Yarn winding machine and yarn winding method

A winding machine and yarn technology, which is applied in the direction of thin material processing, conveying filamentous materials, transportation and packaging, etc., and can solve the problems of package yarn skipping, unwinding, poor winding and tightening force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

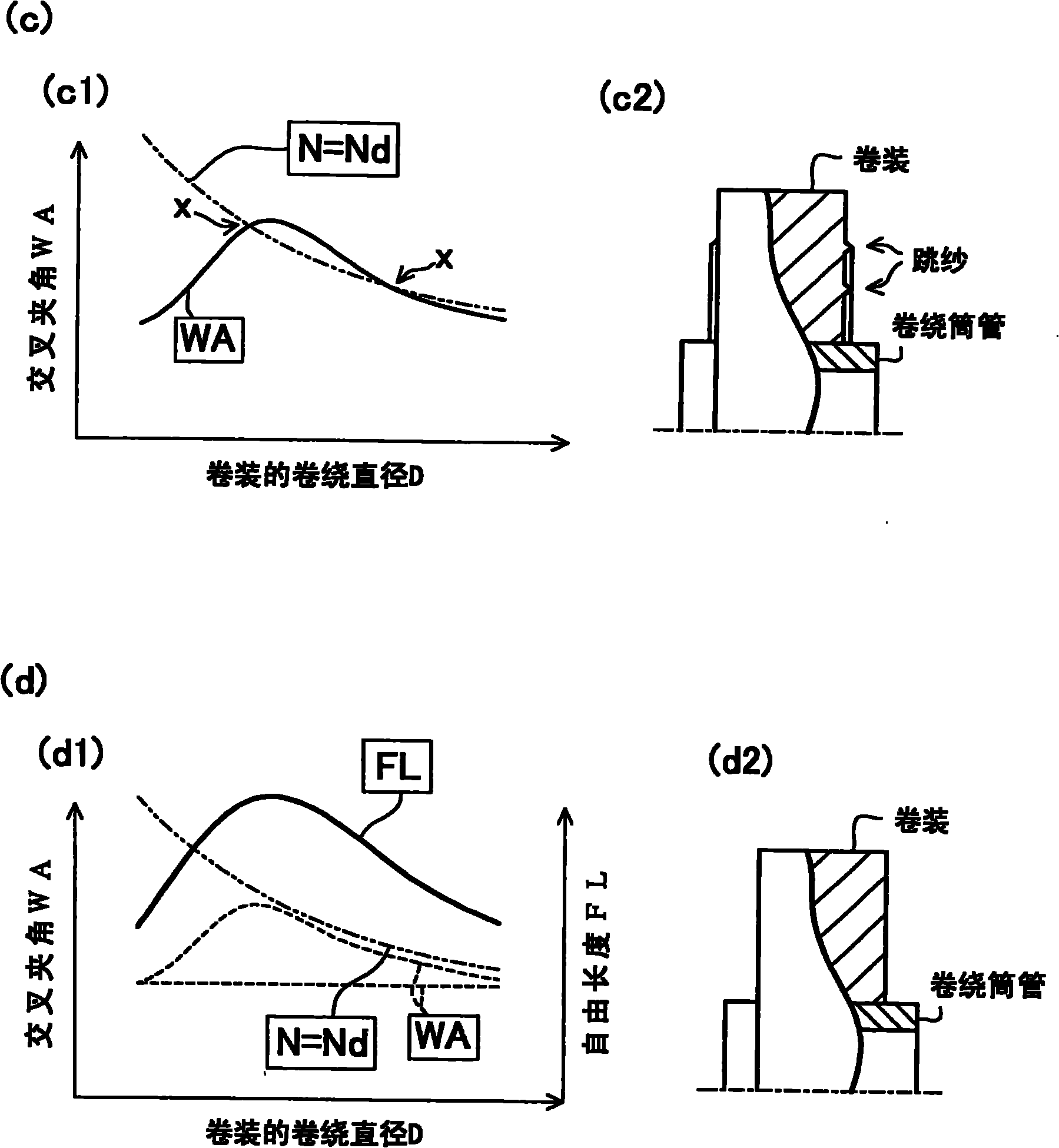

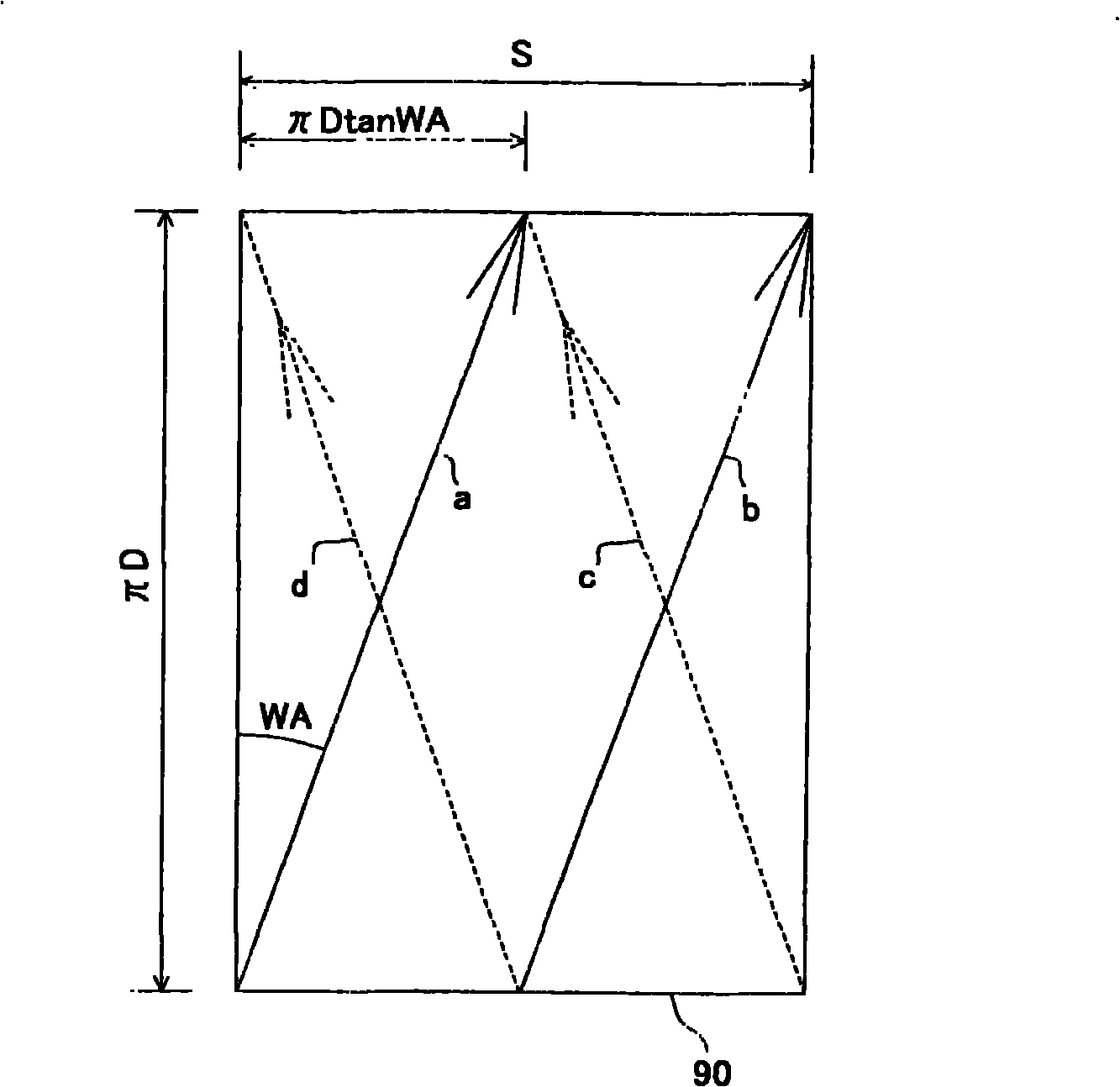

[0042] Hereinafter, a winder 1 as a yarn winding machine according to the first embodiment of the present invention will be described based on the drawings. Image 6 This is a front view of the winder according to the first embodiment of the present invention. Figure 7 System diagram for the winder.

[0043] The winder 1 winds an elastic yarn 2 as a yarn onto a bobbin 3 to form a package 4 (refer to Picture 10 ) Of the yarn winding machine. In addition, although the yarn winding machine that winds the elastic yarn 2 will be described below, the invention of the present application is not limited to this, and may be a yarn winding machine that winds yarns of other yarn types. Such as Image 6 As shown, the winder 1 has a body frame 5, a turntable 6, a sliding box 16, a traverse device 7, a contact roller 8, and a free length changing unit 9. Such as Figure 7 As shown, each structure of the winder 1 is electrically connected to the control unit 80 (control device). The control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com