Damage-proof automobile front hood supporting frame

A kind of support frame, anti-damage technology, applied in the direction of vehicle parts, superstructure sub-assembly, transportation and packaging, etc., can solve environmental and human health hazards, flame retardant performance can not reach UL94-VO level, material physical properties decline, etc. problems, to ensure the safety of personnel and property, prevent the diffusion of dense smoke and toxic gases, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 100Kg of bis(2,3-epoxycyclopentyl)ether and 50Kg of bis(4-amino-3-methylcyclohexyl)methane into the reactor, stir at 120°C for 30 minutes; then add 40Kg of adipic acid di (3,4-epoxy-6-methylcyclohexylcarboxylic acid), stirred for 1 hour, then added 10Kg glass microspheres and 25Kg methacrylic acid, and stirred at 130°C for 20 minutes to obtain an epoxy composition; 100Kg dinaphthyl Add carbonate, 60Kg dicyclohexyl carbonate, 10Kg mica to butanone, stir at 50°C for 20 minutes, then add 18Kg dihydroxy polydiethylsiloxane, 25Kg amine phosphate, 20Kg N-methylol acrylamide, under ventilation , Stir at 110°C for 10 minutes to obtain a carbonate composition; heat and mix 60Kg of epoxy composition and 180Kg of carbonate composition, then add it into a mold, and heat press at 100°C and 1MPa for 3 minutes to obtain an elastic material. After testing, the flame retardancy is UL94V1; the elongation at break is 54%; the flexural elasticity is 210MPa.

Embodiment 2

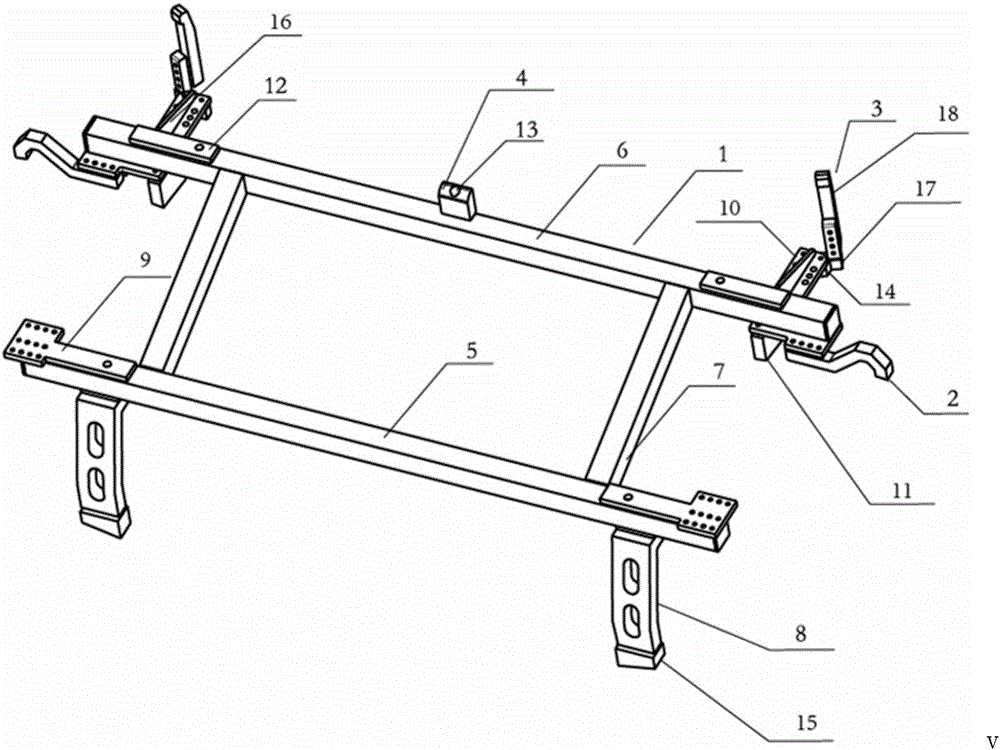

[0026] See attached figure 1, the anti-damage automobile front hatch support frame of the present invention comprises a trapezoidal body 1, a support frame handle 2, a limiting block 3 and a positioning block 4; the trapezoidal body is connected to the first side by the first side 5, the second side 6 Two connecting rods 7 on the second side are formed; the lower surface of the first side of the trapezoidal body is equipped with supporting legs 8; the supporting legs are provided with mounting holes; There are installation holes on the board, and the installation position of the T-shaped connecting plate is located directly above the installation position of the supporting legs; the lower surface of the second side of the trapezoidal body is equipped with an L-shaped connecting plate 10; the two sides of the L-shaped connecting plate are provided with Mounting holes; the lower surface of the L-shaped connecting plate is equipped with supporting feet 11 and the support frame ha...

Embodiment 3

[0029] The anti-damage automobile front hatch support frame of the present invention comprises a trapezoidal body, a support frame handle, a limit block and a positioning block; Composed of rods; the lower surface of the first side of the trapezoidal body is equipped with supporting legs; the supporting legs are provided with mounting holes; the upper surface of the first side of the trapezoidal body is equipped with a T-shaped connecting plate, and the T-shaped connecting plate is provided with mounting holes. The installation position of the plate is located directly above the installation position of the supporting legs; the lower surface of the second side of the trapezoidal body is equipped with an L-shaped connecting plate; both sides of the L-shaped connecting plate are provided with mounting holes; the lower surface of the L-shaped connecting plate is equipped with Support feet and support frame handles; the support frame handles are installed on the L-shaped connecting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com