Patents

Literature

63results about How to "Effective control of settlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

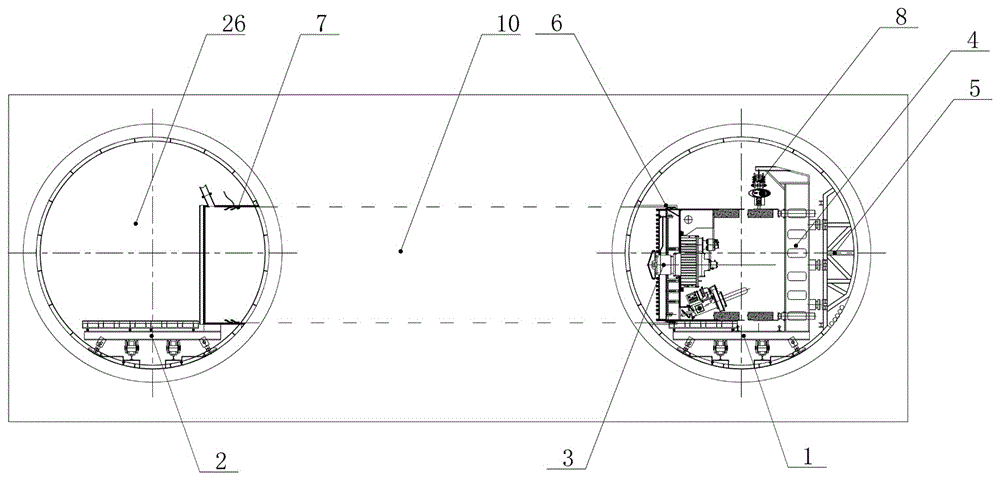

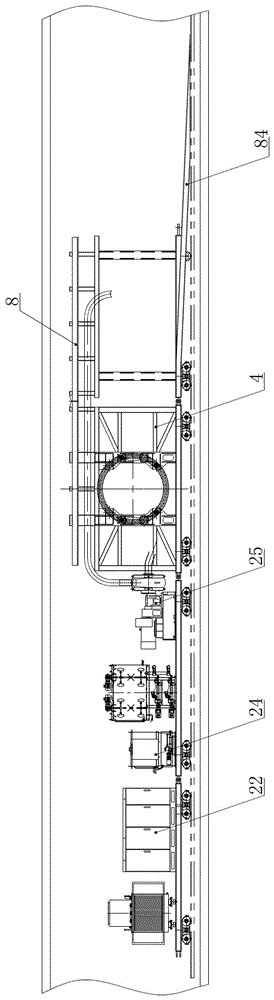

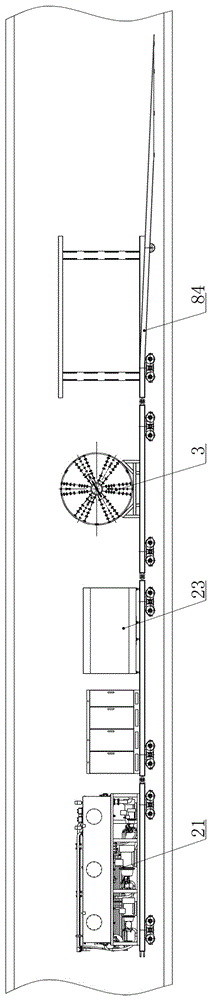

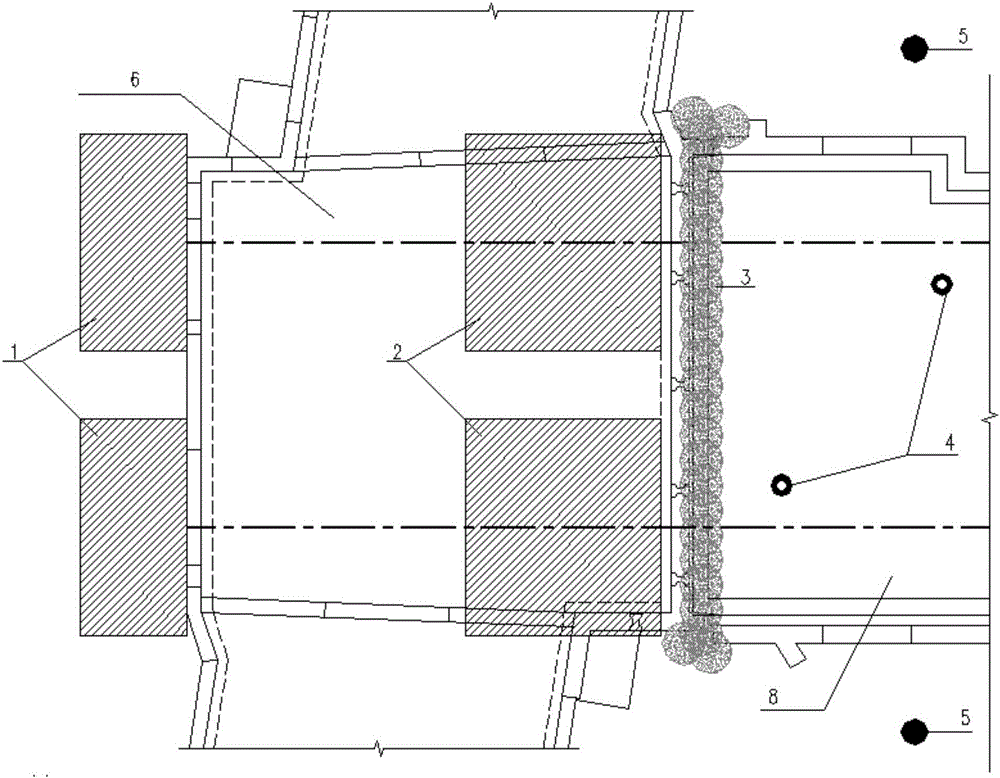

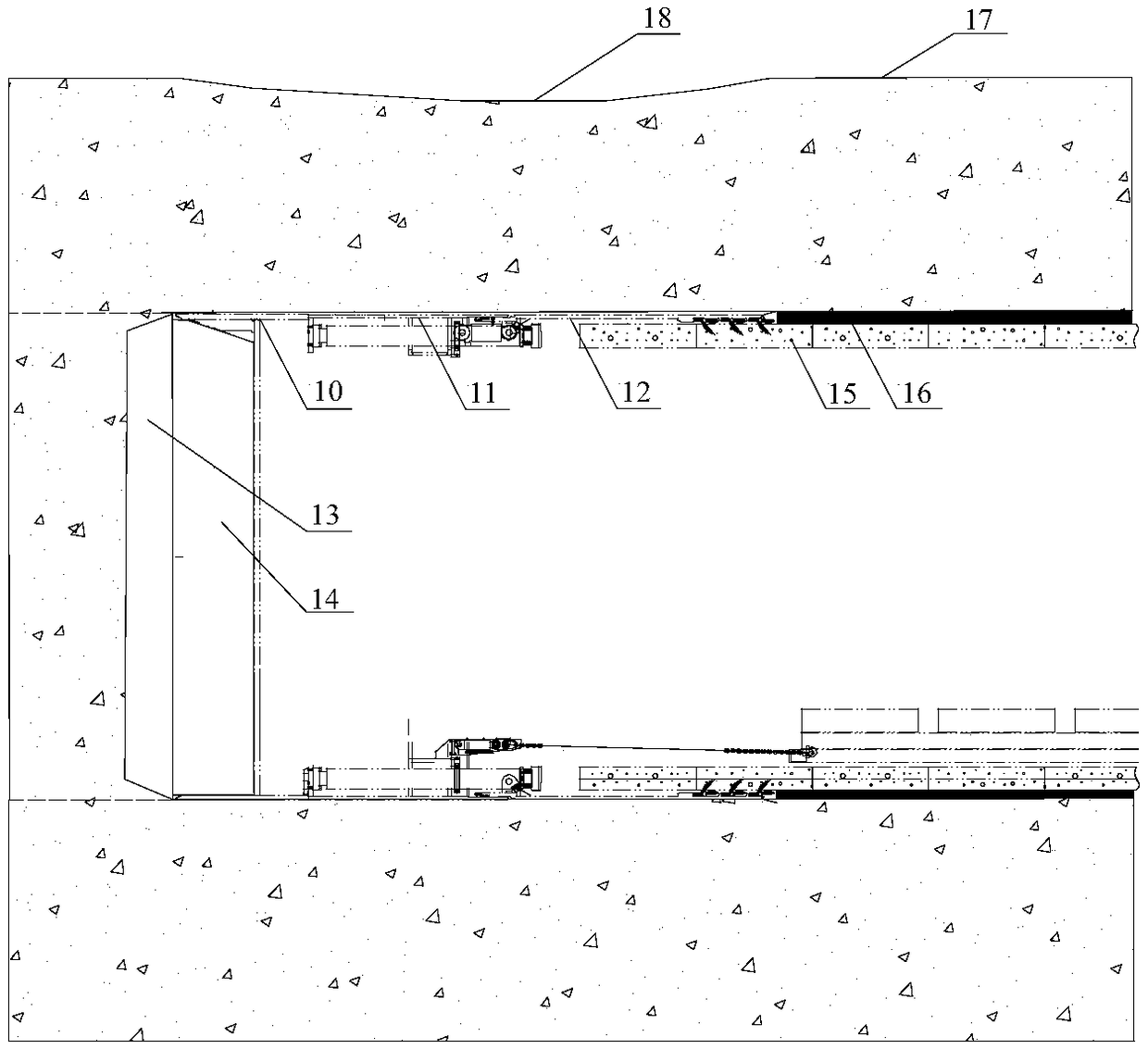

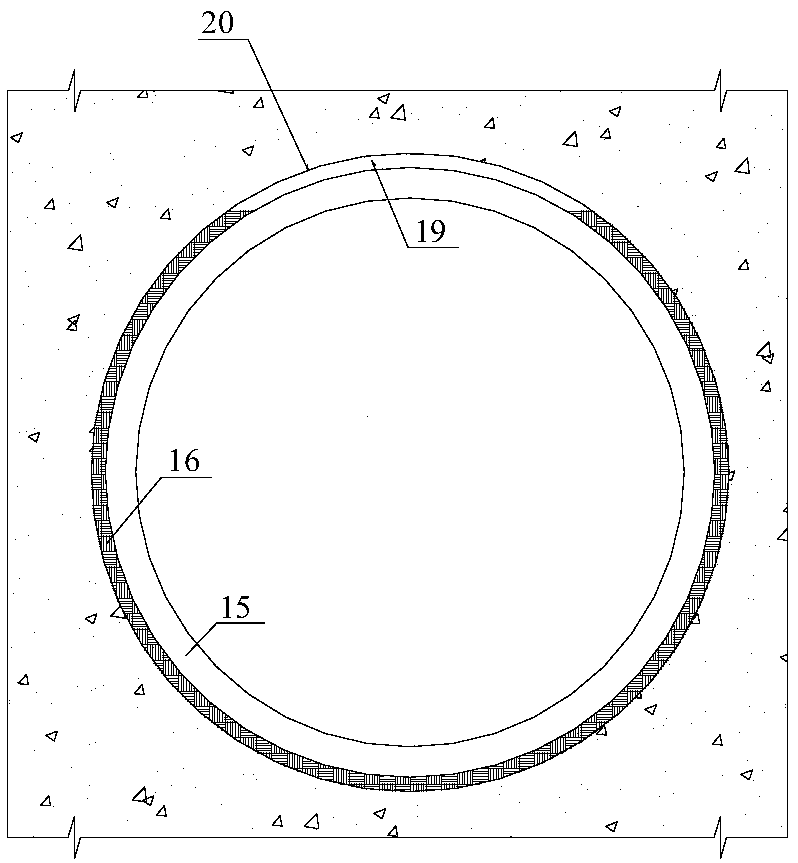

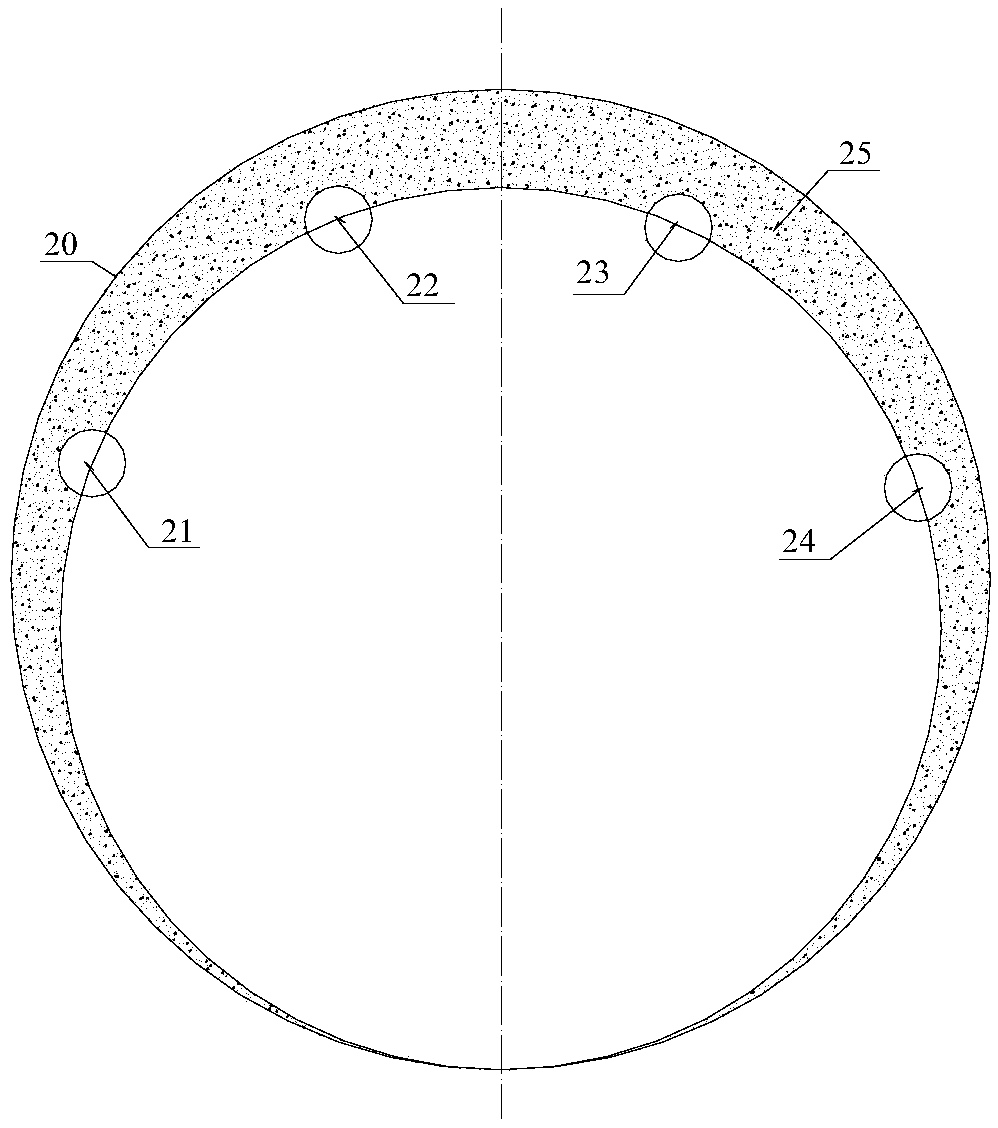

Shield tunneling machine for tunnel connecting passageway and connecting passageway tunneling method of shield tunneling machine

ActiveCN106437735AReaction support enoughCompact and reasonable structure designTunnelsShield tunnelingUltimate tensile strength

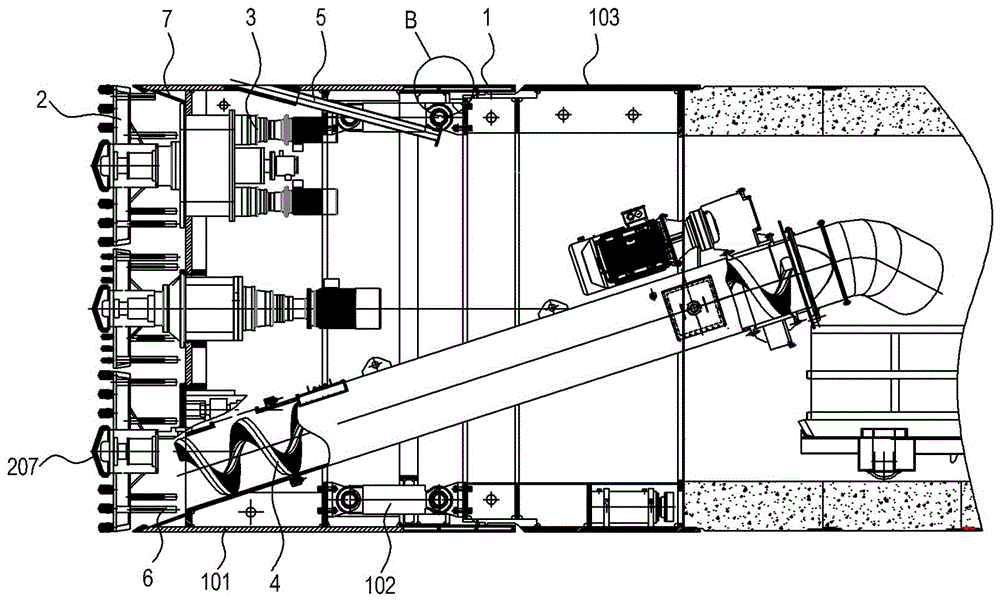

The invention belongs to the technical field of tunnel construction equipment, and relates to a shield tunneling machine for a tunnel connecting passageway and a connecting passageway tunneling method of the shield tunneling machine. The shield tunneling machine comprises a start end supporting walking platform and a receiving end supporting walking platform which are respectively arranged on material transportation rails in two main tunnels, a shield tunneling machine main unit, a counterforce supporting frame and a main tunnel supporting assembly which are respectively arranged on the start end supporting walking platform and a corresponding main tunnel duct piece, and a start end socket sealing assembly and a receiving end socket sealing assembly which are respectively arranged at the start end and the receiving end of the connecting passageway, wherein a duct piece hanging assembly is arranged on the start end supporting walking platform; a jacking tunneling assembly is arranged between the counterforce supporting frame and the shield tunneling machine main unit. The shield tunneling machine can realize automatically mechanical excavation; the labor intensity is greatly reduced, the energy consumption is reduced, and the cost is reduced; meanwhile, equipment construction is stable, and the efficiency is high; settling of the ground is effectively controlled, and the construction risk is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

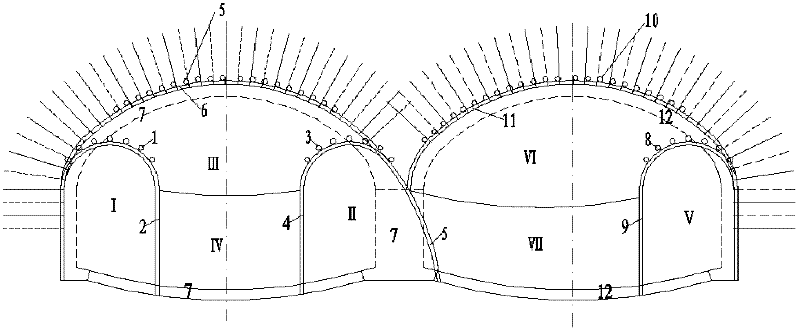

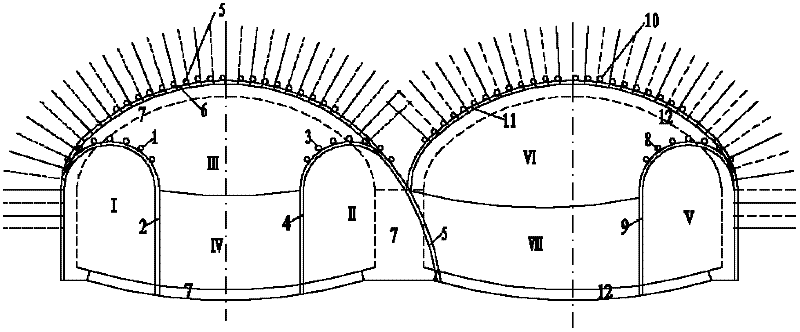

Rapid construction method of weak surrounding rock large-section multi-arc tunnel

InactiveCN102373930AImprove construction progressShorten the construction periodUnderground chambersTunnel liningStructure of the EarthRapid construction

The invention discloses a rapid construction method of a weak surrounding rock large-section multi-arc tunnel. According to the invention, in tunnel construction, the main tunnel on one side of the multi-arc tunnel and the place of a partition wall are synchronously excavated; the tunnel excavation is implemented by using a double side-wall heading method; then, a primary support and the partition wall are constructed before the secondary lining of the tunnel; and finally, the main tunnel on the other side of the multi-arc tunnel is excavated by using a single side-wall heading method, and a corresponding support structure is built. Compared with the traditional multi-arc tunnel construction method, the construction method disclosed by the invention does not need to cut through a middle guide tunnel and build the partition wall before excavating the main tunnels on the two sides, thereby greatly accelerating the construction of the multi-arc tunnel, shortening the construction period and properly lowering the construction cost.

