Automobile top cover decoration strip mounting structure

A technology for car roof and installation structure, applied in vehicle parts, transportation and packaging, etc., can solve the problems of easy shaking and unstable fixation, and achieve the effect of preventing loosening, smooth appearance and preventing water leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

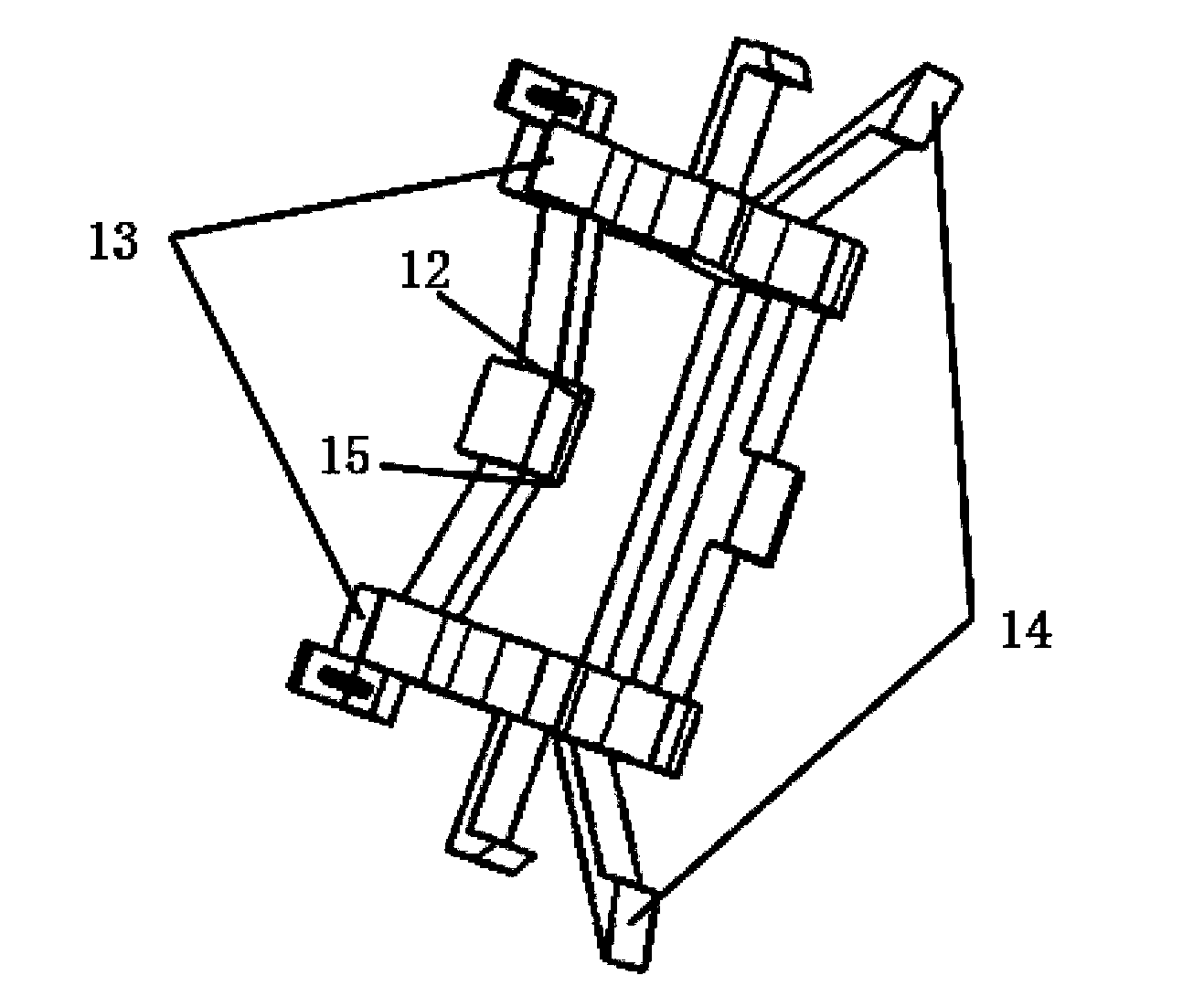

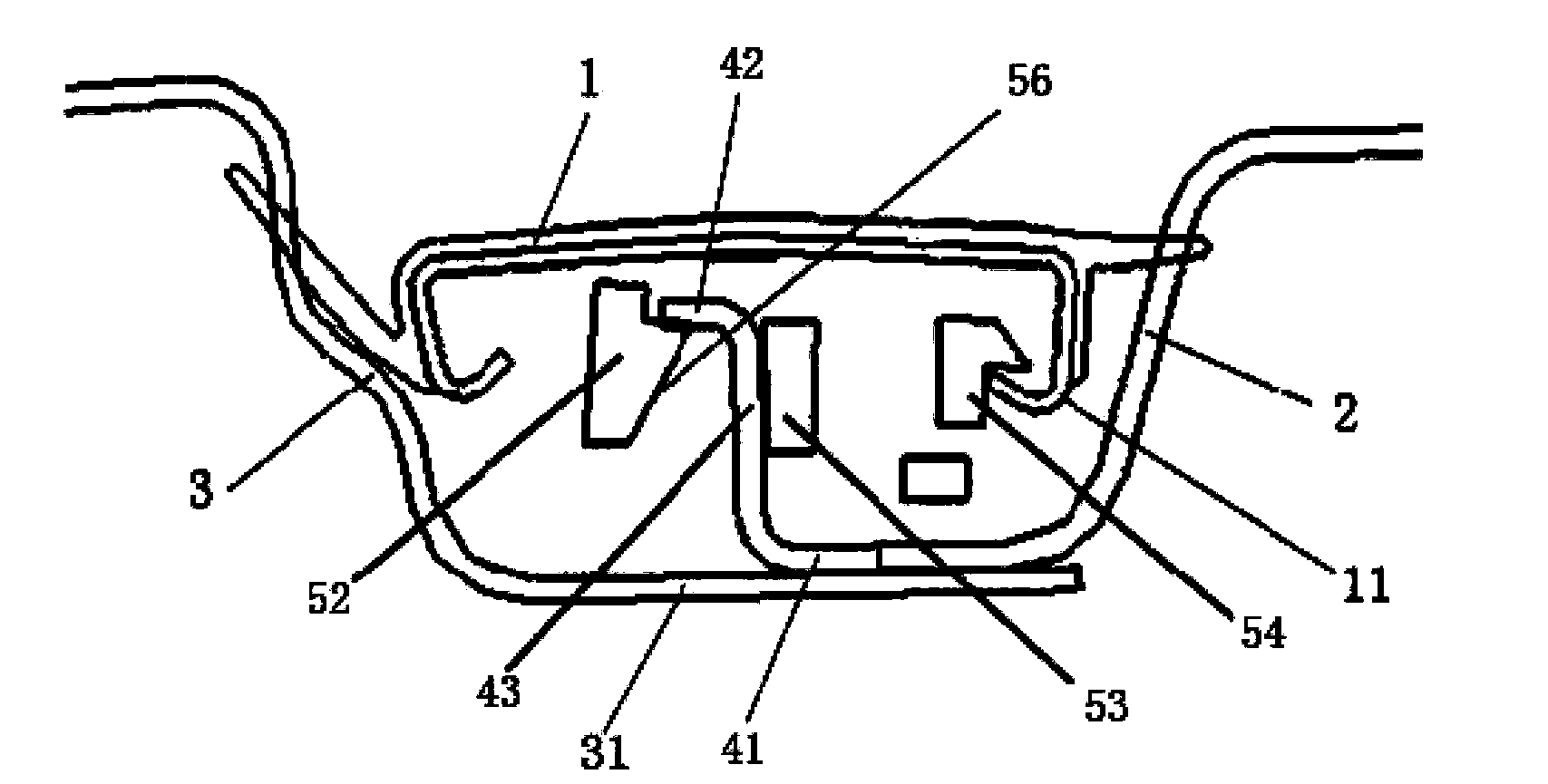

