A control method for roadway roof deformation under high level stress

A roadway roof and stress action technology, which is applied in tunnels, earthwork drilling, tunnel lining, etc., can solve problems such as high horizontal stress, deformation of roadway roof and surrounding rock at shoulder angles, difficulty in controlling deformation of roadway roof, etc., and achieve enhanced bearing capacity , avoid the instability of the whole section, and improve the overall anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

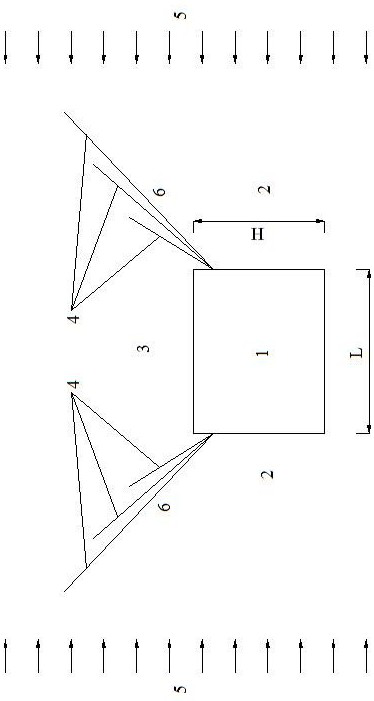

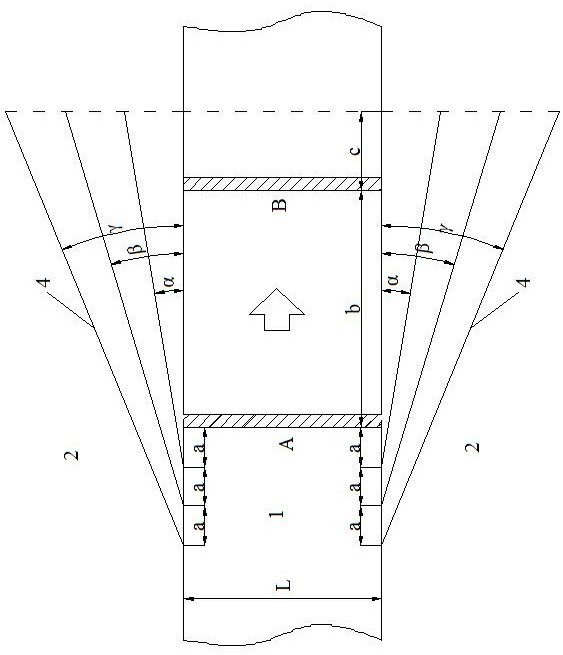

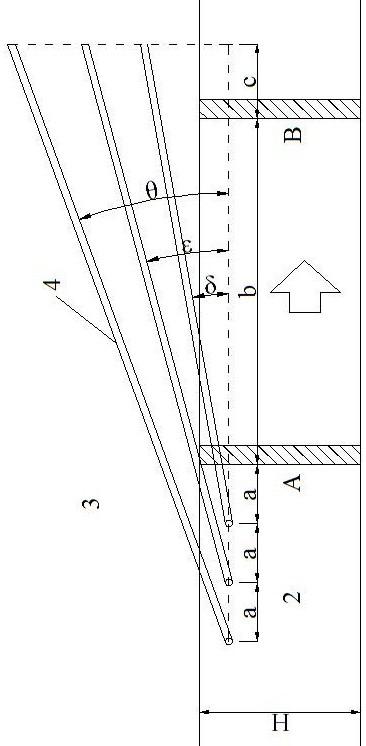

[0023] Such as Figure 1-Figure 7 As shown, the present invention proposes a method for controlling deformation of roadway roof under high-level stress, comprising the following steps,

[0024] (1) Design the section of roadway 1. On the basis of reserved roadway deformation, comprehensively consider the needs of ventilation, transportation, pedestrians, equipment installation and production safety clearance, and determine the reasonable width of roadway 1 as L meters and height as H m;

[0025] (2) Before excavating the roadway 1, closely follow the driving head A, and drill a group of inclined upward leading pressure relief drilling holes 4 on both sides of the roadway roof 3 on the upper part of the two sides 2 of the roadway to unload the high pressure on both sides of the roadway roof 3. Horizontal stress 5, transfer the high level stress 5 to the deep part of the roadway roof 3, and provide deformation compensation space for the surrounding rock 6 at the shoulder angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com