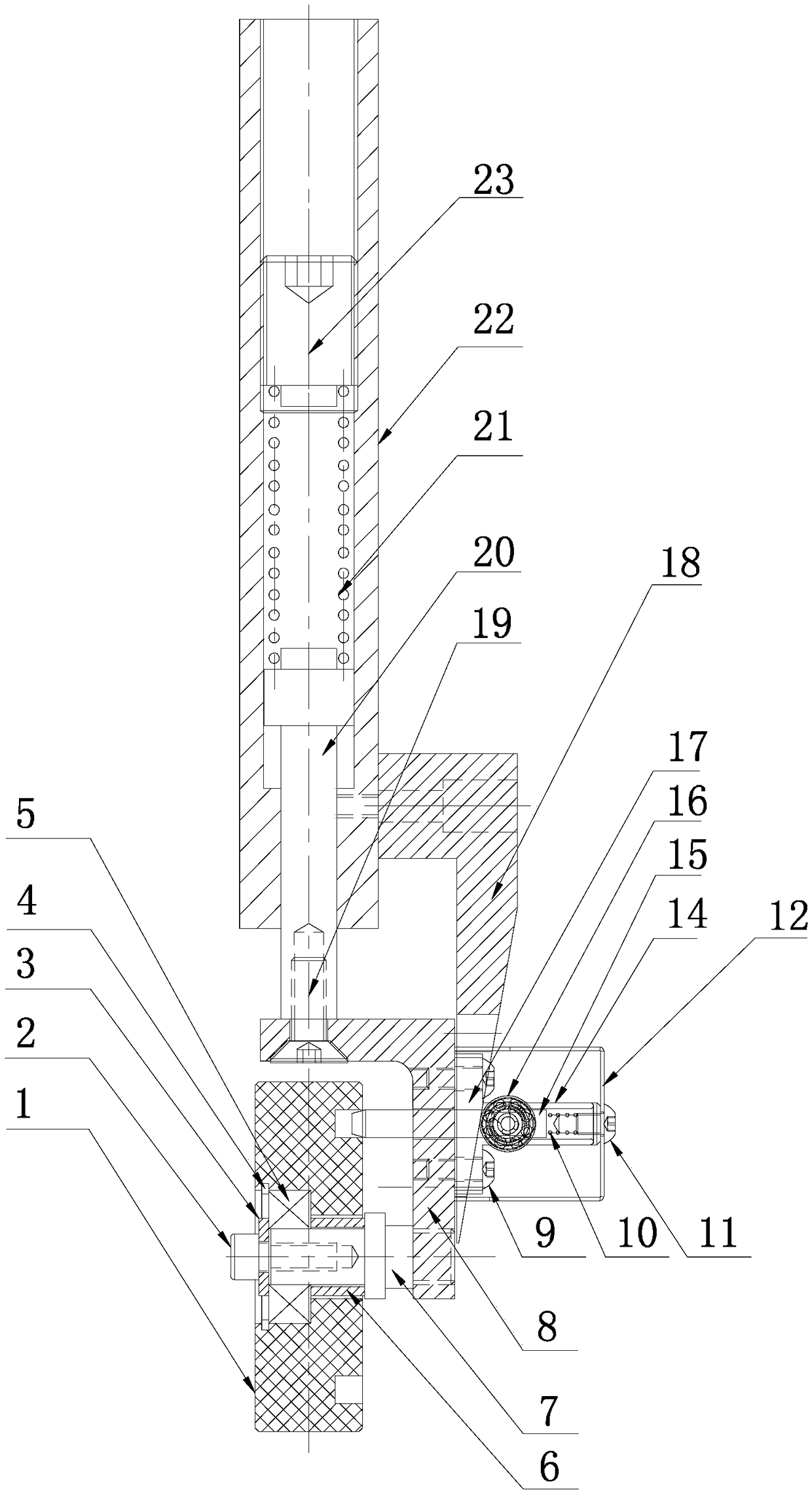

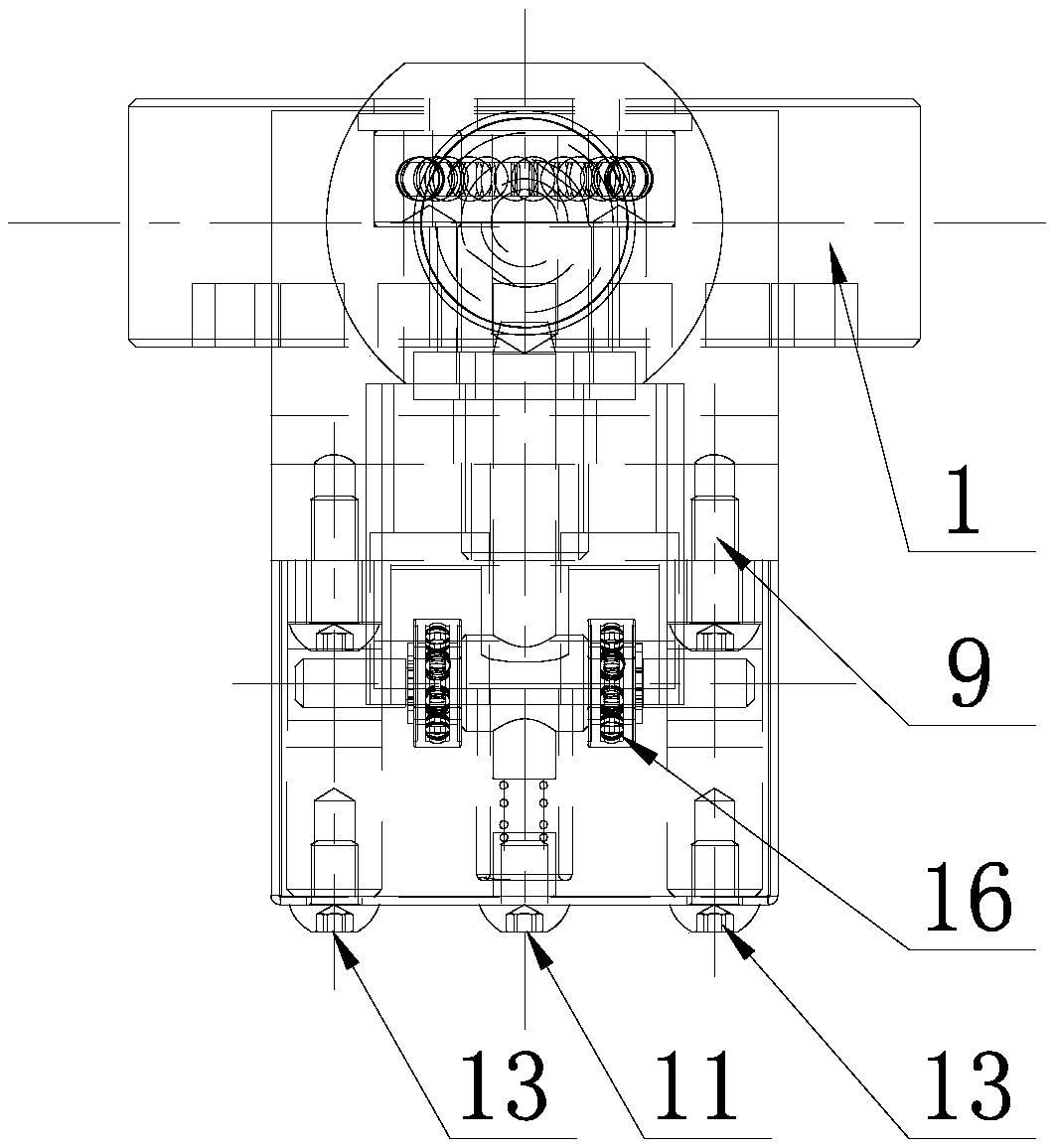

Underwater mechanical low-noise separation device

InactiveCN108035946AGuaranteed to be installed in placeAvoid misuseSecuring devicesLow noiseUnderwater

The invention relates to an underwater mechanical low-noise separation device. The separating device mainly solves the problem that an existing separation device is disposable, the impact load of structural members is large, the separation noise is large, and water is polluted after action. According to the technical scheme, the underwater mechanical low-noise separation device comprises an upperbase body, a lower base body, a hydraulic pressure spring, a hydraulic pressure rod, a hydraulic pressure film, a nut, a compression ring, a top cover, a cylindrical table, a safety pin, a separationspring, steel balls, a plug screw, a sealing gasket, a plug, a large sealing ring and a small sealing ring, wherein the hydraulic pressure rod penetrates through a round hole formed in a middle partition plate in an inner cavity of the upper base body to be arranged in the inner cavity of the upper base body, the hydraulic pressure film is arranged in an upper cavity of the upper base body, and the outer edge of the hydraulic pressure film makes contact with the upper surface of the middle partition plate of the inner cavity of the upper base body. The underwater mechanical low-noise separation device has the advantages that the hydraulic pressure is used as the driving force, other power sources are not needed, the structure is simple, operation is convenient, and the specified water depth can be reached to relieve mechanical limiting so as to realize low-noise separation.