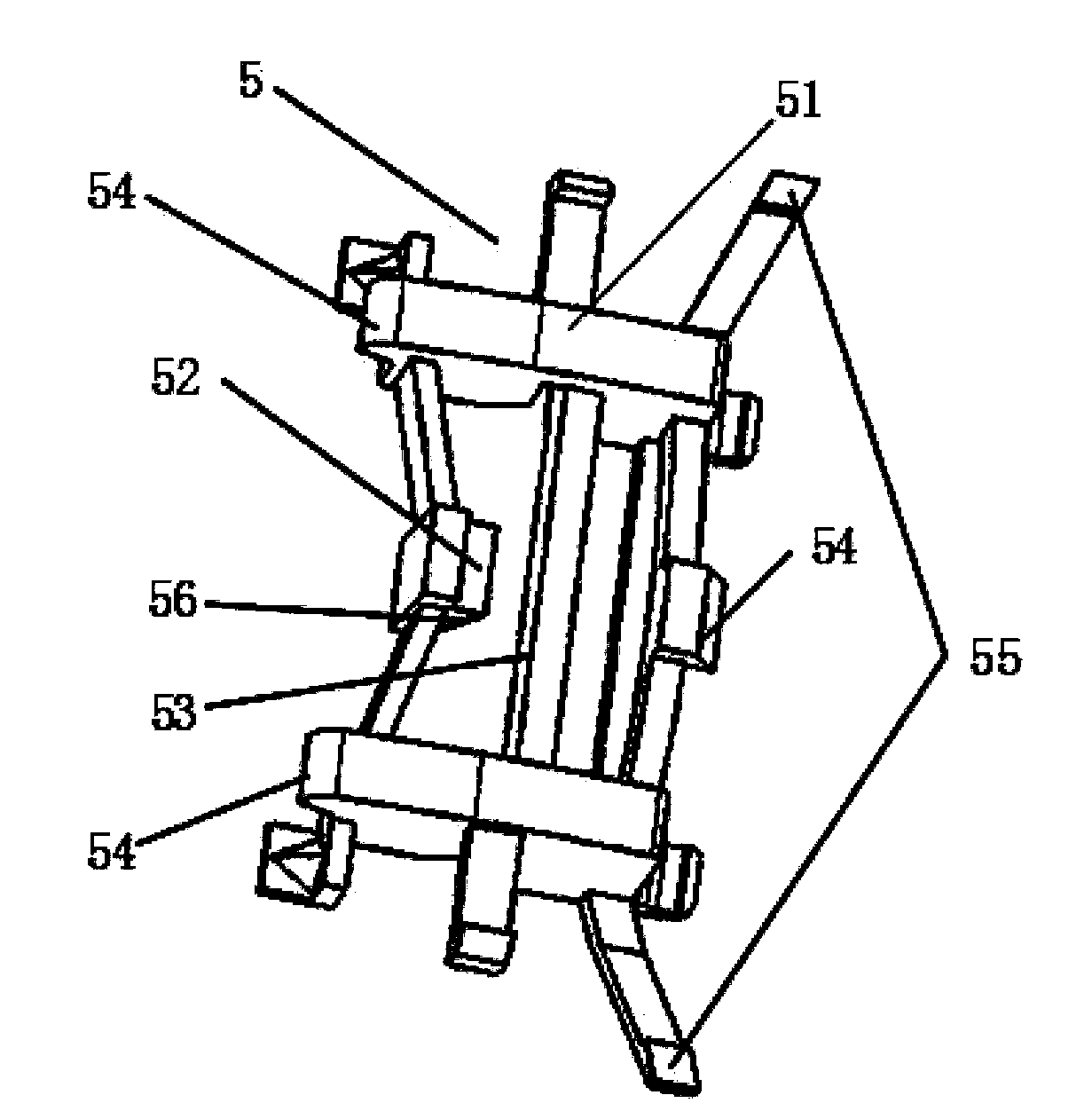

[0019] see Figure 2 to Figure 4 The shown installation structure for a roof trim strip of an automobile comprises a roof trim strip 1, a top cover flange 2 with a reverse "L" shaped cross section and a side wall flange 3 with an "L" shaped cross section. The straight section of the cover flange is overlapped on the right part of the straight section 31 of the side wall flange to form a groove, and there are 7 "Z"-shaped connections distributed at equal distances in the groove. The lower straight 41 of each connector is fixedly connected to the middle part of the bottom surface of the groove; it also includes 7 clamping members 5, each of which is connected to the vertical section 43 of the “Z” shaped connector 4 Cooperate with the upper straight section 42; the top cover decorative strip 1 is respectively matched and connected with the top cover flange 2, the side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com