Owner:CENT SOUTH UNIV

Forward coal mining by filling method

InactiveCN101749020ASolve stressSolve problems such as air leakage in gobsUnderground miningSurface miningMining engineeringEarth surface

The invention provides a forward coal mining technique by a filling method, comprising the following characteristics: simultaneously pushing the working surface and the gate road of coal mining, thereby tunneling, mining and filling old empty region. The invention can reduce 20-30% of tunneling rate and 10-15% of workers, the filling ratio of the goaf reaches over 95%. The problems that the maintenance is difficult to carry out because of great pressure of the surrounding rock along retaining, the goaf leaks air, the production is continuously tense, coal resource is wasted and the like are solved, and the non-disturbance of earth surface is effectively controlled.

Owner:ZIBO WANGZHUANG COAL MINE

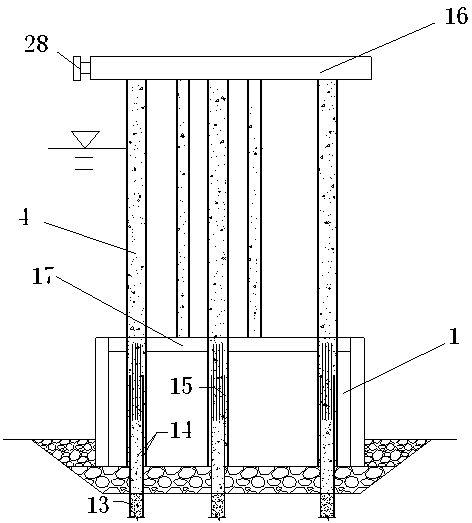

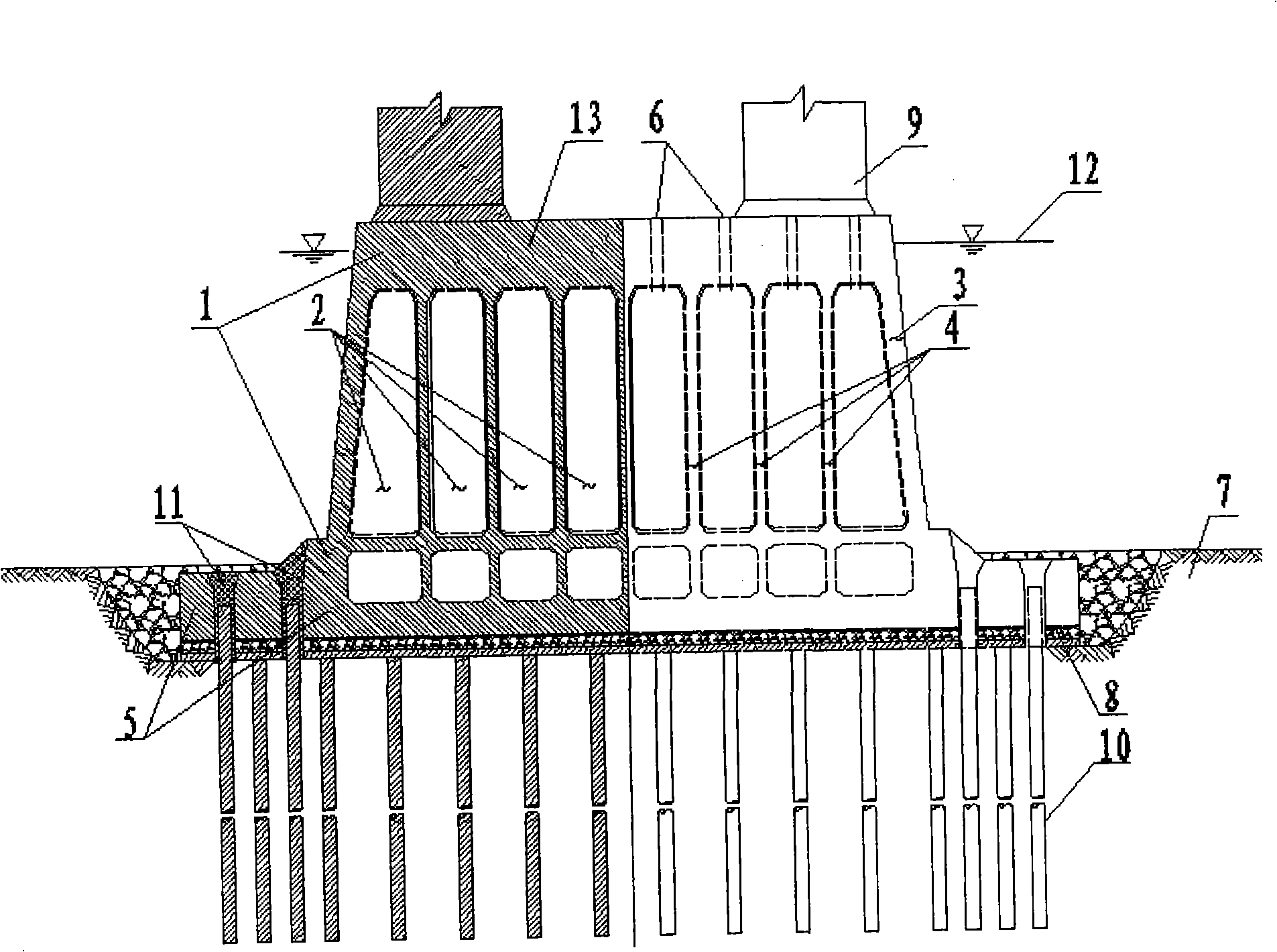

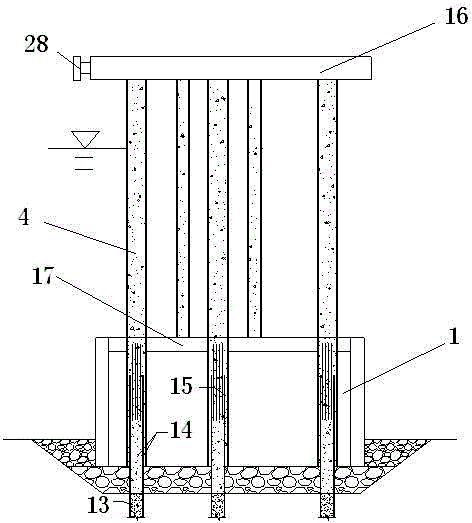

Deepwater open type wharf with combined foundation and method for constructing deepwater open type wharf

The invention discloses a deepwater open type wharf with a combined foundation. A foundation support system of the deepwater open type wharf comprises a caisson gravity structure system and a pile foundation structure system which are fixedly assembled and connected with each other, a caisson is fixed onto a submarine foundation bed in an implantation manner, the pile foundation structure system is of a concrete-filled steel pipe pile bundle structure comprising through long piles and non-through piles, steel pipe piles arranged along the insides of steel casings are driven into a rock-soil bearing stratum to form the through long piles, and the bottoms of the non-through piles are embedded into a top plate of the caisson to be fixedly connected with the top plate of the caisson, so that the wharf with the combined foundation which comprises an open type pile foundation and the gravity caisson is formed. The invention further provides a method for constructing the wharf. The method includes prefabricating the combined foundation on a land; processing the submarine foundation bed; positioning and sinking the combined foundation; manufacturing the through long piles; manufacturing an upper wharf face plate. The deepwater open type wharf and the method have the advantages that merits of the gravity structure and merits of a pile foundation structure are combined with one another, the problem of differential settlement is effectively solved, wharf apron mooring conditions are improved, and the wharf is high in bearing capacity and good in durability.

Owner:SHANGHAI UNIV

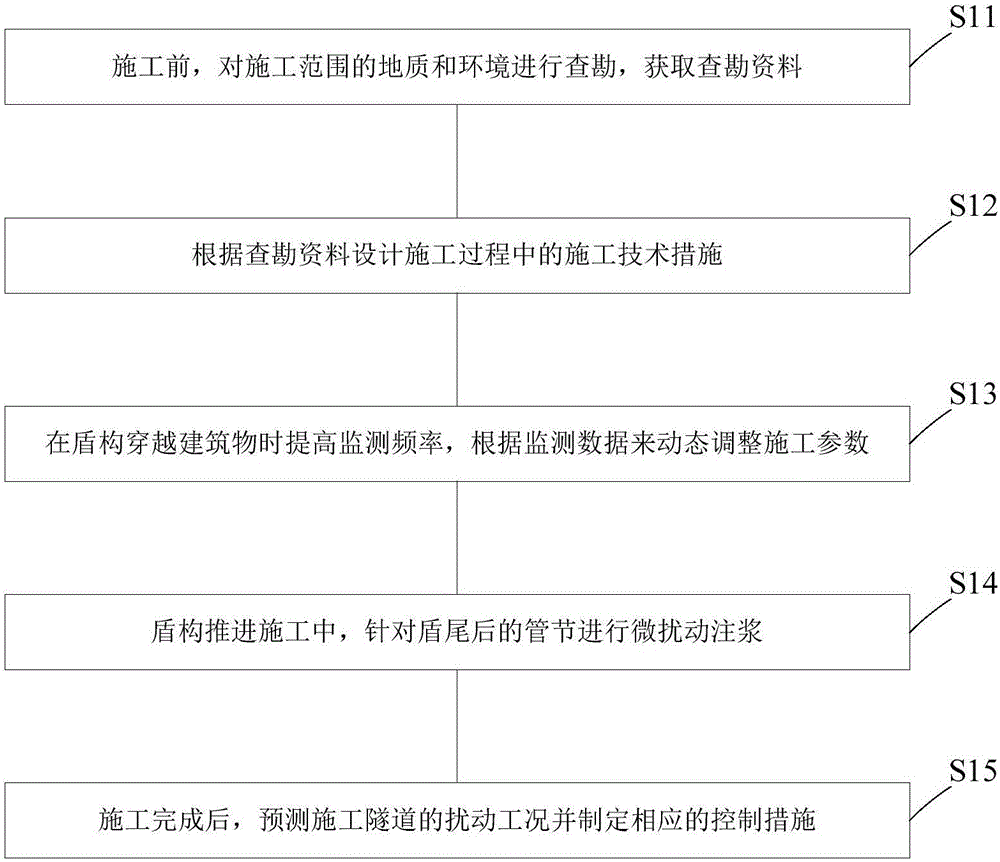

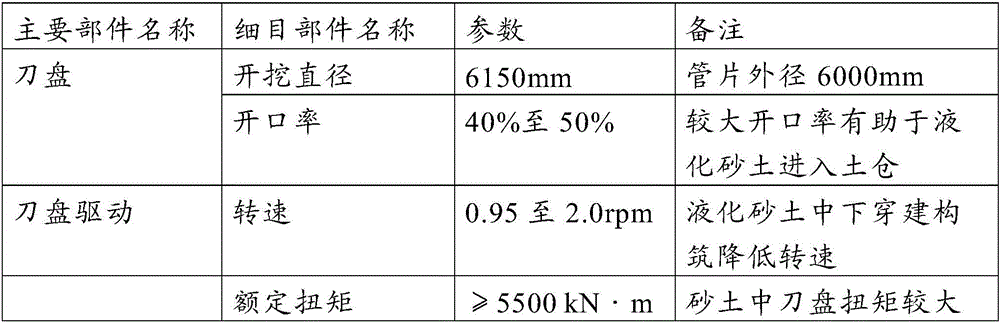

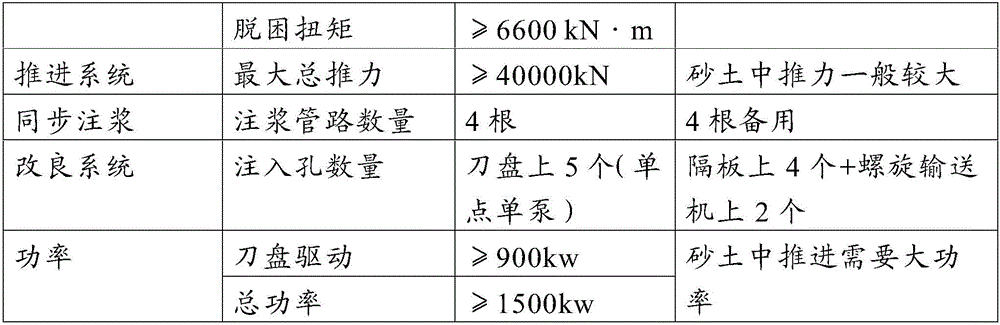

Construction method suitable for making shield penetrate through building in close range on liquefied sandy soil stratum

ActiveCN105804761APrevent liquefactionGood service statusUnderground chambersBuilding constructionsArchitectural engineeringEnvironment of Albania

The invention relates to a construction method suitable for making a shield penetrate through a building in a close range on a liquefied sandy soil stratum. The construction method comprises the steps that before construction, the geology and environment of a construction range are surveyed, and survey data are obtained; construction technical measures in the construction process are designed according to the survey data; the monitoring frequency is increased when the shield penetrates through the building, and construction parameters in the construction technical measures are dynamically adjusted according to monitored monitoring data; during pushing construction of the shield, pipe sections 8-10 rings away from the shield tail after being detached from the shield tail are subjected to micro-disturbance grouting, and the grouting pressure is controlled to be smaller than or equal to 0.3 Mpa; and after construction is finished, the disturbance condition of a construction tunnel is predicted, and corresponding control measured are set out. According to the construction for making the shield penetrate through the building in a close range on the liquefied soil stratum, a micro-disturbance construction control technique is adopted, the situation that liquefied sandy soil is liquefied due to disturbance in the shield pushing process can be avoided, settlement is effectively controlled, and the building safety is guaranteed.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

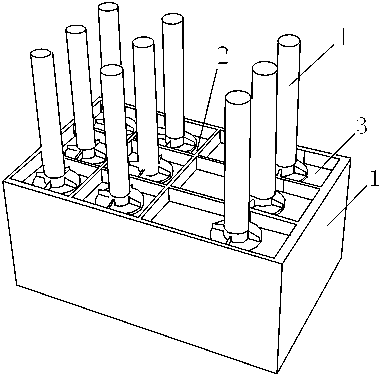

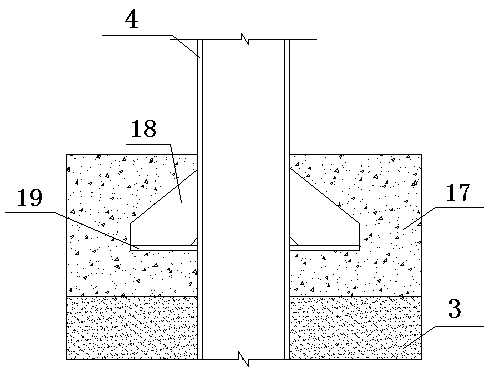

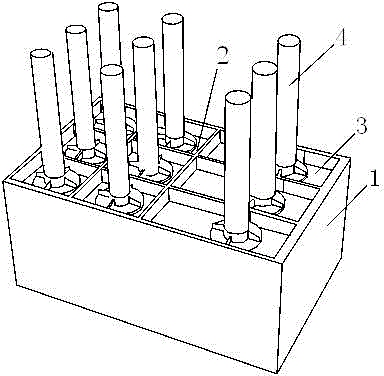

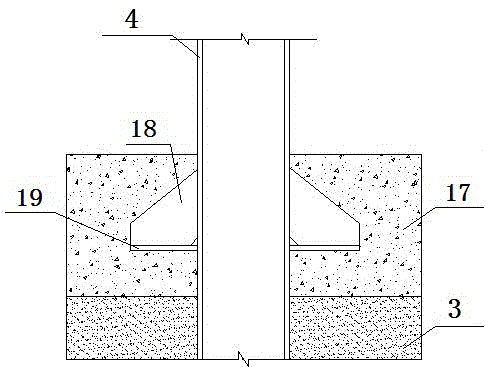

Steel cavity stranded caisson-pile inverse-way composite base and construction method

ActiveCN101294394AEffective control of settlementReduce settlementCaissonsBulkheads/pilesRiver bedEngineering

The invention relates to a composite foundation composed of a caisson with a steel cavity and piles constructed by the reverse operation method, and a construction method thereof, belonging to the bridge construction technology. The composite foundation comprises a caisson, a foundation bed, and piles. The caisson is composed of a steel cavity, an outer wall, an inner wall with a partition wall structure, a caisson cover, and a caisson bottom platform, wherein the caisson cover is preserved with water pumping and gas delivery holes, which are doubled as inspection holes. The caisson is arranged above the foundation bed and placed inside water, bridge piers are arranged on the caisson cover, the periphery of the caisson bottom platform is connected with the piles constructed by the reverse operation method, and the piles are inserted into the foundation bed and the sea bed or river bed through sinking pile preserved holes. After a foundation trench is excavated, a ship is located by riprapping to form the foundation bed, and the foundation bed is leveled by a platform type foundation bed riprapping leveling ship. The piles are connected with the caisson by pouring concrete in the preserved holes in the caisson. The inventive composite foundation utilizes the buoyancy force of the caisson steel cavity and considers the combined action of the piles, soil and the caisson to share partial external load by the sea bed or the river bed. The composite foundation optimizes the pile foundation design, reduces settlement during bridge service period, and reduces construction cost.

