Construction method for carrying out non-excavation subway station through composite pipe joint structure

A technology for subway stations and construction methods, which is applied in underground chambers, earth-moving drilling, wellbore lining, etc., to achieve the effect of reducing engineering risks and controlling land subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Such as Figure 1 to Figure 8 As shown, a kind of construction method utilizing composite pipe joint structure of the present invention to implement non-excavation subway station comprises the following steps:

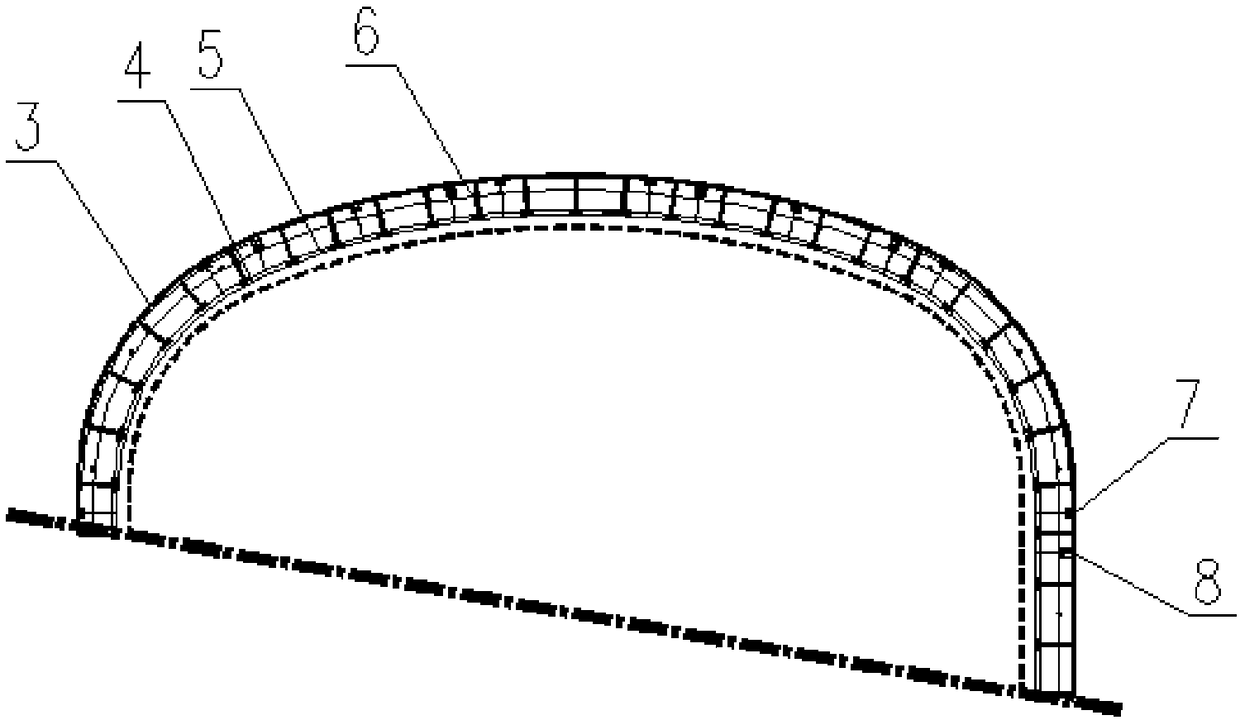

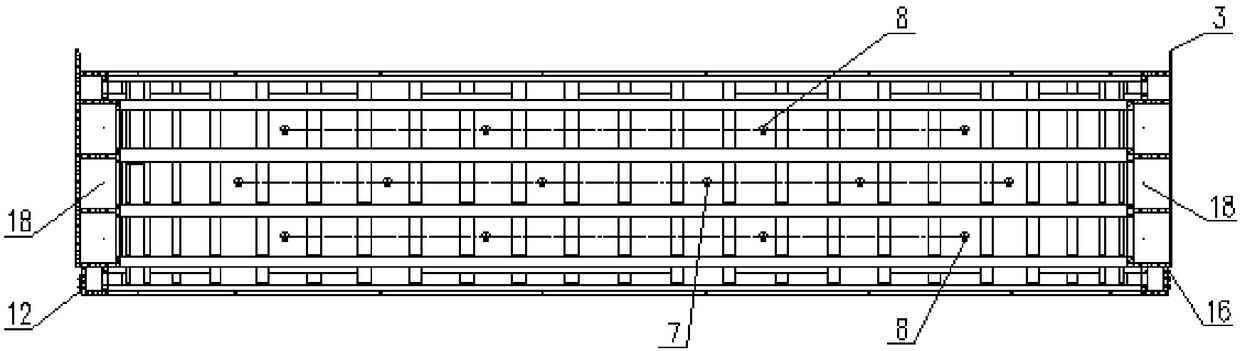

[0035] Step (1), the thickness direction of the steel ring is composed of two layers of steel plates inside and outside, the inner steel plate 4 has concrete pouring holes 5, the steel plates are connected by ribs 6, and the inner side of the outer steel plate 3 is provided with plum blossom-shaped studs 9, It is used for connecting the inner and outer steel plates with post-cast concrete; the outer steel plate 3 is provided with anti-friction mud grouting holes 7 and secondary grouting holes 8 .

