Earth pressure balance shield synchronous slurry injection structure and construction assistance system

An earth pressure balance shield and mud injection technology, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problem that the gap between the shield excavation surface and the outer diameter of the segment is not fully filled, and the shield tunneling attitude is difficult to control. , the effect is not ideal and other problems, to achieve the effect of reducing the probability of wrapping the shield body, reducing the probability of surging, and reducing the amount of synchronous grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

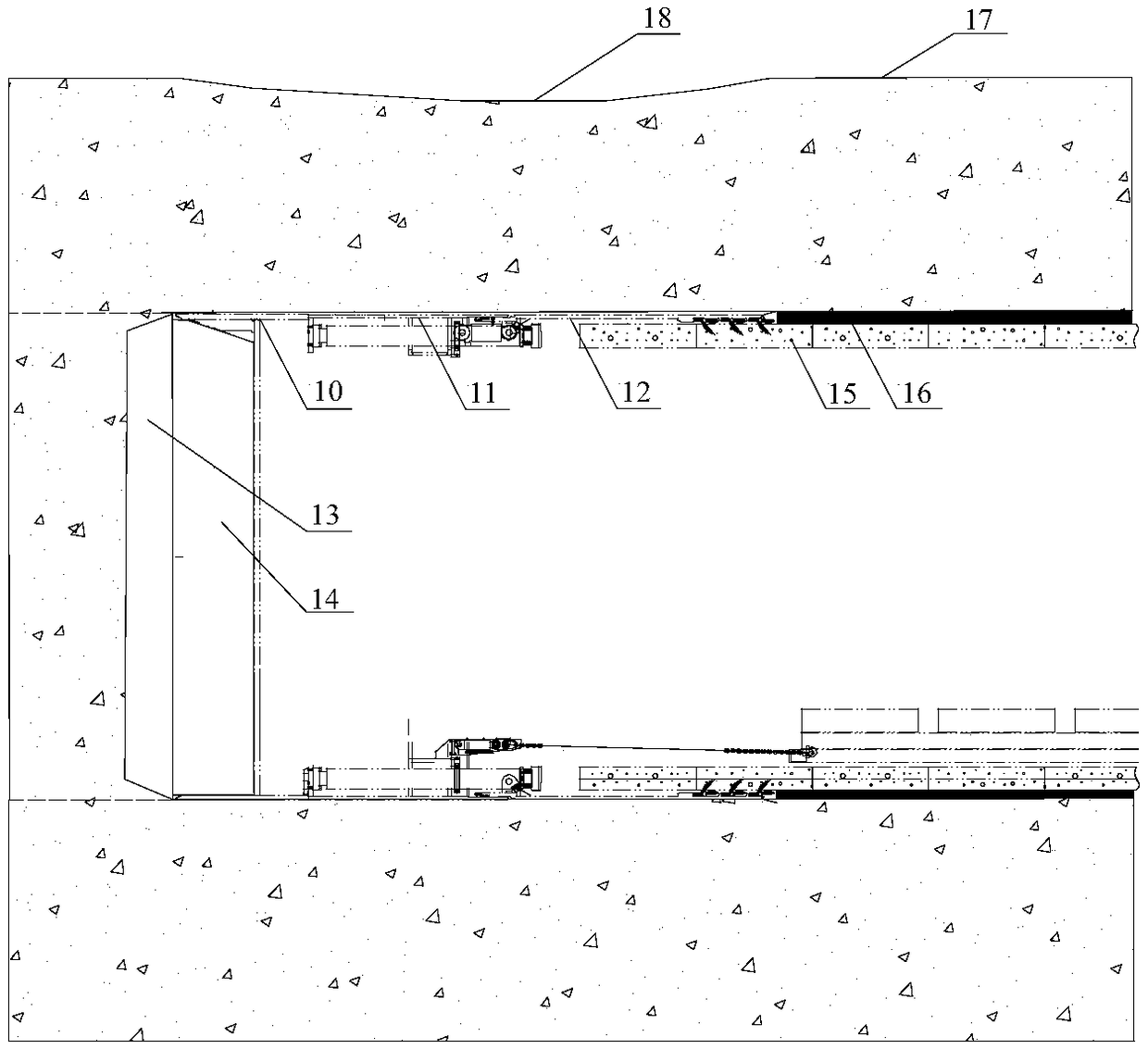

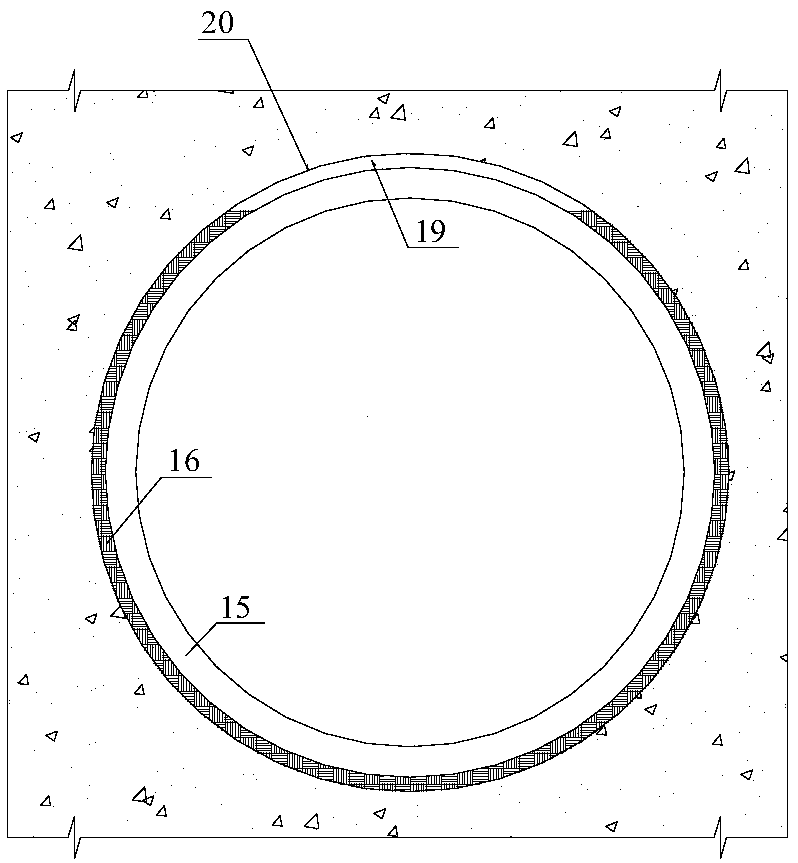

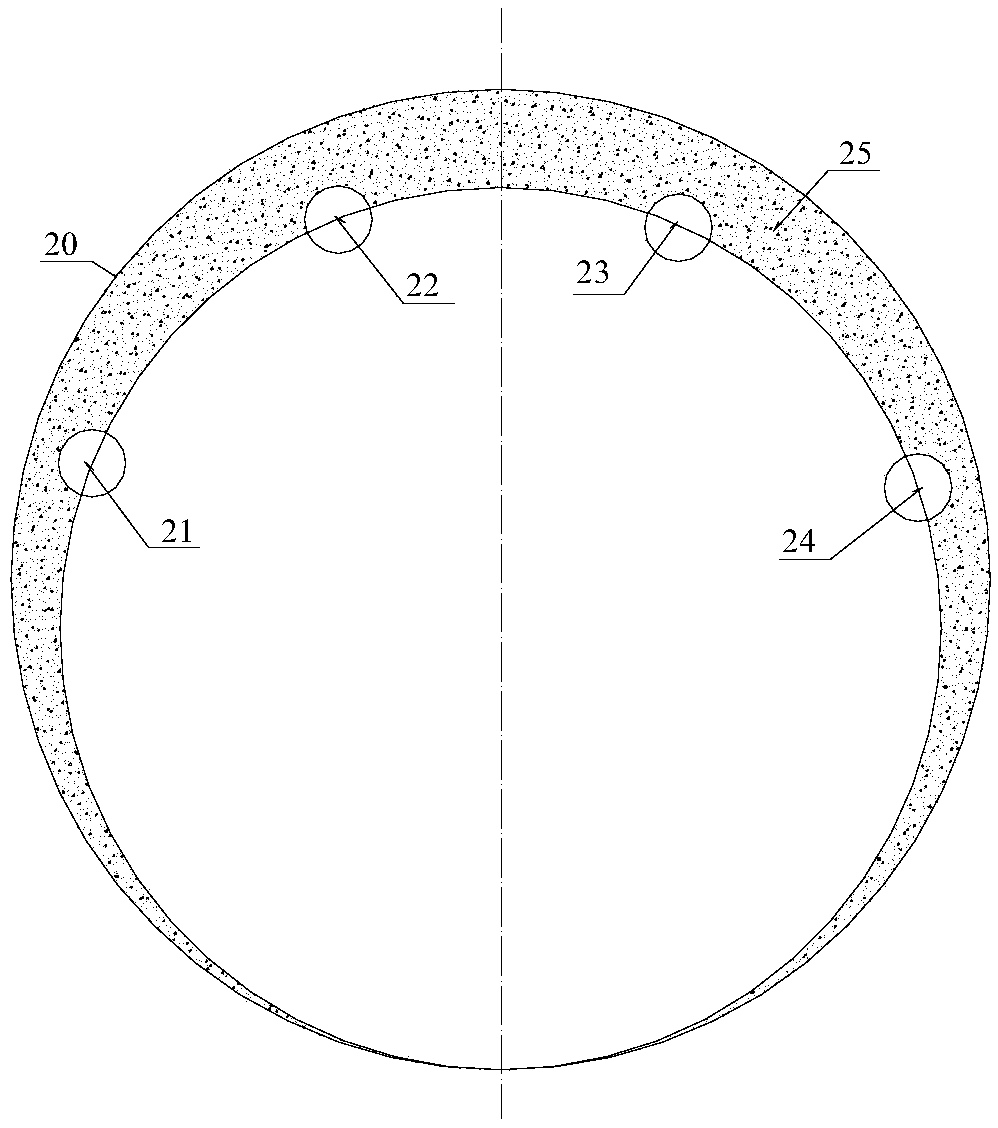

[0017] refer to figure 1 , a synchronous mud injection structure of an earth pressure balance shield of the present invention, the shield body includes a cutter head 13, a soil cabin 14, a front shield 10, a middle shield 11, a shield tail 12, and a segment behind the shield tail 12 The synchronous grouting in the gap between 15 and the shield excavation surface 20 forms the synchronous grouting filling layer 16 . refer to image 3 and Figure 4 , the middle shield 11 is provided with circumferentially spaced mud injection ports, through which plastic mud is injected into the space outside the shield between the shield body and the tunnel excavation surface 20, and the plastic mud is injected into the front shield 10 and shield tail 11 The space outside the shield diffuses, and the space outside the shield is densely filled to form a plastic mud fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com