Owner:CCCC HIGHWAY CONSULTANTS

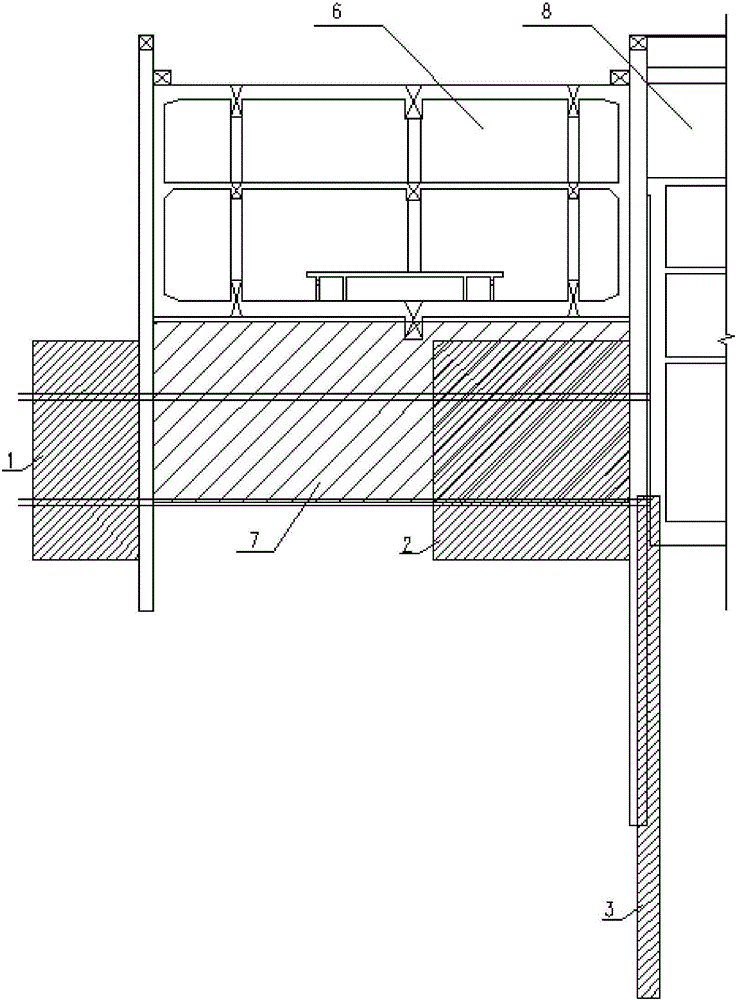

Transverse tunnel cover method for shallow-buried underground excavation large underground space construction

ActiveCN104863597AReduce spanMany working surfacesUnderground chambersTunnel liningSpatial structureGround settlement

The invention discloses a transverse tunnel cover method for shallow-buried underground excavation large underground space construction. Foundation pits or pilot tunnels are formed, in the longitudinal direction of underground space, of the tops of side walls of the underground space to be constructed, temporary transverse stress structures are formed inside the foundation pits or the pilot tunnels at a time and located above a top plate of the underground space to be constructed and are controllable in rigidity, the temporary transverse stress structures are connected with piles inside the foundation pits or the pilot tunnels to form a temporary transverse top cover-pile bearing system, and under protection of the transverse top cover-pile bearing system, a single-span or multi-span and a single-layer or multi-layer underground space structure can be constructed in a sequential construction mode or in an inverse construction mode. In shallow-buried underground excavation large underground space structure construction, ground settlement is effectively controlled, constructed building deformation is reduced, the construction risks are reduced, the construction period is shortened, and the construction cost is lowered.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

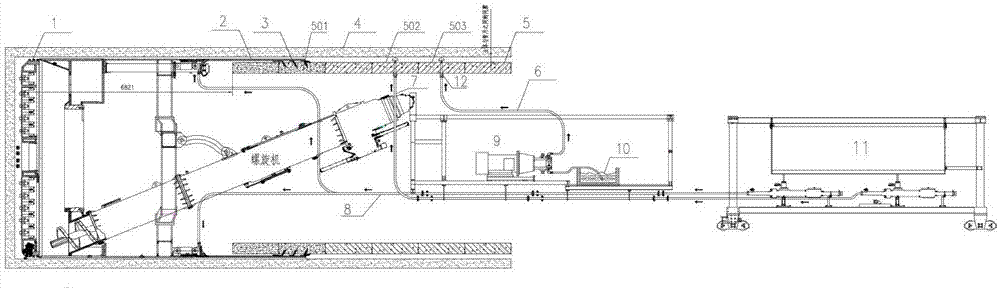

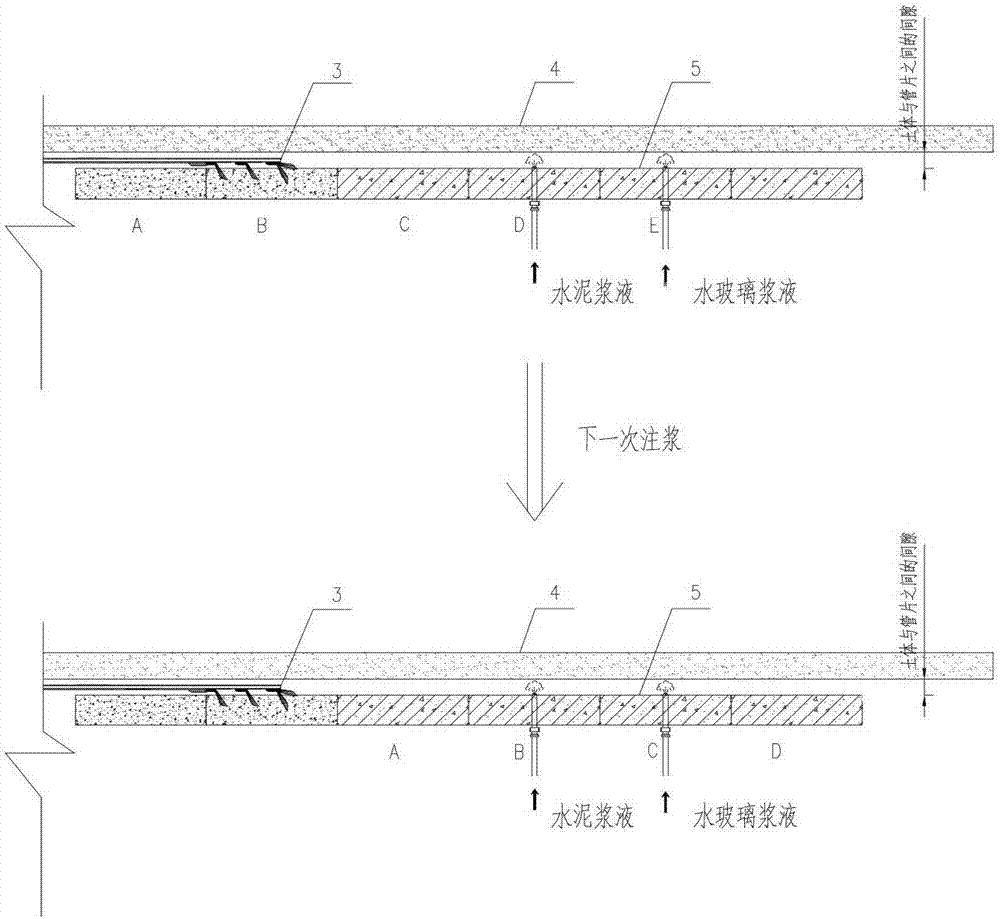

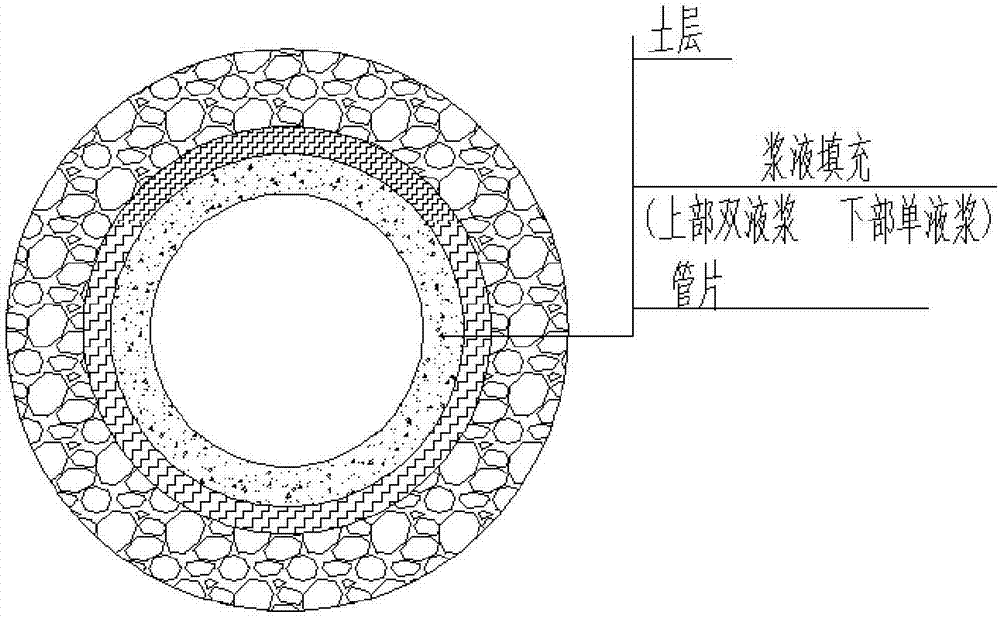

Anti-subsidence control method by supplying grouting in real time in shield construction

ActiveCN107120121AImprove timelinessImprove effectivenessUnderground chambersTunnel liningMaterial resourcesSlurry

The invention discloses an anti-subsidence control method by supplying grouting in real time in shield construction. According to the anti-subsidence control method, a shield machine cutter, a shield shell, a shield tail brush, around soil layers, segments, a first annular segment, a second annular segment, a third annular segment, a water glass grout grouting pipe, an auxiliary synchronous grouting pipe, a main synchronous grouting pipe, a water glass grout grouting pump, a water glass grout preparation barrel, a shield machine cement grout synchronous grouting box and a ball valve are included. Synchronous grouting and secondary grout supplying are effectively integrated, cement injection and water glass injection are organically combined, therefore the timeliness and the effectiveness of filling of gap in the backs of the segments are strengthened, disturbances caused by intersection construction of a traditional secondary grouting and normal tunneling of the shield machine are eliminated, compared with the traditional secondary grouting method, cement grout does not need to be prepared separately, the grouting amount is greatly decreased by separately pumping the water glass grout, the construction schedule is speeded up, the automation level is improved by taking full use of self equipment of the shield machine, and the manpower and material resources are saved.

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD +1

Micro disturbance tunneling method used for shield machine to tunnel under building on rich water weak formation

InactiveCN103527209ASettlement controlEffective control of settlementTunnelsGround layerShield machine

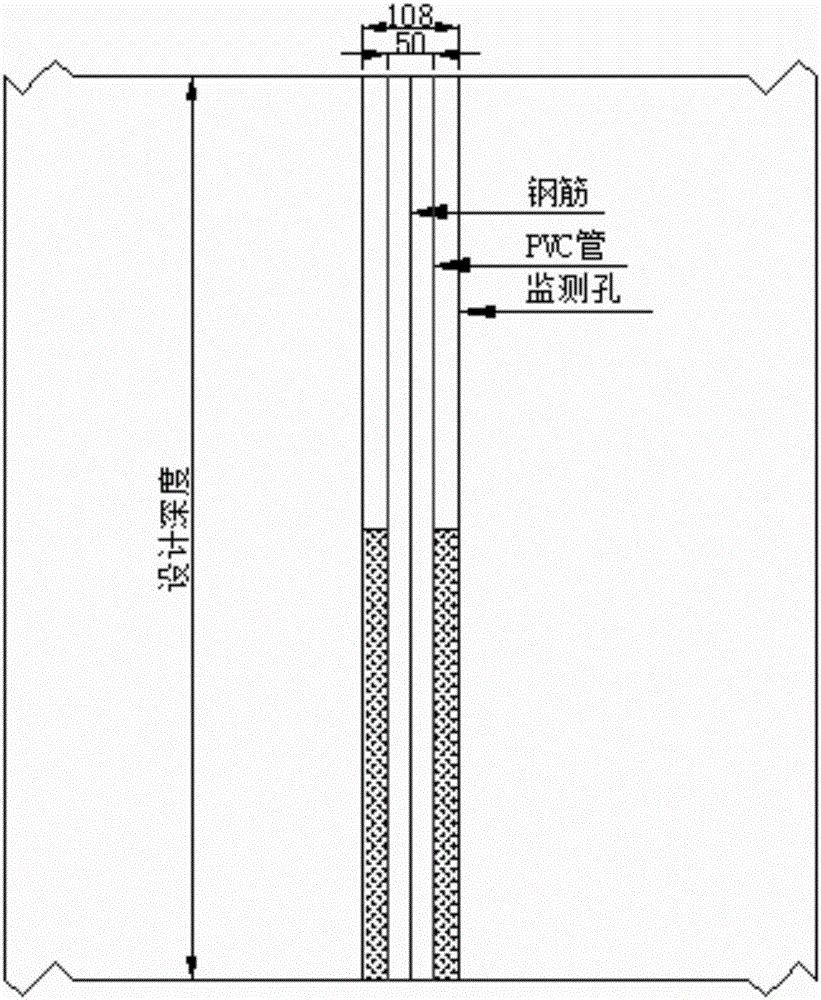

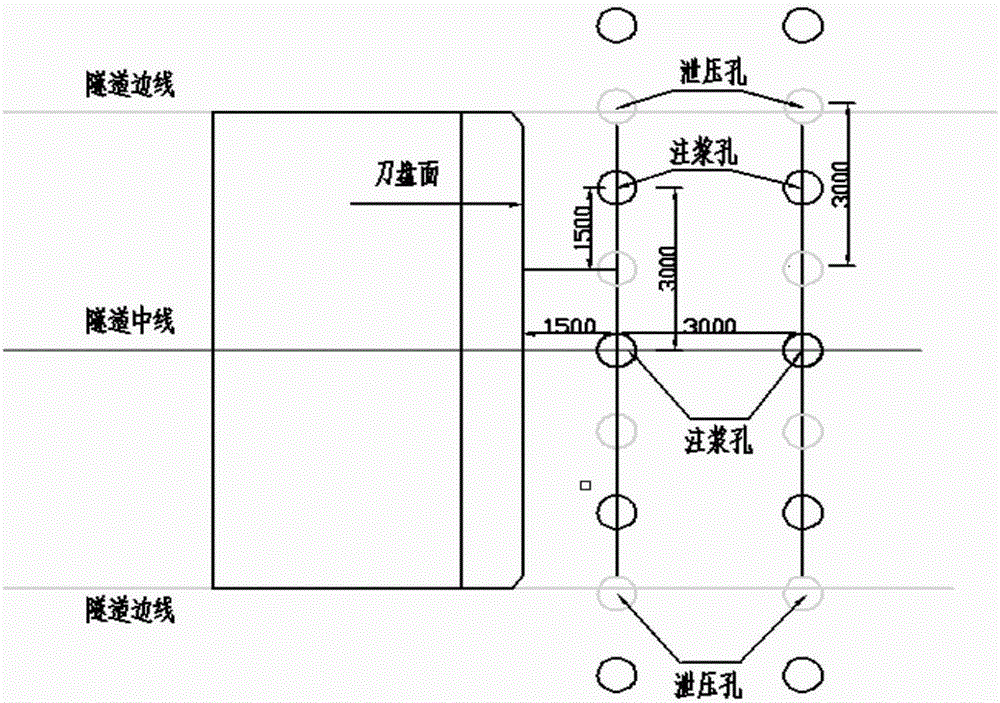

The invention discloses a micro disturbance tunneling method used for a shield machine to tunnel under a building on a rich water weak formation, and belongs to the technical field of shield machine tunneling engineering. The method includes the steps of (1) selecting a shield machine cutter head suitable for the rich water weak formation, (2) inspecting work performance of the shield machine before the shield machine crosses the building, (3) carrying out muck improvement according to different soil layers, (4) setting soil pressure according to the upheaval degree in front of the cutter head, (5) setting tunneling speed according to the different soil layers, (6) determining synchronous grouting amount and secondary compensation grouting amount, pressure and grouting time, and (7) arranging and monitoring observation points when the shield machine tunnels under the building. When the shield machine tunnels under the building, the preceding processes are strictly carried out, micro disturbance caused by shield machine tunneling for the building is achieved, the settlement value of the building can be controlled to range from 3mm to negative 10mm, influences are hardly caused for the building, and safety of the building above the shield tunnel is guaranteed.

