Jacking pipe enclosure construction method of cross aisle of end of metro station

A subway station and construction method technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as high construction costs, narrow construction scope, and long construction period, so as to avoid manual underground excavation, reduce engineering risks, Controlling the effect of land subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

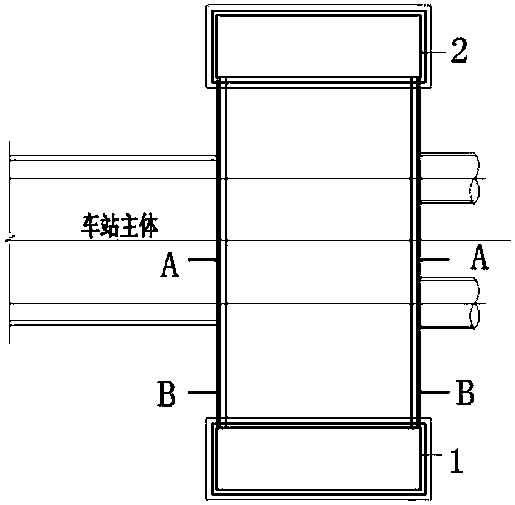

[0042] Such as Figure 1 to Figure 14 As shown, the pipe jacking enclosure construction method of the cross passage at the end of the subway station; the steps are as follows:

[0043] a. The pipe jacking originating shaft and the pipe jacking receiving shaft 2 at both ends of the cross passage at the end of the subway car are respectively constructed by using the open cut method;

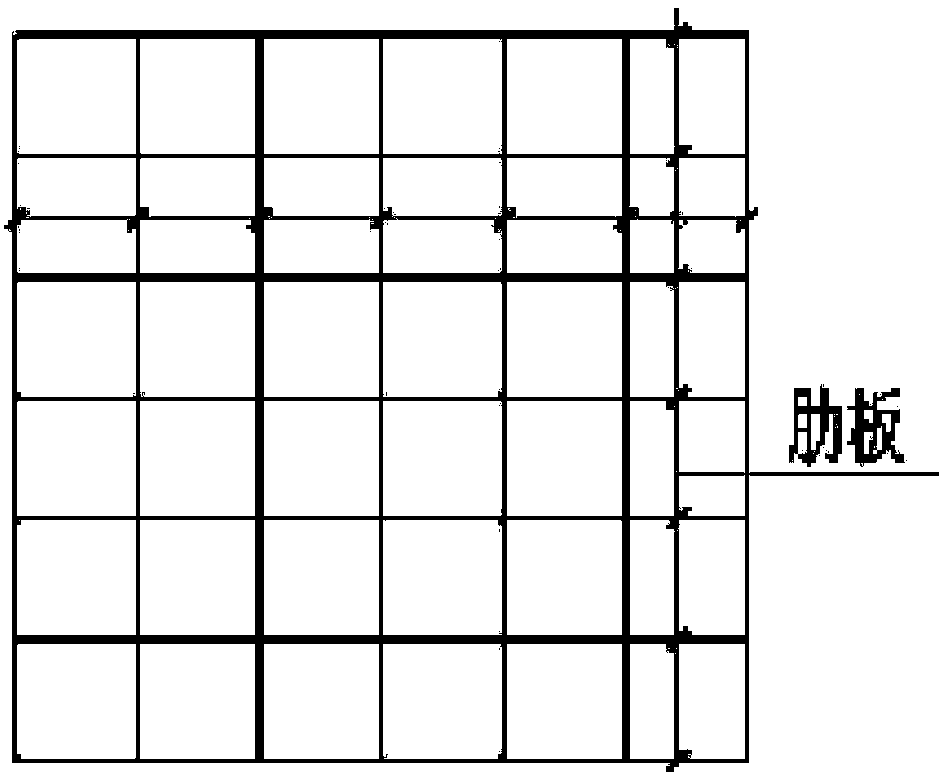

[0044] b. Install the pipe jacking machine to the pipe jacking starting shaft 1, and set several steel pipe pieces;

[0045] c. According to the order from bottom to top and from outside to inside, push the pipe jacking one by one to complete the setting of steel pipe pieces;

[0046] d. After the pipe jacking is completed, water-stop material is injected into the joint between two adjacent steel pipe pieces, and each connecting box forms a water-stop closed large space as a whole;

[0047] e. Complete the construction of the main structure of the cross passage in several steel pipe sheet areas; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com