Deep water open composite foundation wharf and its construction method

A combined foundation and open technology, applied in the direction of basic structure engineering, embankment, coastline protection, etc., can solve the problems of poor adaptability to overloading of the wharf surface, limited structural bearing capacity, and high requirements for foundation bearing capacity, so as to reduce the number of underwater operations , strong adaptability, and the effect of increasing lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

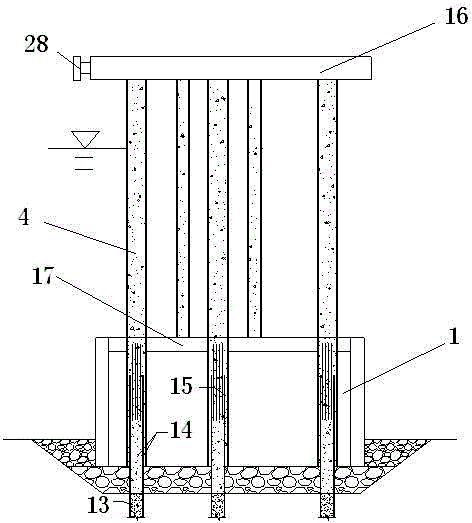

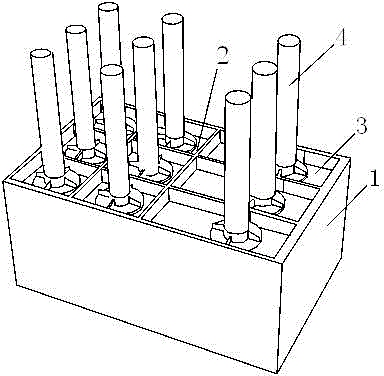

[0048] In this example, see Figure 1 to Figure 4 , a deep-water open-type composite foundation wharf, its wharf panel 16 is fixedly connected to the subsea foundation bed through a foundation support system, the front end of the wharf panel 16 is provided with a fender member 28, and the foundation support system consists of a caisson gravity structure system and a pile foundation The structure system is fixedly assembled and connected. The caisson gravity structure system is formed by implanting caisson 1 on the subsea foundation bed. The side wall of caisson 1, the caisson top plate 17 and the caisson bottom plate form an airtight chamber. The pile foundation structure system consists of a A series of through long piles and another series of non-through piles form a steel pipe concrete beam structure. Inside the caisson 1, there are a series of reserved pile steel casings 4 vertically penetrating the upper and lower ends of the caisson 1. The top opening of the steel casing ...

Embodiment 2

[0052] This embodiment is basically the same as Embodiment 1, especially in that:

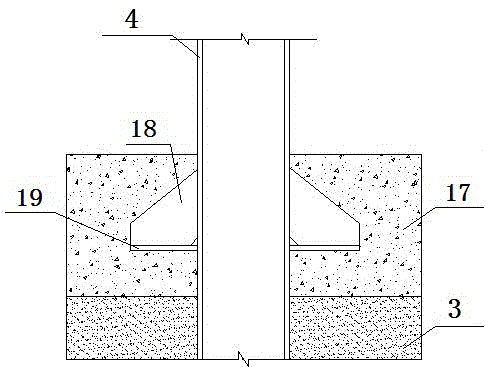

[0053] In this example, see Figure 5 to Figure 18 A series of flat-head welding studs 20 are fixedly arranged on the outer wall of the lower part of the non-penetrating pile at the position of the caisson roof 17, and an anchoring steel plate 23 is fixedly connected to the bottom of the non-penetrating pile, and the flat-head welding studs 20 and the anchoring steel plate 23 together form a non-penetrating The riveted joint between the pile and the caisson roof 17 is fixed. When pouring concrete to manufacture the caisson roof 17, an embedding cup groove 21 embedded in the bottom node of the non-penetrating pile is reserved in the caisson roof 17, and concrete is poured into the embedding cup groove 21 to form a concrete The joint part 22 fixes and combines the riveted node parts of the non-penetrating piles with the caisson roof 17, and the concrete-filled steel pipe pile bundle formed by the...

Embodiment 3

[0061] This embodiment is basically the same as Embodiment 2, and the special features are:

[0062] Only one steel casing 4 is arranged in each compartment, so that each steel casing 4 is closely connected with the concrete joint areas in different compartments in the caisson roof 17, and the compartments arranged vertically and horizontally in the caisson roof 17 Just above the intersection point of the plate 2, an embedding cup groove 21 is reserved for embedding the bottom node of the non-penetrating pile, and concrete is poured into the embedding cup groove 21 to form a concrete junction 22, and the riveted node part of the non-penetrating pile is fixedly combined with the caisson top plate 17 together. Place the steel casing 4 in the appropriate position of each compartment, where the size of the third row of compartments is larger than that of the first two rows, that is, the width dimensions of the three rows of compartments are arranged according to 8m, 8m and 10m res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com