Owner:BEIJING JIAOTONG UNIV

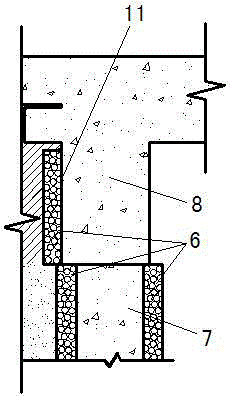

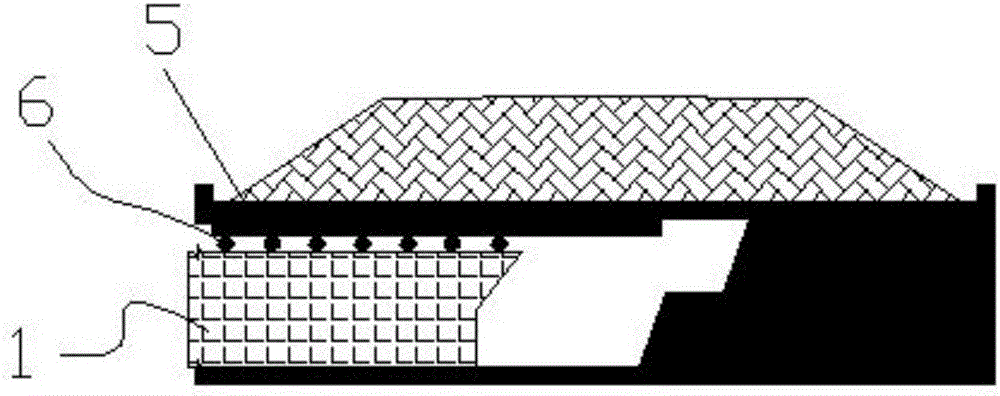

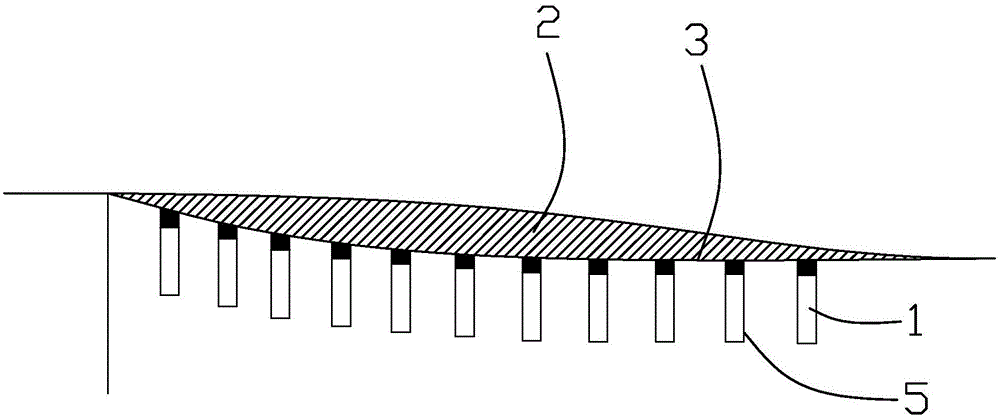

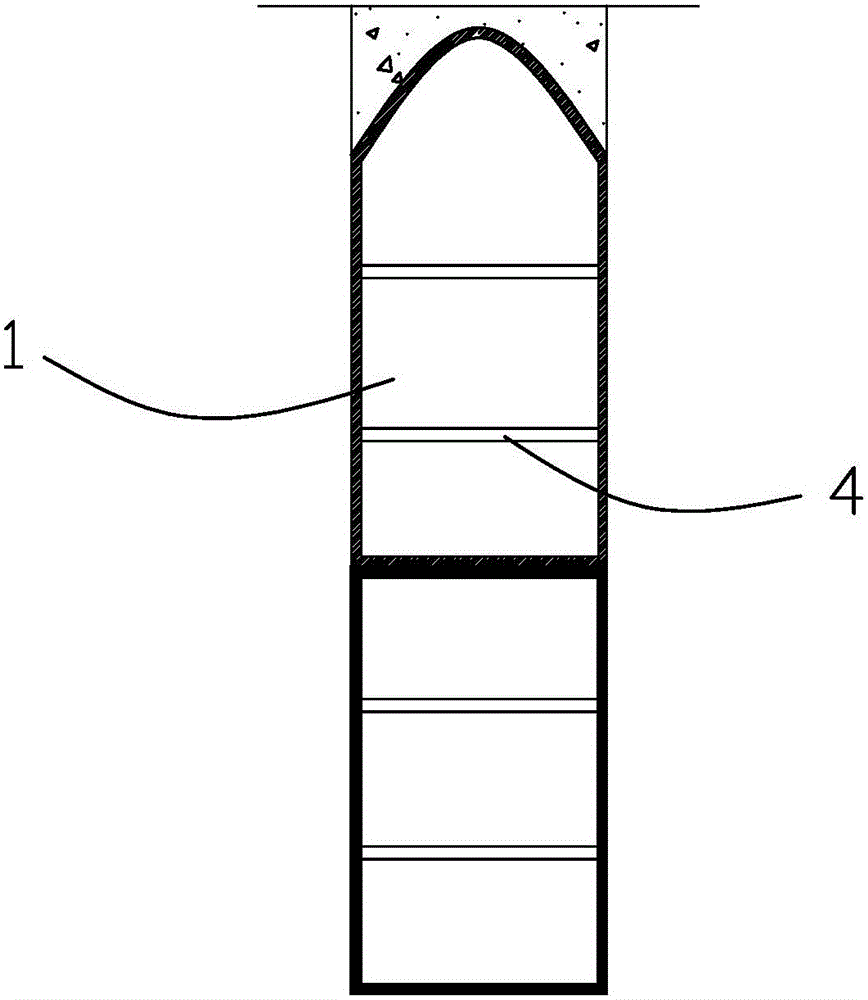

Structure and method for controlling jointless abutment back subsidence and pavement cracking by using reinforcement geotextile

InactiveCN103981802AImprove integrityIncrease stiffnessPaving detailsBridge structural detailsAbutmentRoad surface

The invention relates to a structure and a method for controlling jointless abutment back subsidence and pavement cracking by using reinforcement geotextile. The bridge abutment of a jointless bridge is connected with an access board, backfill reinforced by multilayer reinforcement geotextile is arranged above the access board, backfill reinforced by multilayer reinforcement geotextile is also arranged under the access board, spacing is formed between the backfill reinforced by multilayer reinforcement geotextile and under the access board, and the wall body of the bridge abutment, an elastic material layer in the spacing is wrapped on the abutment back of the abutment, the wall body of the abutment is supported on a single rank of piles, the periphery of the single rank of piles is also wrapped by an elastic material layer, and the access board is obliquely arranged, and a discrete material layer is arranged at the tail end of the access board. With the reinforcement principle of the reinforcement geotextile and ingenious structural arrangement, a flexible structural layer with good overall integrity and higher rigidity is formed, so that the abutment back subsidence and pavement cracking of the jointless bridge are effectively controlled, the rigid-and-flexible stable transition of the road and bridge transition section is realized, and the structure and method are particularly applicable to jointless bridges with integral type abutments.

Owner:FUZHOU UNIV

Environment-friendly shield construction single-liquid synchronous grouting slurry

ActiveCN101935198AHigh energy consumptionSolve the problem of occupying a lot of landSolid waste managementHigh energySlurry

The invention relates to materials applicable to underground engineering construction, in particular to environment-friendly shield construction single-liquid synchronous grouting slurry. The slurry comprises the following materials in percentage by weight: 55 to 70 percent of sand, 10 to 20 percent of desulphurization gypsum, 10 to 20 percent of fly ash and the balance of additive and water, wherein the additive is a water-soluble high-molecular polymer thickening agent and / or a high-performance polycarboxylic water reducing agent; the water-soluble high-molecular polymer thickening agent is 0.5 to 1.0 percent of the total weight of the desulphurization gypsum and the fly ash; and the high-performance polycarboxylic water reducing agent is 0.75 to 1.25 percent of the total weight of the desulphurization gypsum and the fly ash. Compared with the conventional single-liquid synchronous grouting, the grouting slurry has the advantages of substituting the lime powder with high energy consumption and high pollution for waste desulphurization gypsum, along with the same performance. The grouting slurry solves the problems of a large amount of land occupied by the desulphurization gypsum and serious environmental pollution, also avoids the use of the lime powder with high energy consumption and high pollution and fulfills the aims of energy conservation and environmental protection. Meanwhile, a new way is found for the application of the desulphurization gypsum.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

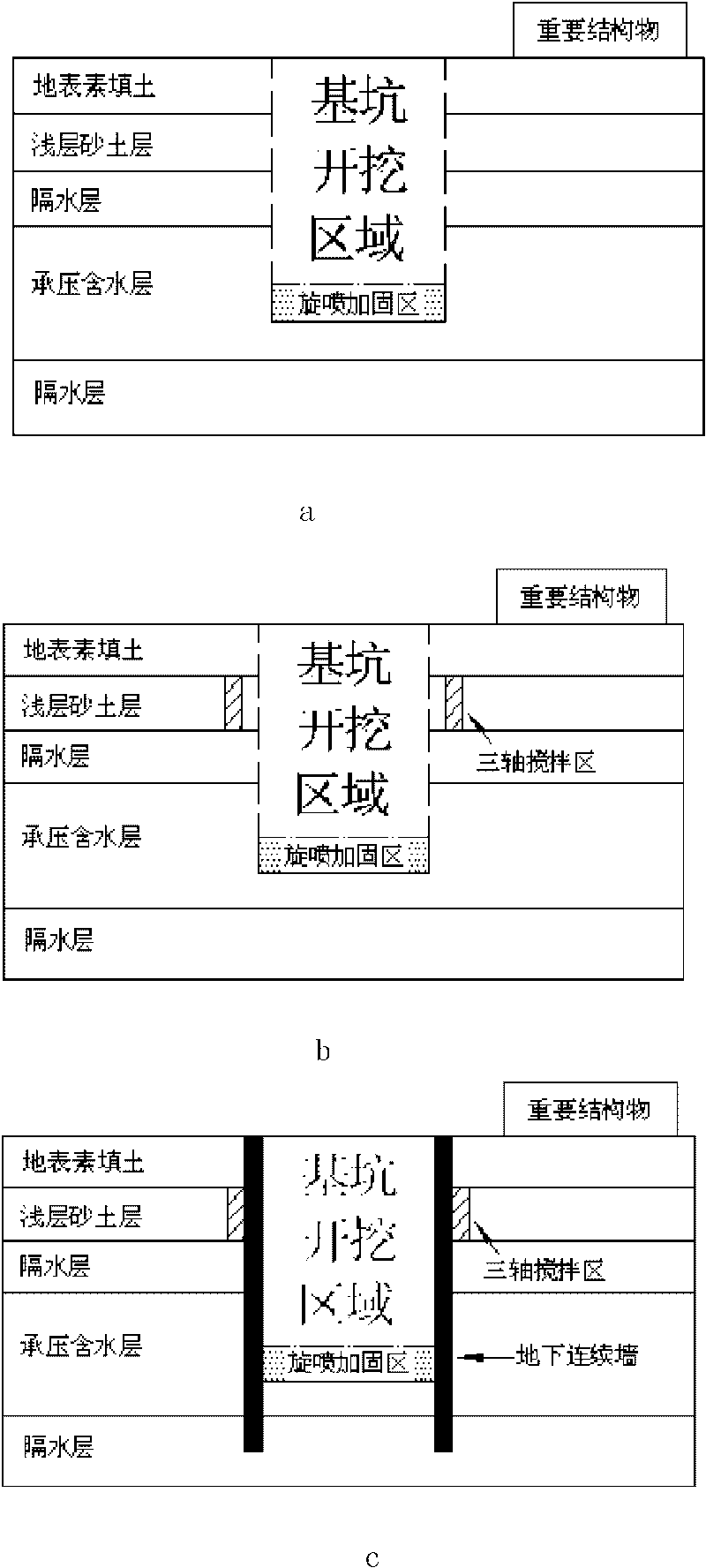

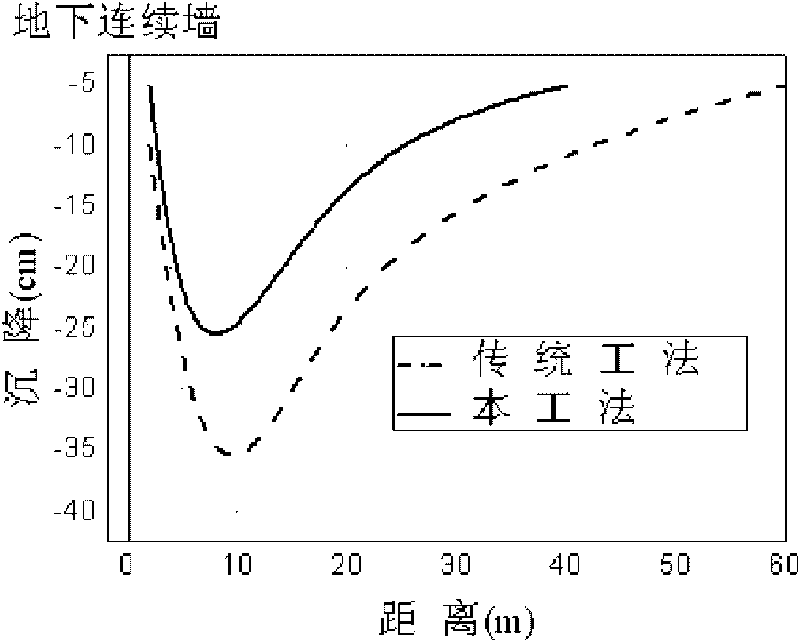

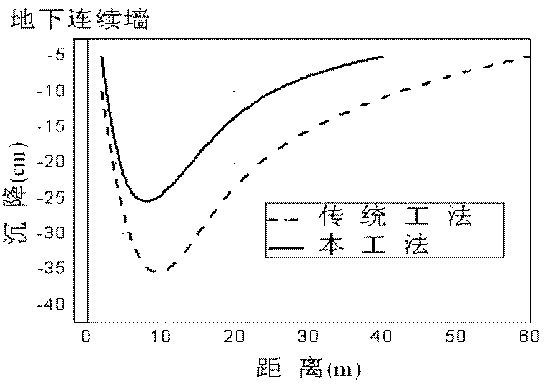

System and method for reinforcing envelop enclosure for shield tunneling beneath existing subway station

ActiveCN106638669AIncrease the difficulty of constructionSettlement control is strictArtificial islandsExcavationsConfined waterSubway station

The invention discloses a system and method for reinforcing an envelop enclosure for shield tunneling beneath an existing subway station. The system comprises a first reinforcing area, a second reinforcing area, a third reinforcing area, a submersible precipitation well and a standby confined water precipitation well, wherein the first reinforcing area is a jet grouting pile reinforcing area which is arranged on the outer side of the existing station, is away from the envelop enclosure on the other side of a foundation pit of a newly built station, and is constructed very close to the envelop enclosure; the second reinforcing area is a freezing method reinforcing area which is constructed very close to a subway envelop enclosure shared by the existing station and the newly built station, and the reinforcing area is close to one side of the existing station; the third reinforcing area is a single-row rodin jet pile (RJP) reinforcing area constructed very close to the subway envelop enclosure shared by the existing station and the newly built station, and the reinforcing area is close to one side of the newly built station; the submersible precipitation well is arranged inside the foundation pit of the newly built station; and the standby confined water precipitation well is arranged outside the foundation pit of the newly built station and serves as a confined water level observation hole. By means of the system and method, the self stability and bearing capacity of soil very close to the envelop enclosure can be effectively improved, the risks of water bursting and sand bursting in case of shield entry and arrival are reduced, and the influence on operation of the existing station is reduced.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +2

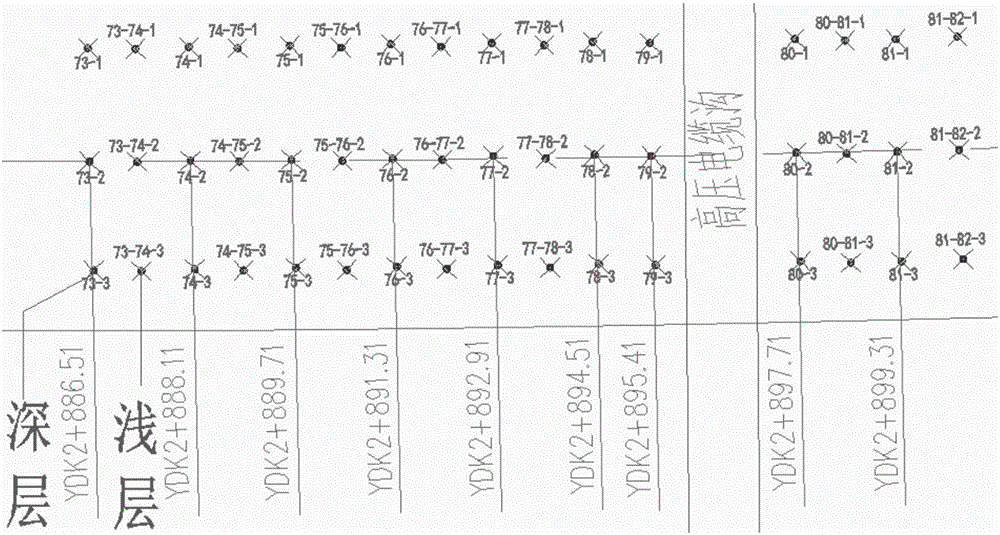

Construction method for controlling peripheral ground subsidence in foundation pit construction

InactiveCN101701460AGuarantee the construction qualityEffective control of settlementExcavationsBulkheads/pilesGround subsidenceSlurry wall

The invention discloses a construction method for controlling peripheral ground subsidence in foundation pit construction and belongs to the technical field of construction works. The construction method comprises the following steps of: drilling holes and taking soil on site for dividing soil layers; determining a top plate and the high level of a bottom plate of each layer of soil; determining depth Dw of the bottom plate of a first layer of confined aquifer and determining distribution and type of underground water; taking soil samples of all soil layers, and determining c values, j values and saturated unit weight g of all the soil samples; leveling a construction site and reinforcing in a way of high-pressure jet grouting; determining an embedding depth of a diaphragm wall; trenching in a foundation to reach the embedding depth of the diaphragm wall in the step 3, and then getting rid of sludge; putting steel reinforcement cages and pouring concrete in the trenches, and connecting all sections of trenches by joints to obtain a reinforced concrete diaphragm wall. The method is simple and can ensure the construction quality of diaphragm walls and can effectively control the peripheral ground subsidence.

