Steel cavity stranded caisson-pile inverse-way composite base and construction method

A technology of composite foundation and construction method, which is applied in the direction of foundation structure engineering, caisson, sheet pile wall, etc., to achieve the effects of reducing foundation scale, shortening construction period, and reducing post-construction settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

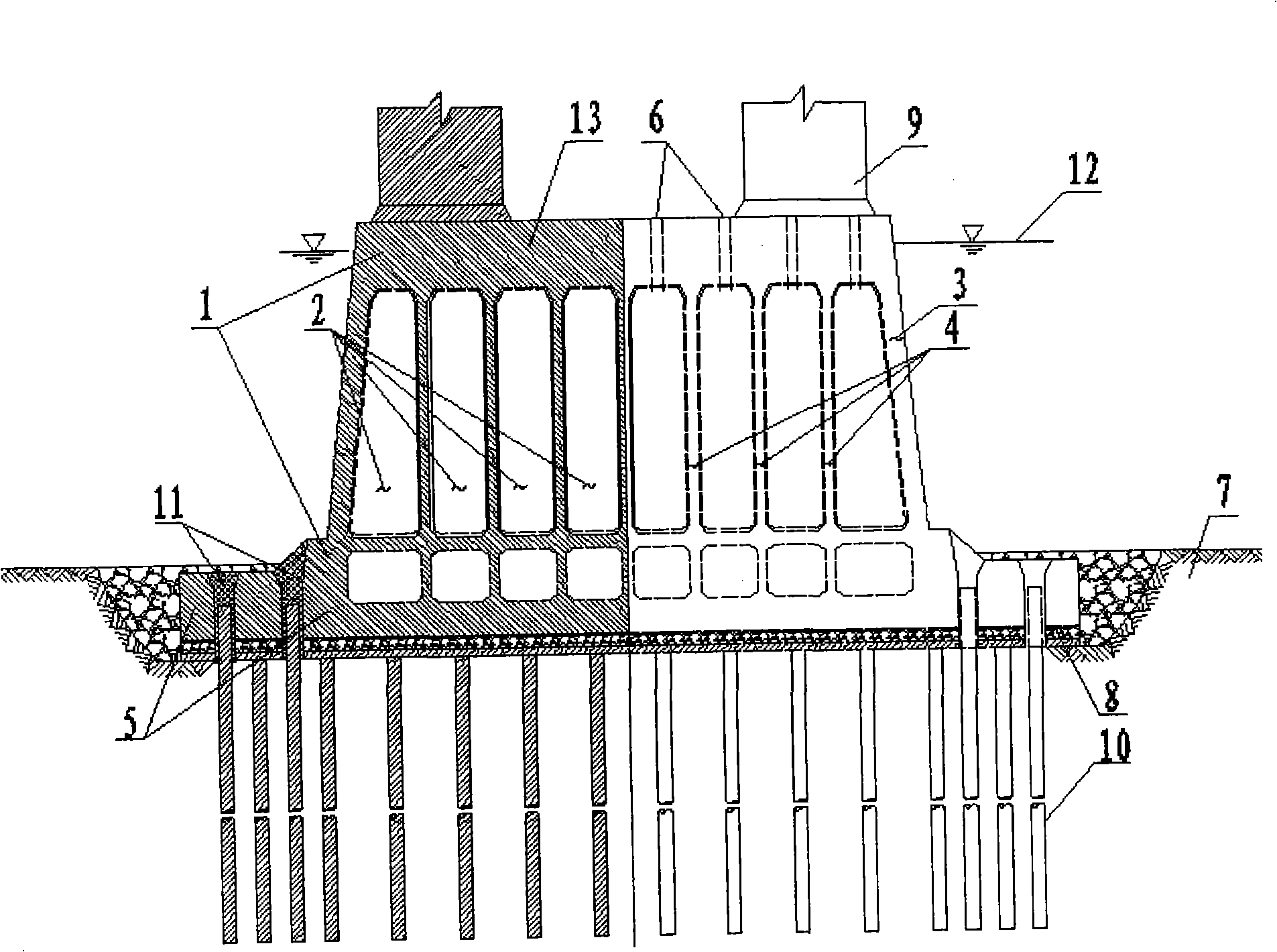

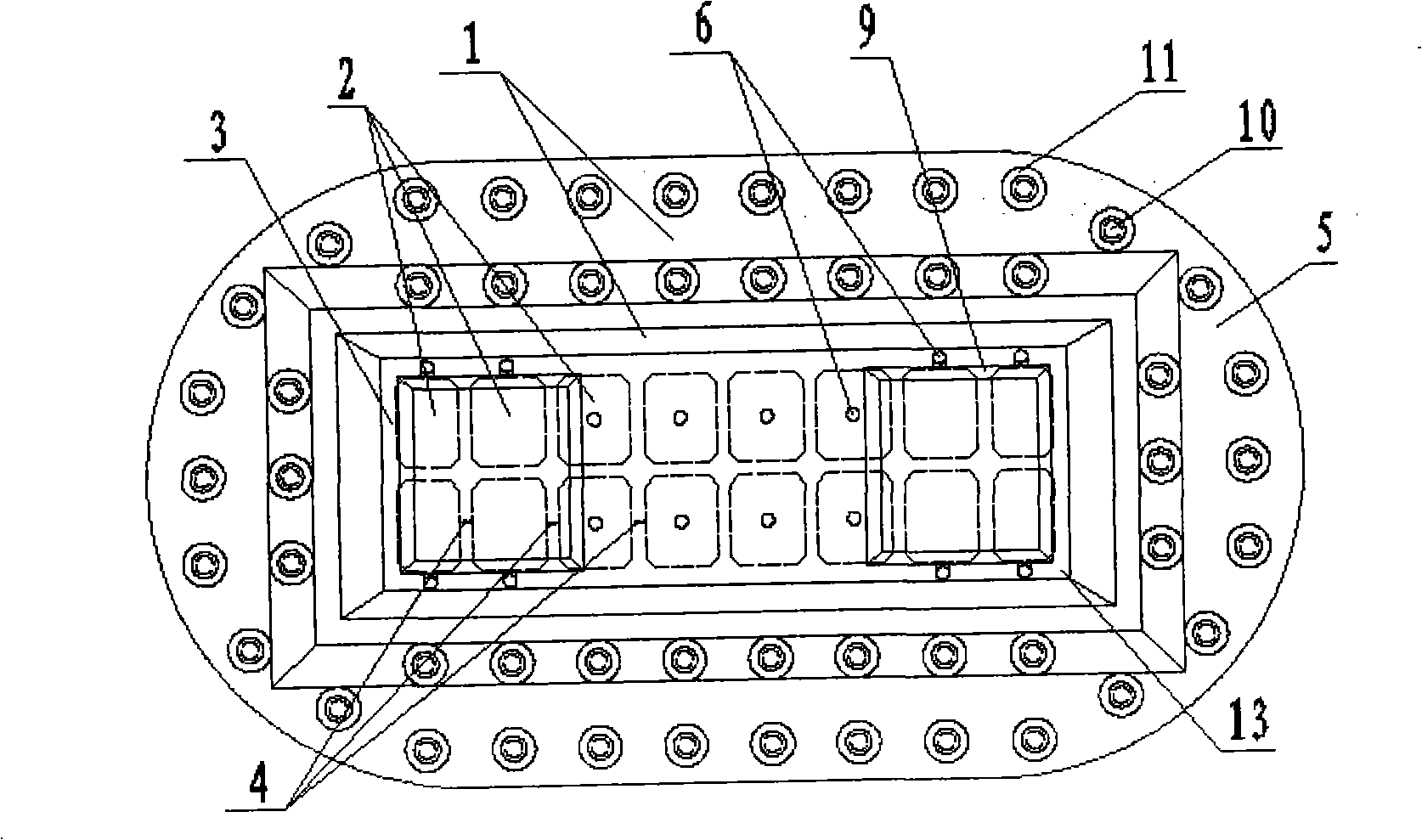

[0031] See figure 1 , 2 , is the structure diagram of "steel cavity caisson-pile reverse method composite foundation" of the present invention, in the figure: caisson 1, steel cavity 2, caisson concrete outer wall 3, caisson partition wall structure inner wall 4, caisson box bottom platform 5, caisson Concrete box roof 13, pumping and air supply hole 6, sea, river or river bed 7, foundation bed 8, bridge tower (pier) 9, pile 10, pile sinking reserved hole 11 and sea, river or river water 12.

[0032] The "steel cavity caisson-pile reverse method composite foundation" of the present invention is used for deep-water foundations of cross-sea (river, river) bridges, and consists of a caisson 1, a foundation bed 8 and piles 10. A caisson 1 is placed on the foundation bed 8, and the surroundings of the caisson 1 are connected with piles 10. The caisson 1 includes a steel cavity 2 formed by a steel plate, a concrete outer wall 3, a concrete partition wall structure inner wall 4, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com