Owner:SHANXI UNIV

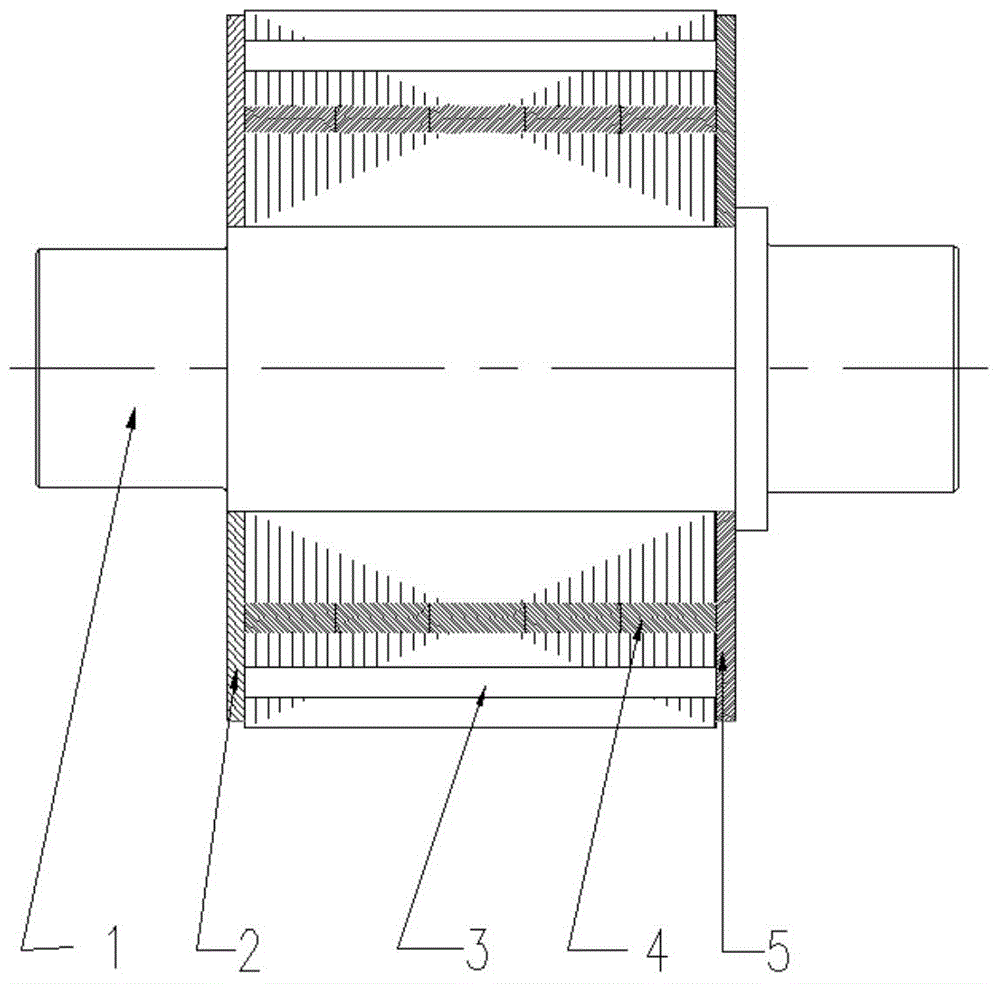

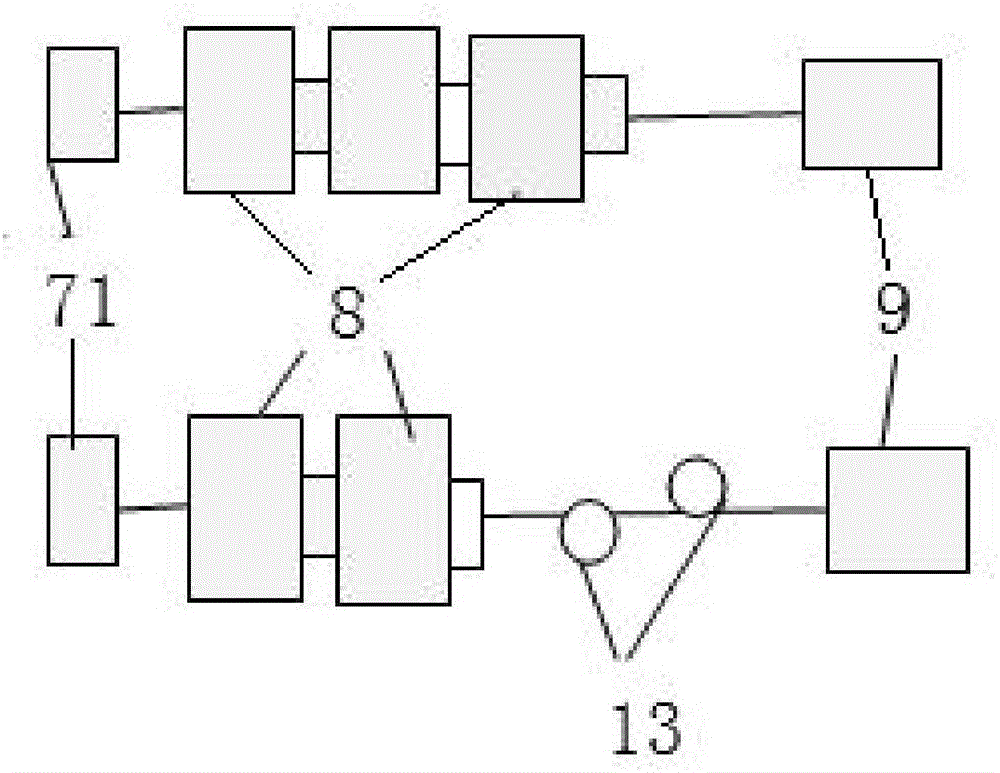

Motor, motor rotor and motor rotor manufacturing method

ActiveCN104467228AEasy to installGuaranteed to be installed in placeMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetEngineering

The invention provides a motor rotor. The motor rotor comprises a rotary shaft and rotor cores matched with the rotary shaft in a sleeving mode, wherein the multiple rotor cores are arranged on the rotary shaft in a layered and sleeving mode in the axial direction of the rotary shaft, a permanent magnet is installed on each layer of rotor cores in the circumferential direction of the rotary shaft and is located in permanent magnet grooves of the rotor cores, and the rotary shaft is sleeved with a front pressing plate and a rear pressing plate which are arranged at the two axial ends of the rotor cores to fix the rotor cores. The rotor cores are arranged in the layered mode, the permanent magnet on each layer can be installed in place and can be controlled easily, and smooth and damage-free installation of the permanent magnets is guaranteed. The invention further provides a motor rotor manufacturing method and a motor comprising the motor rotor.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

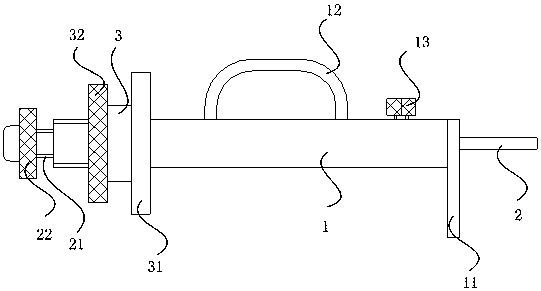

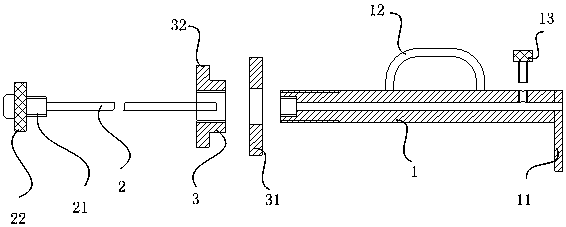

Locomotive motor gear hot-charging limiting tool and installation method

InactiveCN108274430AGuaranteed to be installed in placeImprove installation qualityMetal working apparatusMetal-working hand toolsEngineeringMotor shaft

The invention provides a locomotive motor gear hot-charging limiting tool and an installation method. The locomotive motor gear hot-charging limiting tool comprises a sleeve, a locating rod and a locating nut, a screw mechanism is arranged on the first end portion of the locating rod, the inner and outer walls of the first end portion of the sleeve are separately provided with thread mechanisms, and the screw mechanism and the locating nut are connected to the first end portion of the sleeve in a threaded mode. The second end portion of the locating rod passes through the sleeve and extends out of the sleeve, the locating nut is provided with a first locating plate, and a second locating plate which is arranged opposite to the first locating plate is arranged on the second end portion of the sleeve. The gear can be installed on a motor shaft in a hot-charging mode through the locomotive motor gear hot-charging limiting tool to improve the efficiency and precision of gear installation.

Owner:CRRC SIFANG CO LTD

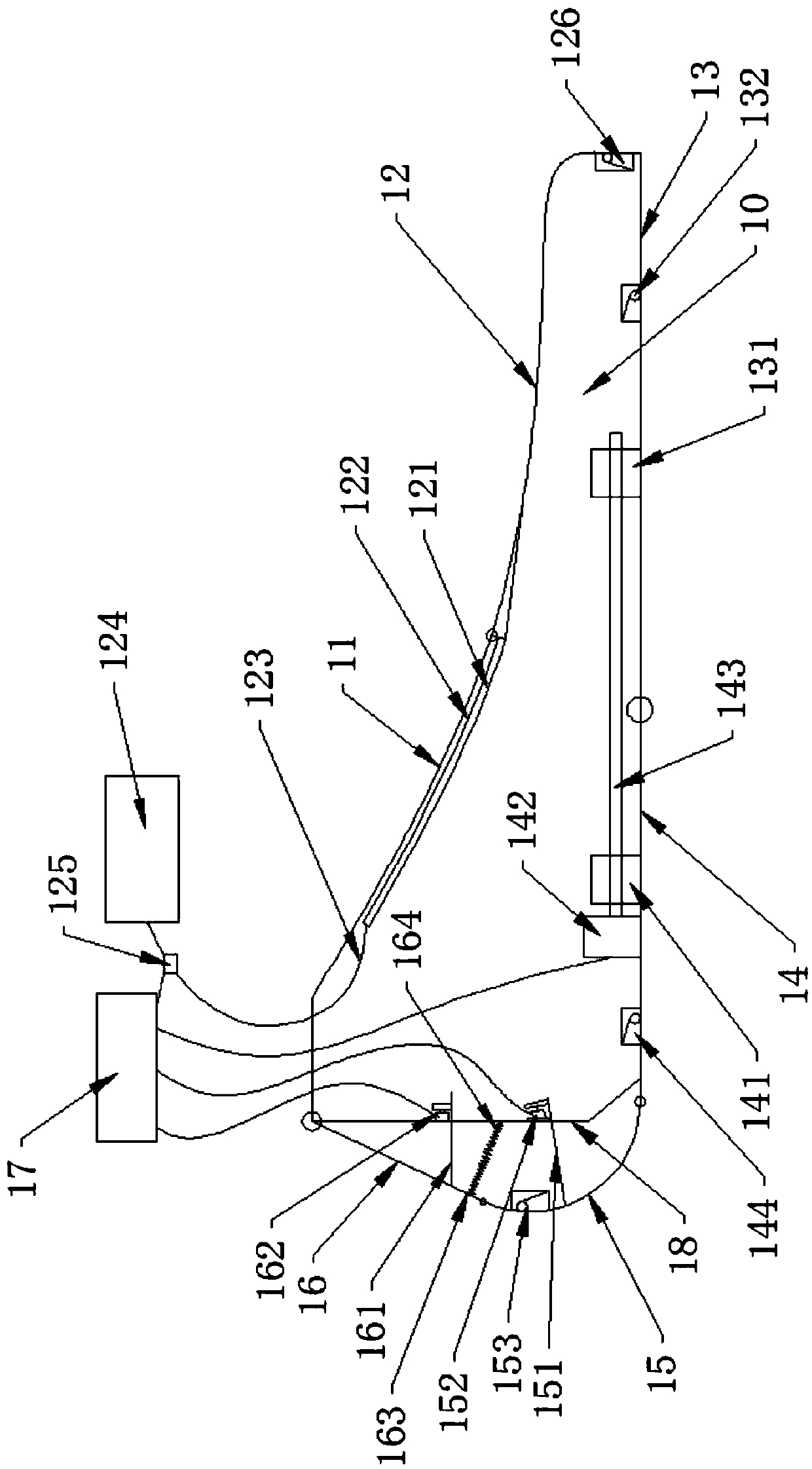

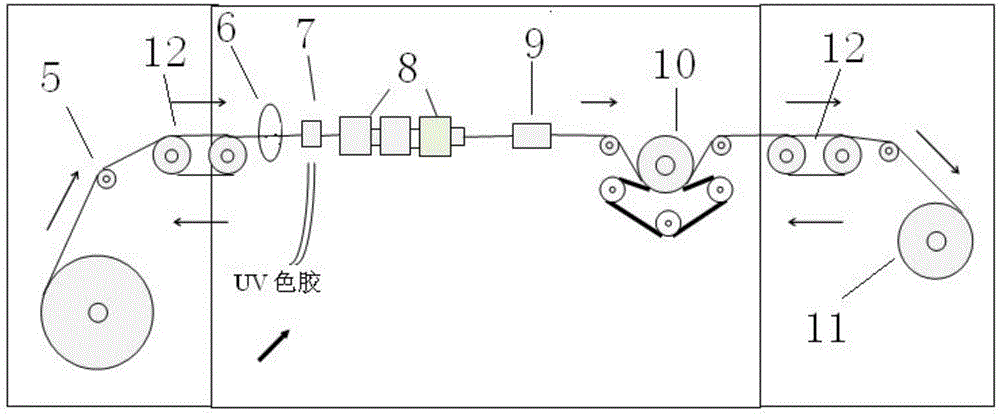

Method of reducing optical fiber coloring unevenness and apparatus thereof

InactiveCN106091993AGuaranteed to be installed in placeReduce free lengthUsing optical meansLight spotEngineering

The invention relates to a method of reducing optical fiber coloring unevenness and an apparatus thereof. The method comprises the following steps that before an optical fiber is assembled, a laser is arranged between a pay-off disc and an eye film die holder; the laser is arranged at a preset center line and irradiates towards an eye film die hole along the set center line; after an eye film is installed, a light spot condition projected by the laser on the eye film is recorded and whether the installed eye film is usable is determined; power of original UV lamps is increased and a quantity of the UV lamps is reduced, and two guide wheels are additionally installed at positions where the UV lamps are removed. The method and the apparatus have advantages that on one hand, through confirming the size of the light spot, whether a center of the light spot is deviated is observed at any time so as to ensure that the eye film is installed on the place; on the other hand, through reducing an optical fiber free length and additionally installing the guide wheels, optical fiber jitter is reduced and adverse factor generation is decreased so as to solve a problem that optical fiber coloring is uneven.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

