Alpha-calcium sulfate hemihydrate/aliphatic polyester composite material and preparation method thereof

A technology of calcium sulfate hemihydrate and composite materials, applied in the field of α-calcium sulfate hemihydrate/aliphatic polyester composite materials and its preparation, can solve problems such as product quality reduction, production equipment damage, inorganic salt inclusions, etc., and achieve inhibition Effects of nucleation and growth, reduction of impurities, and mild production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

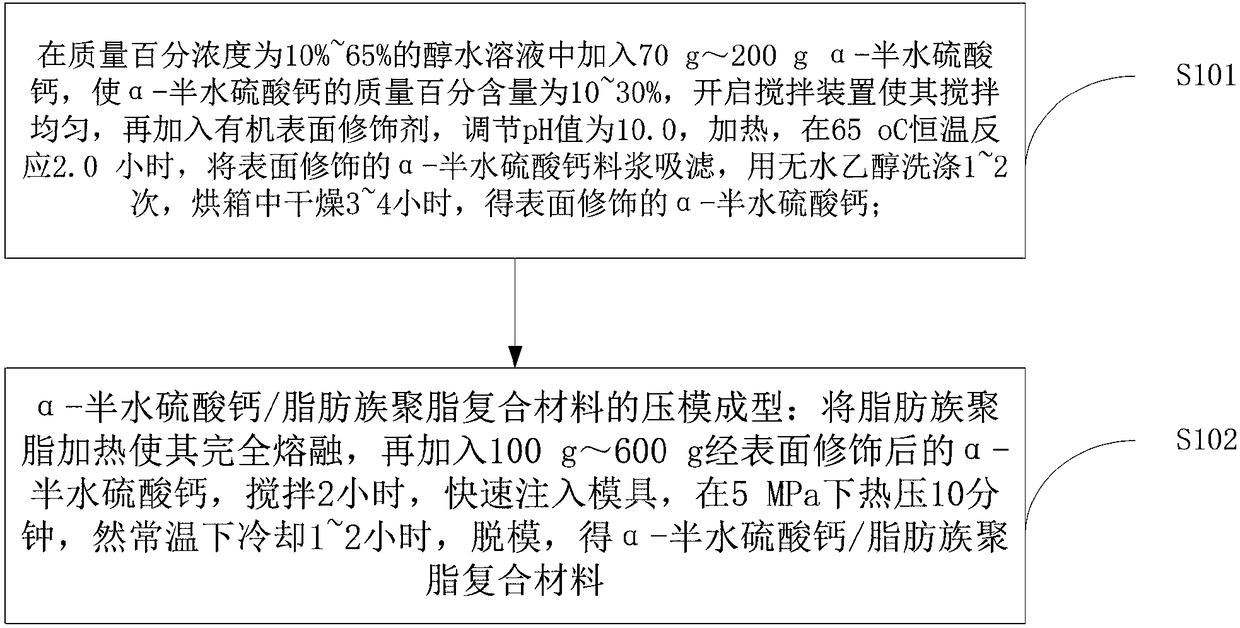

[0024] Such as figure 1 Shown, the preparation method of the α-calcium sulfate hemihydrate / aliphatic polyester composite material that the embodiment of the present invention provides comprises the following steps:

[0025] S101: Add 70g to 200g of α-calcium sulfate hemihydrate to the aqueous alcohol solution with a mass percentage concentration of 10% to 65%, so that the mass percentage of α-calcium sulfate hemihydrate is 10 to 30%, and turn on the stirring device to make it Stir evenly, then add an organic surface modifier, adjust the pH value to 10.0, heat, and react at a constant temperature of 65°C for 2.0 hours, suction filter the surface-modified α-calcium sulfate hemihydrate slurry, and wash it with absolute ethanol for 1 to 2 times , drying in an oven for 3 to 4 hours to obtain surface-modified α-calcium sulfate hemihydrate;

[0026] S102: Compression molding of α-calcium sulfate hemihydrate / aliphatic polyester composite material: heat the aliphatic polyester to mel...

