Sample frame with elastic materials and used for assembling front cover of automobile

A kind of elastic material and front cover technology, which is applied in the field of automobile front cover assembly equipment, can solve the problems of harm to the environment and human health, the flame retardancy cannot reach UL94-VO level, and the decline of material physical properties, so as to achieve the control of installation accuracy , improve stability and force balance, and avoid cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Add 100Kg of bis(2,3-epoxycyclopentyl)ether and 50Kg of bis(4-amino-3-methylcyclohexyl)methane into the reactor, stir at 120°C for 30 minutes; then add 40Kg of adipic acid di (3,4-epoxy-6-methylcyclohexylcarboxylic acid), stirred for 1 hour, then added 10Kg glass microspheres and 25Kg methacrylic acid, and stirred at 130°C for 20 minutes to obtain an epoxy composition; 100Kg dinaphthyl Add carbonate, 60Kg dicyclohexyl carbonate, 10Kg mica to butanone, stir at 50°C for 20 minutes, then add 18Kg dihydroxy polydiethylsiloxane, 25Kg amine phosphate, 20Kg N-methylol acrylamide, under ventilation , Stir at 110°C for 10 minutes to obtain a carbonate composition; heat and mix 60Kg of epoxy composition and 180Kg of carbonate composition, then add it into a mold, and heat press at 100°C and 1MPa for 3 minutes to obtain an elastic material. After testing, the flame retardancy is UL94V1 level; the elongation at break is 54%; the flexural elastic rate is 210MPa.