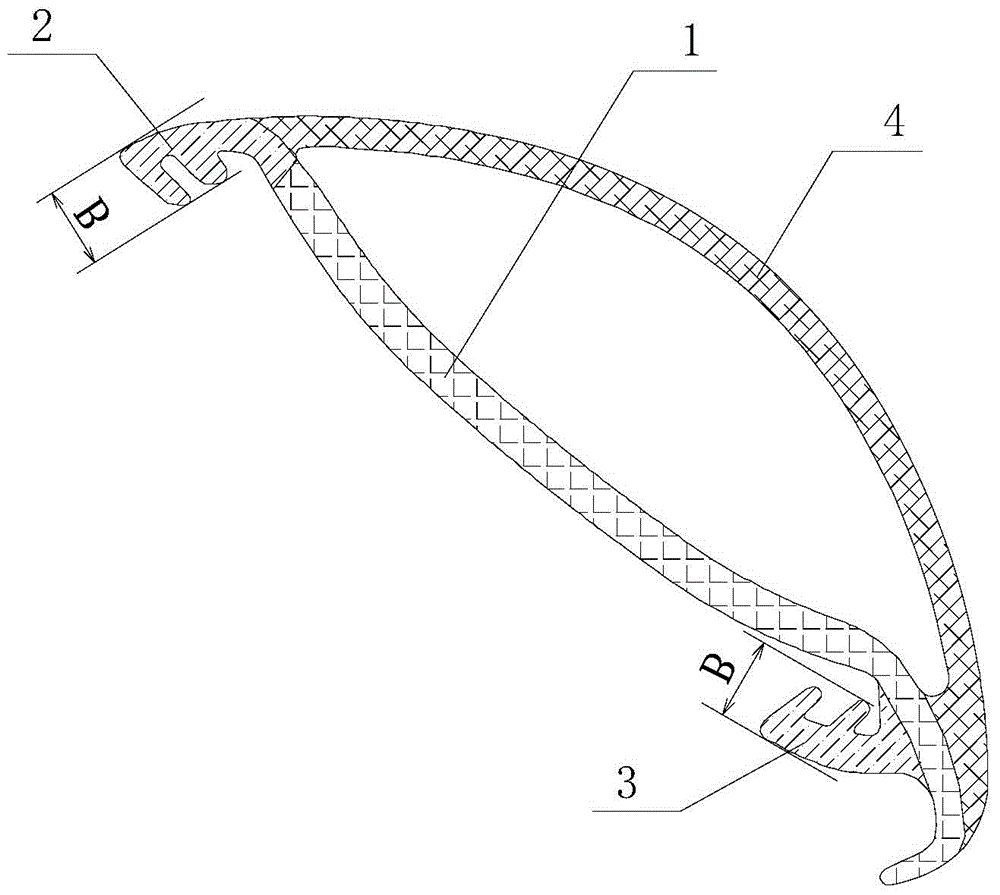

Rubber sealing strip used for outer protective plate of automobile door

ActiveCN104589977AAvoid deformation failureReduce the amount of interferenceEngine sealsVehicle sealing arrangementsHardnessCo extrusion

The invention provides a rubber sealing strip used for an outer protective plate of an automobile door. The rubber sealing strip used for the outer protective plate of the automobile door is composed of a middle plate-shaped supporting portion, a first insertion claw portion, a second insertion claw portion and an outer arc protruding portion. The two insertion claw portions are located on the two sides of the plate-shaped supporting portion respectively, and the outer arc protruding portion is located on the two sides of the plate-shaped supporting portion. The rubber sealing strip is characterized in that a multi-body co-extrusion forming technology is adopted by the rubber sealing strip, and the hardnesses of the two insertion claw portions, the hardness of the plate-shaped supporting portion and the hardness of the outer arc protruding portion become smaller gradually. According to the rubber sealing strip, the hardnesses of the materials of different portions are adjusted by utilizing the multi-body co-extrusion technology, the two insertion claw portions have high hardness, so that the tension of the two insertion claw portions in the installation groove become larger, enough anti-disengagement strength is guaranteed, curling deformation caused in the assembly process is reduced, the assembly speed is increased, it is guaranteed that the rubber sealing strip can be installed in place, and the assembly quality is improved; the plate-shaped supporting portion has the moderate hardness, and therefore ineffectiveness caused by deformation of the sealing strip is avoided; the hardness of the outer arc protruding portion is low, so that the fit performance between the outer arc protruding portion and a metal plate of a door frame is improved, and therefore the leakproofness between the automobile door and the door frame is improved.

Owner:天津华涛汽车塑料饰件有限公司

Construction method of diversion channels for ecological management of riverway

InactiveCN113235523AGuaranteed adaptabilityGuaranteed to be installed in placeBreakwatersQuaysEnvironmental resource managementEcological environment

The invention relates to the technical field of river ecological management, in particular to a construction method of diversion channels for ecological management of a riverway. The construction method comprises the following steps of cofferdam water pumping, terrain shaping, cement mixing pile construction, diversion canal construction, hard revetment and diversion canal connection construction and lift pump well construction. The diversion channels are arranged on the two sides of the river channel, sewage polluting the river channel is intercepted, collected and purified through the diversion channels on the two sides of the river channel, the ecological environment of the urban river channel is not damaged, and the regional water environment is greatly improved; and a sealed sewage conveying channel is formed between the diversion channels and a hard revetment, and cement mixing piles are arranged at the bottoms of the diversion channels for reinforcement treatment, so that on one hand, a waterproof curtain is formed to block underground water leakage, and on the other hand, a composite foundation is formed to improve the bearing capacity of the foundation and prevent leakage caused by later settlement of the diversion channels.