Embodiment 1

[0031] (1) Surface modification of α-calcium sulfate hemihydrate

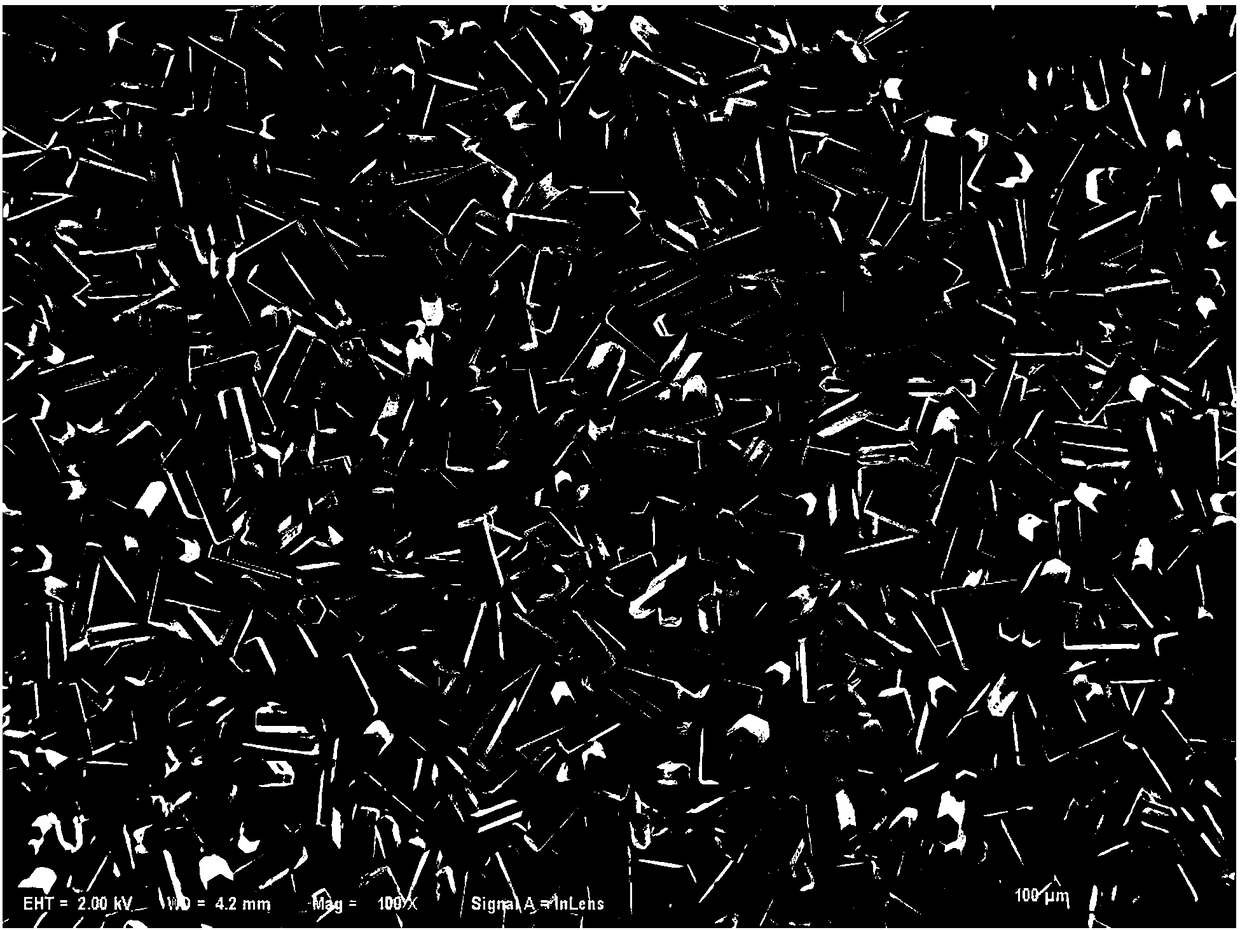

[0032] Add 70g of α-calcium sulfate hemihydrate to 500g of 10wt% ethanol aqueous solution, stir, then add 2.5g of hyaluronic acid, adjust the pH value to 10.0, heat, and react at a constant temperature of 65°C for 2.0 hours, and the surface-modified α-calcium sulfate hemihydrate Suction filter the slurry, wash 2 times with absolute ethanol, and dry in a drying oven to obtain surface-modified α-calcium sulfate hemihydrate. The scanning electron microscope picture is as follows: figure 1 shown.

