Expansion valve control method, and expansion valve

An expansion valve, refrigerant technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problem of taking too long to cool down, and achieve the effect of improving response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

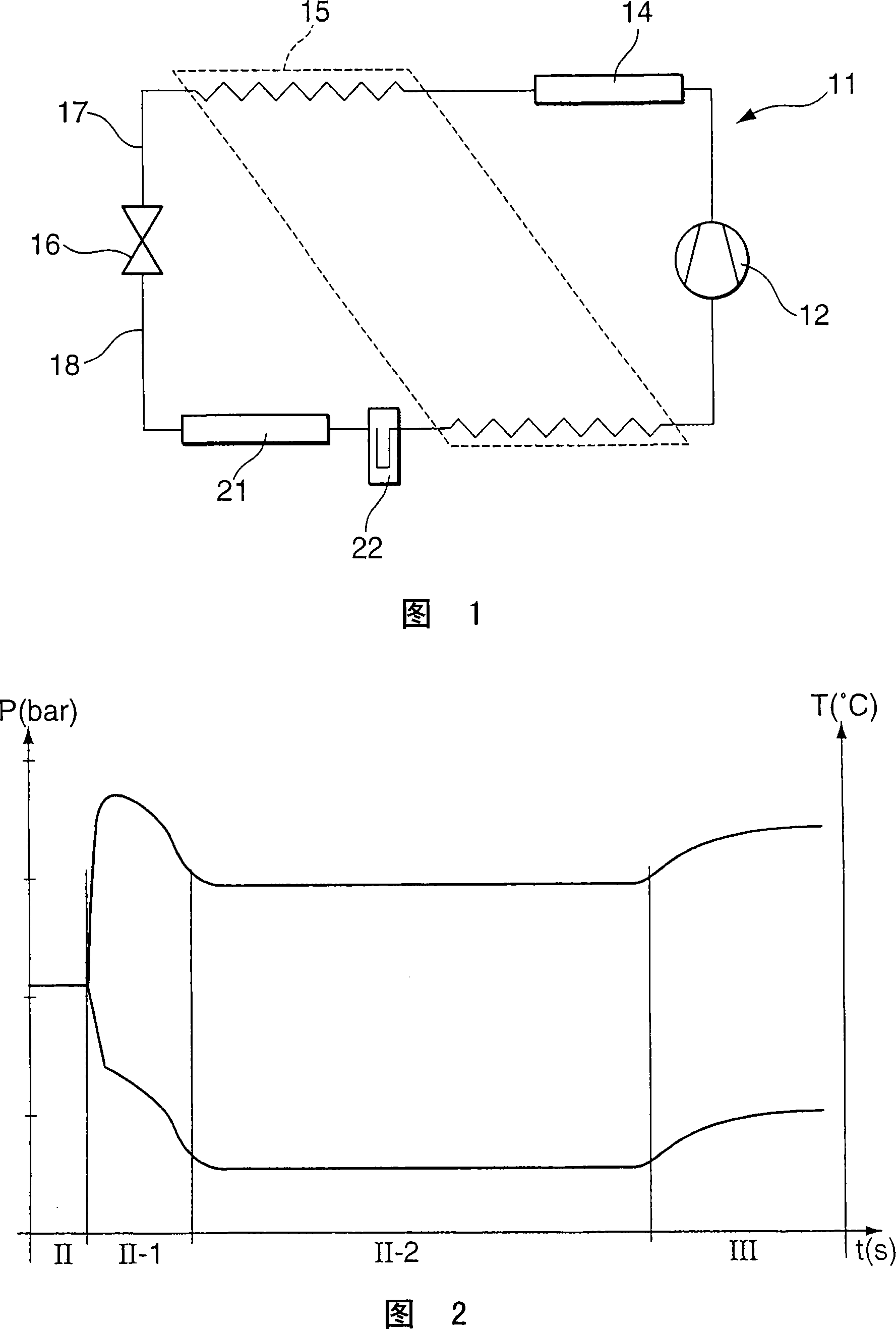

[0026] Figure 1 shows a refrigeration circuit 11 preferably operated with carbon dioxide. The refrigeration circuit 11 is used, for example, in a vehicle air conditioning system. The compressor 12 supplies the compressed refrigerant on the high-pressure side to the external heat exchanger 14 . The latter is connected to the environment and outputs heat to the outside. Connected downstream of the latter is an internal heat exchanger 15 which supplies refrigerant to an expansion valve 16 via a feed line 17 . Upstream of the high-pressure side expansion valve 16 there is an inlet pressure which can be 120 bar, for example, in summer. Refrigerant flows through expansion valve 16 and to the low pressure side. On the output side, under steady state conditions, the expansion valve 16 has a pressure between 35-45 bar. The refrigerant cooled by the pressure release enters the interior heat exchanger 21 via the discharge line 18 and will remove heat from the environment, with the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com