Owner:无锡本源建设工程有限公司

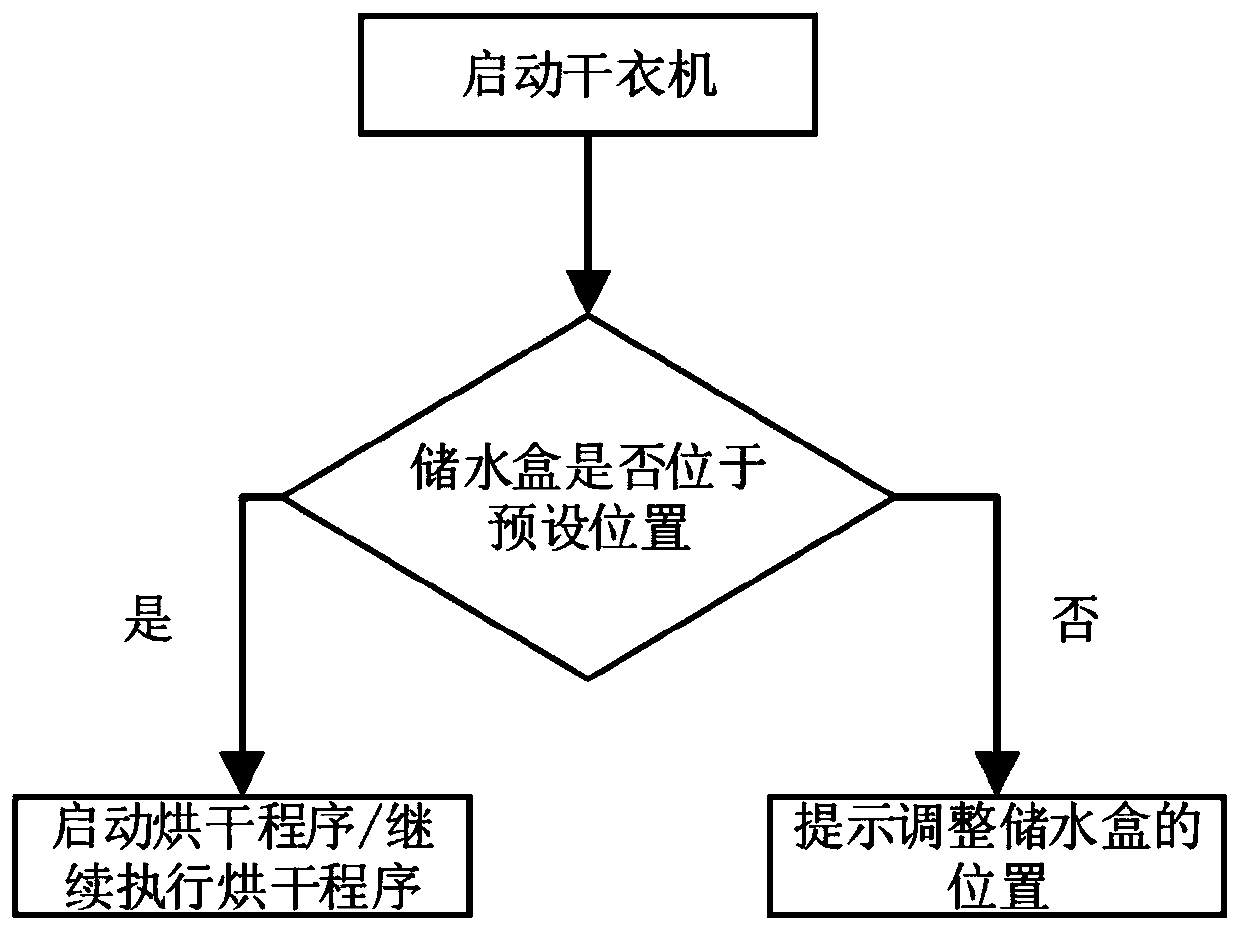

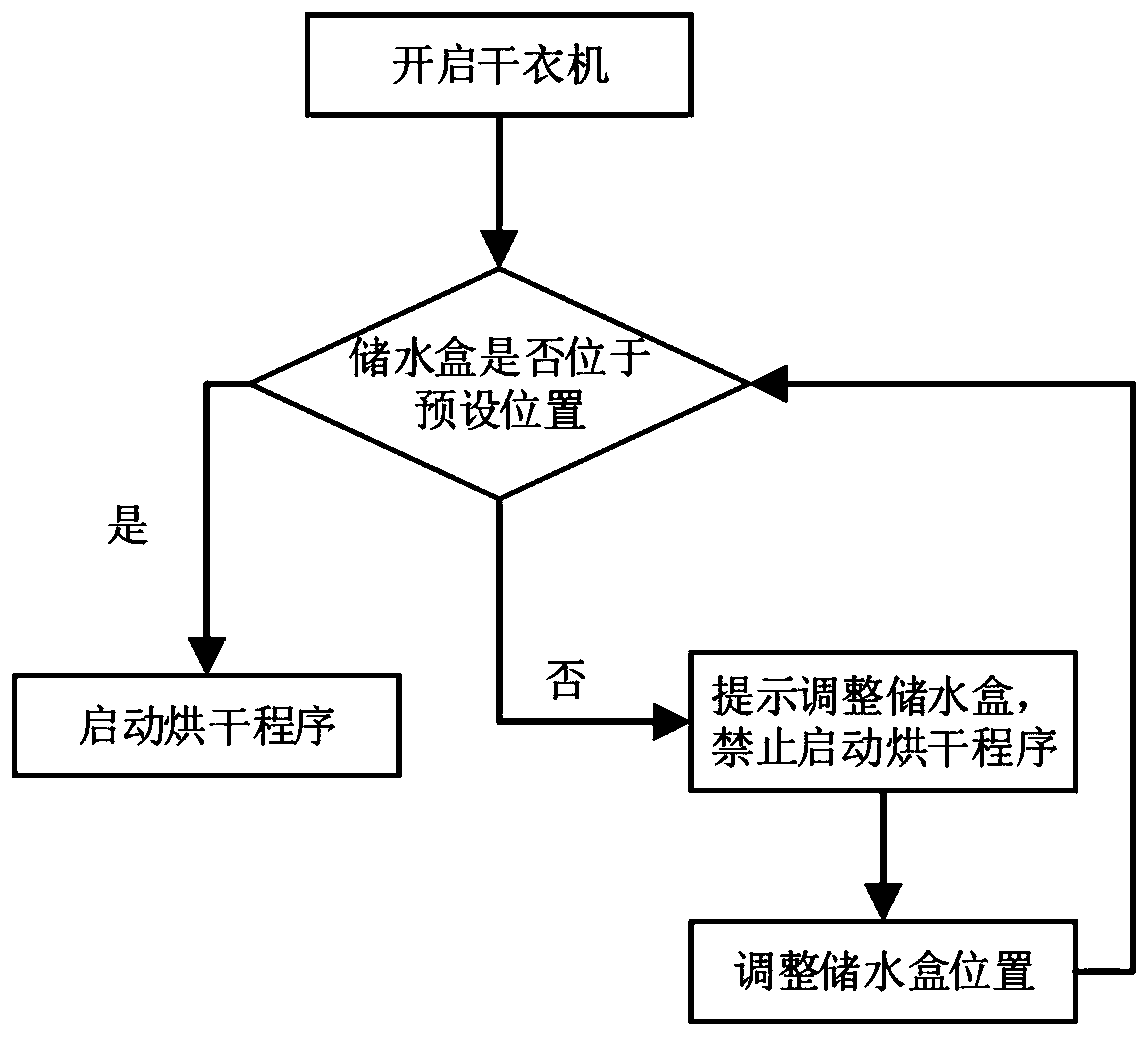

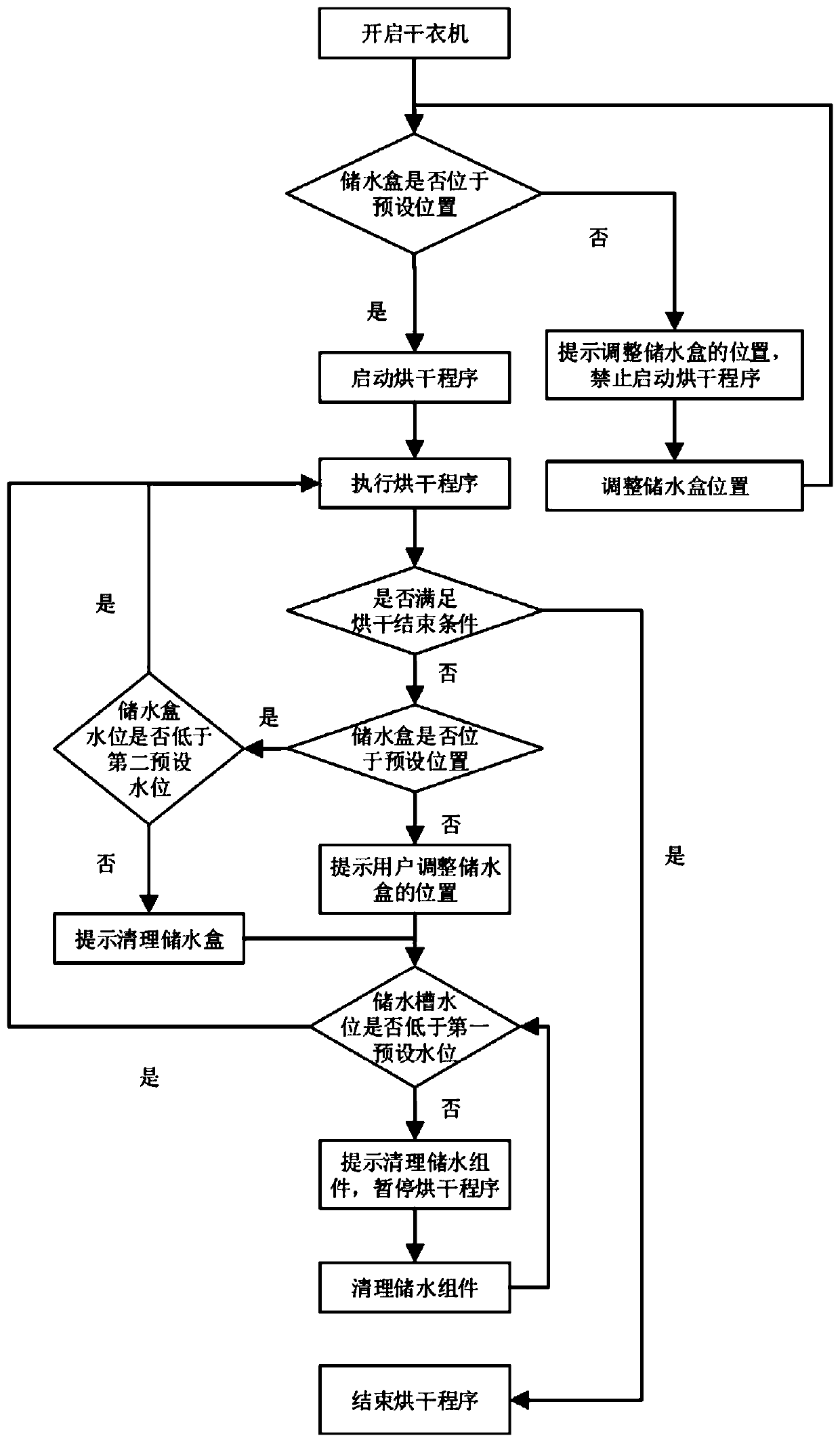

Clothes drying method and clothes dryer

PendingCN110485133AImprove satisfactionGuaranteed inflowTextiles and paperLaundry driersWater storageWater storage tank

The invention relates to the technical field of household appliances, in particular to a clothes drying method and a clothes dryer. The clothes drying method comprises the steps that after the clothesdryer is started, whether a water storage box is located at a preset position or not is detected; if the water storage box is not located at the preset position, a user is reminded to adjust the position of the water storage box. The clothes drying method has the function of detecting whether the water storage box is installed in place or not, and if the water storage box is not installed in place, the user can receive a corresponding prompt. The user can select to adjust the position of the water storage box according to the prompt so that condensed water can be pumped into the water storagebox from a water storage tank, and the water in the water storage box can enter the water storage tank after overflowing. When the clothes dryer detects that a water storage assembly is full of the water, the water storage box and the water storage tank are both filled with the condensed water. The situation that a machine mistakenly prompts to clean the water storage box is avoided, the situation that the water storage box is frequently cleaned by the user under the condition that the water storage box is not full is avoided, the clothes drying efficiency is ensured, and the satisfaction degree of the user is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

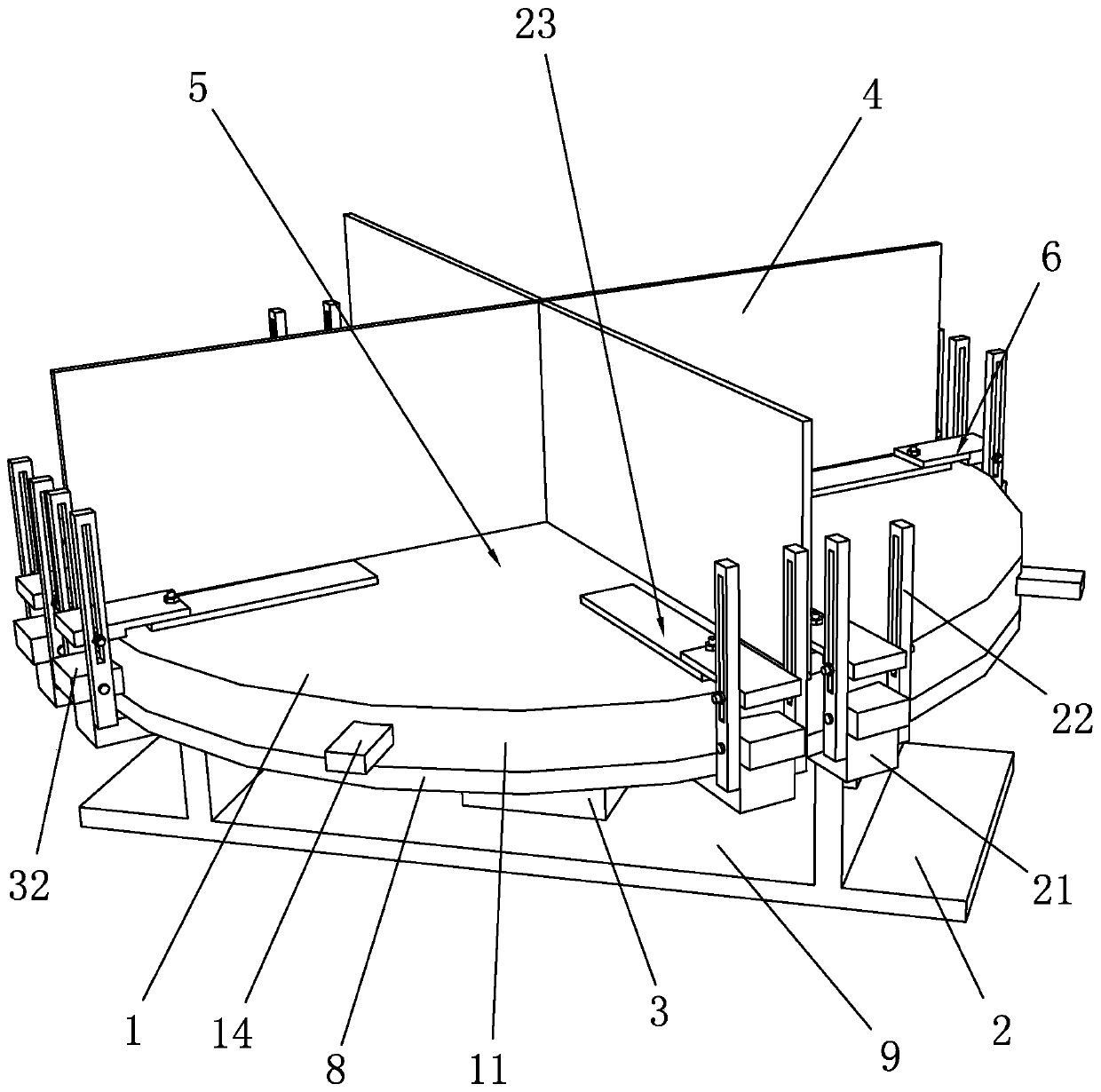

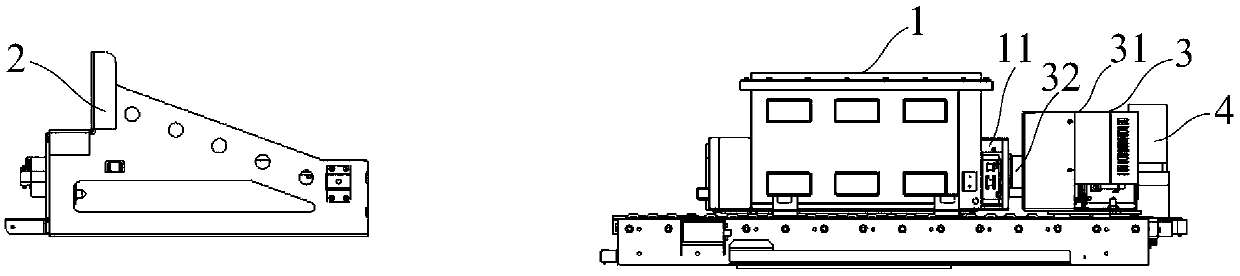

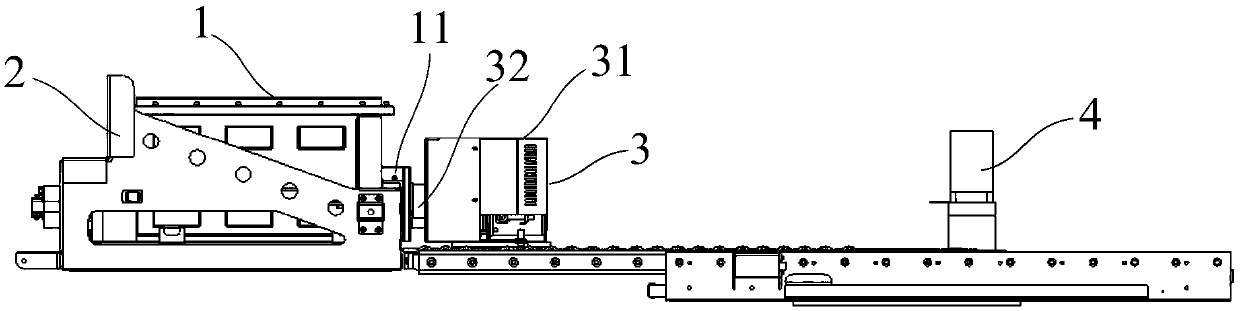

Workpiece supporting device for machine tool and mounting method of workpiece supporting device

PendingCN110449919AFacilitate automatic operationEnsure the firmness of the installationLarge fixed membersMetal working apparatusFriction lossEngineering

The invention discloses a workpiece supporting device for a machine tool. The workpiece supporting device for the machine tool includes a supporting platform, a fixing seat and a rotating motor, a baffle is arranged on the supporting platform, the baffle separates the supporting platform into two or more workspaces, each workspace is internally provided with a positioning assembly, a rotating discis arranged on the bottom surface of the supporting platform, and a support plate matched with the supporting platform is arranged on the top surface of the fixing seat. The invention discloses a mounting method. The mounting method includes the following steps of (1) mounting of the rotating disc and the supporting platform; (2) mounting of the baffle and the supporting platform; (3) mounting ofthe support plate and the fixing seat; (4) mounting of the supporting platform and the support plate; (5) mounting of the positioning assembly and the supporting platform; and (6) mounting of the workpiece supporting device and the machine tool. The workpiece supporting device is ingenious and reasonable in overall structure design, the working efficiency of the machine tool is improved, the friction loss of the supporting platform is reduced, and the energy consumption loss is lowered; and in the mounting process, through auxiliary design of a mounting seat and a positioning sleeve, the mounting difficulty of the workpiece supporting device is reduced, and operational safety during mounting is improved.