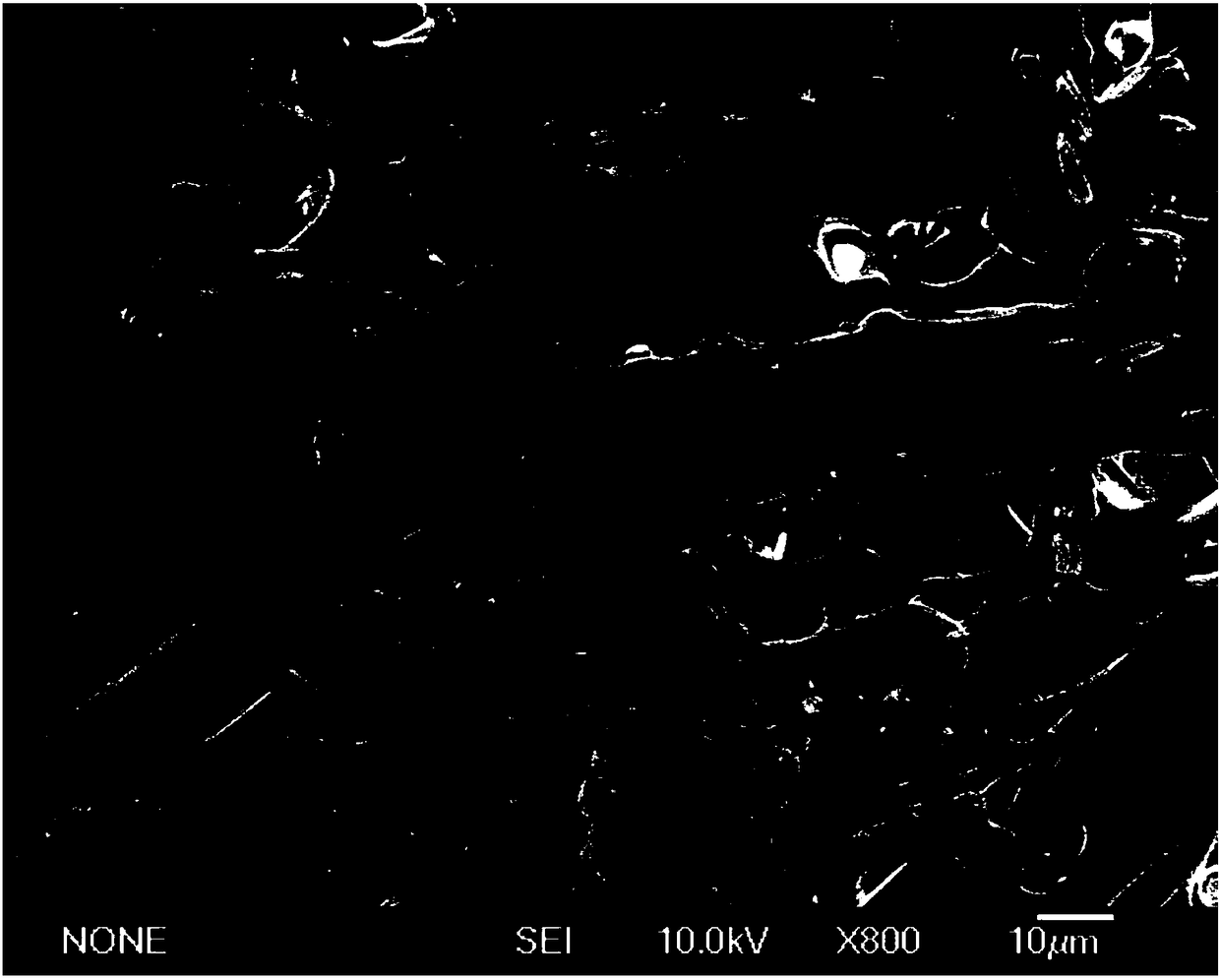

[0033] (2) Preparation of α-calcium sulfate hemihydrate / polycaprolactone composite material

[0034] Heat 400g of polycaprolactone at 60-65°C to make it melt completely, then add 600g of surface-modified α-calcium sulfate hemihydrate, stir for 2 hours, quickly inject into the mold, hot press at 5MPa for 10 minutes, and then cool at room temperature After 1 hour, the mold was demoulded to obtain the α-calcium sulfate h...

Embodiment 2

[0036] (1) Surface modification of α-calcium sulfate hemihydrate

[0037]Add 100g of α-calcium sulfate hemihydrate to 500g of 30wt% ethanol aqueous solution, stir, then add 3.0g of hyaluronic acid, adjust the pH value to 10.0, heat, and react at a constant temperature of 65°C for 2.0 hours, and the surface-modified α-calcium sulfate hemihydrate The slurry was suction filtered, washed twice with absolute ethanol, and dried in a drying oven to obtain surface-modified α-calcium sulfate hemihydrate.

[0038] (2) Preparation of α-calcium sulfate hemihydrate / polycaprolactone composite material

[0039] Heat 500g of polycaprolactone at 60-65°C to make it melt completely, then add 500g of surface-modified α-calcium sulfate hemihydrate, stir for 2 hours, quickly inject into the mold, hot press at 5MPa for 10 minutes, and then cool at room temperature After 1 hour, the mold was demoulded to obtain the α-calcium sulfate hemihydrate / aliphatic polyester composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com