Bridgehead car jump restoration and precaution method based on load reduction

A technology of bridge head jumping and prevention methods, which is applied in road repair, roads, roads, etc., can solve the problems of large impact on traffic operation, inconvenient construction, incompleteness, etc., and achieve the effect of reducing the amount of replacement works, simple construction, and control of settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

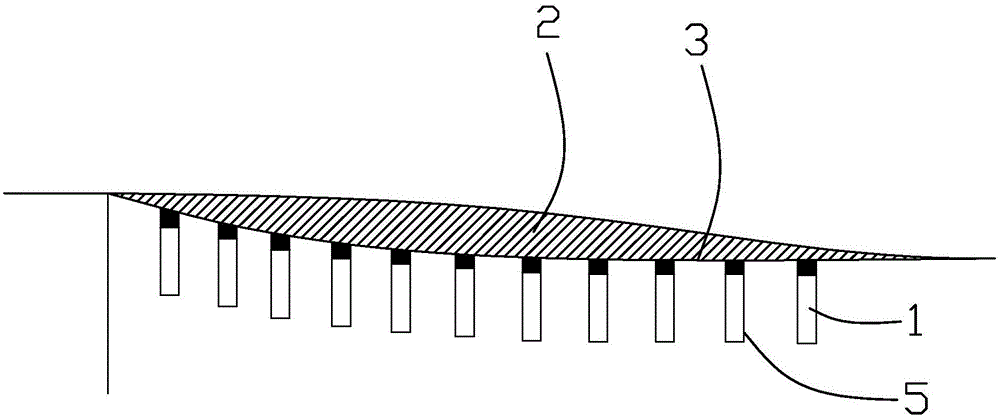

[0032] In this embodiment, a method for repairing and preventing vehicle jumping at the bridge head based on load reduction includes the following steps:

[0033] S1. Drill holes at intervals on the original road surface at the bridge head;

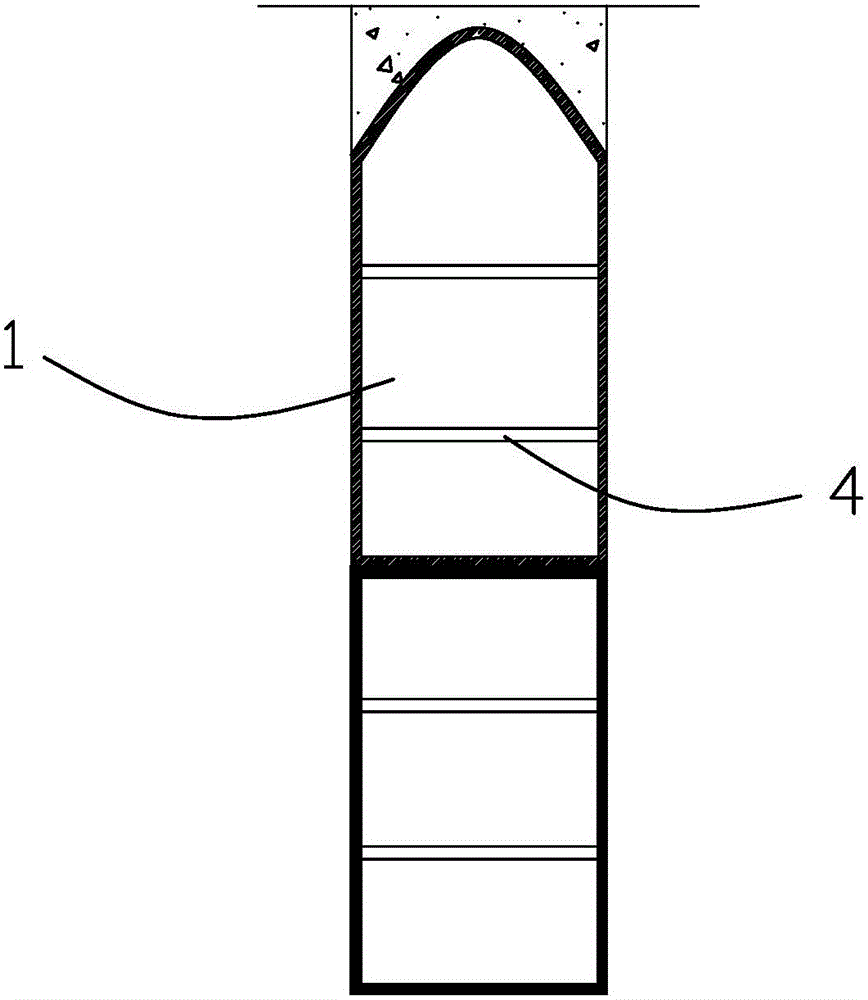

[0034] S2. Embed a sealed high-strength hollow cylinder 1 in the hole, and then backfill the hole until it is flush with the original road surface at the bridge head;

[0035] S3. Add pavement to the original road surface at the bridgehead, and repair the alignment of the bridgehead.

[0036] In step S1, the construction personnel do not need to fully dig the original road surface, such as figure 1 As shown, holes are drilled at intervals on the original road surface 1, and drilling or digging is used for the drilling construction, depending on the actual situation. And the number of perforations depends on the load shedding required. The diameter of the hole 5 in the present embodiment is 60cm, and the depth of the hole is determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com