Elastic yarn winding system and elastic yarn winding machine and elastic yarn winding method

An elastic yarn and winding machine technology, which is applied in the field of elastic yarn winding, can solve the problems of difficult setting of distance X, inability to stabilize the turning point, and difficulty in free length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

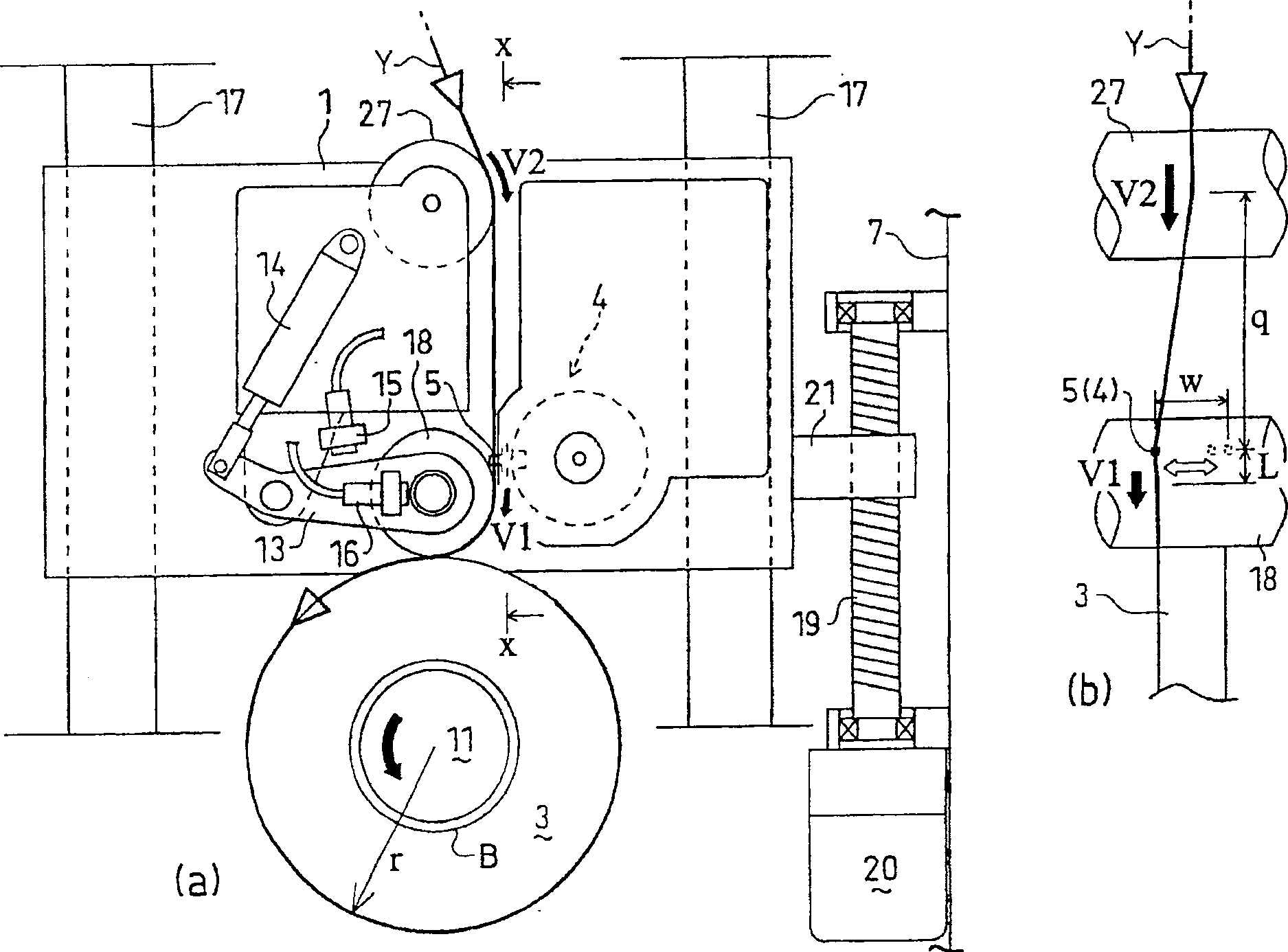

[0030] Embodiments of the present invention will be described.

