Method for building spherical crown type furnace top by laying bricks

A furnace roof and masonry technology, which is applied in the field of metallurgy, can solve the problems of large design span, high masonry precision, and environmental hazards of the spherical crown type furnace roof of fluidized roasting furnaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

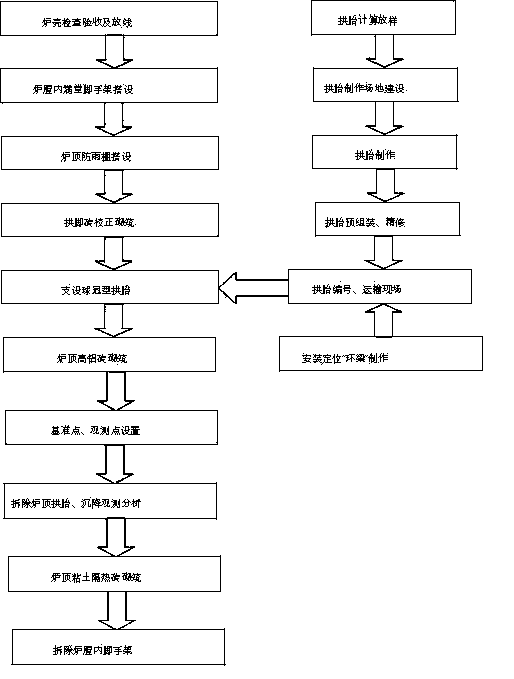

[0027] A kind of spherical crown roof masonry method of the present invention comprises the following steps:

[0028] (1) Erection of scaffolding in the furnace: Firstly, the furnace shell is inspected and laid out. According to the structural characteristics of the furnace shell, an equilateral octagonal scaffolding is erected along the furnace shell; vertical poles are gradually added to the expansion section of the furnace to form a corbel shape. ;

[0029] (2) Erection of the rain-proof shed on the furnace roof: set up scaffolding around the furnace roof, cover a layer of rain-proof tents along the scaffolding, and fix them; set up horizontal bars on the scaffolding outside the furnace roof and the scaffolding in the whole hall, and the horizontal bars are formed by the center of the furnace Set up radially, then cover the rainproof tent and fix it;

[0030] (3) Correction and masonry of arched bricks: the arched bricks of the furnace roof should be laid before installing...

Embodiment 2

[0042] A kind of spherical crown roof masonry method of the present invention comprises the following steps:

[0043] (1) Erection of scaffolding in the furnace: Firstly, the furnace shell is inspected and laid out. According to the structural characteristics of the furnace shell, an equilateral octagonal scaffolding is erected along the furnace shell; vertical poles are gradually added to the expansion section of the furnace to form a corbel shape. ;

[0044] (2) Erection of the rain-proof shed on the furnace roof: set up scaffolding around the furnace roof, cover a layer of rain-proof tents along the scaffolding, and fix them; set up horizontal bars on the scaffolding outside the furnace roof and the scaffolding in the whole hall, and the horizontal bars are formed by the center of the furnace Set up radially, then cover the rainproof tent and fix it;

[0045] (3) Correction and masonry of arched bricks: the arched bricks of the furnace roof should be laid before installing...

Embodiment 3

[0057] A kind of spherical crown roof masonry method of the present invention comprises the following steps:

[0058] (1) Erection of scaffolding in the furnace: Firstly, the furnace shell is inspected and laid out. According to the structural characteristics of the furnace shell, an equilateral octagonal scaffolding is erected along the furnace shell; vertical poles are gradually added to the expansion section of the furnace to form a corbel shape. ;

[0059] (2) Erection of the rain-proof shed on the furnace roof: set up scaffolding around the furnace roof, cover a layer of rain-proof tents along the scaffolding, and fix them; set up horizontal bars on the scaffolding outside the furnace roof and the scaffolding in the whole hall, and the horizontal bars are formed by the center of the furnace Set up radially, then cover the rainproof tent and fix it;

[0060] (3) Correction and masonry of arched bricks: the arched bricks of the furnace roof should be laid before installing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com