The bearing structure of the frame body at the male corner of the segmented scaffolding

A bearing structure and scaffolding technology, applied in the field of cantilevered scaffolding, can solve the problems of stress concentration and uneven appearance, and achieve the effect of avoiding concentrated force, beautiful appearance, and reducing the amount of steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below is engineering embodiment of the present invention:

[0031] The project is located in Changsha City. It is a high-rise residential building with a frame shear wall structure and a standard floor height of 3 meters. The external scaffolding for construction at the sun corners adopts cable-stayed simply supported beam double-row scaffolding.

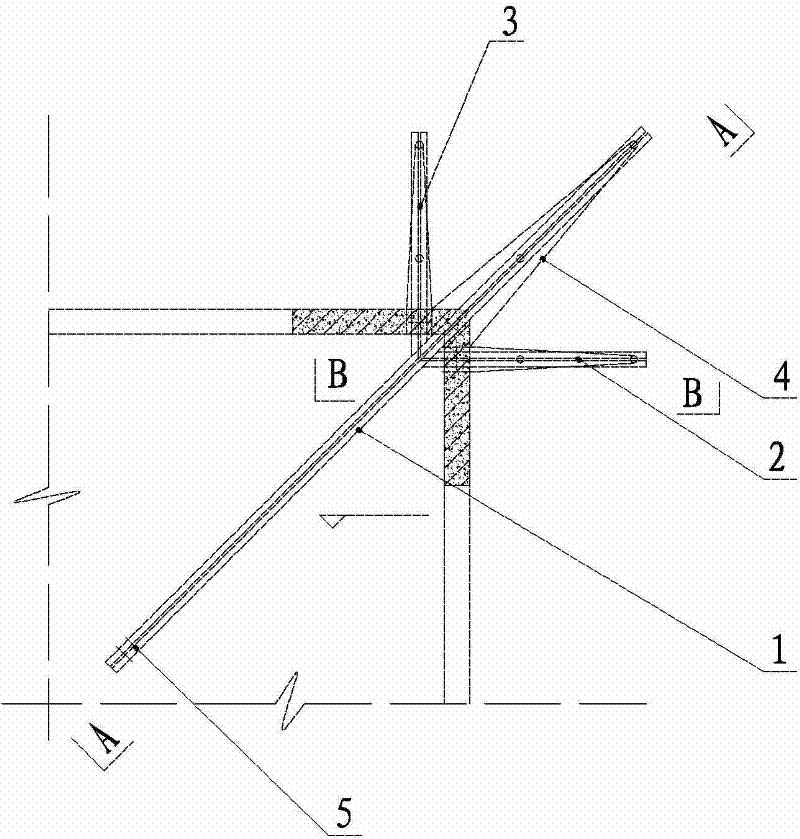

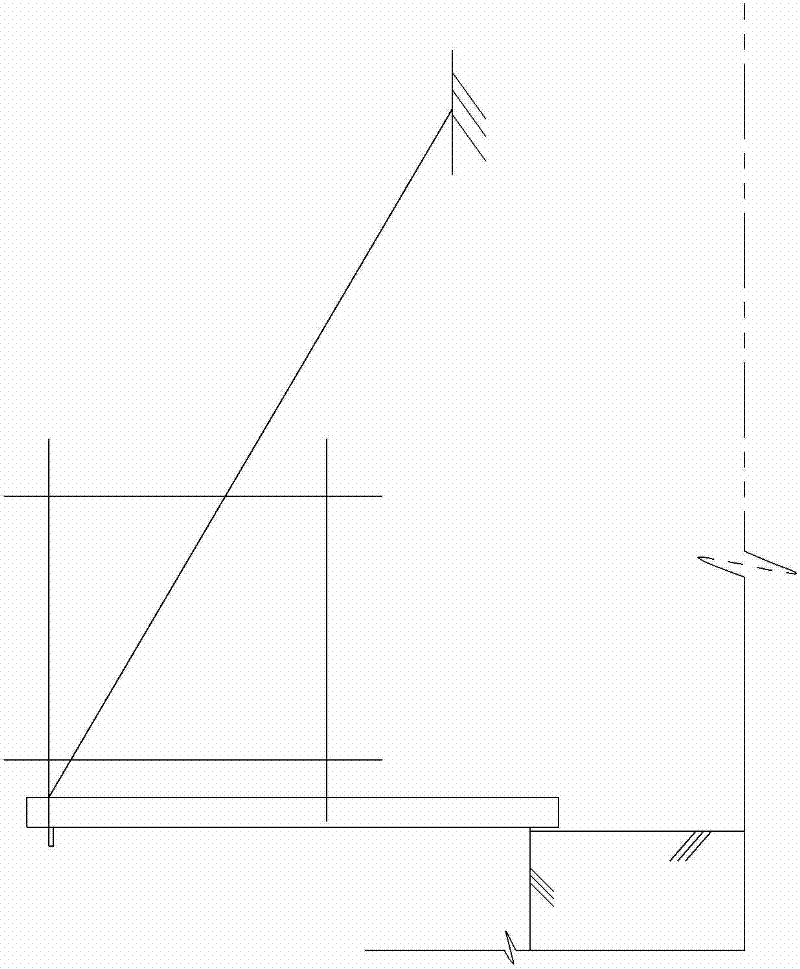

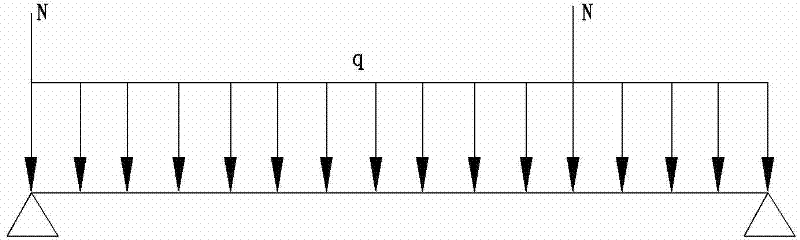

[0032] Such as figure 1 As shown, the frame load-bearing structure at the male corner of the scaffold includes 3 steel beams: main beam 1, left sub-beam 2, right sub-beam 3 and 6 cable-stayed wire ropes 4. The steel wire ropes 4 are respectively arranged on the outer ends of the beams, that is, two cable-stayed steel wire ropes are arranged on each shaped steel beam, one of which is used as a stress member, and the other is used as a safety protection rope. The main beam 1 is arranged along the bisector of the sun angle, and the left sub-beam 2 and the right sub-beam 3 are respectively arranged on both sides of the main gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com