Owner:SHANGHAI JIAO TONG UNIV

Construction method for penetrating existing pipeline below super shallow buried tunnel shield

Owner:SHIJIAZHUANG TIEDAO UNIV

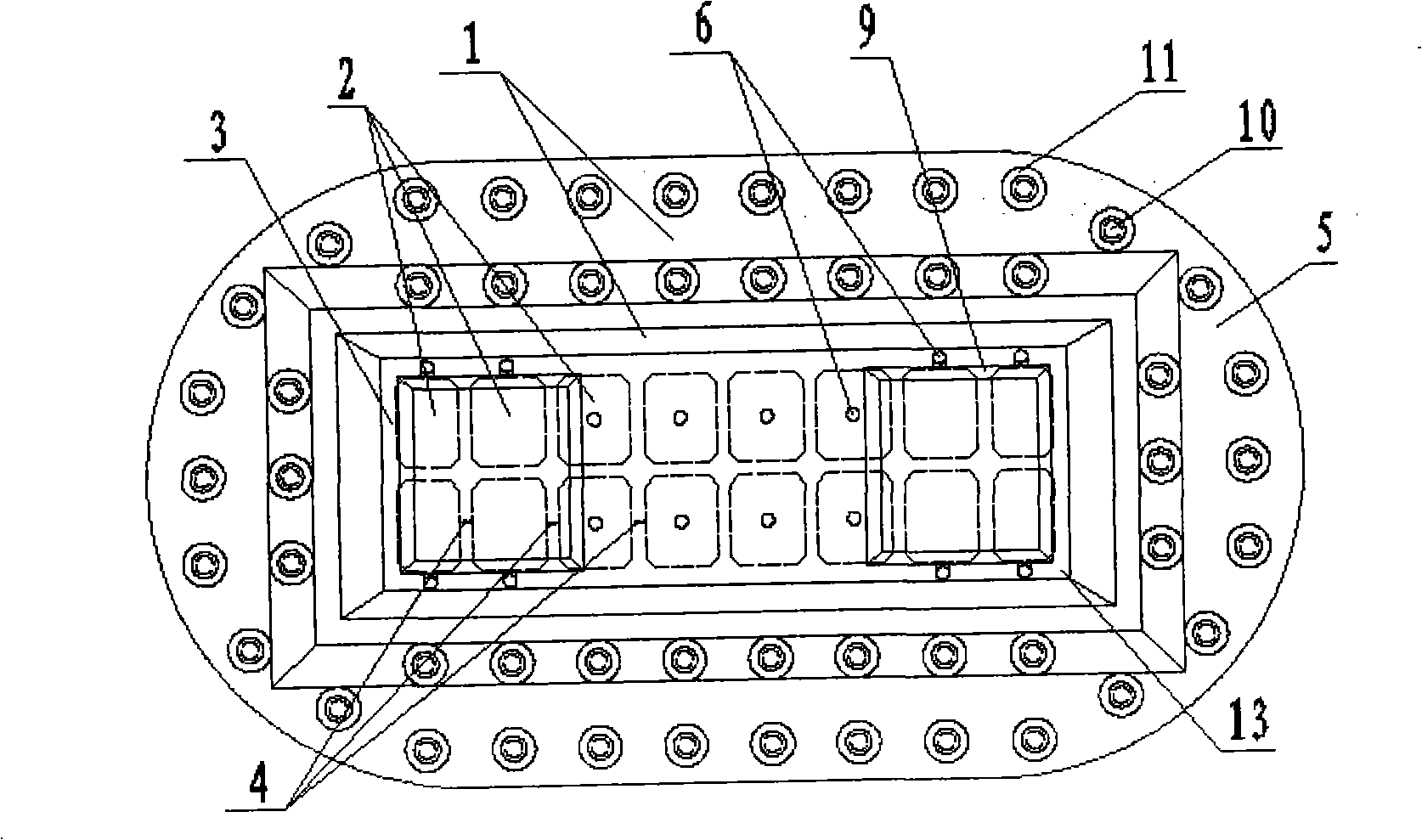

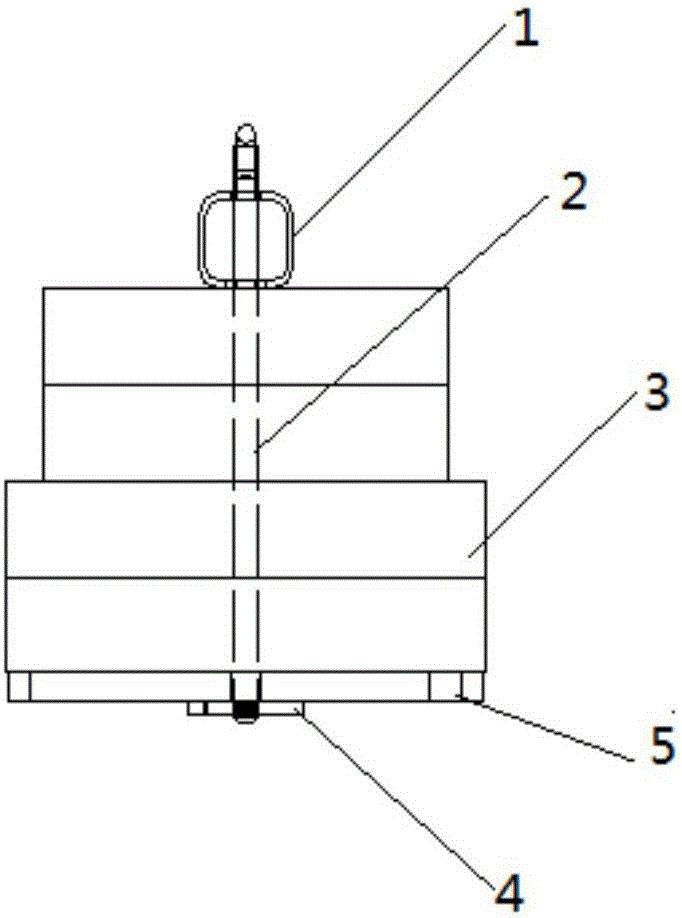

Same-plane multi-cutter-disc rectangular tunneling machine used in water-rich pebble stratum

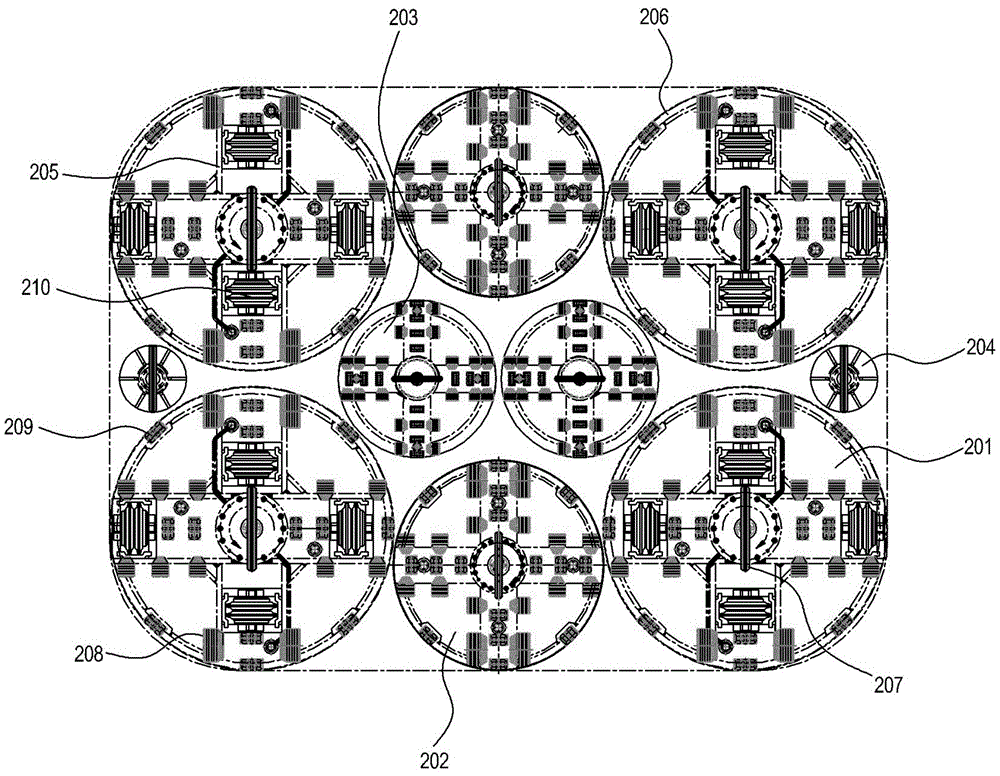

The invention relates to the technical field of tunnel construction equipment, in particular to a same-plane multi-cutter-disc rectangular tunneling machine used in a water-rich pebble stratum. The same-plane multi-cutter-disc rectangular tunneling machine comprises a shield body, a cutter disc mechanism, a cutter disc driving mechanism and a residue soil delivery mechanism, wherein the cutter disc mechanism comprises 10 cutter discs symmetrically arranged on the same plane and comprises large cutter discs, middle cutter discs, small cutter discs and miniature cutter discs, the 10 cutter discs perform cooperative rotation on the same plane and do not interfere mutually. An advanced grouting pipe is obliquely arranged at the upper portion of the shield body. The excavation cutter discs of the same-plane multi-cutter-disc rectangular tunneling machine used in the water-rich pebble stratum are located on the same plane, unique structures of the cutter discs make the adaptability of the tunneling machine to the water-rich pebble stratum improved greatly, meanwhile an excavating face is effectively supported, soil body collapse is avoided, soil body sedimentation can be effectively controlled, and accordingly the life safety of workers is ensured.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

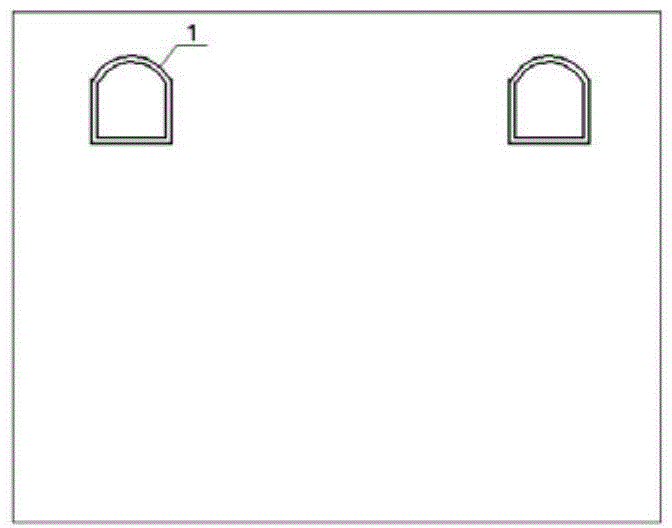

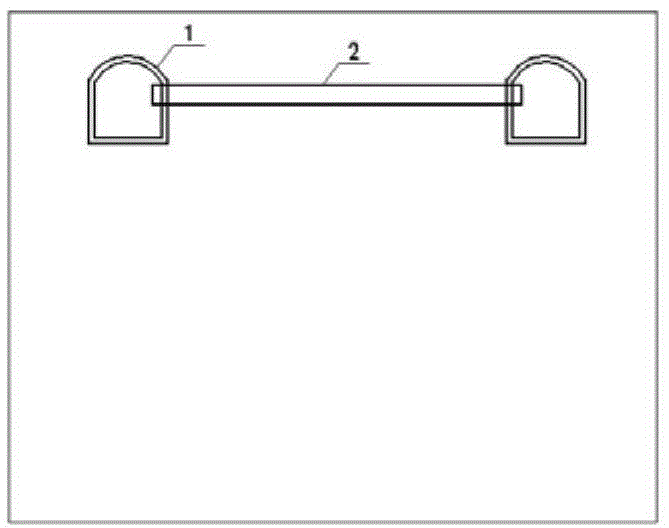

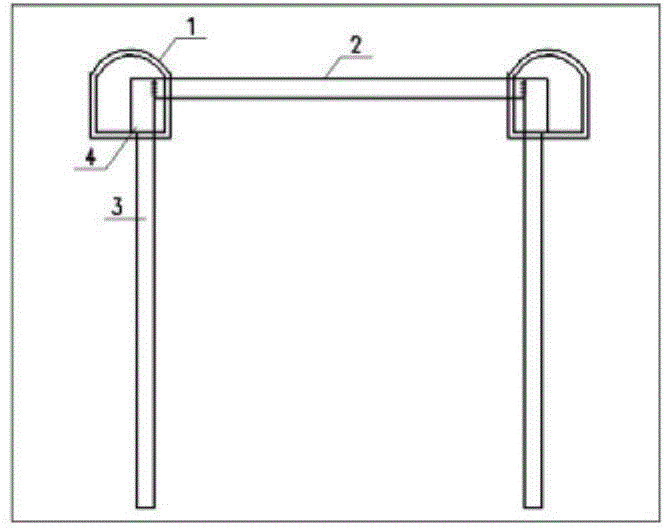

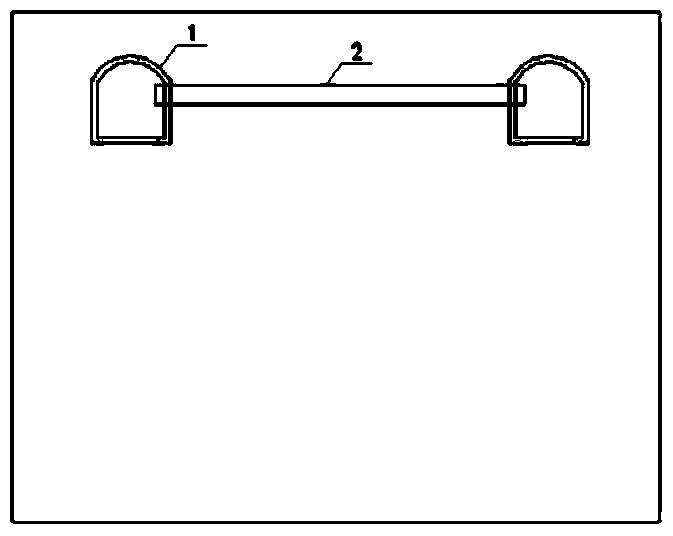

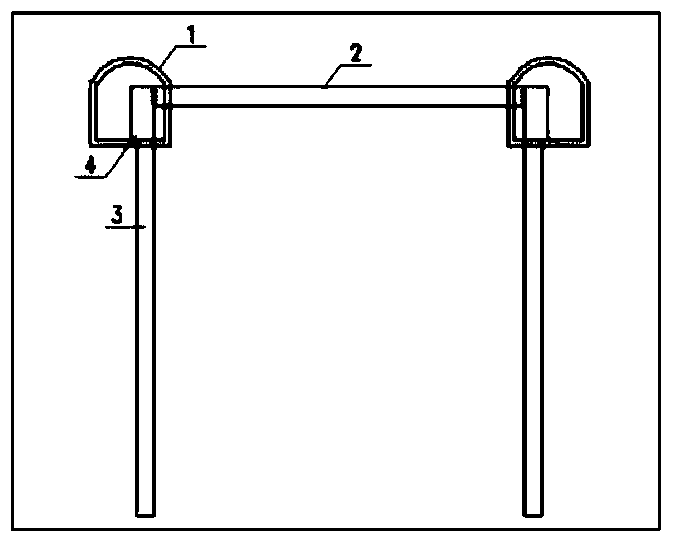

Settlement-resistant supporting structure of loess tunnel and construction method thereof

InactiveCN105888699AImprove carrying capacityControl tunnel settlementUnderground chambersTunnel liningControl measureSteel plates

The invention discloses a settlement-resistant supporting structure of a loess tunnel and a construction method thereof. The settlement-resistant supporting structure of the loess tunnel is characterized in that main tunnel arch frames are connected through longitudinal rods, wherein foot locking anchor pipes are arranged at connecting points between the longitudinal rods and the main tunnel arch frames and are positioned at the bottom parts of the longitudinal rods; sectional steel supporting legs are correspondingly arranged at the outer sides of arch feet at two sides of the main tunnel arch frames; the sectional steel supporting legs and the arch feet of the main tunnel arch frames form inverted Y-shaped supports; supporting cushion steel plates are arranged at the bottom parts of the sectional steel supporting legs and the main tunnel arch frames. According to the settlement-resistant supporting structure of the loess tunnel, the arch feet are enlarged to bear the pressure of surrounding rock together with initial ejected supporting concrete, so as to achieve co-stressing of multi-truss arch frames; the rod system type stressing is replaced by board system type stressing; the prior control measure is particularly suitable for IV-level gravity damping collapse Q3 sandy loess accompanying with geological conditions like shallow burying, bias pressure, high moisture content and low bearing capacity.

