Transverse tunnel cover method for shallow-buried underground excavation large underground space construction

A technology for underground space and shallow buried underground excavation, which is applied to underground chambers, shaft equipment, wellbore lining, etc., and can solve the problems of pipe curtain construction accuracy, joint joint process and high joint strength requirements, and it is impossible to open up the construction work surface. High precision requirements and other issues, to achieve the effect of clear force transmission, low construction precision requirements, and low construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

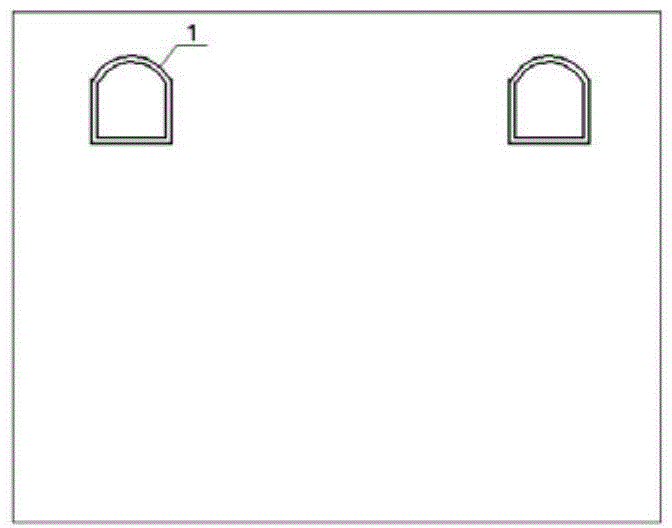

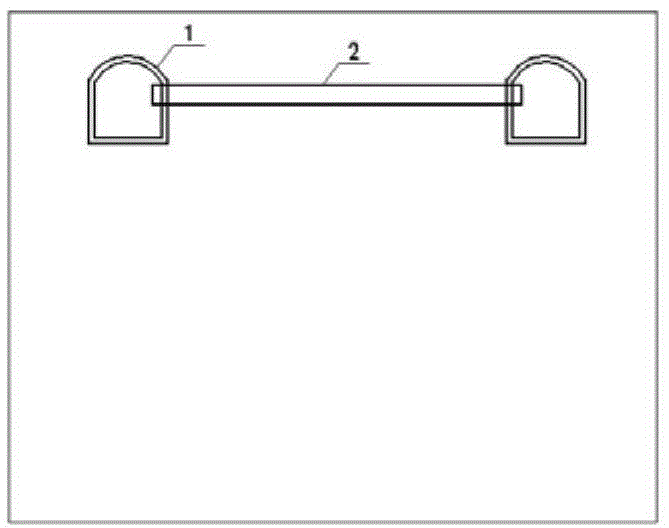

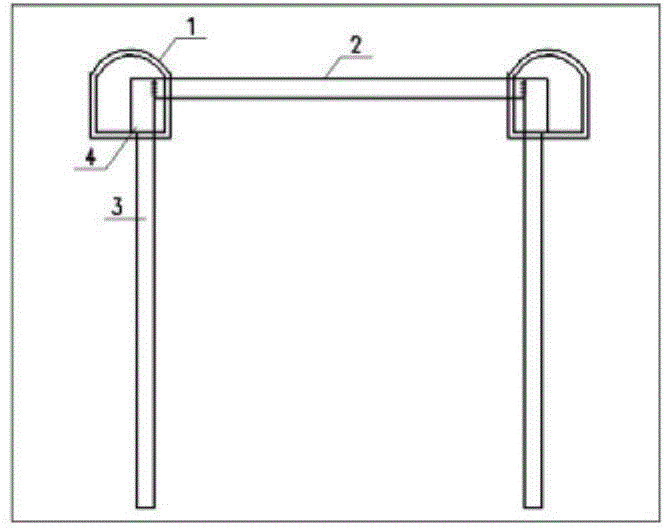

[0058] According to the present invention, a kind of horizontal hole cover method for the construction of large-scale underground space under shallow buried excavation, the construction steps are as follows:

[0059] On the top of the side wall of the proposed underground space, the foundation pit or pilot hole is arranged longitudinally along the underground space, and a rigid layer above the roof of the proposed underground space is formed at one time through non-excavation techniques (such as pipe jacking method, horizontal drilling rig, etc.) Controllable temporary lateral force structure, and connected with the piles in the foundation pit or pilot tunnel to form a temporary lateral roof-pile bearing system, under the protection of the lateral roof-pile bearing system, it can be operated in a forward or reverse direction Span or multi-span, single-layer or multi-layer underground space structure.

[0060] The first construction steps of the present invention are as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com