Clamping spring loading device of ball valve automatic assembling machine

A technology of automatic assembly machine and circlip, which is applied in the field of machinery, can solve the problems of product processing delay, difficulty in enterprise recruitment, low assembly efficiency, etc., and achieve the effect of high degree of automation, high degree of firmness, and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

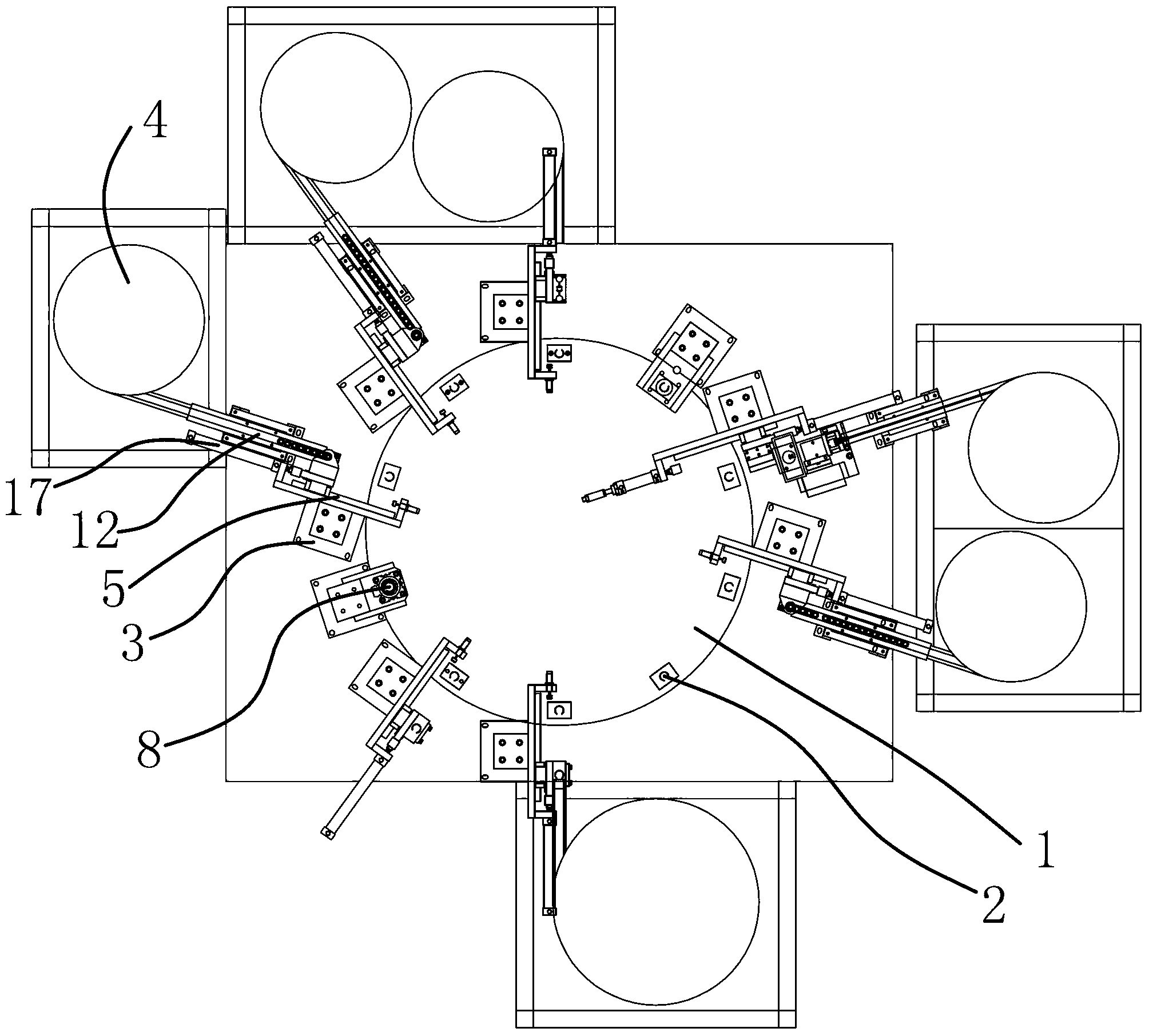

[0031] Such as figure 1 As shown, the circlip loading device is a part of the ball valve automatic assembly machine. The assembly machine includes a disc-shaped workbench 1 that can rotate around its axis. Seat 2, mold base 2 is fixed on the workbench 1 by bolt, has the fixing groove of fixing valve body on the mold base 2, and this jump ring loading device is positioned at the side of workbench 1.