Owner:CHINA TIESIJU CIVIL ENG GROUP

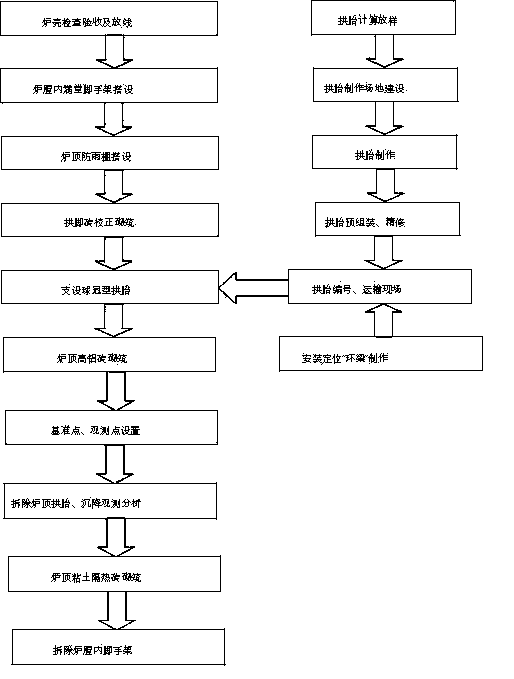

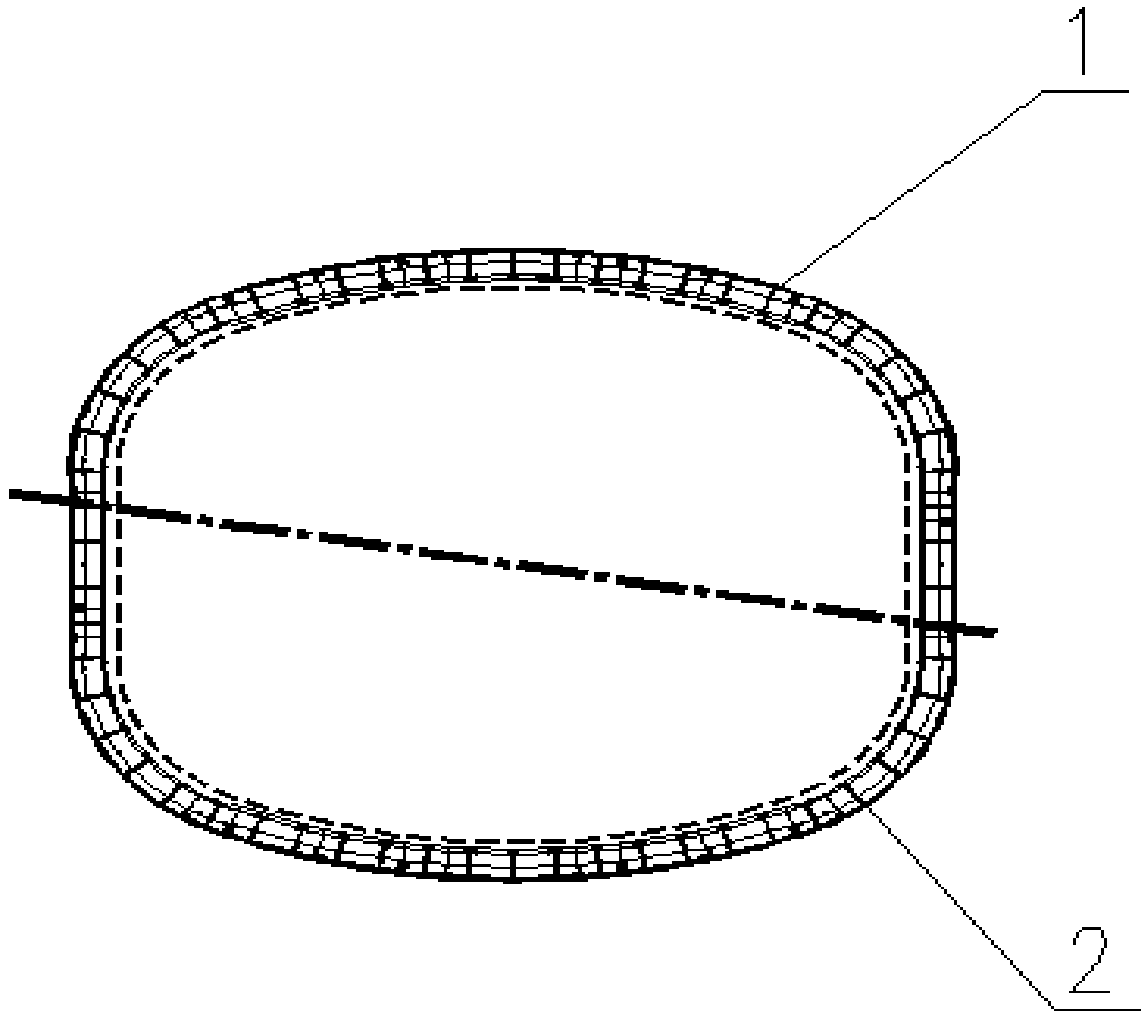

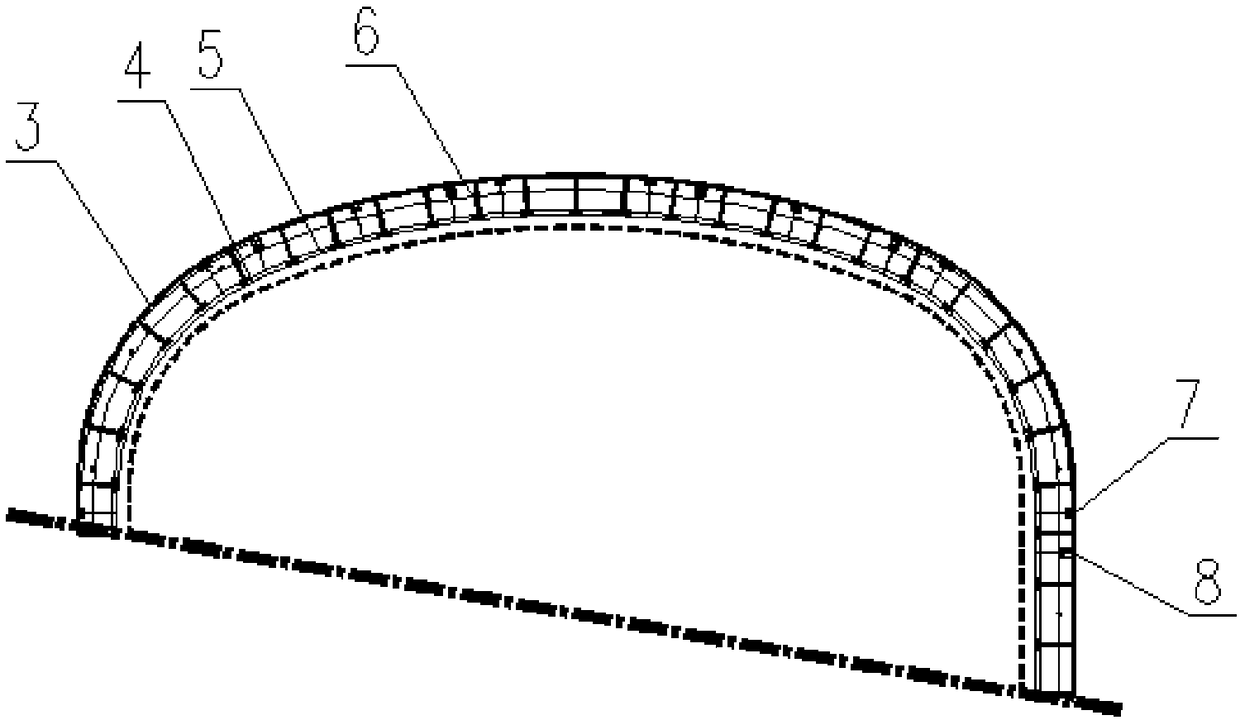

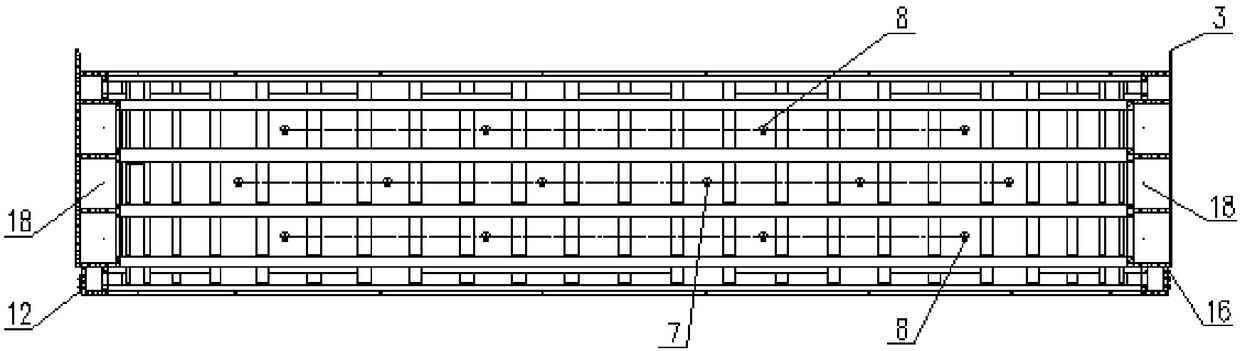

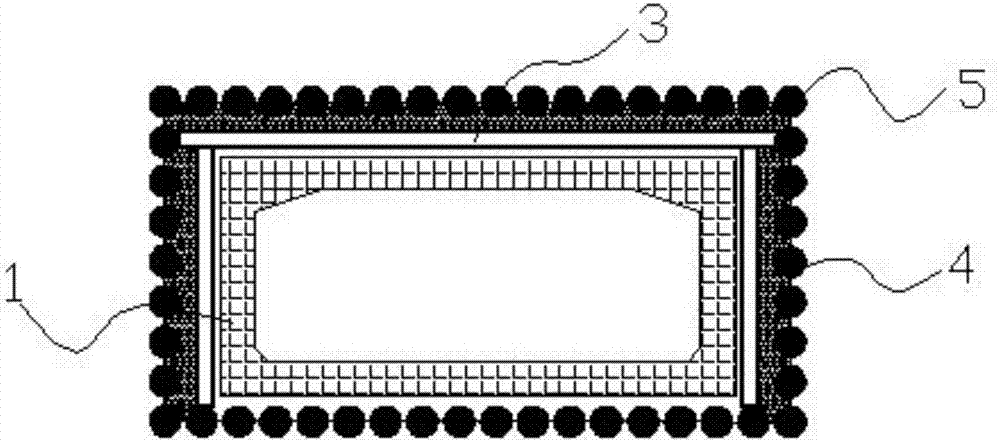

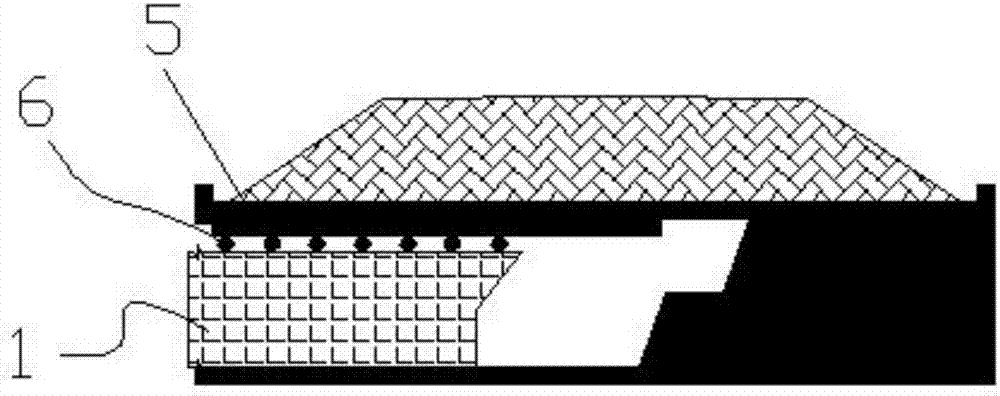

Method for building spherical crown type furnace top by laying bricks

ActiveCN104061786AEffective control of settlementSimple and fast constructionFurnace crowns/roofsBrickThermal insulation

The invention discloses a method for building a spherical crown type furnace top by laying bricks. The method includes the following steps of firstly, establishing a scaffold in a hearth; secondly, correcting and laying skew blocks; thirdly, erecting a spherical crown type arch green body, wherein the arch green body is manufactured first, the arch green body is erected with the skew blocks as the positioning standard, and the arch green body is manufactured through the first step of calculating and lofting the arch green body, the second step of establishing the field for manufacturing the arch green body, the third step of manufacturing the arch green body, the fourth step of preassembling and refining the arch green body and the fifth step of manufacturing an installation positioning annular beam; fourthly, laying furnace top bricks; fifthly, detaching the furnace top arch green body, observing and analyzing sedimentation, laying clay thermal insulation bricks on the furnace top, and detaching the scaffold in the hearth. The method has the advantages of being capable of effectively controlling sedimentation of the furnace top, simple and rapid in construction, high in integrality and high in building accuracy.

Owner:七冶建设集团有限责任公司 +1

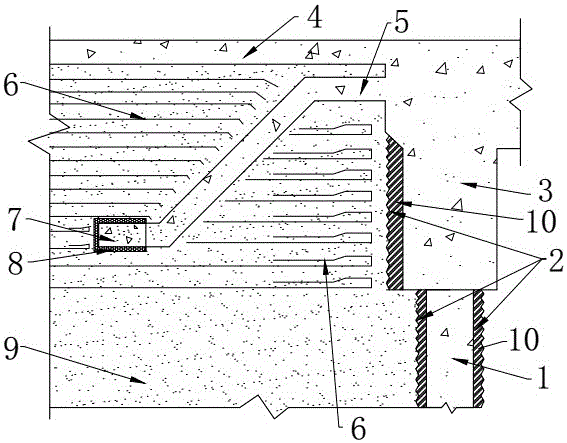

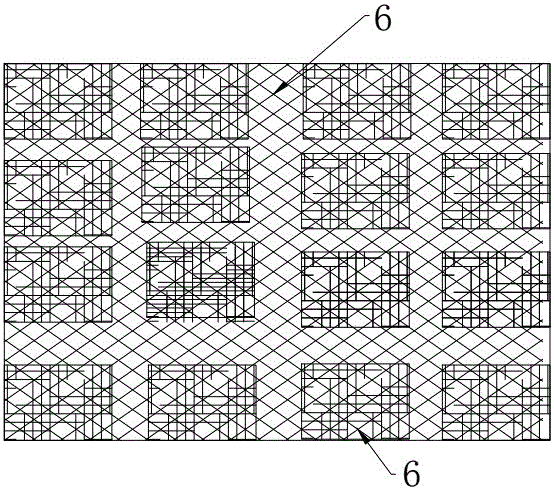

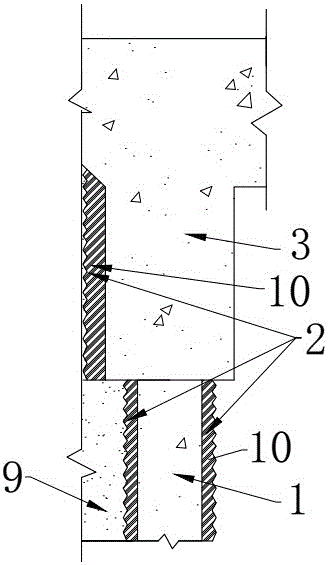

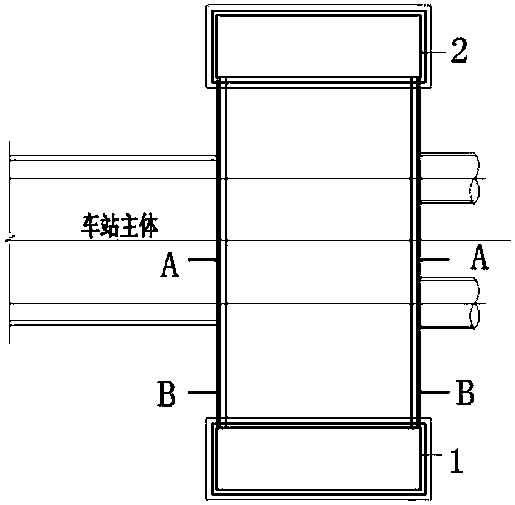

Construction method for carrying out non-excavation subway station through composite pipe joint structure

InactiveCN108266205AEffective control of settlementSettlement controlUnderground chambersTunnel liningReinforced concreteSoft clay

The invention discloses a construction method for carrying out a non-excavation subway station through a composite pipe joint structure. A platform layer and a station hall layer of the station adoptsteel segments in specific forms correspondingly, and the steel segments adopt upper semicircles and lower semicircles to be assembled into rings; the steel rings are connected through inserting openings; the steel segments adopt inner and outer layer steel pieces, the interlayers between the inner layer steel pieces and the outer layer steel pieces are provided with rib plates and filled with concrete; and after the steel segments are assembled into a station structure, a reinforcement concrete combination layer is cast into the station structure in situ so as to meet construction of a secondary structure inside the station and form the station overall-type structure. The station can be constructed in a water-rich saturated soft clay stratum through an undermining method, excavation of part of existing roads and removal of pipelines can be avoided, the engineering risk is reduced, and auxiliary measures do not need to be adopted; and ground settlement can be effectively controlled, and station structure construction can be completed with rapid, safe, environmentally friendly and efficient effects.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Earth pressure balance shield synchronous slurry injection structure and construction assistance system

PendingCN108868799AImprove construction progressStop lossUnderground chambersTunnel liningInjection portSlurry

The invention relates to an earth pressure balance shield synchronous slurry injection structure and a construction assistance system. The earth pressure balance shield synchronous slurry injection structure and a construction assistance system is characterized in that a shield body comprises a cutter head, an earth cabin, a front shield, a middle shield and a shield tail, and a synchronous-injection filling layer is formed in a gap between a segment at the rear of the shield tail and a shield excavation face; the middle shield is provided with slurry injection ports which are annularly arranged at intervals, plastic slurry is injected into the gap, between the shield body and a tunnel excavation face, outside the shield, the plastic slurry diffuses towards the gaps, outside the shield, ofthe front shield and the shield tail and densely fill the gaps outside the shield to form the plastic slurry filling layer, and the synchronous-injection slurry is prevented from flowing into the earth cabin. By the earth pressure balance shield synchronous slurry injection structure and the construction assistance system, the synchronous-injection slurry can be prevented from running off into the earth cabin through the outer side of the shield body, synchronous slurry injection quantity is lowered greatly, and accordingly construction cost is lowered.

Owner:POWERCHINA RAILWAY CONSTR +1

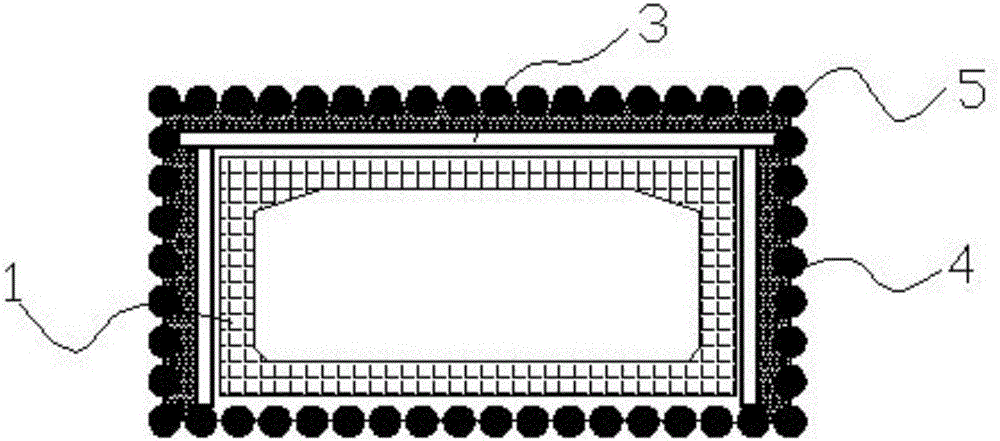

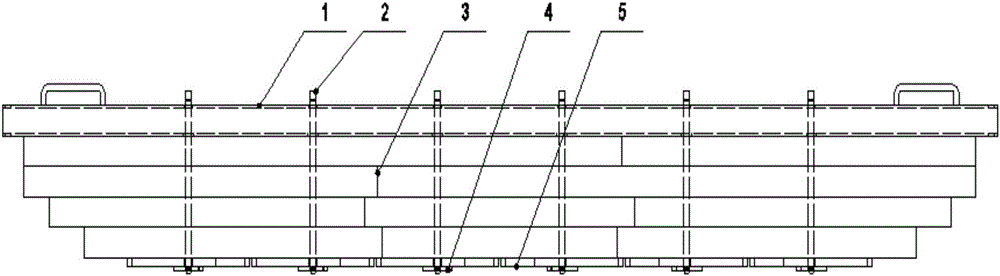

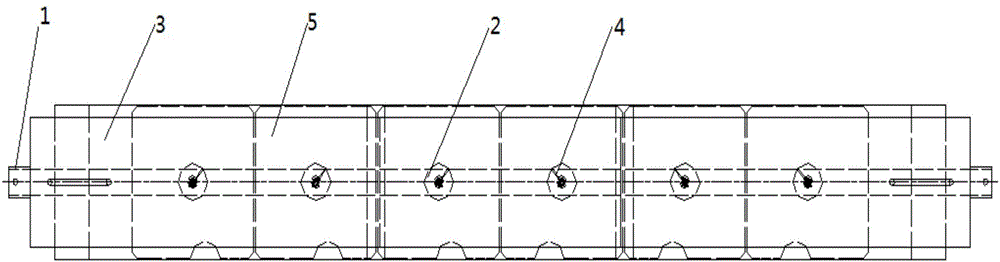

Box culvert jacking device and box culvert jacking method

The invention provides a box culvert jacking device which comprises a box culvert, three layers of steel gratings, jet concrete, four rows of pipe curtains and joist steel.The four rows of pipe curtains are arranged to be a hollow cube, every two adjacent upper-row pipe curtains are connected through the corresponding joist steel, every two adjacent left-row pipe curtains are connected through the corresponding joist steel, every two adjacent right-row pipe curtains are connected through the corresponding joist steel, one layer of steel gratings are connected with the row of pipe curtain located on the upper portion in the hollow cube, the other two layers of steel gratings are connected with the two rows of pipe curtains on the two side faces in the hollow cube respectively, each layer of steel gratings are filled with jet concrete, and the box culvert is inserted into the hollow cube.The invention further provides a box culvert jacking method.By means of the box culvert jacking device, difficulty appearing in construction can be overcome, and higher benefits can be created.By means of the box culvert jacking method, subgrade settlement can be effectively controlled, and the method is suitable for box culvert jacking under the hard geological condition.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