Owner:新昌卡戎机械科技有限公司

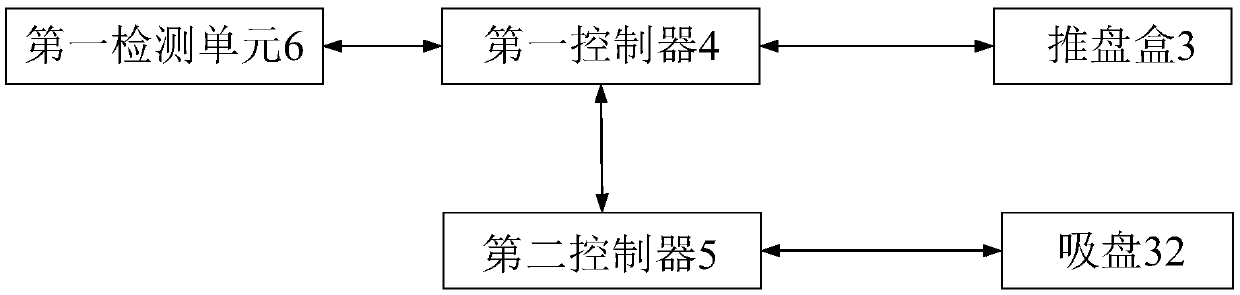

Battery box locking control system and control method

ActiveCN110884384AGuaranteed to be installed in placeStop smoothCharging stationsVehicular energy storageSeparated stateControl system

The invention provides a battery box locking control system and a battery box locking control method, which are used for loading a battery box into a battery bin, and a first controller is used for driving a push disc box to move forwards so as to enable the battery box to enter the battery bin; a second controller is used for switching the push disc box and the battery box between a connected state and a separated state; a first detection unit is used for sending a first signal to the first controller and the second controller after detecting that the sucker retracts to a first preset position, the first controller is further used for stopping driving the tray pushing box to move forwards after receiving the first signal, and the second controller is further used for controlling the traypushing box to be separated from the battery box after receiving the first signal. According to the battery box locking control system and the battery box locking control method, by arranging the sucking disc capable of retracting inwards and the first detection unit for detecting the limit position, the disc pushing box has a buffering process before being stopped, it is guaranteed that the discpushing box can be stably stopped, and it is guaranteed that the battery box is installed in place in the battery bin.

Owner:AULTON NEW ENERGY AUTOMOTIVE TECHNOLOGY GROUP

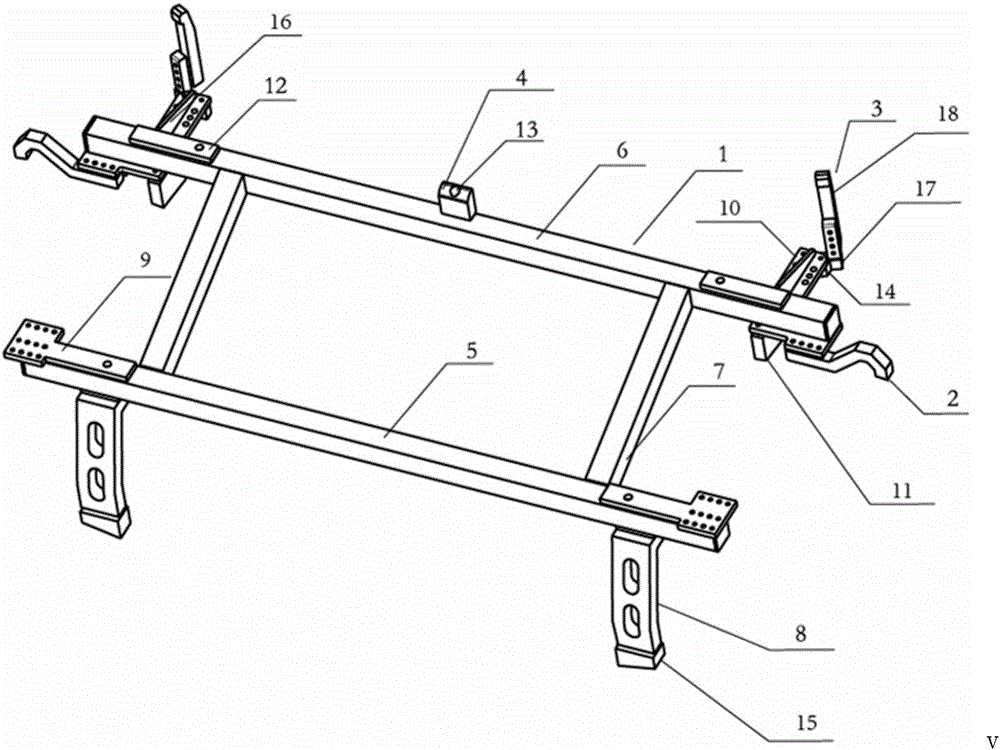

Damage-proof automobile front hood supporting frame

ActiveCN106080798AImprove flame retardant performanceSimple responseSuperstructure subunitsMicaFormic acid

The invention discloses a damage-proof automobile front hood supporting frame which comprises a trapezoidal body, supporting frame handles, limiting blocks and a positioning block. Supporting legs are mounted on the lower surface of the first edge of the trapezoidal body, elastic materials are connected to the lower portions of the supporting legs, and the elastic materials are prepared from an epoxy composition and a carbonic ester composition. The epoxy composition is composed of bis(2,3-epoxy cyclopentyl)ester, adipic acid bis(3,4-epoxy-6-methyl cyclohexyl formic acid), bis(4-amino-3-methyl cyclohexyl)methane, glass beads and methacrylic acid. The carbonic ester composition is composed of dinaphthyl, dicyclohexyl carbonic ester, mica, dyhydroxyl polydiethylsiloxane, amine phosphate and N-hydroxymethyl acrylamide. The damage-proof automobile front hood supporting frame is arranged on an automobile front cabin body and stabilized through the supporting legs and supporting feet, the supporting legs are located above automobile headlamps, the position of the supporting frame can be moved through the supporting frame handles, and the limiting blocks and the positioning block are matched to guarantee that a front hood is mounted in place.

Owner:江苏德川汇汽车科技有限公司

Method for testing retaining force of stator core of brushless motor

PendingCN114413753AGuaranteed to be installed in placeImprove detection efficiencyUsing optical meansApparatus for force/torque/work measurementBrushless motorsControl engineering

The invention discloses a brushless motor stator iron core retention force testing method. The method comprises the following steps: S1, putting a stator into detection equipment, and starting the detection equipment after setting qualified parameters according to the model of the stator; s2, stator installation in-place detection is carried out through detection equipment, and resetting is carried out; comparing the first group of data with set qualified parameters, and if the first group of data is not qualified, stopping the machine and giving an alarm; if yes, entering the step S3; s3, the equipment is started again to carry out pressure testing on the iron core of the stator, and resetting is carried out; obtaining a second group of data, comparing the second group of data with set qualified parameters, and if the second group of data is within a qualified range, determining that the stator core retention is qualified; otherwise, the product is unqualified; s4, taking out the stators and classifying the stators; the device is simple in structure and convenient to use, the installation reliability of the shell and the iron core of the stator is detected through the displacement sensor and the pressure sensor, and the detection efficiency of workers is greatly improved.

Owner:德恩科电机(常州)有限公司

Nuclear power plant horizontal multi-stage centrifugal pump core package disassembling and assembling tool and method

ActiveCN111055233AEasy measurement of channelingEfficient measurement of channelingPump componentsPumpsNuclear plantNuclear power

The invention relates to the technical field of nuclear power maintenance, and particularly discloses a nuclear power plant horizontal multi-stage centrifugal pump core package disassembling and assembling tool and method. The disassembling and assembling tool and method is characterized in that an upper supporting ring, a middle supporting seat and a bottom plate are fixed through supporting ribplates, and the upper supporting ring, the middle supporting seat and the bottom plate are parallel to one another; when a core package is disassembling, the pump core package is slowly lifted and stably placed on a disassembling tool, so that the outer edge of the pump core package is clamped on the upper supporting ring, and then subsequent disassembling operation is completed. According to thenuclear power plant horizontal multi-stage centrifugal pump core package disassembling and assembling tool and method, manpower is greatly liberated, on-site core package disassembling and rotor channeling amount measurement operation becomes simple and efficient, and equipment damage risks as well as safety risks can be reduced.