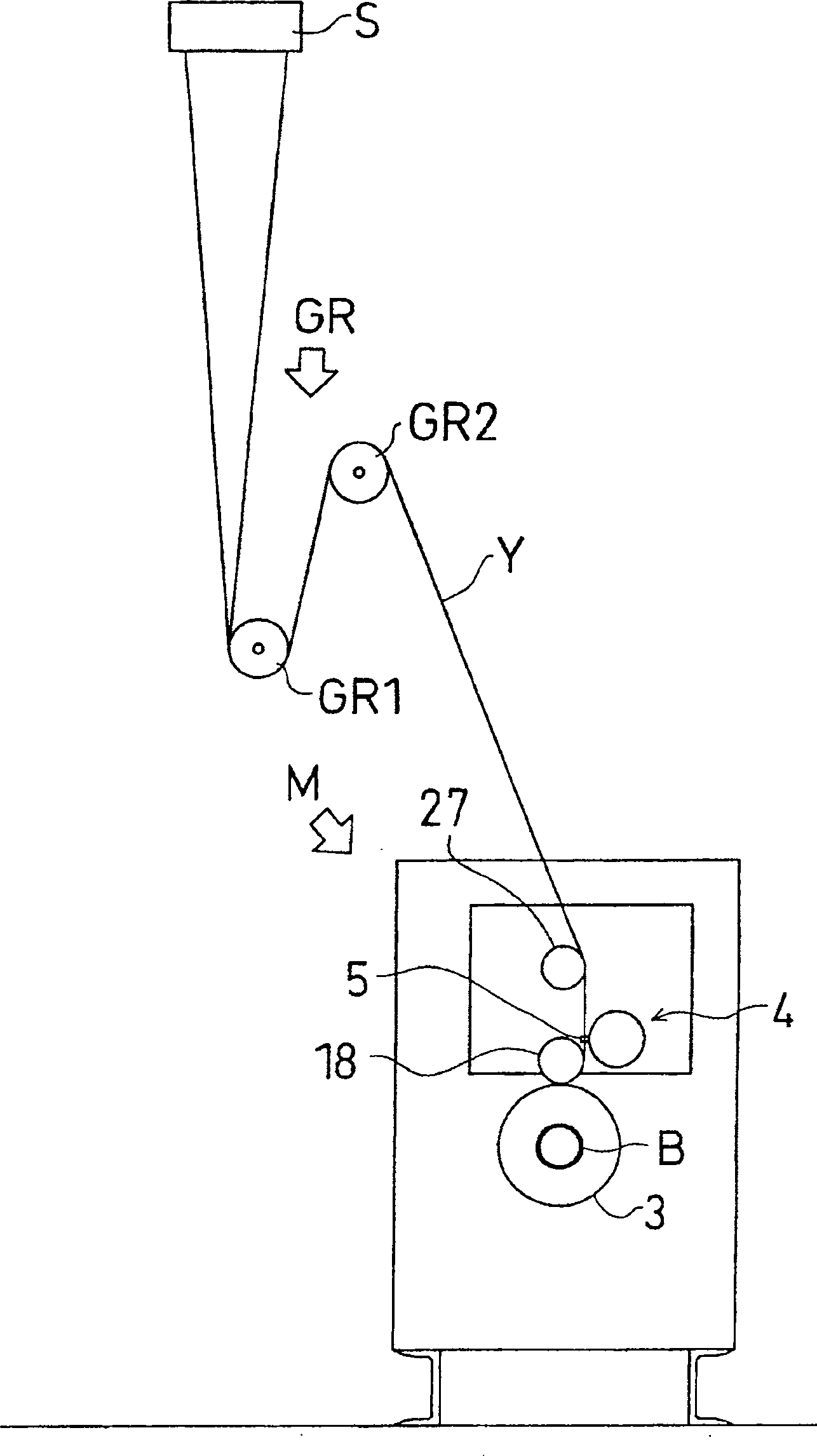

[0031] figure 1 The entire elastic yarn winding system is shown. The elastic yarn winding system comprises a monofilament spinning machine S, a guide roller for receiving and feeding an elastic monofilament yarn Y such as a polyurethane monofilament yarn spun from the monofilament spinning machine S For GR, and Elastic Yarn Winder M. The guide roller pair GR includes an upstream guide roller GR1 and a downstream guide roller GR2. The upstream guide roller GR1 receives the elastic monofilament yarn Y from the monofilament spinning machine S and determines the quality of the elastic yarn Y. The downstream guide roller GR2 is arranged downstream of the guide roller GR1 in the direction of yarn travel and changes the direction of yarn travel.