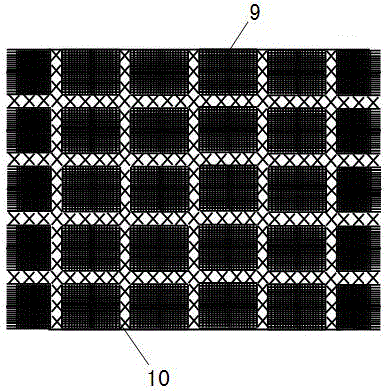

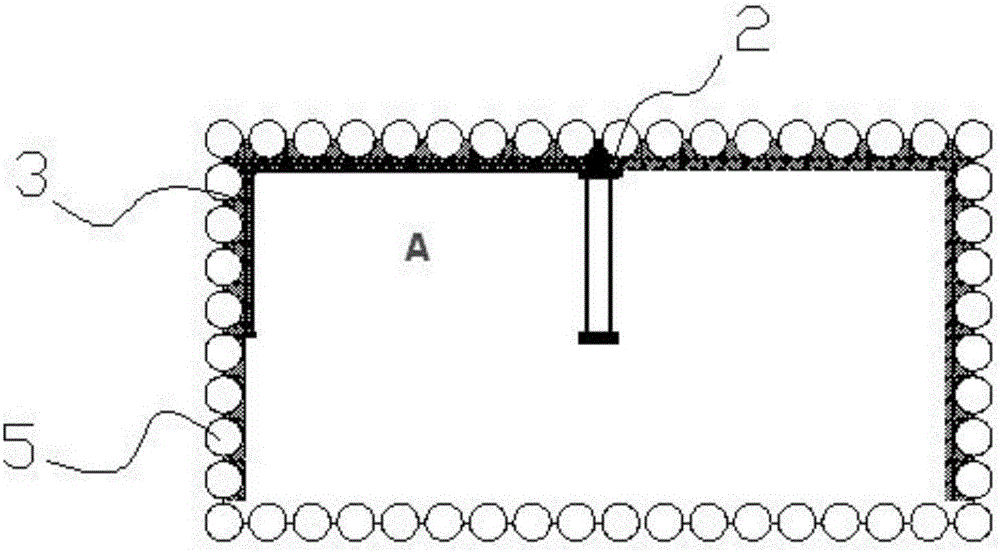

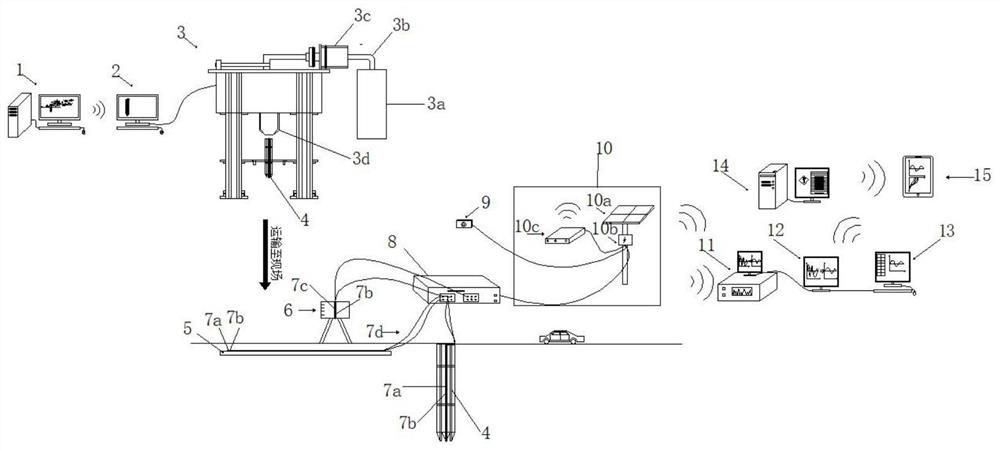

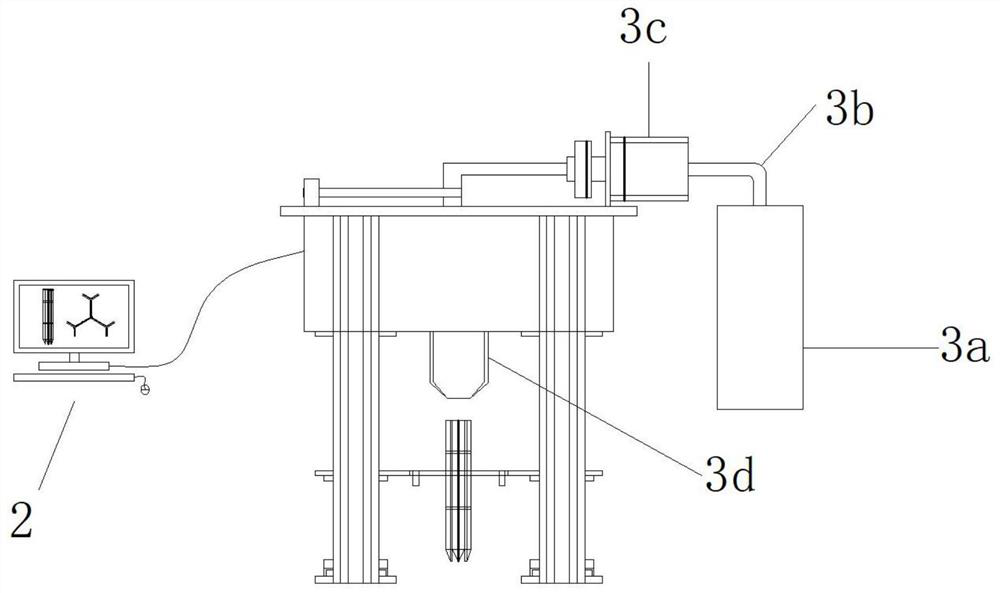

Expressway soft foundation intelligent processing and monitoring system and monitoring and early warning method

PendingCN111896049AImprove bearing capacityAccording to the law of stress diffusionProgramme controlBatteries circuit arrangementsSolar powerSnowflake

The invention discloses an expressway soft foundation intelligent processing and monitoring system and a monitoring and early warning method. The system comprises a highway soft foundation processingscheme cloud database module, , a snowflake-shaped steel sheet pile 3D printing module, a snowflake-shaped steel sheet pile deformation optical fiber sensing module, a roadbed settlement optical fibersensing module, a climate change optical fiber sensing module, an optical fiber data automatic acquisition and transmission module, an on-site road condition monitoring module, a solar power supply and data transmission module, an optical fiber data processing and analysis module, a monitoring result display module, a highway soft foundation processing effect evaluation module, a soft foundationprocessing effect cloud platform data management and early warning module and a mobile phone remote receiving module. During monitoring, 3D printing and snowflake-shaped steel sheet piles are used forrapid construction, BOTDR is used for monitoring roadbed settlement, snowflake-shaped steel sheet pile deformation and climate information, an evaluation result is displayed on a mobile phone mobileterminal in the form of a chart, and remote monitoring and long-term evaluation are realized for a road section secondary reinforcement scheme with an unsatisfactory processing effect.

Owner:HOHAI UNIV

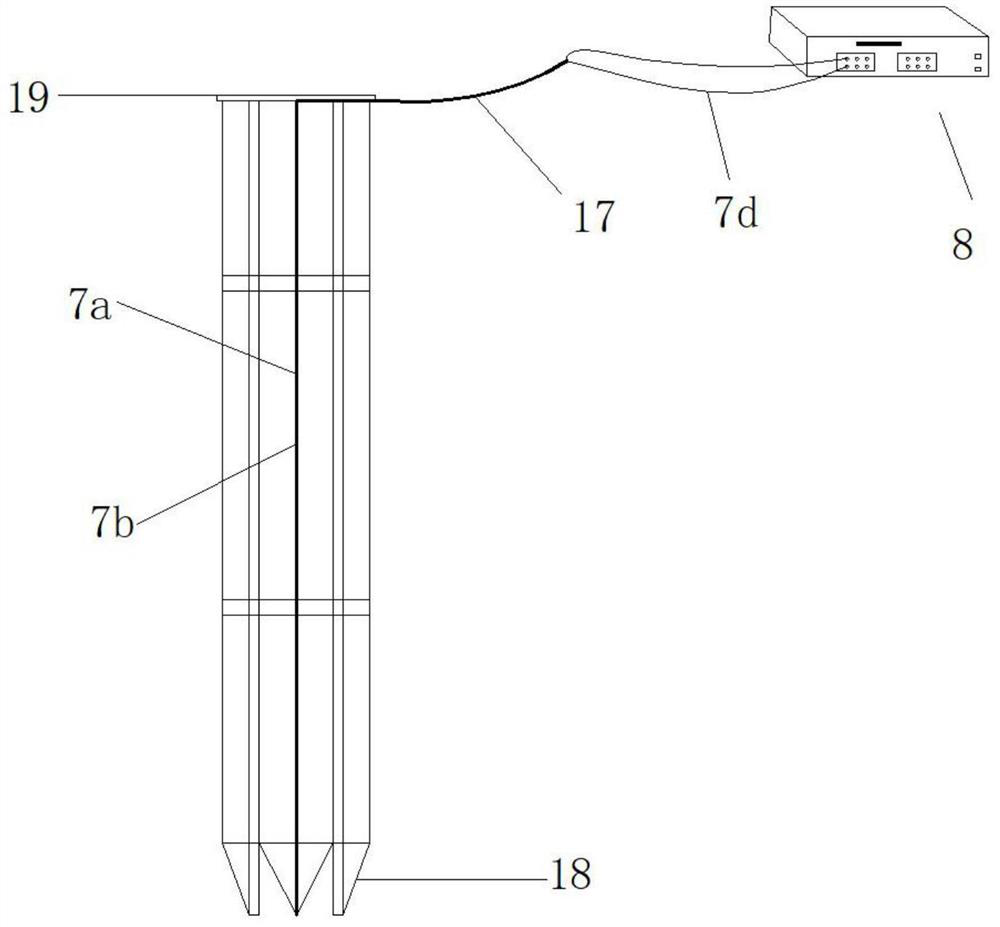

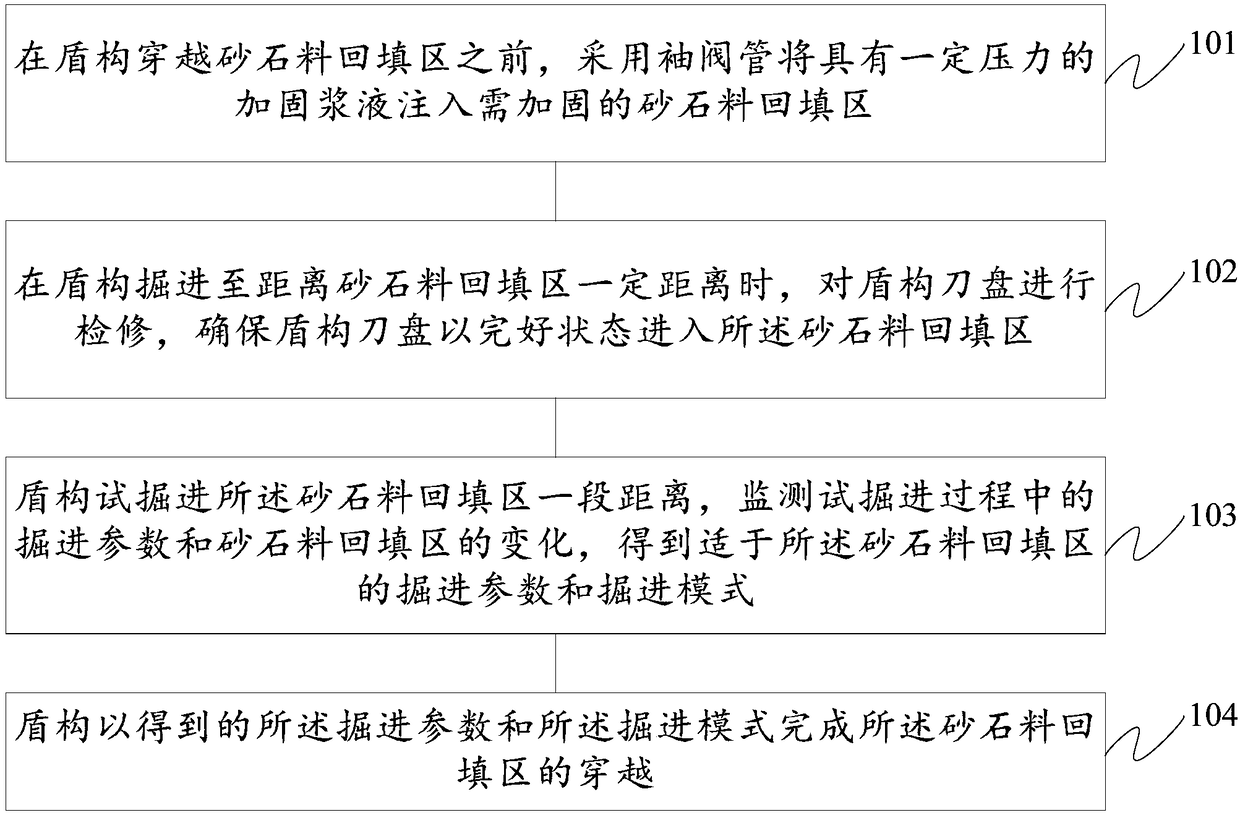

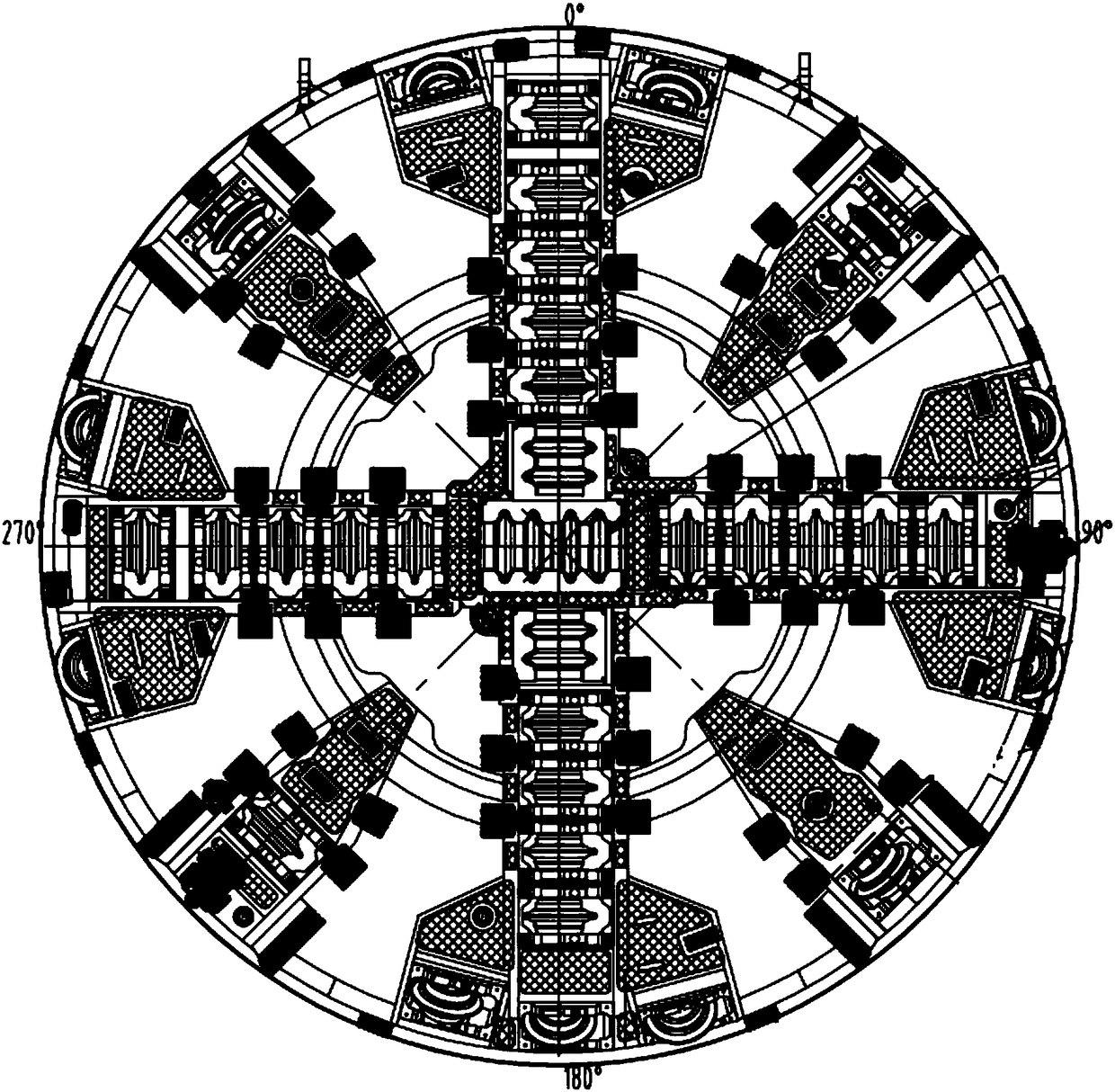

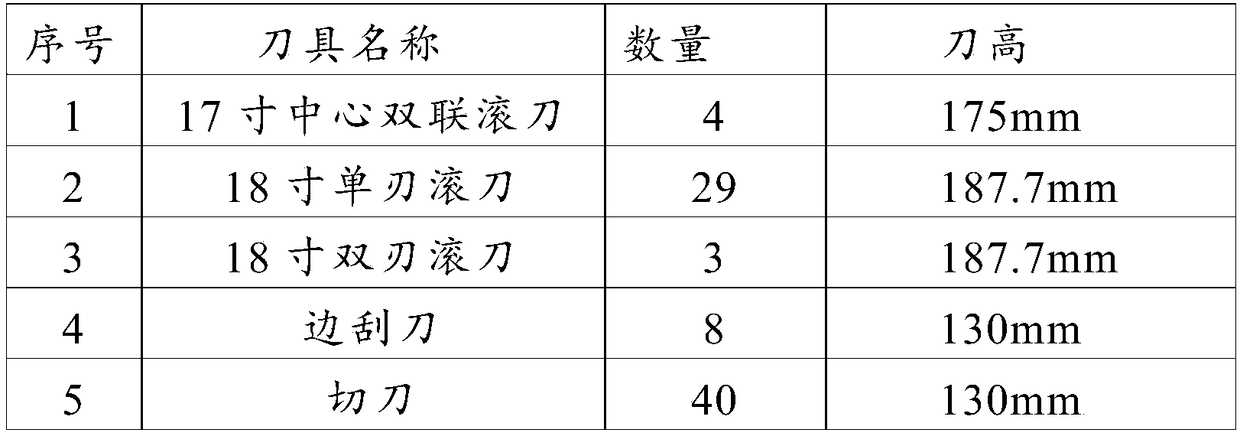

Construction method for crossing of shield through sand and gravel backfill area

The invention discloses a construction method for crossing of a shield through a sand and gravel backfill area. The construction method comprises the steps that before the shield crosses through the sand and gravel backfill area, through a sleeve valve pipe, reinforcing slurry with certain pressure is injected into the sand and gravel backfill area needing to be reinforced; when the shield conducts tunneling to be away from the sand and gravel backfill area by a certain distance, a shield cutterhead is overhauled, and it is ensured that the shield cutterhead enters the sand and gravel backfillarea in an intact state; the shield tries to conduct tunneling into the sand and gravel backfill area by a section of distance, tunneling parameters and change of the sand and gravel backfill area inthe tunneling trying process are monitored, and the tunneling parameters and modes suitable for the sand and gravel backfill area are obtained; and the shield crosses through the sand and gravel backfill area according to the obtained tunneling parameters and modes. According to the construction method, the filling effect of loess cement paste slurry in a loose peddle layer is good, clay cement slurry with sample cores visible partially wraps peddle, consolidation is good, certain strength is achieved, in the shield propelling process, the soil pressure can be built, and shield propelling safety is ensured.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