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

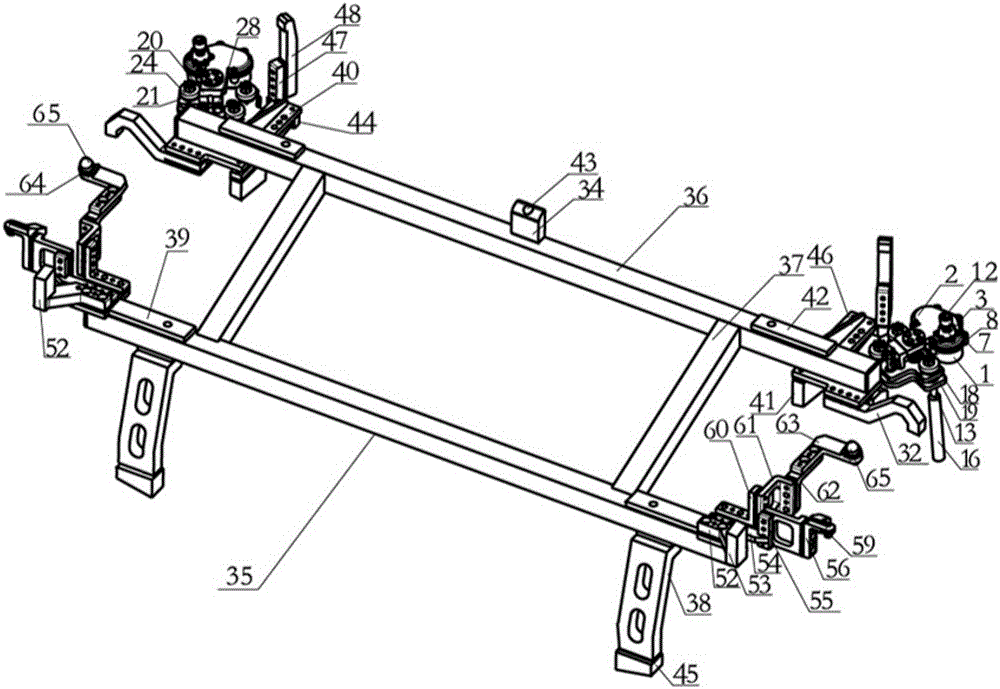

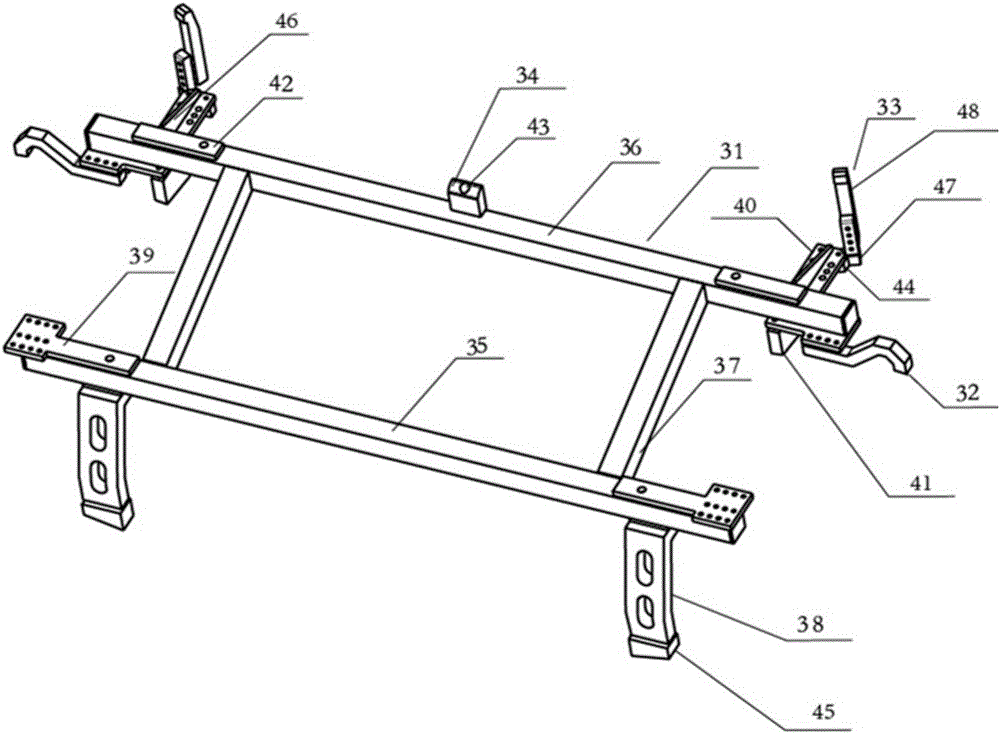

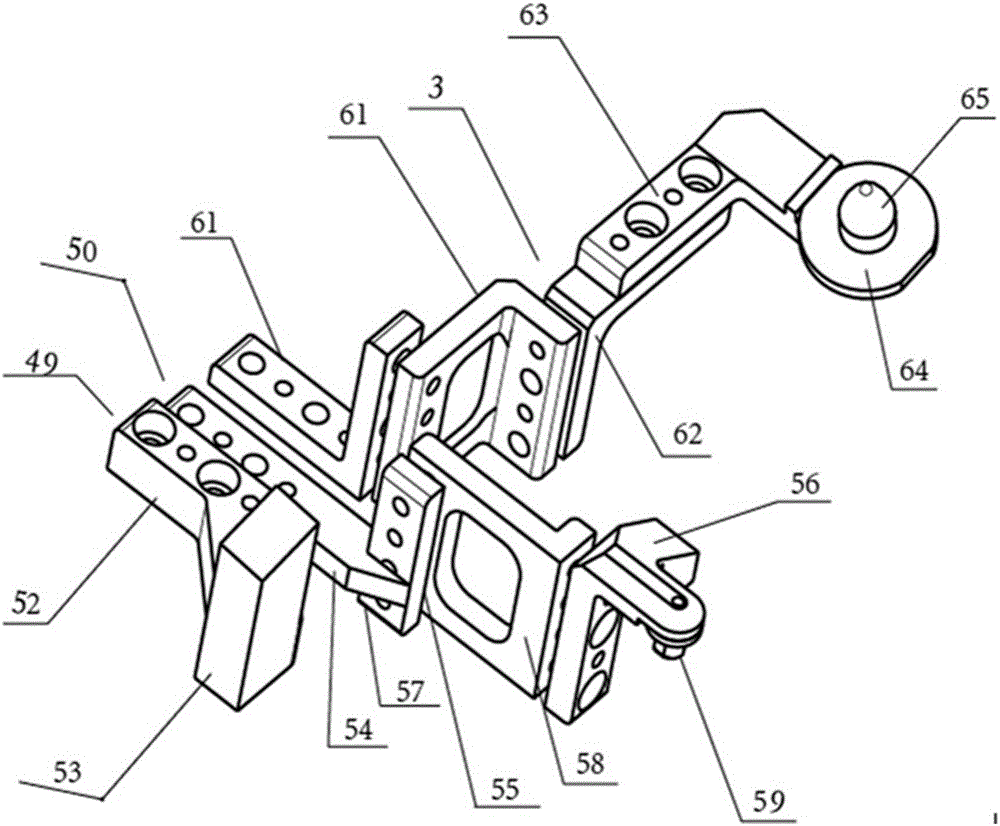

Sample frame with elastic materials and used for assembling front cover of automobile

The invention discloses a sample frame with elastic materials and used for assembling a front cover of an automobile. The sample frame comprises a front cabin cover supporting frame, a connecting piece for assembling the front cover, a front cover assembling and fastening device and a front cover centering device, wherein the front cover assembling and fastening device comprises a hollow casing, a cover body, a protective cap, a force application gear, a force transferring gear, a stressing gear and a pipette tip; the front cover centering device comprises an upper plate, a lower plate, a fixing plate, elastic cylindrical pins, a positioning pin and an aligning pin, wherein the elastic cylindrical pins and the aligning pin penetrate through the lower plate and the upper plate; the connecting piece for assembling the front cover comprises a first assembly, a second assembly and a third assembly, wherein the second assembly is positioned between the first assembly and the third assembly; and the front cabin cover supporting frame comprises a trapezoid body, supporting frame handles, limiting blocks and a positioning block, wherein supporting legs connected with the elastic materials are arranged on the lower surface of a first edge of the trapezoid body. The sample frame used for assembling the front cover of the automobile disclosed by the invention can be used for adjusting the precision between the front cover and an automobile body when the front cover is assembled, the stability for assembling the front cover is guaranteed, and the quality and the security coefficient of products are improved.

Owner:江苏德川汇汽车科技有限公司

Stably-positioned die for stamping forming of automobile metal plate and stamping process of stably-positioned die

ActiveCN112475041AAvoid breakingImprove pass rateShaping toolsMetal-working feeding devicesSheet metal stampingStamping process

The invention relates to the technical field of stamping forming, in particular to a stably-positioned die for stamping forming of an automobile metal plate and a stamping process of the stably-positioned die. The stably-positioned die for stamping forming of the automobile metal plate comprises a supporting frame, a die body, a positioning device and a stamping device, and the die body, the positioning device and the stamping device are installed on the supporting frame; the die body comprises an upper die and a lower die which are adaptive; the stamping device is connected with an installation plate and drives the installation plate to move up and down, the upper die is installed on the installation plate, and the lower die is provided with a placing groove used for placing the metal plate; and the positioning device comprises a first positioning assembly and a second positioning assembly. The stably-positioned die for stamping forming of the automobile metal plate comprises the supporting frame, the die body, the positioning device and the stamping device, the die body, the positioning device and the stamping device are installed through the supporting frame, the stamping devicedrives the die body to perform stamping forming on the metal plate, the metal plate is positioned through the positioning device, the metal plate is prevented from deviating in the stamping process,the stamping effect is ensured, and the defective rate is reduced.

Owner:吉安市瑞鹏飞精密科技有限公司

Transfer structure

PendingCN109158874AIncrease the scope of useGuaranteed to be installed in placeAssembly machinesMetal working apparatusMechanical engineeringEngineering

Owner:SUZHOU RS TECH

Fixed-pressure rolling tool

PendingCN109228377AEffectively remind and control the intensityRemind and control the intensityDomestic articlesLocking mechanismReciprocating motion

The invention discloses a fixed-pressure rolling tool. The fixed-pressure rolling tool comprises a handle and a sliding rod, wherein the handle is provided with an axial central hole, and the slidingrod is inserted into the central hole of the handle in a sliding manner; a roller mounting frame is connected to one end, stretching out of the handle, of the sliding rod, and the other end of the sliding rod is connected with one end of a second spring located in the central hole of the handle, the other end of the spring pushes against the inner wall of the central hole of the handle; a roller is rotatably arranged on the roller mounting frame, and positioning holes are peripherally and uniformly formed in the side surface of the roller; an elastic locking mechanism which is inserted into orremoved from the positioning holes is arranged on the other side of the roller mounting frame; and an oblique plane pushing mechanism for driving the elastic locking mechanism to do a reciprocating motion is arranged on the outer wall of the handle. According to the fixed-pressure rolling tool, an operator can be effectively reminded of applying a proper force to the handle when a glue strip is insufficiently stressed, and the glue strip can be rolled only through a certain pressure, so that the mounting quality of the sealing glue strip is guaranteed; and the fixed-pressure rolling tool is simple in structure, convenient to operate and easy to implement.