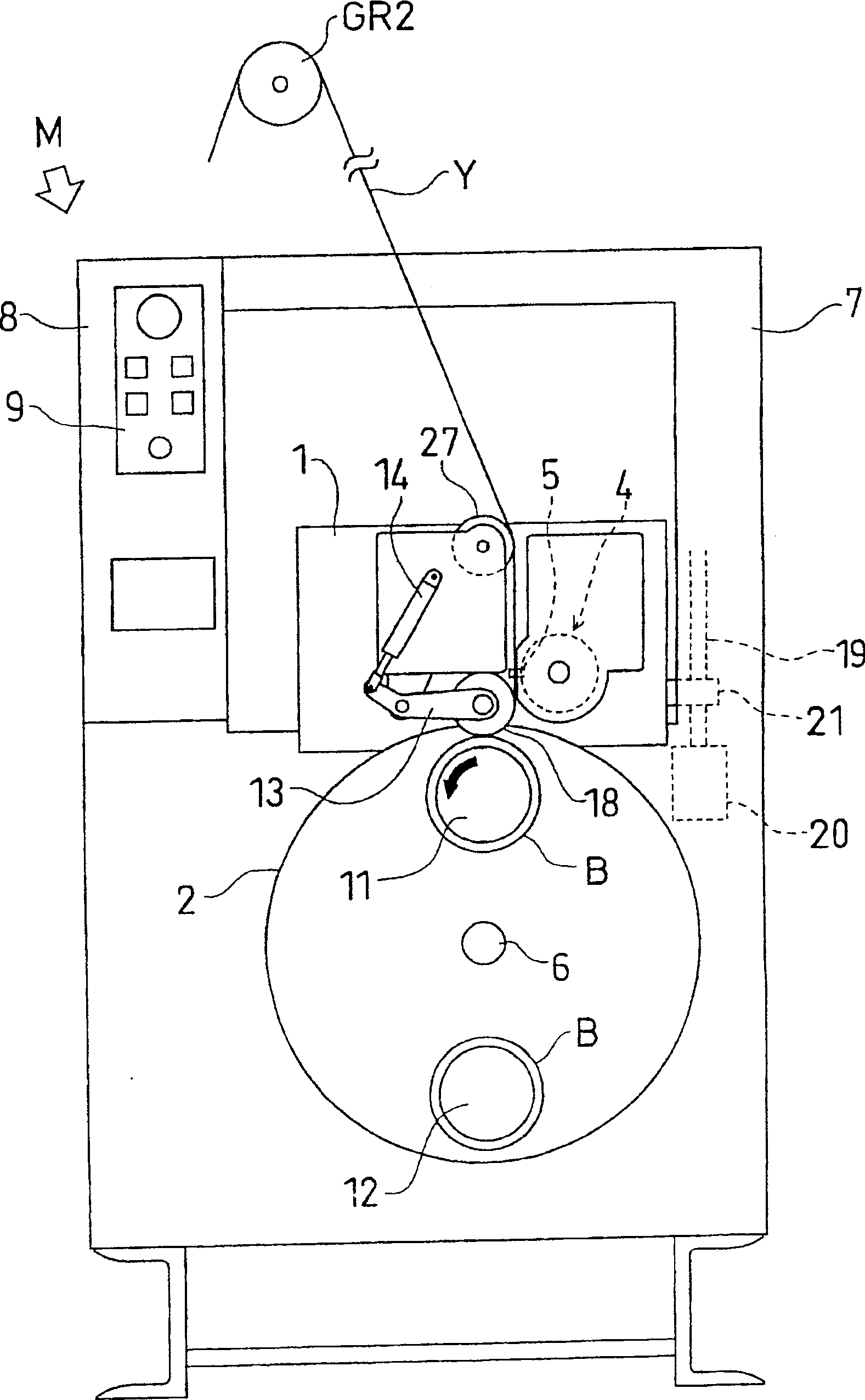

[0032] figure 2 The overall structure of the elastic yarn winding machine M is shown. The elastic yarn winding machine winds the elastic yarn Y fed from the guide roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com