Precise filter

A precision filter and filter element technology, which is applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of difficulty in adoption, short-circuit leakage of filtration, and small space, etc., to achieve convenient installation, ensure filtration effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

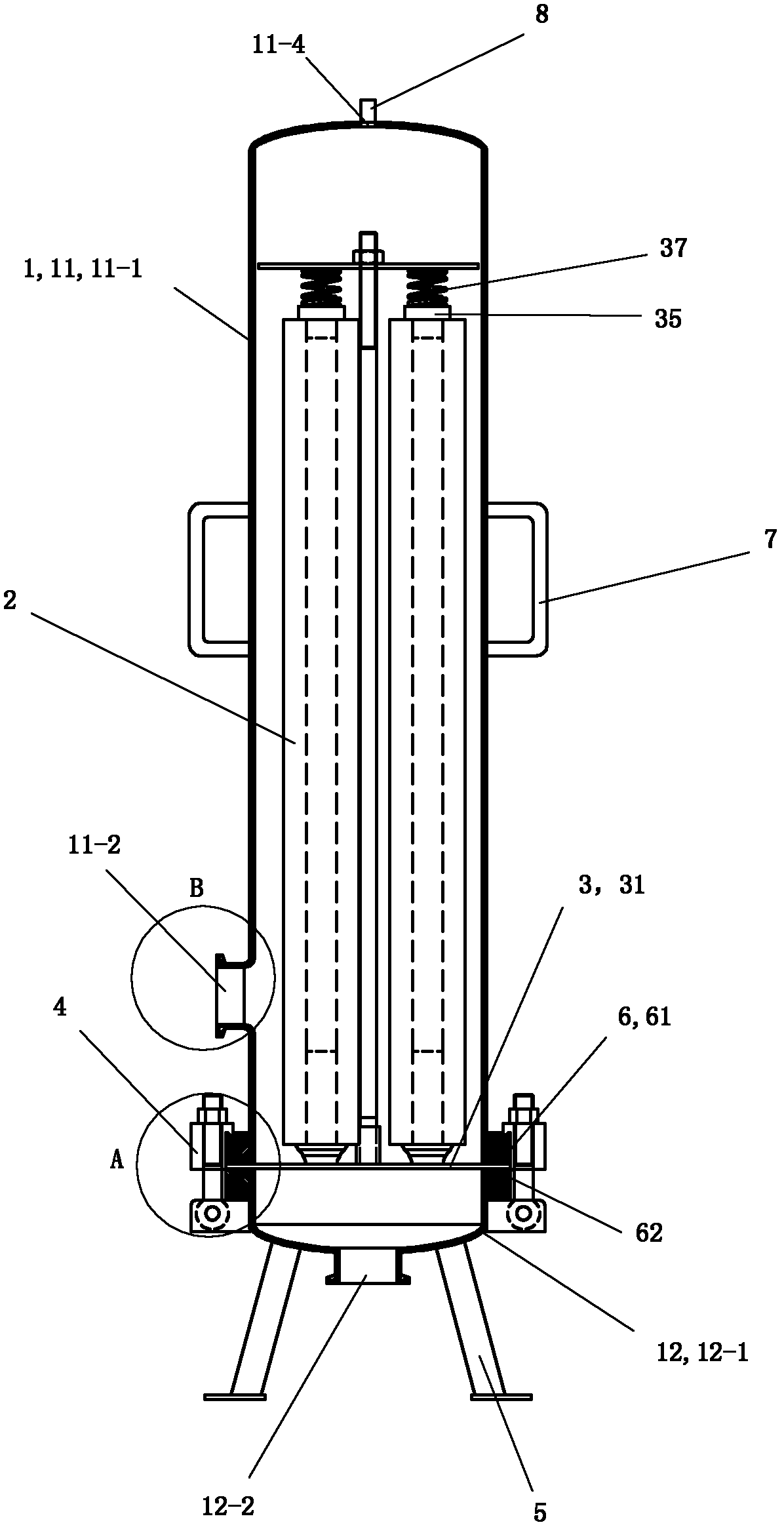

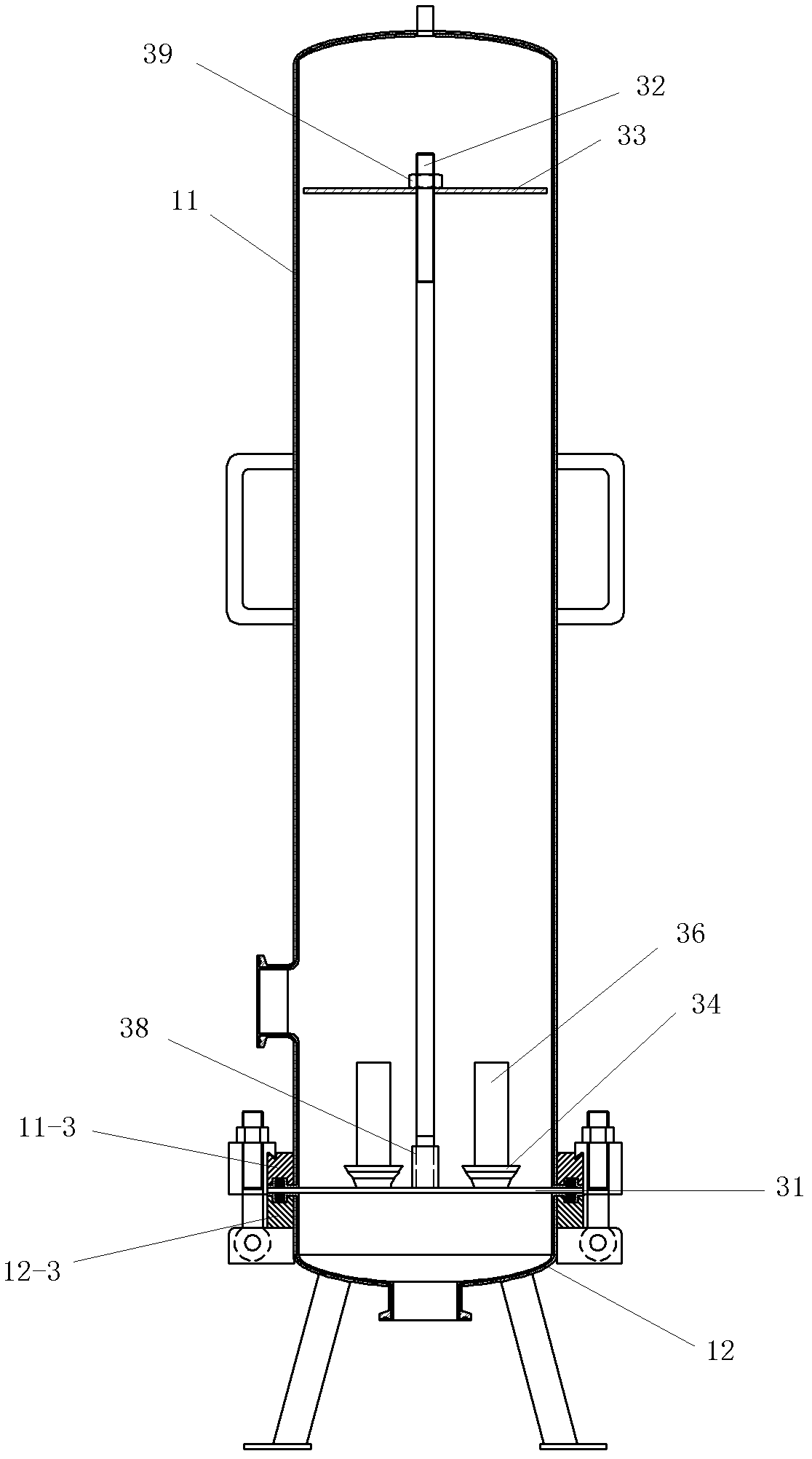

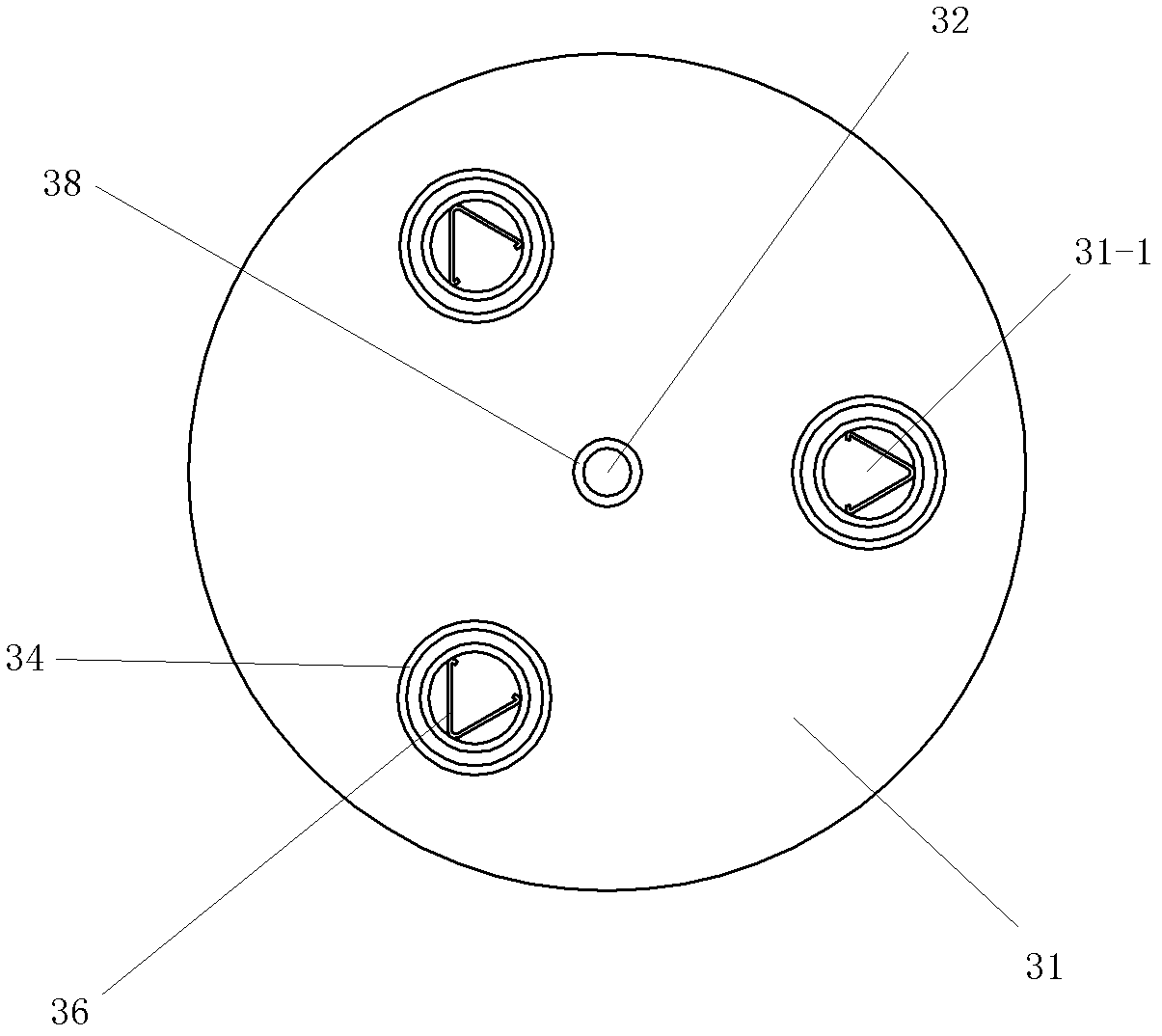

[0052] See figure 1 , The precision filter of this embodiment is composed of a cylinder body 1, a filter element 2, a filter element mounting frame 3, a connector 4, a support column 5, a sealing ring 6, a handle 7 and an exhaust valve 8. The filter element 2 is installed on the filter element mounting frame 3 , the filter element mounting frame 3 is arranged in the cylinder body 1 , and the support column 5 is arranged on the bottom of the cylinder body 1 .

[0053] See figure 1 with Figure 5 , the cylinder body 1 includes a main cylinder body 11 located at the upper part and a lower cylinder body 12 located at the lower part. The main cylinder body 11 and the lower cylinder body 12 are detachably and hermetically fixedly connected by corresponding connecting pieces 4 .

[0054] See figure 1 with Figure 5 , the main cylinder 11 is a cylindrical shell with a top cover opening downward. The main cylinder 11 includes a metal cylinder 11a and a corrosion-resistant coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com