Drawing mouth

A yarn feeder and yarn technology, used in spinning machines, open-end spinning machines, and continuously wound spinning machines, etc., can solve the problems of rotor speed limitation, high surface temperature, etc., and achieve effective wear protection, Improve heat dissipation, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

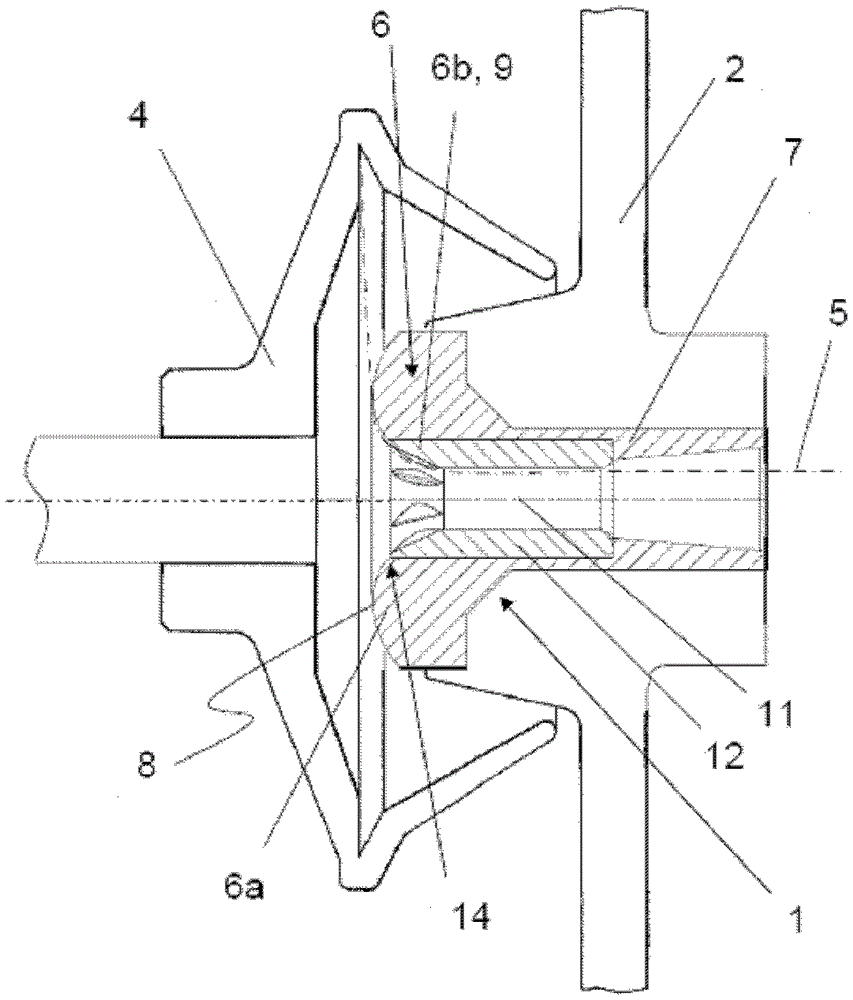

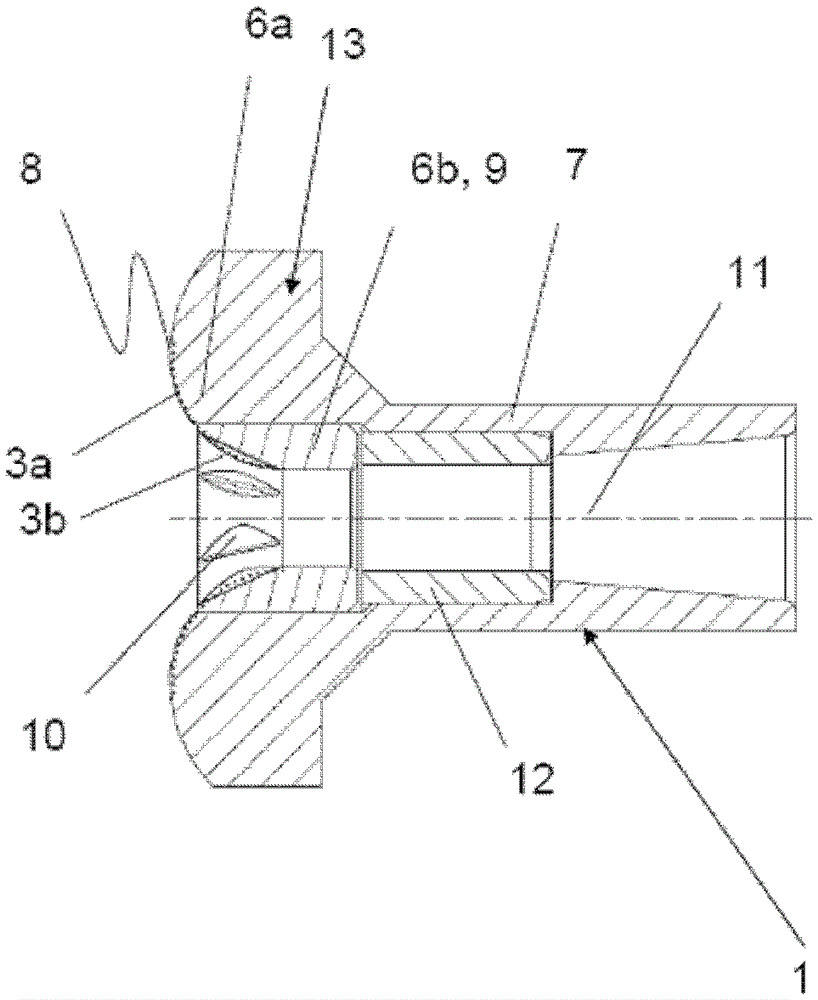

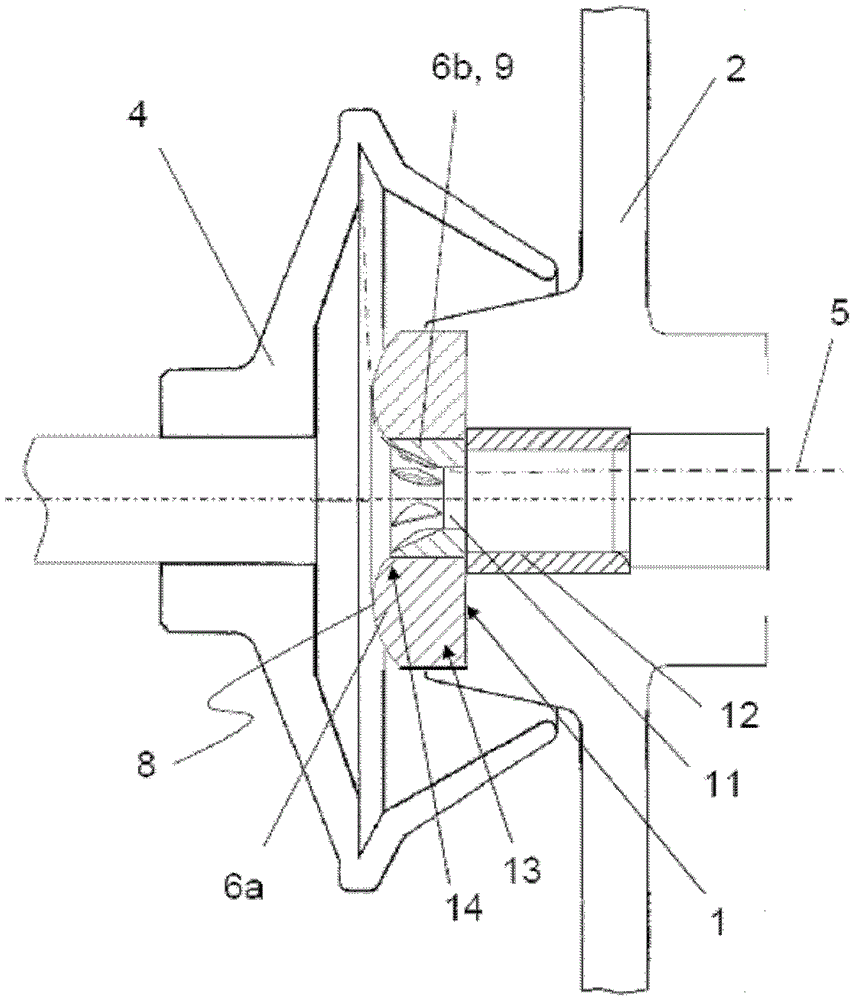

[0027] figure 1 The illustrated spinning nozzle 1 according to the invention is fixed in a known manner in a shroud 2 of a rotor housing, not shown here. Yarn drawing mouth 1 is used for guiding the yarn 5 made on the spinning rotor 4 to make it turn around, and here the yarn is represented by a dotted line. Wherein, the rotational speed of the spinning rotor 4 reaches up to 150,000 revolutions per minute, and the drawing speed of the finished yarn 5 is, for example, 250 m / min. When the rotor 4 rotates, the yarn 5 is moved around the surface of the yarn drawing mouth 1 in the manner of crank transmission.

[0028] In this embodiment, the yarn drawing nozzle 1 is composed of the yarn drawing nozzle funnel 6 and the yarn drawing nozzle shaft 7, the yarn 5 turns on the yarn drawing nozzle funnel, and the yarn drawing nozzle shaft is used to fix the yarn drawing nozzle 1 on the shield of the spinning device 2 within. Due to the uninterrupted contact with the high-speed circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com