Surgical stapler staple-cabin assembly with mounting security safety unit

A safety insurance and stapler technology, which is applied to surgical fixation nails and other directions, can solve the problems of increasing patient medical costs, low reliability, and increasing production costs, and achieves the effects of reducing medical burden, ensuring surgical safety, and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

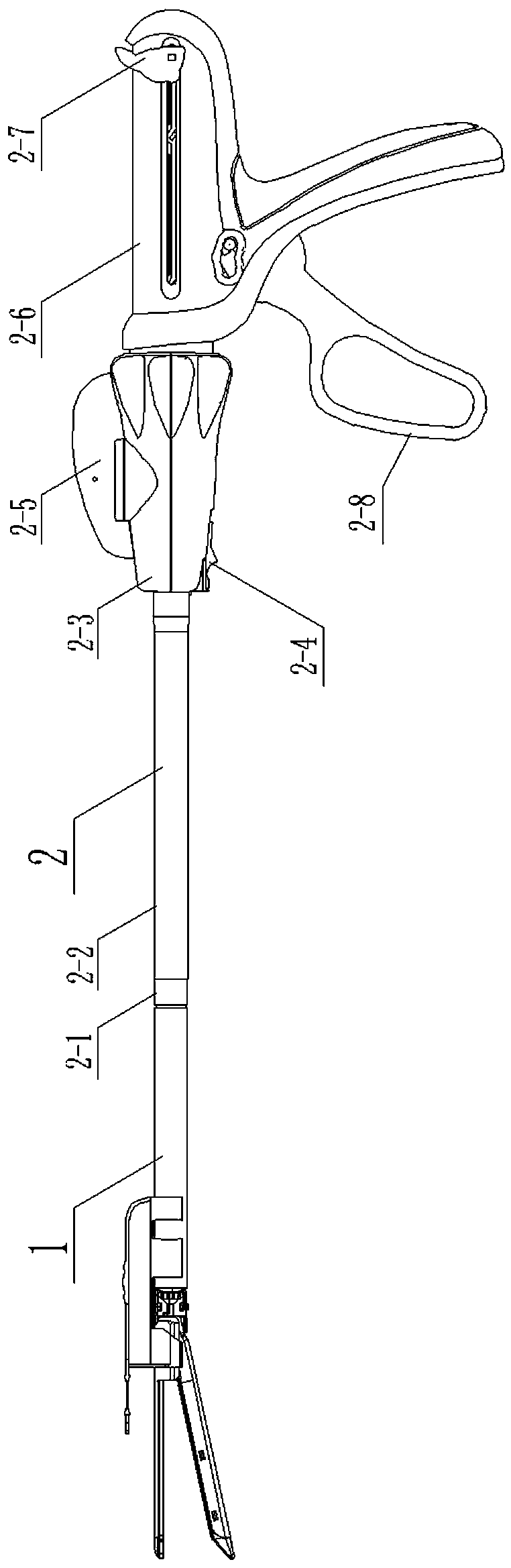

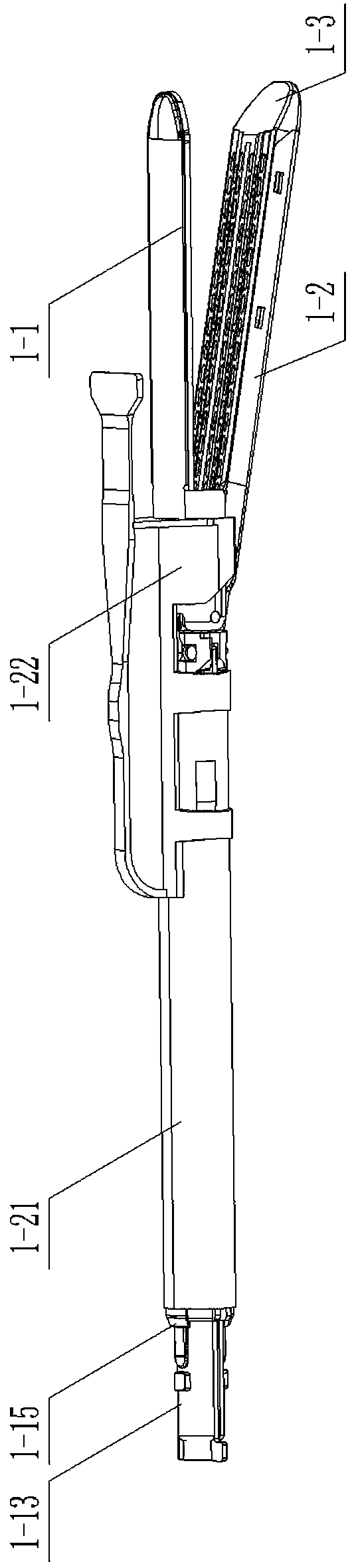

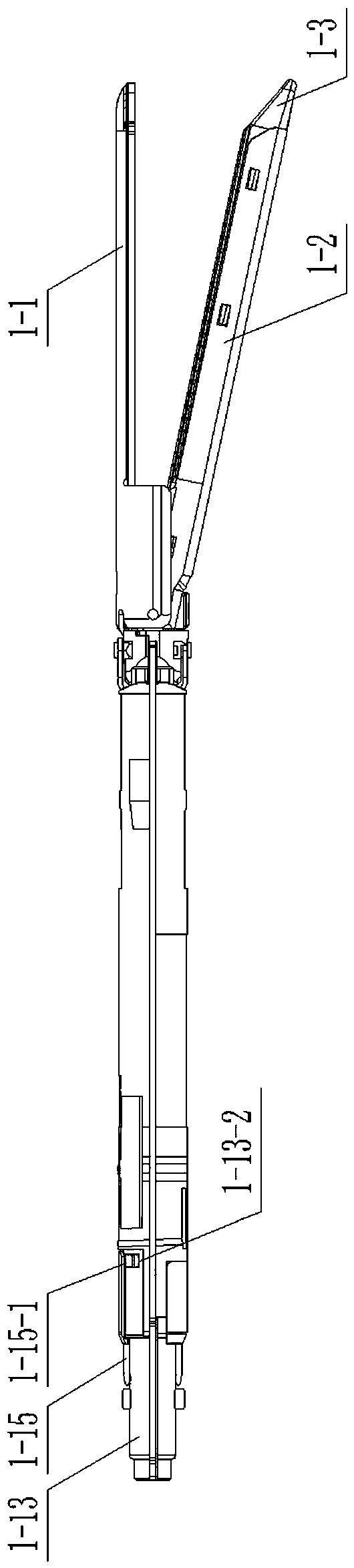

[0088] A staple cartridge assembly for a surgical stapler with a safety device installed includes a nail abutment seat 1-1, a staple cartridge seat 1-2, a staple cartridge 1-3, a push piece 1-4, a titanium nail 1-5, and a push block 1 -6, staple cartridge spring 1-7, lower adapter 1-8, upper adapter 1-9, rotating head pin 1-10, staple cartridge seat pin 1-11, connecting piece 1-12, upper half shell 1-13, lower half shell 1-14, arc buckle 1-15, anti-expansion plate 1-16, H-shaped block 1-17, cutting knife 1-18, driving sleeve 1-19, steering hook 1- 20. Sleeve 1-21 and protective cover 1-22.

[0089] There are six rows of several staple guide grooves 1-1-1 on the above-mentioned nail abutment seat 1-1, a cutting groove 1-1-2 in the middle, a protective cover positioning hole 1-1-3 at the end, and a Locate connection holes 1-1-4.

[0090] The staple cartridge seat 1-2 has a U-shaped structure as a whole, with a knife feed slot 1-2-1 in the middle, two positioning holes 1-2-2 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com