Integrated bridge abutment structure for controlling earth pressure behind abutment and filled earth settlement and construction method

InactiveCN106638280AIncrease stiffnessAvoid crackingRoadwaysBridge structural detailsRoad surfaceAbutment

The invention relates to an integrated bridge abutment structure for controlling earth pressure behind an abutment and filled earth settlement and a construction method. The integrated bridge abutment structure comprises an abutment body and a lapping plate, wherein an upper filled earth layer and a lower filled earth layer which are reinforced and firmed by a plurality of layers of geogrids are laid above and below the lapping plate respectively in the vertical direction, the upper filled earth layer upward extends to be laid on the road surface, and the lower filled earth layer downward extends to be laid on the abutment. A first gap is reserved between the upper filled earth layer and the lower filled earth layer and the surface of the lapping plate and the surface of the abutment body respectively. An end opening formed in the upper horizontal end of the lapping plate is in rigid connection with the abutment body. The end portion of the lower horizontal end of the lapping plate is sealed by a rectangular steel sleeve, a second gap is reserved between the inner side of the rectangular steel sleeve and the outer side of the lower horizontal end of the lapping plate and is filled with a rubber layer immersed with grease, and the outer surface of the rectangular steel sleeve is coated with an anticorrosive coating. The integrated bridge abutment structure utilizes good deformation of the lapping plate and reinforcement and firming of the geogrids, is good in integrity, improves pavement strength and effectively controls settlement behind the integrated bridge abutment.

Owner:FUZHOU UNIV

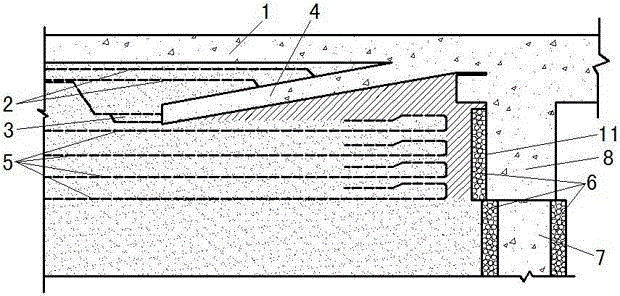

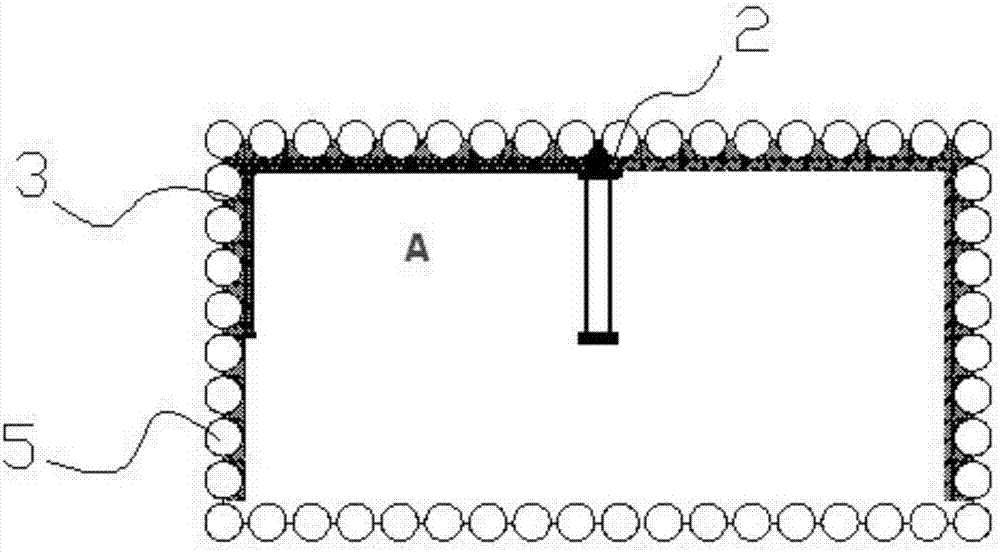

Jacking pipe enclosure construction method of cross aisle of end of metro station

ActiveCN107762519AEffective control of settlementFinish quicklyUnderground chambersTunnel liningGround subsidenceMetro station

The invention discloses a jacking pipe enclosure construction method of a cross aisle of the end of a metro station. The jacking pipe enclosure construction method comprises the following steps that firstly, a jacking pipe starting well and a jacking pipe receiving well at the two ends of the cross aisle of the end of the metro station are built correspondingly by adopting an open digging construction method; secondly, a pipe jacking device is mounted on the pipe jacking starting well, and a plurality of steel pipe sheets are arranged; jacking pipes are pushed one by one according to the orderfrom bottom to top and from outside to inside so as to complete arrangement of the steel pipe sheets; after pushing of the jacking pipes is completed, a water-stop material is injected into a joint of every two adjacent steel pipe sheets, and connection box bodies integrally form a water-stop sealed large space; building of the main structure of the cross aisle is completed in the area of the multiple steel pipe sheets; and finally the rest of soil mass is dug step by step, and construction of the cross aisle is completed. According to the jacking pipe enclosure construction method, the situations that an existing road is dug and an existing pipeline is removed can be avoided, manual underground digging is avoided, the engineering risk is reduced, auxiliary measures do not need to be taken while ground subsidence can be controlled effectively, and construction of the metro station can be completed rapidly, safely, environmentally and efficiently.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Deep water open composite foundation wharf and its construction method

The invention discloses a deepwater open type wharf with a combined foundation. A foundation support system of the deepwater open type wharf comprises a caisson gravity structure system and a pile foundation structure system which are fixedly assembled and connected with each other, a caisson is fixed onto a submarine foundation bed in an implantation manner, the pile foundation structure system is of a concrete-filled steel pipe pile bundle structure comprising through long piles and non-through piles, steel pipe piles arranged along the insides of steel casings are driven into a rock-soil bearing stratum to form the through long piles, and the bottoms of the non-through piles are embedded into a top plate of the caisson to be fixedly connected with the top plate of the caisson, so that the wharf with the combined foundation which comprises an open type pile foundation and the gravity caisson is formed. The invention further provides a method for constructing the wharf. The method includes prefabricating the combined foundation on a land; processing the submarine foundation bed; positioning and sinking the combined foundation; manufacturing the through long piles; manufacturing an upper wharf face plate. The deepwater open type wharf and the method have the advantages that merits of the gravity structure and merits of a pile foundation structure are combined with one another, the problem of differential settlement is effectively solved, wharf apron mooring conditions are improved, and the wharf is high in bearing capacity and good in durability.

Owner:SHANGHAI UNIV

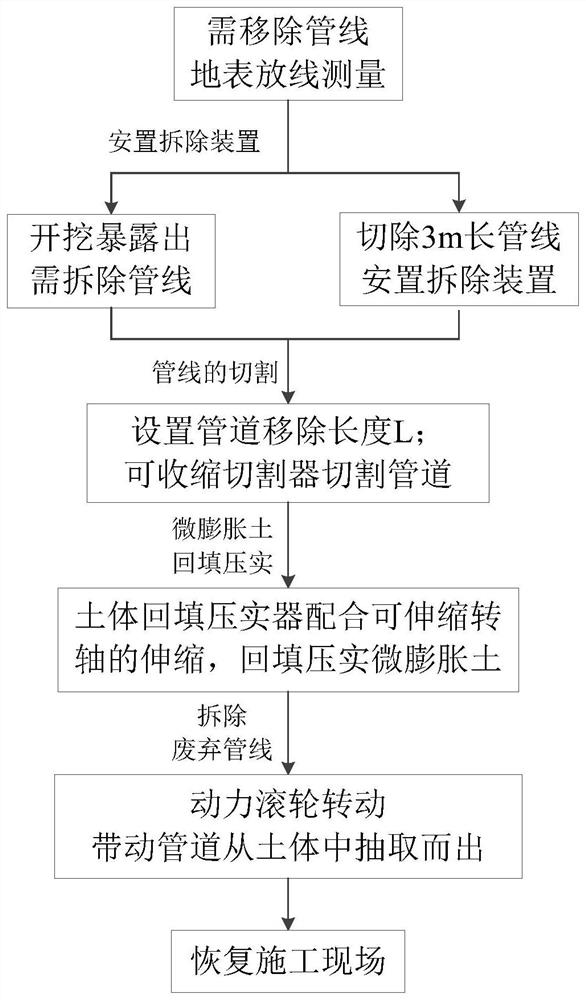

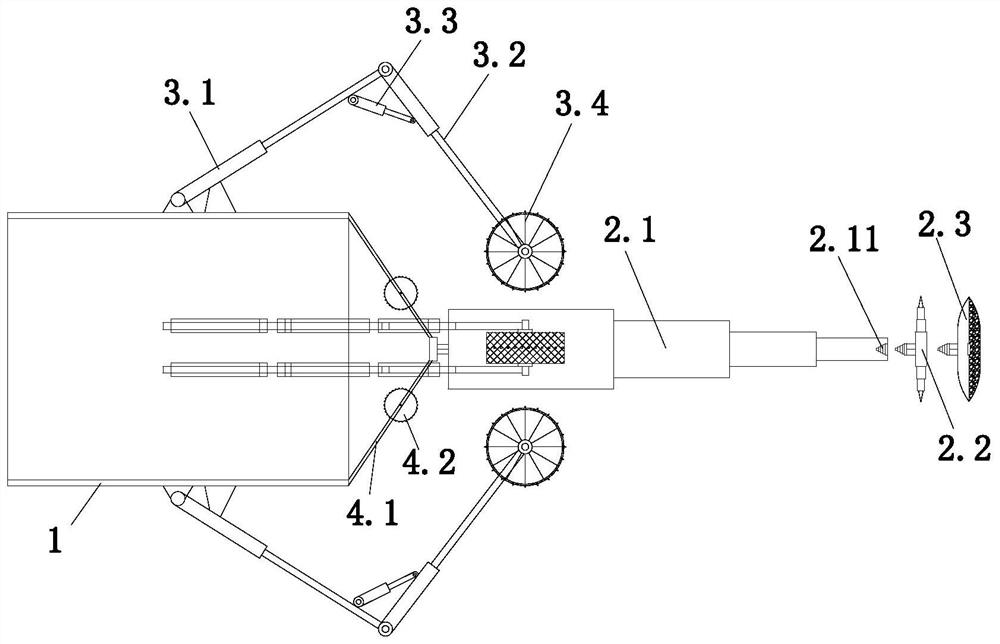

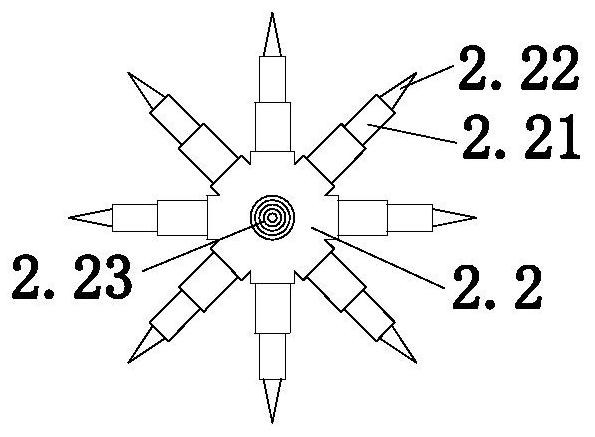

Dismantling and backfilling integrated device suitable for underground flexible pipeline and working method thereof

ActiveCN113073722AAchieve trenchless demolitionAutomated compaction and backfillSewer pipelinesMechanical engineeringIntegrated devices

The invention discloses a dismantling and backfilling integrated device suitable for an underground flexible pipeline. The dismantling and backfilling integrated device comprises a machine body, and a telescopic pipeline cutting and backfilling mechanism, a pipeline withdrawing mechanism and a pipeline decomposing mechanism are arranged on the machine body. During construction, firstly, a telescopic pipeline cutter is fed into a pipeline through the telescopic pipeline cutting and backfilling mechanism, and the pipeline is cut off by the telescopic pipeline cutter; after the pipeline is cut off, the telescopic pipeline cutter is detached, a soil body backfilling compactor is installed, and the cut-off pipeline is gradually filled with a soil body and extruded to be dense; and finally, a power roller of the pipeline withdrawing mechanism presses the surface of the pipeline, the power roller rotates to extract the cut-off pipeline out of the soil body, and meanwhile, when the pipeline penetrates through the pipeline decomposing mechanism, a cutting knife wheel on the pipeline decomposing mechanism rotates at a high speed to decompose and cut the removed pipeline. The underground waste pipeline can be efficiently dismantled, compaction and backfilling of the soil body can be achieved, disturbance is small, and land subsidence can be effectively controlled.

Owner:CHINA HARBOUR ENGINEERING

A Construction Method for Shallow Burying and Undercover Excavation of Large-Scale Underground Space - Horizontal Hole Covering Method

ActiveCN104863597BMany working surfacesLow construction precision requirementsUnderground chambersTunnel liningSpatial structureSystem construction

The invention discloses a transverse tunnel cover method for shallow-buried underground excavation large underground space construction. Foundation pits or pilot tunnels are formed, in the longitudinal direction of underground space, of the tops of side walls of the underground space to be constructed, temporary transverse stress structures are formed inside the foundation pits or the pilot tunnels at a time and located above a top plate of the underground space to be constructed and are controllable in rigidity, the temporary transverse stress structures are connected with piles inside the foundation pits or the pilot tunnels to form a temporary transverse top cover-pile bearing system, and under protection of the transverse top cover-pile bearing system, a single-span or multi-span and a single-layer or multi-layer underground space structure can be constructed in a sequential construction mode or in an inverse construction mode. In shallow-buried underground excavation large underground space structure construction, ground settlement is effectively controlled, constructed building deformation is reduced, the construction risks are reduced, the construction period is shortened, and the construction cost is lowered.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

A box culvert jacking device and box culvert jacking method

The invention provides a box culvert jacking device which comprises a box culvert, three layers of steel gratings, jet concrete, four rows of pipe curtains and joist steel.The four rows of pipe curtains are arranged to be a hollow cube, every two adjacent upper-row pipe curtains are connected through the corresponding joist steel, every two adjacent left-row pipe curtains are connected through the corresponding joist steel, every two adjacent right-row pipe curtains are connected through the corresponding joist steel, one layer of steel gratings are connected with the row of pipe curtain located on the upper portion in the hollow cube, the other two layers of steel gratings are connected with the two rows of pipe curtains on the two side faces in the hollow cube respectively, each layer of steel gratings are filled with jet concrete, and the box culvert is inserted into the hollow cube.The invention further provides a box culvert jacking method.By means of the box culvert jacking device, difficulty appearing in construction can be overcome, and higher benefits can be created.By means of the box culvert jacking method, subgrade settlement can be effectively controlled, and the method is suitable for box culvert jacking under the hard geological condition.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

Building method for heat insulation materials on top of hearth

The invention provides a building method for heat insulation materials on the top of a hearth, and relates to the technical field of hearth building. The method comprises the following steps that the heat insulation materials are selected and machined into flat plates of through hole structures; at least two flat plates are selected to be overlaid; the overlaid flat plates are fixed through at least two first bearing parts and at least two second bearing parts, a module assembly is formed, and an anchoring part is installed at the bottom of the module assembly through second bearing parts. The module assembly is fixedly connected to a beam on the top of the hearth. According to the building method for the heat insulation materials on the top of the hearth, the defect that light heat insulation materials are poor in strength is overcome, the heat insulation effect on the top of the hearth is good, the utilization space is enlarged, building is convenient, and the labor intensity of workers is relieved.

Owner:HENGLI ELETEK

Bridgehead car jump restoration and precaution method based on load reduction

ActiveCN105926421AEffective control strengthEffective controlRoads maintainenceFoam concreteRoad surface

The invention discloses a bridgehead car jump restoration and precaution method based on load reduction. The problem that car jump at bridgeheads exists in the prior art is solved, and the problems that methods adopted at present has high requirements for materials, a long curing time is needed during forming, the construction period is long, and the influence on traffic operation is large are solved. The method comprises the steps that holes are drilled at intervals in the original road face of a bridgehead; hollow barrels are buried in the holes, and the holes are backfilled until the holes are flush with the original road face of the bridgehead; and a road face is additionally laid on the original road face of the bridgehead to restore the bridgehead line shape. The method has the advantages that through the load reduction method, the strength and performance of the original road face are fully used to achieve the purpose of load reduction, and then later settlement is effectively controlled and treated; the hollow barrels are buried in the holes, the curing time needed by slurry or foam concrete is omitted, the displacement work amount is reduced, and the influence period on the traffic is short; and machines are not needed for mounting, and construction is simpler, more convenient and more economical than that of foam concrete.

Owner:姜正晖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com