Embodiment 2

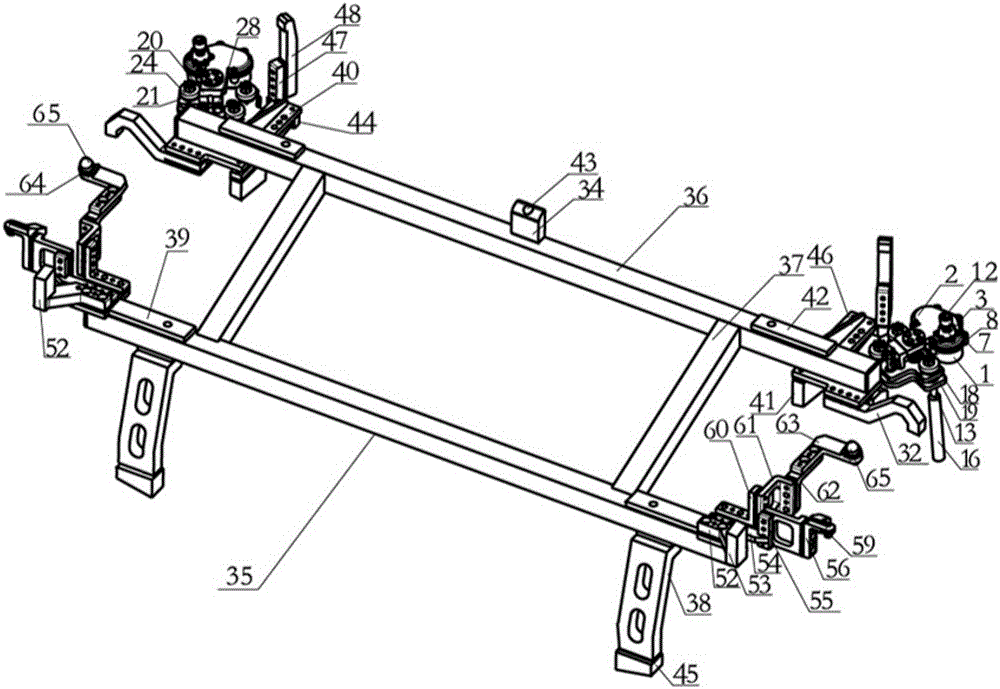

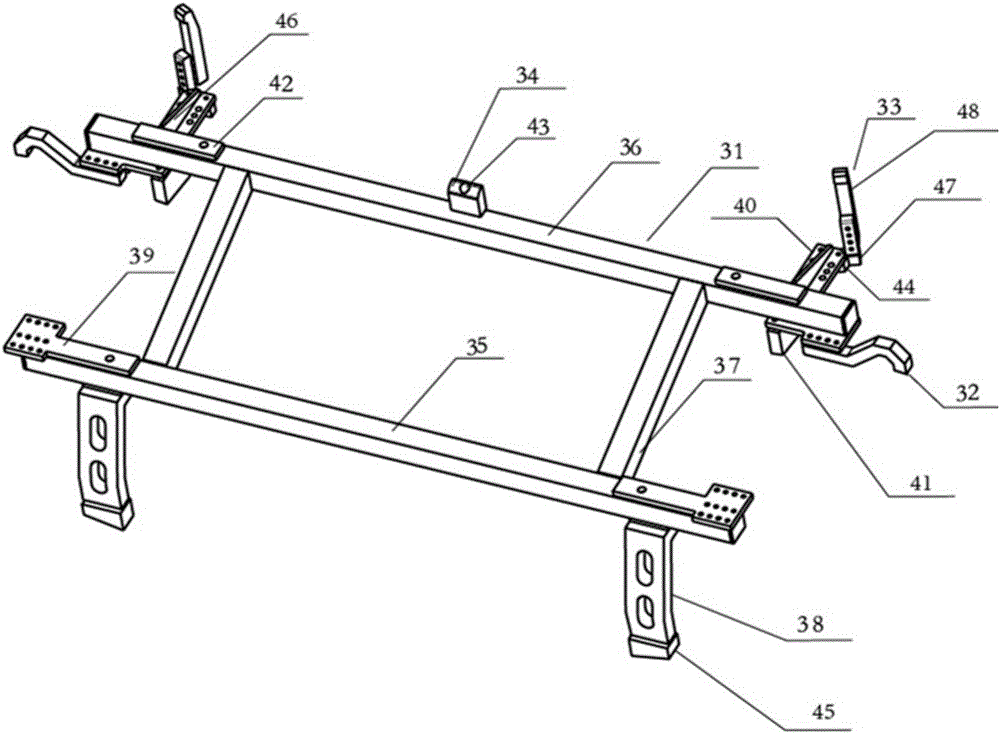

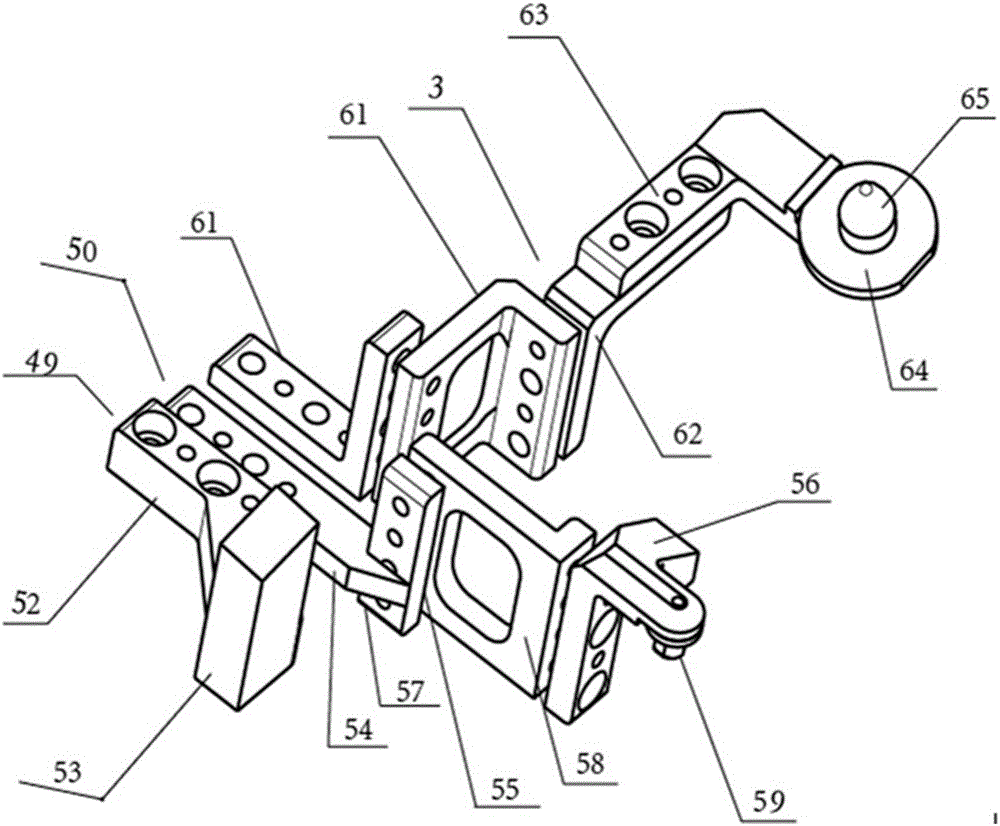

[0050] See attached Figure 1-7 :

[0051] An automobile front cover assembly sample frame with elastic materials, including a front hatch cover support frame, a front cover assembly connector, a front cover assembly fastening device and a front cover centering device; the front cover assembly fastening device includes a hollow Shell 1, cover body 2, protective cap 3, force applying gear 4, force transmitting gear 5, force receiving gear 6 and gun head 7; force applying gear, force transmitting gear and force receiving gear are installed in the hollow shell; cover The body is located above the hollow shell, and the cover and the hollow shell are provided with five screw mounting caps 8 correspondingly. The screws are located in the screw mounting caps to connect the cover and the shell; There is a mounting plate 9, and there are screw holes on the mounting plate, which can connect the protective cap and the cover body through screws; the hollow shell is an elliptical structur...

Embodiment 3

[0060] An automobile front cover assembly sample frame with elastic materials, including a front hatch cover support frame, a front cover assembly connector, a front cover assembly fastening device and a front cover centering device; the front cover assembly fastening device includes a hollow Shell, cover, protective cap, force applying gear, force transmitting gear, force receiving gear, gun head and extension rod; force applying gear, force transmitting gear and force receiving gear are installed in the hollow shell; cover is located in the hollow On the top of the shell, three screw mounting caps are set corresponding to the cover and the hollow shell. The screws are located in the screw mounting caps to connect the cover and the shell; There are screw holes on the board, which can connect the protective cap and the cover body through screws; the oval structure, the protective cap is a disc-shaped structure; the force applying gear, the force transmitting gear, and the force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com