Owner:广州东振机电设备有限公司

Clamping mechanism for clamping and replacing diaphragm

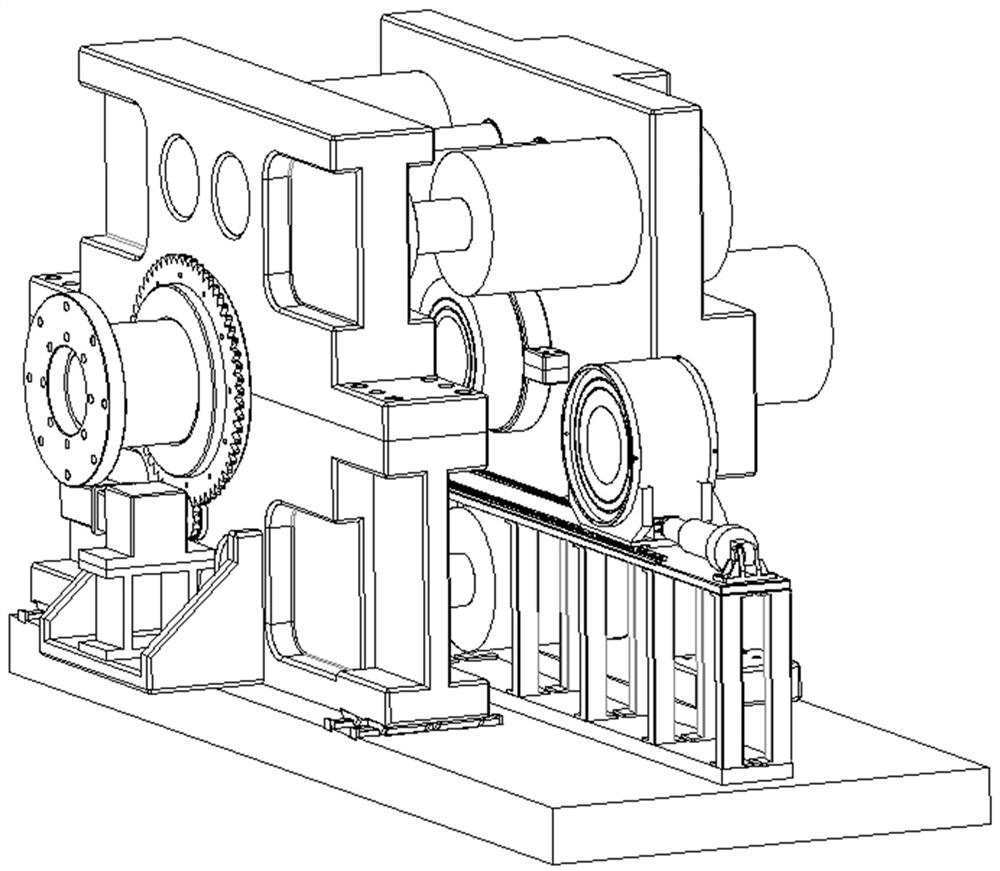

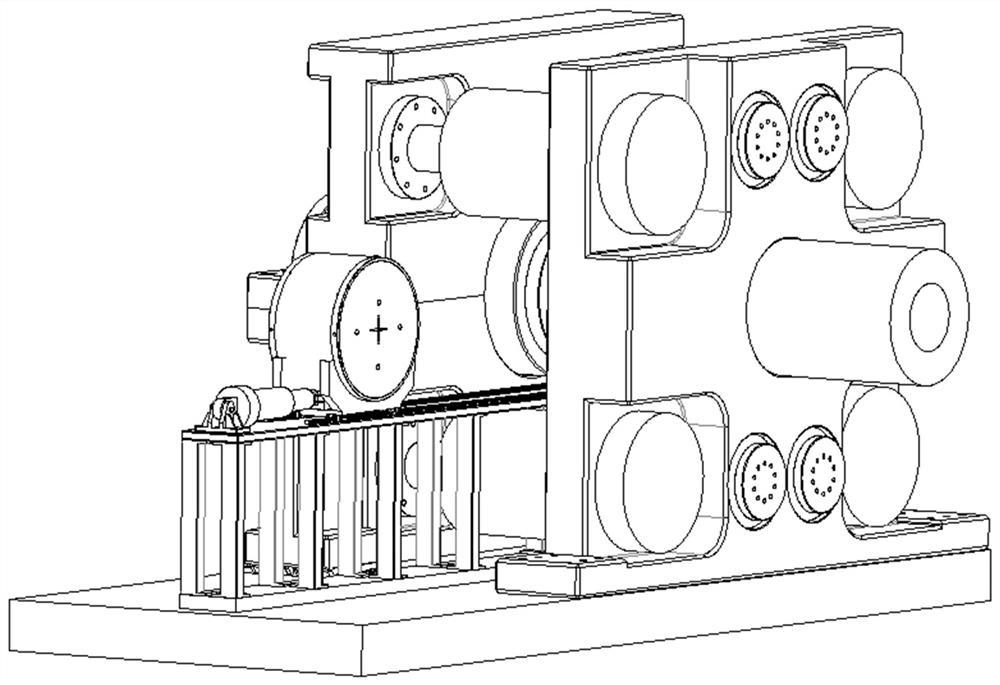

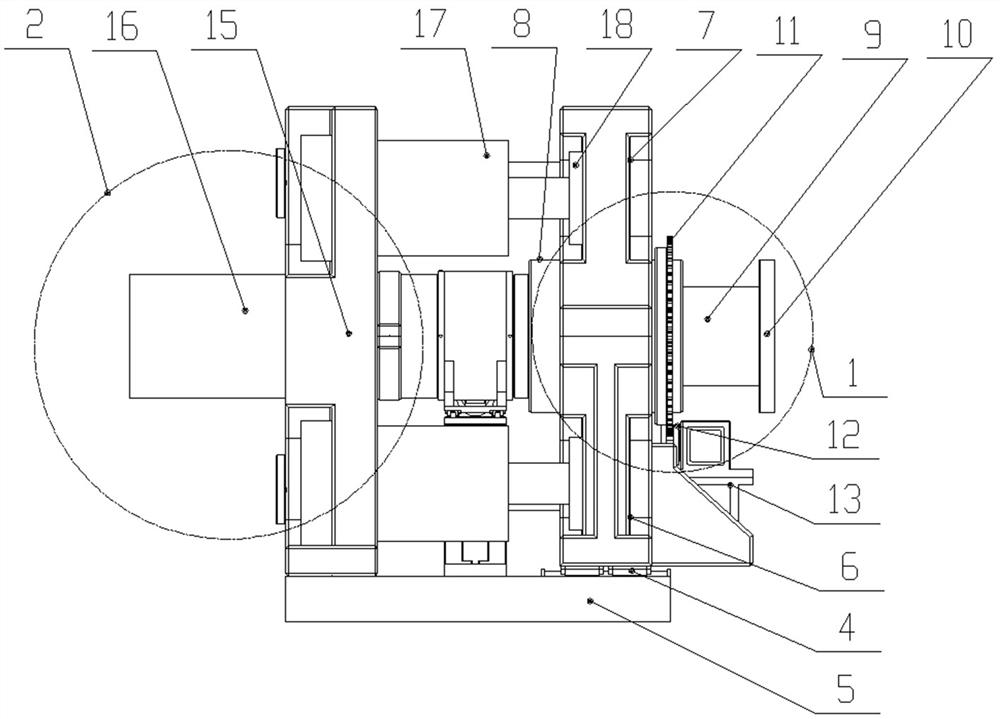

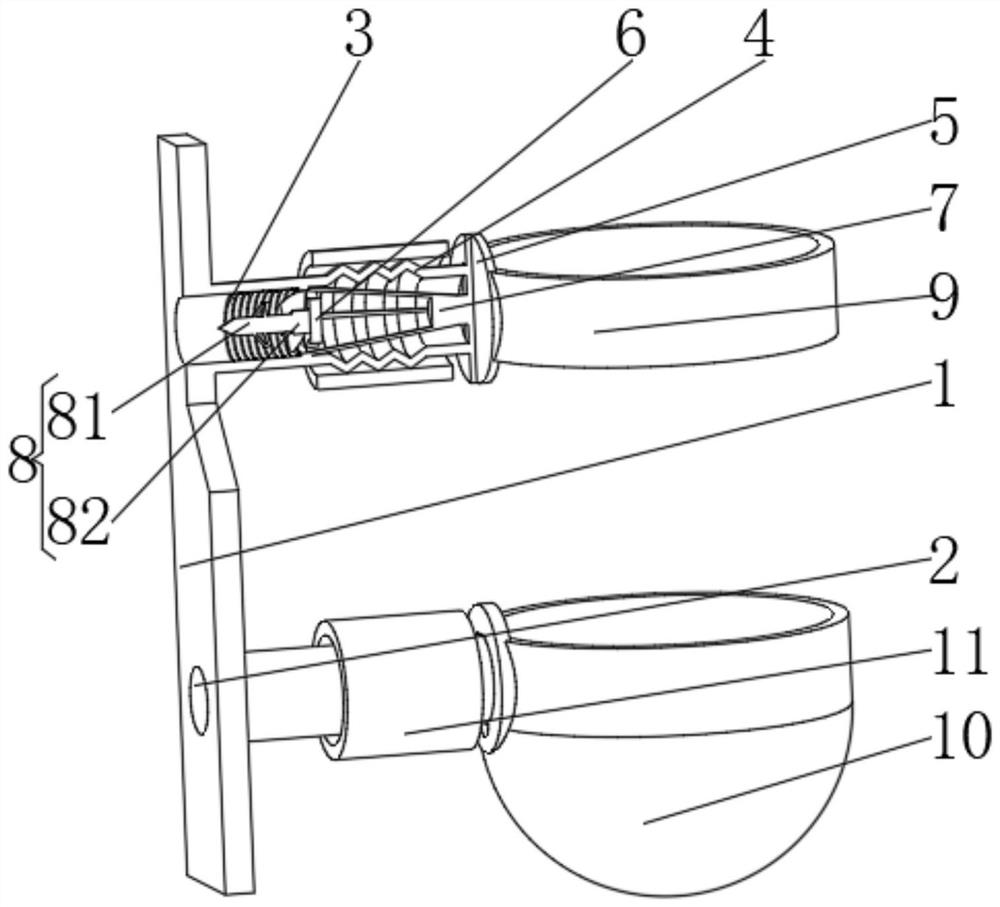

PendingCN114112287AGuaranteed positional relationshipGuaranteed to be installed in placeAerodynamic testingMechanicsAxial displacement

A clamping mechanism for clamping and replacing a diaphragm adopts a split type structural design and comprises a driving section clamping mechanism, a driven section clamping mechanism and a diaphragm replacing mechanism which are sequentially designed from left to right, and the diaphragm replacing mechanism is located between the driving section clamping mechanism and the driven section clamping mechanism. The driving section clamping mechanism can achieve axial feeding of pipelines and can also achieve axial displacement of the whole supporting seat, the driven section clamping mechanism achieves axial position fixing of butt-joint pipelines, and the diaphragm replacing mechanism achieves clamping and replacing of diaphragms between two pipelines. Reliable sealing and clamping among the driving section, the diaphragm and the driven section can be achieved through cooperation of the driving section, the diaphragm and the driven section, and safety and reliability of the whole test pipeline are guaranteed. On the driving form of each degree of freedom, the design which is simple in structure and convenient to install and debug is adopted, effective adjustment of displacement between the pipeline and the diaphragm is guaranteed, and the space utilization rate can be fully improved. According to the design of the structural form, all the mechanisms are relatively independent, interference among the mechanisms is small, the structure is simple, operation is convenient, and efficiency is high.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Resident fire extinguisher magnetic protection portable fixing frame

The invention discloses a resident fire extinguisher magnetic protection portable fixing frame. The resident fire extinguisher magnetic protection portable fixing frame comprises a movable plate, wherein acceleration pipe frames are movably connected to the inner surfaces of mounting holes, annular pipes are fixedly connected to the sides, away from the movable plate, of the acceleration pipe frames, and end pipe frames are fixedly connected to the sides, away from the acceleration pipe frames, of the annular pipes; a magnetic attraction plate is fixedly connected to the side, close to each ring pipe, of the inner surface of an inner cavity of each acceleration pipe frame, an ejection mechanism is fixedly connected to the side, close to the corresponding ring pipe, of each magnetic attraction plate, and a fixing bolt is movably connected to the side, away from the corresponding ejection mechanism, of each magnetic attraction plate; and magnetic buckles are movably connected with the positions, located at the upper middle position of the movable plate, of the end pipe frames, and the sides, away from the movable plates, of the end pipe frames. The invention relates to the technicalfield of fire extinguishers. A fire extinguisher is fixed through limiting mechanisms, so that children are prevented from playing, the safety of the children and the surrounding safety are protected,clamping and locking are conducted through magnetic force, the taking convenience is enhanced, the using efficiency is prevented from being affected, and the rescue speed is improved.

