small drone body

A technology for small unmanned aerial vehicles and fuselage, applied in the direction of fuselage frame, toy aircraft, toys, etc., can solve the problems of high cost, increased weight, high strength, etc., to prevent local instability, reduce cost, and reduce aircraft weight and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

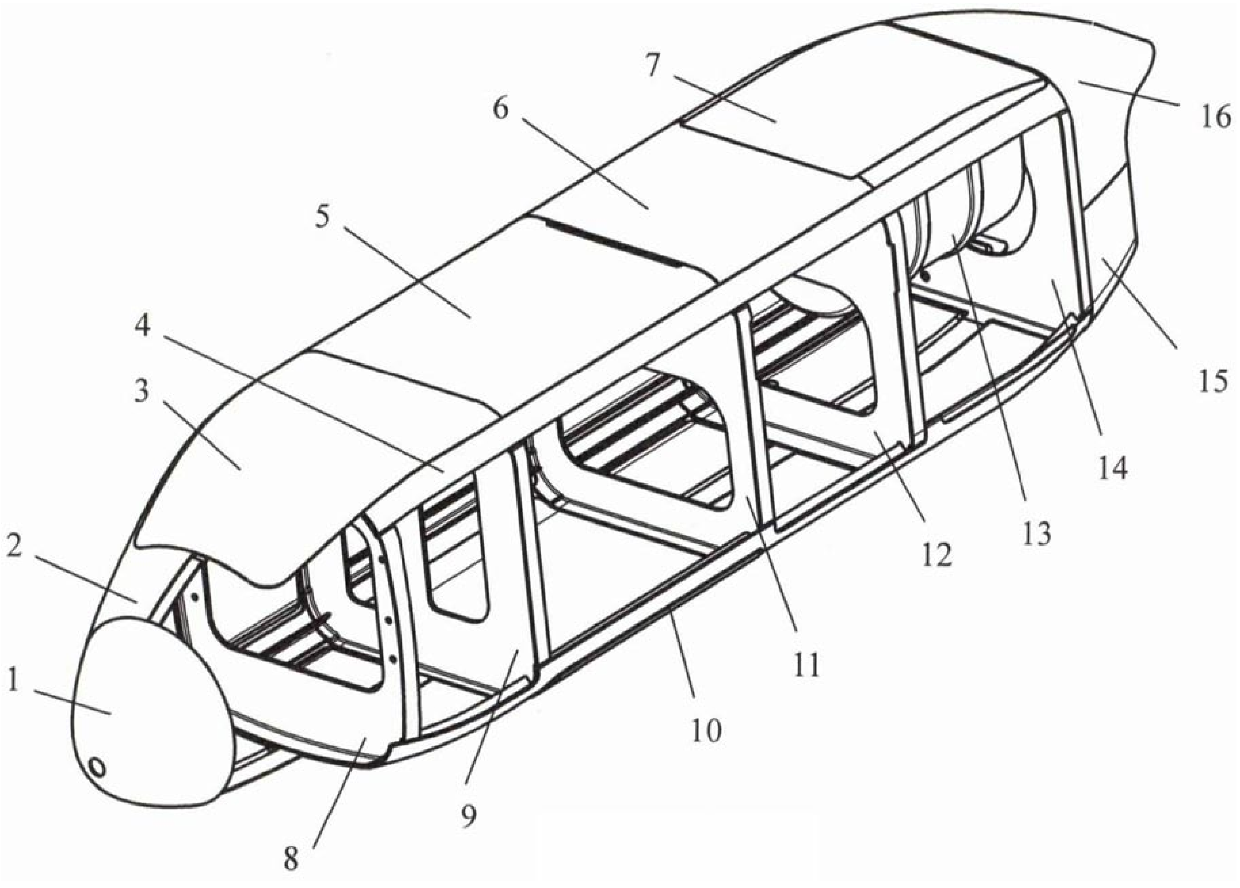

[0019] Fig. 1 describes the main structure of the whole small unmanned aerial vehicle fuselage. The entire fuselage structure can include five frames, four

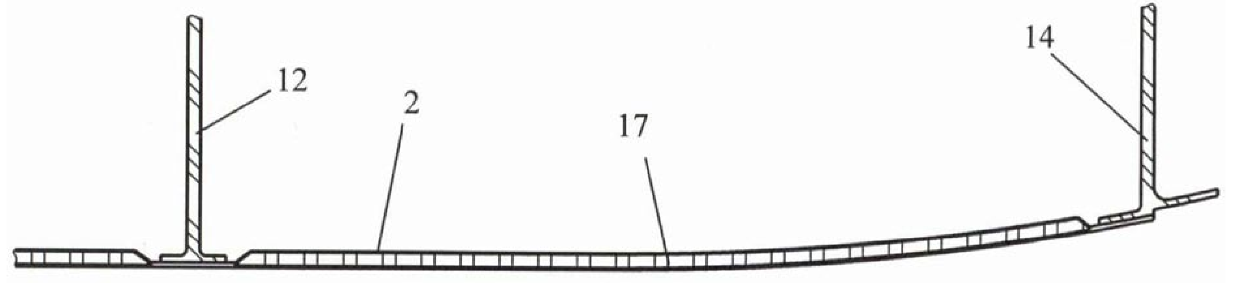

[0022] The stringers are of fiberglass laminate construction. The section of the longitudinal beam is T-shaped, and the edge strips on it are connected with the skin and the mouth cover.