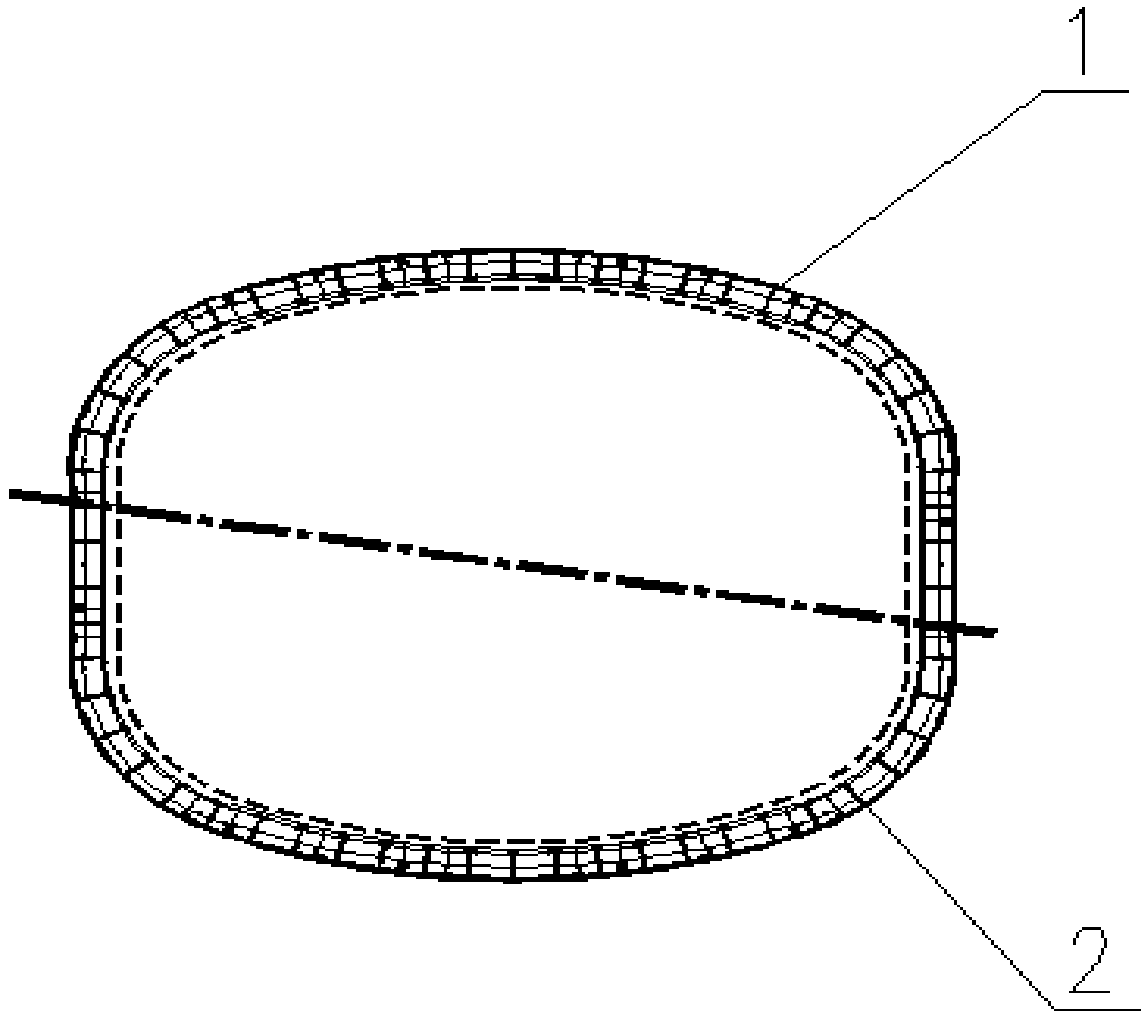

[0036] Step (2), the steel ring is assembled from the upper half ring 1 and the lower half ring 2; the connection between the upper half ring 1 and the lower half ring 2 is provided with a circumferential bolt hole 18 and a groove welding seam, and the upper half ring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com