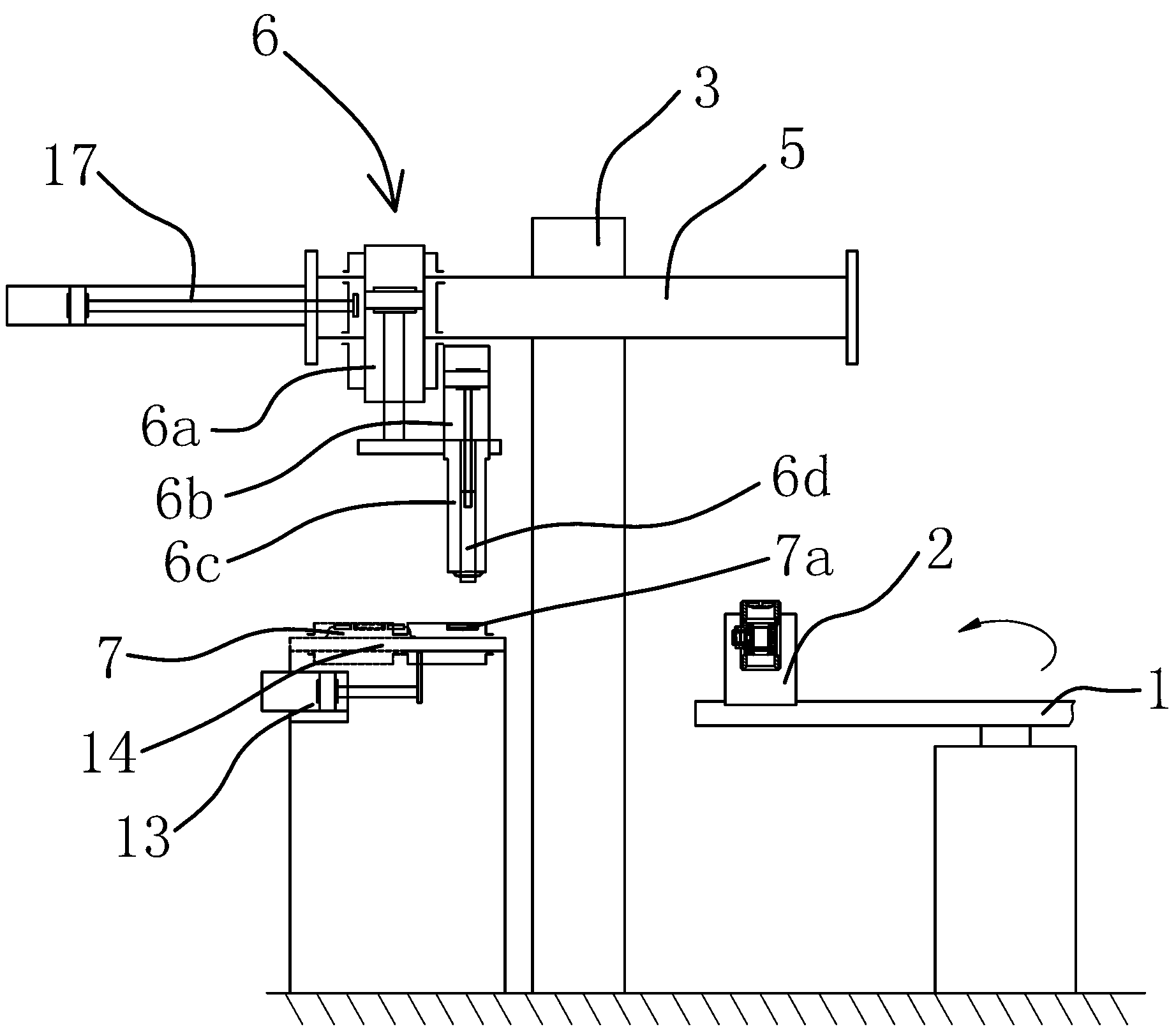

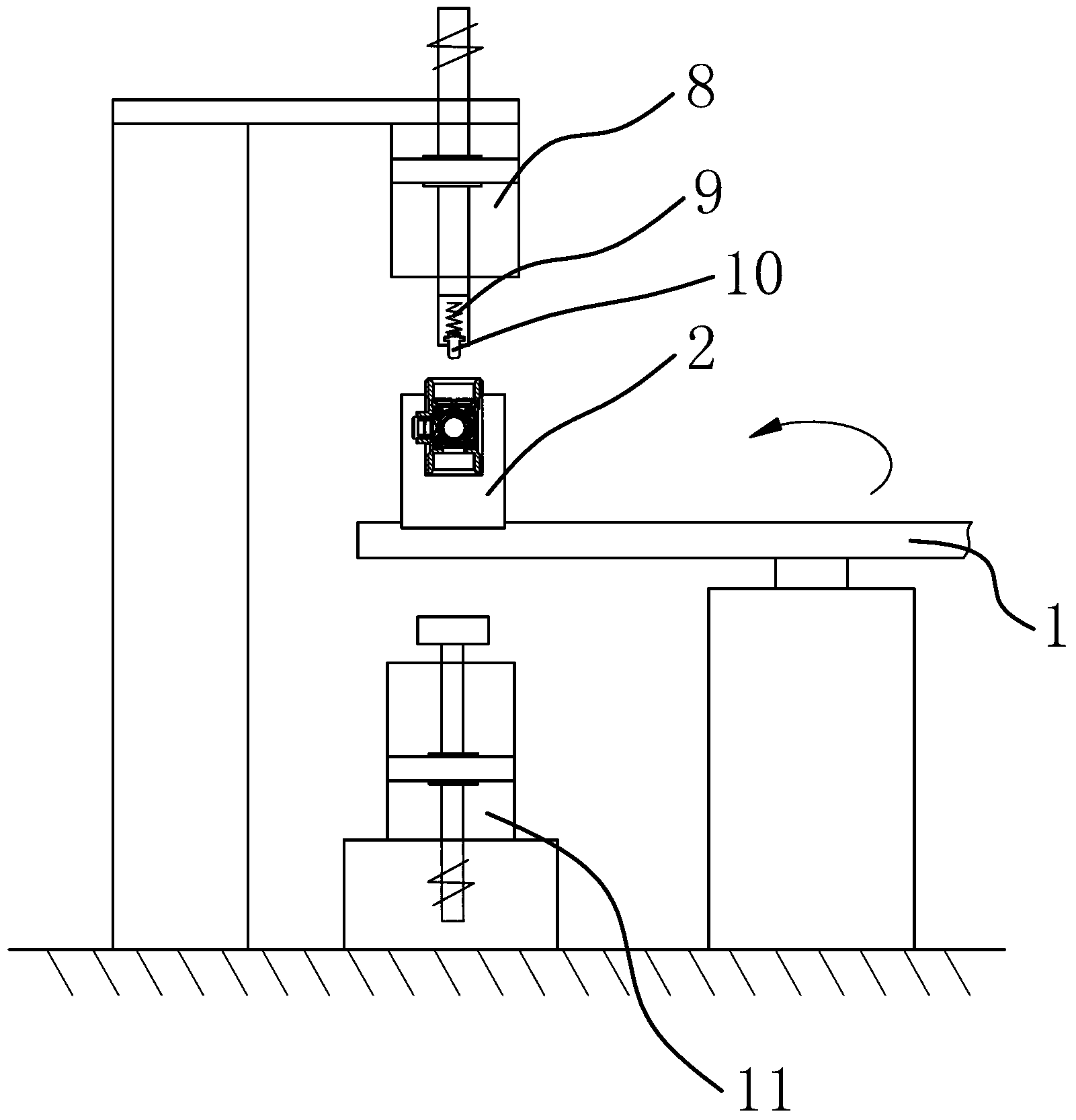

[0032] Such as figure 2 , image 3 As shown, the clamp spring loading device includes a support 3, a vibrating tray 4, a drive mechanism, a manipulator 6, a slide block 7, a compression cylinder 8, a spring 9, a punch 10 and a top disc cylinder 11.

[0033] The bracket 3 is located on the side of the workbench 1, the top of the bracket 3 is fixedly connected with a horizontal guide rail 5, and a manipulator 6 is movably connected to the horizontal guide rail 5, and the manipulator 6 includes a slide plate, a lifting cylinder 6a, a core-pulling cylinder 6b, a guide cylinder 6c a...

Embodiment 2

[0038] Such as Figure 4 As shown, the structure and principle of the present embodiment and the first embodiment are basically the same, the difference is that in the present embodiment, the driving mechanism includes a horizontal cylinder one 15 and a slide rail 16, and the horizontal cylinder one 15 and the slide rail 16 are fixed on a fixed On the frame, the piston rod of the horizontal cylinder-15 is fixedly connected with the body 7b of the slide block 7, and the slide block 7 is installed in the slide rail 16, and the direction of the slide rail 16 is consistent with the telescopic direction of the piston rod of the horizontal cylinder-15, and the horizontal cylinder The expansion and contraction of a 15 piston rod drives the slide table 14 to move along the slide rail 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com