Settlement-resistant supporting structure of loess tunnel and construction method thereof

A technology for supporting structures and loess tunnels, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve problems such as affecting the progress of tunnel construction and taking a long time in the processing process, avoiding the shutdown of the tunnel face, controlling tunnel settlement, and improving The effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

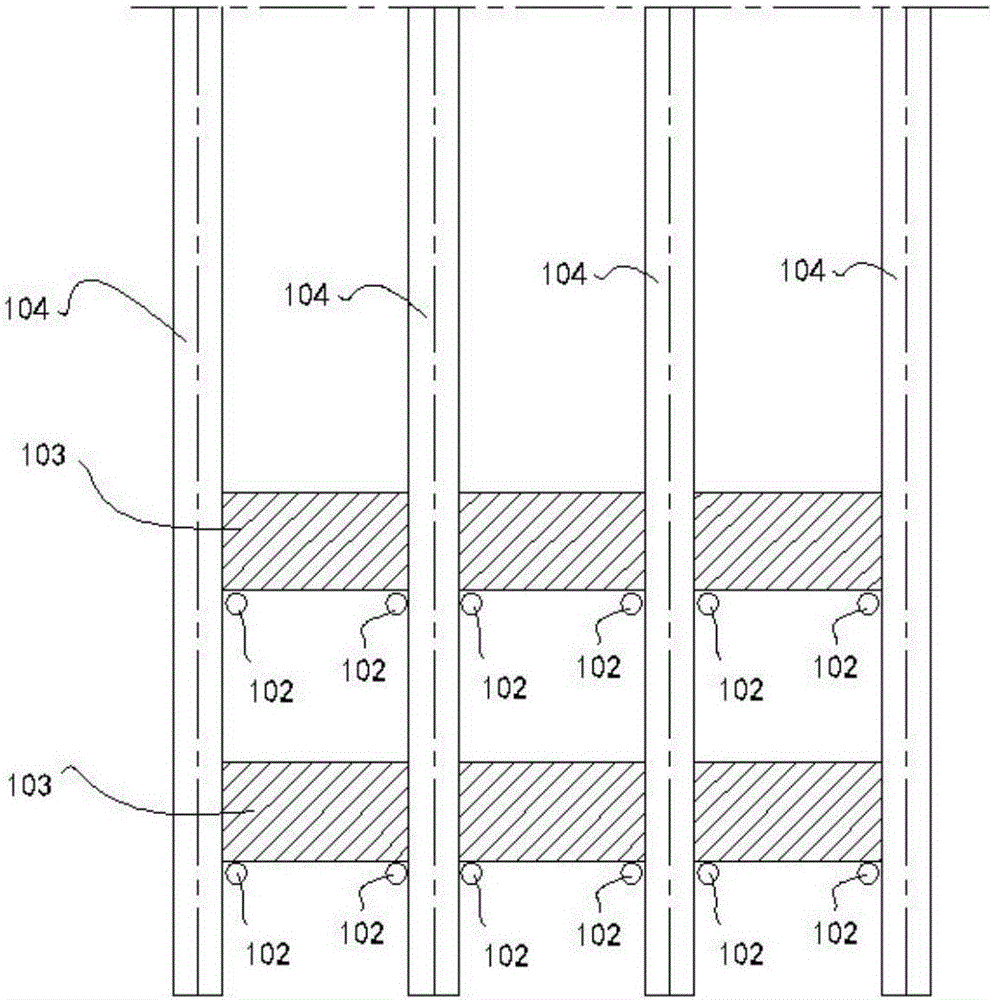

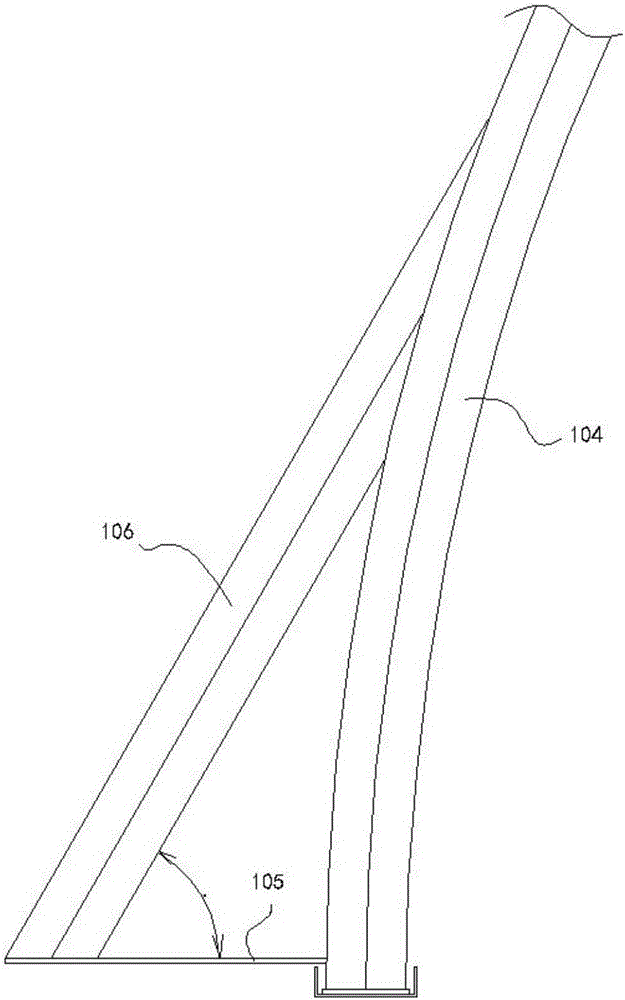

[0025] see figure 1 and figure 2 , in this embodiment, the anti-subsidence support structure of the loess tunnel is to arrange the main tunnel arches 104 at intervals along the longitudinal direction of the tunnel. Connection, at the connection node position between the longitudinal bar 103 and the main hole arch 104, the bottom of the longitudinal bar 103 is provided with a locking foot anchor pipe 102; Shaped steel legs 106 are arranged on the outside of the outer side, and the arch feet of the shaped steel legs 106 and the main hole arch 104 form a "herringbone" character support;

[0026] In specific implementation, the corresponding measures also include: on both sides of the main hole arch 104, the longitudinal rods 103 are spaced along the circumferential direction of the main hole arch 104, and at least two roads are arranged at intervals on each side of the main hole arch 104. The included angle between the medium-sized steel leg 106 of the enlarged arch foot and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com