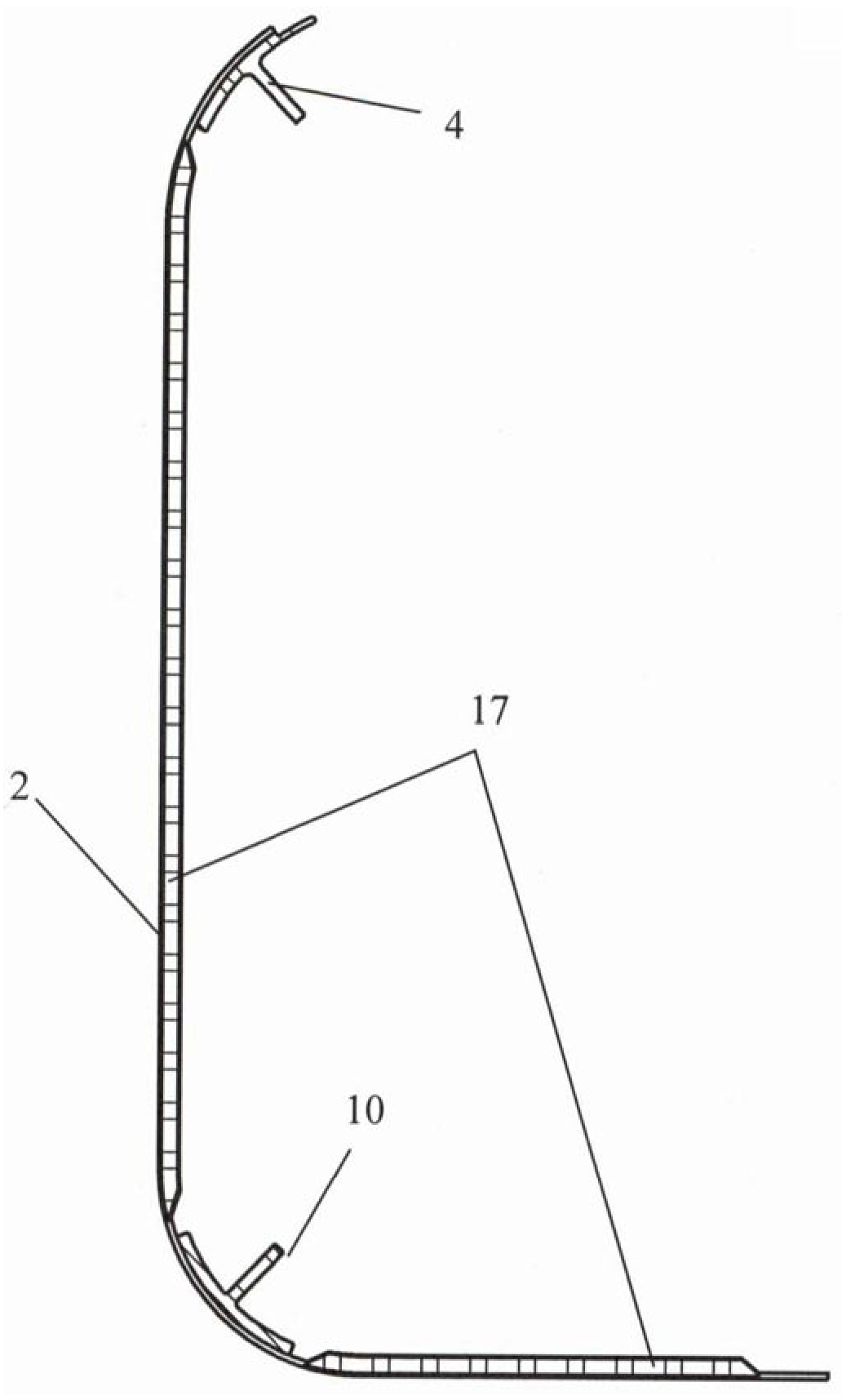

[0023] The right piece skin 2 of non-metallic material is a co-cured sandwich structure of aramid paper honeycomb core and glass fiber panel. folder

[0025] For reducing weight, each mouth cover 3,5,6,7 is the same as the skin, and is a sandwich structure. The edge of the cover is the connecting part, same as

[0026] The nose cover 1 and the umbrella cabin 13 are integral shell structures of glass fiber laminates. Frontmost machine head cover 1 is used for structure

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com