Owner:台州市腾阳窗饰有限公司

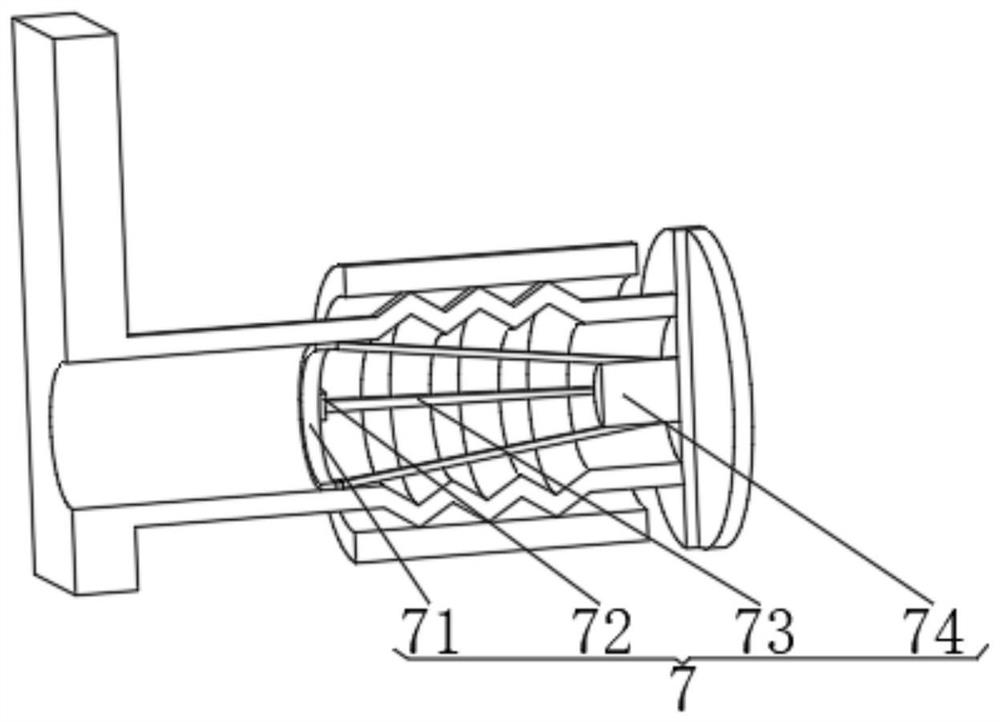

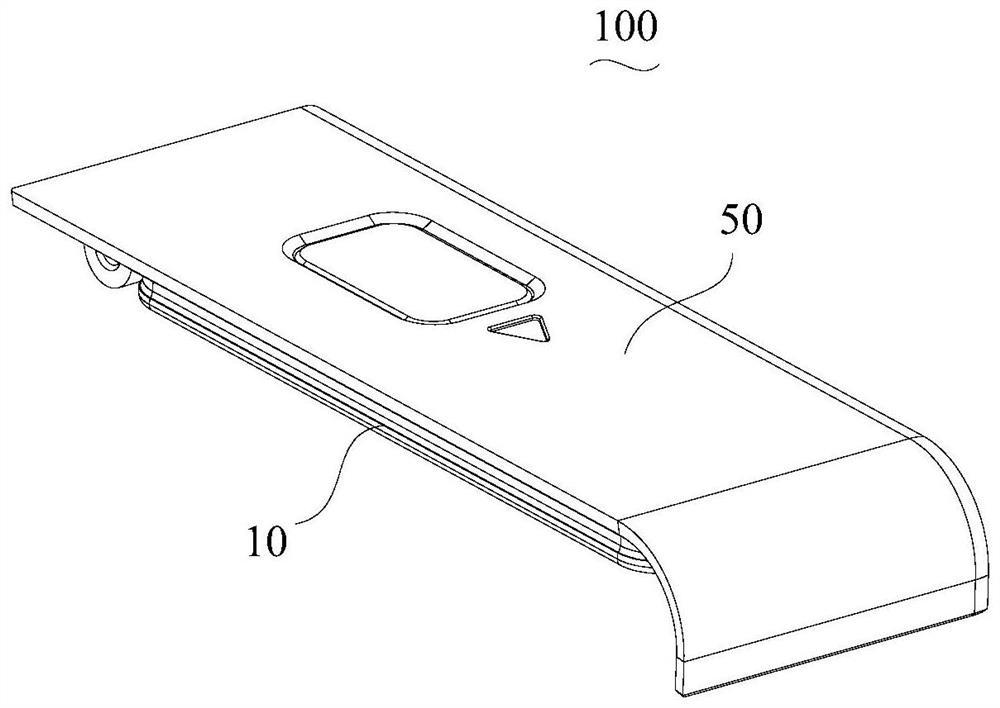

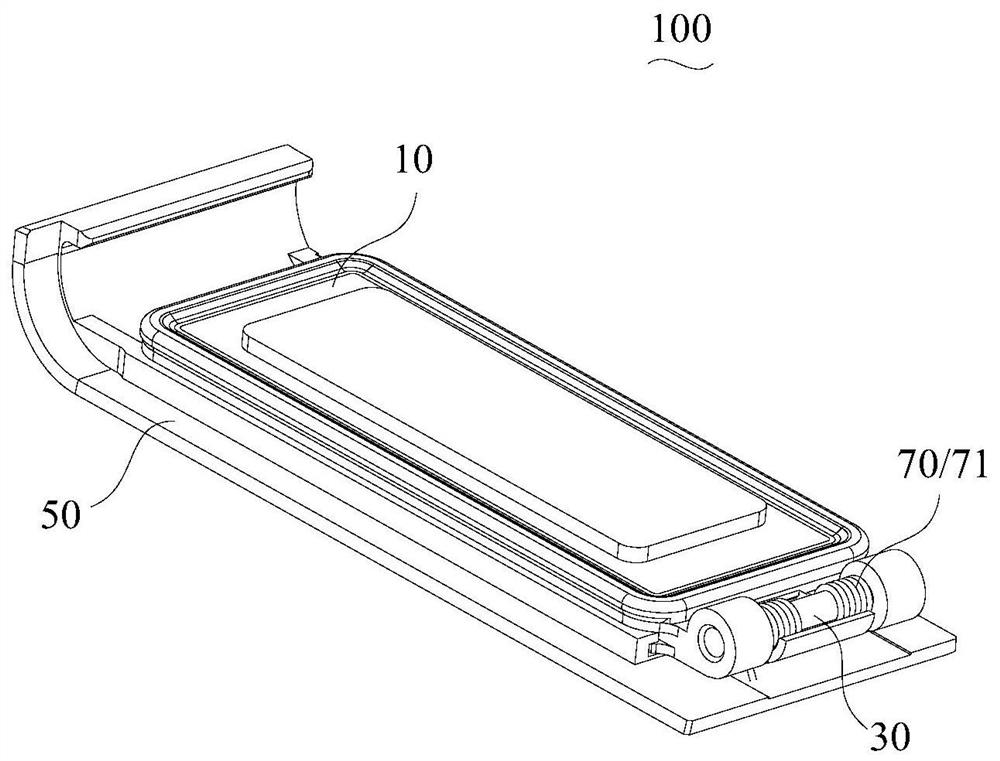

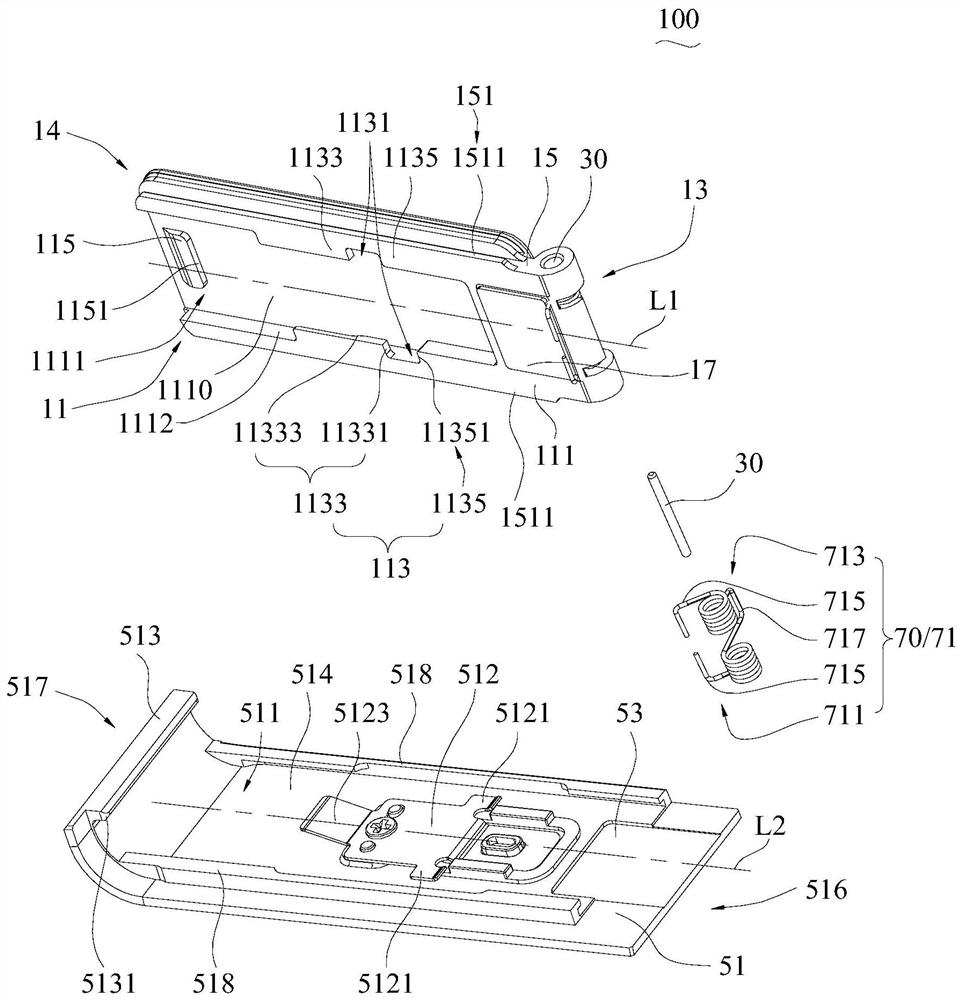

Flip mechanism, housing, electronic equipment, movable platform and camera

ActiveCN113228835ASimple locking structureLow costCasings/cabinets/drawers detailsCamera body detailsControl theoryMechanical engineering

The present application provides a flip mechanism (100). The flip mechanism (100) includes a rotating part (10) and a sliding cover assembly (50). The rotating part (10) is provided with a guide portion (151) and a first stop portion (113). The sliding cover assembly (50) includes a sliding cover (51) and a limit part (512), The limiting member (512) includes a first limiting portion (5121), The first limiting portion (5121) cooperates with the first stopping portion (113) to restrict a sliding cover (51) from moving along a guide portion (151).

Owner:SZ DJI TECH CO LTD

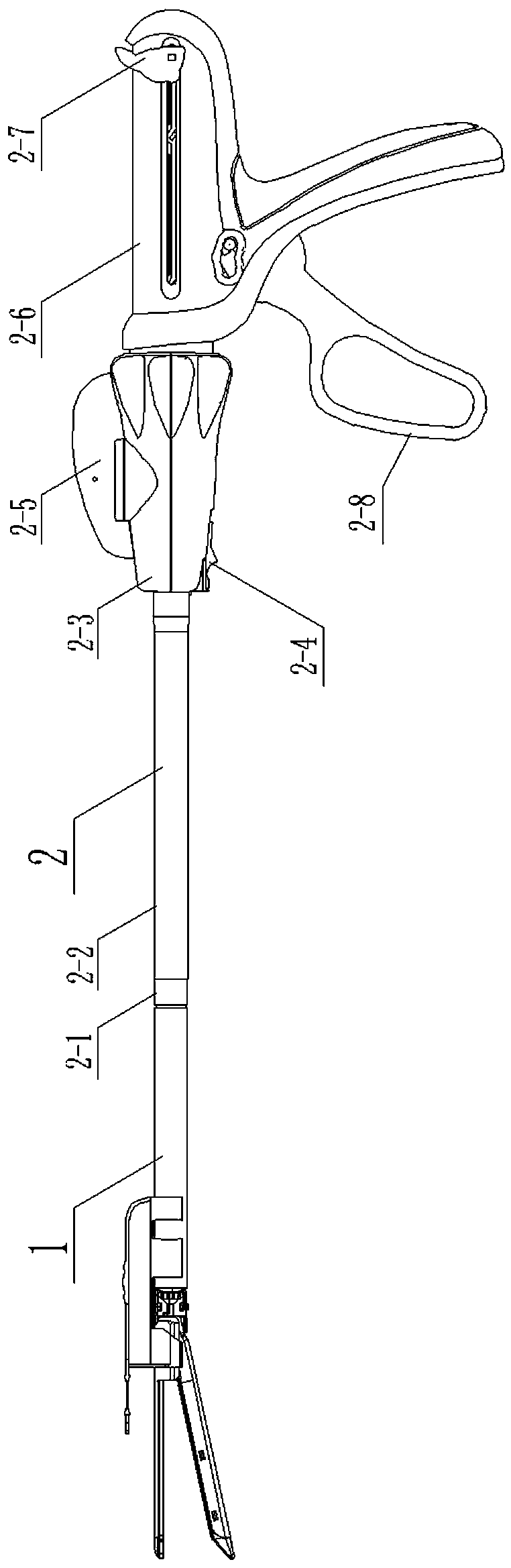

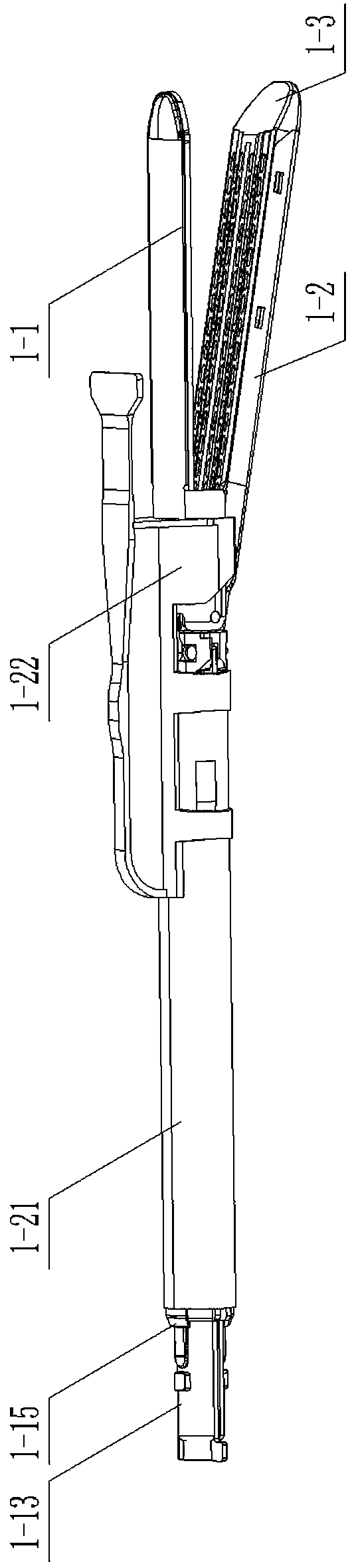

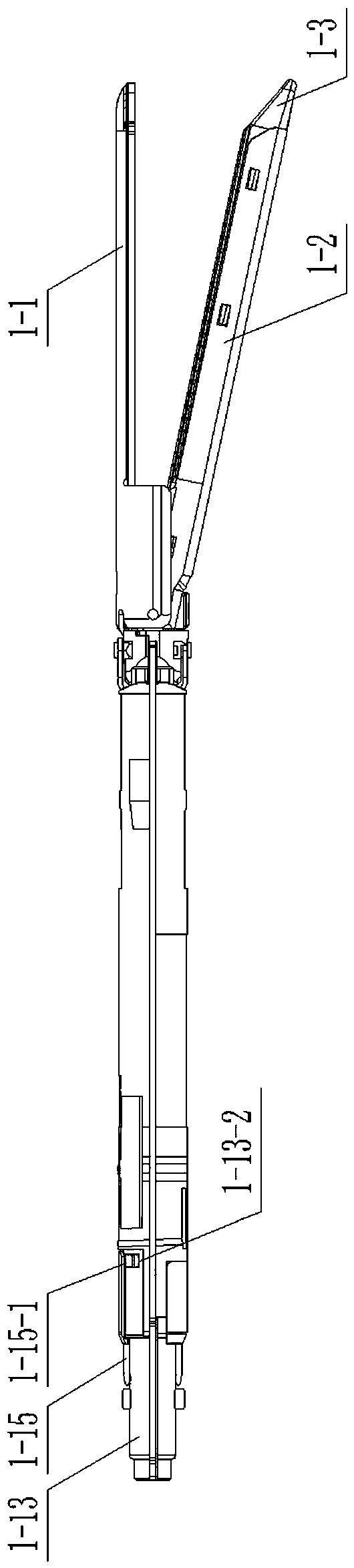

Surgical stapler staple-cabin assembly with mounting security safety unit

PendingCN110664450AReasonable designCompact structureSurgical staplesEngineeringMechanical engineering

The invention relates to a surgical stapler staple-cabin assembly with a mounting security safety unit. The surgical stapler staple-cabin assembly is a surgical stapler supporting device for applyinga linear-row stapler to intra-cavity tissue and meanwhile cutting the tissue within the linear-row stapler, and is used for avoiding the situation that a staple cabin assembly is not assembled well and accordingly cannot be in use. The surgical stapler staple-cabin assembly includes a staple abutting base, a staple cabin base, rotary head pins, an upper rotary joint, a lower rotary joint, staple cabin spring pieces, a staple cabin, a push block, push pieces, suture staples, staple cabin base pins, an upper half shell, a lower half shell, H-shaped blocks, rising prevention plates, an arc clamp,a cutter, a drive sleeve, a sleeve pipe, a steering pull hook and a protection cover. A limit block is arranged at the inner side of the arc clamp, two clamp pins are arranged at the tail end of thearc clamp, and a fixing point is arranged at the tail end of each clamp pin. A cutter guide groove is formed in the middle of the lower half shell, an arc clamp guide hole is formed in the middle-backportion of the lower half shell, two guide fixing blocks are arranged at the tail end of the lower half shell, two limit pits are formed in front of the guide fixing blocks respectively, and a limitopening is formed in the tail end of a cutter assembly.

Owner:VICTOR MEDICAL INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com