A U-shaped steel support and a method for controlling roadway surrounding rock by graded active loading

A type of steel and roadway technology, which is applied in the field of U-shaped steel brackets and graded active loading control roadway surrounding rock, can solve the problems of insufficient overall rigidity, U-shaped steel brackets can only be passively stressed, and bracket damage, etc., to improve support strength and support The reliability of the support, the avoidance of local instability, and the effect of improving the support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

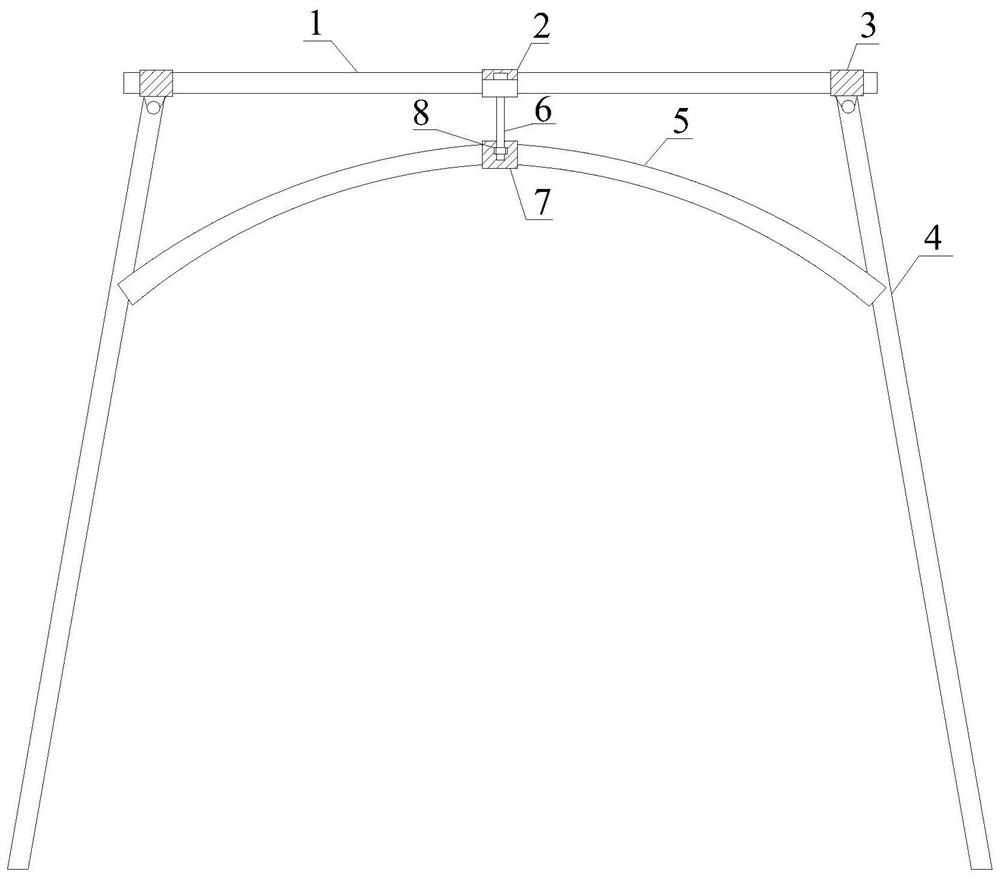

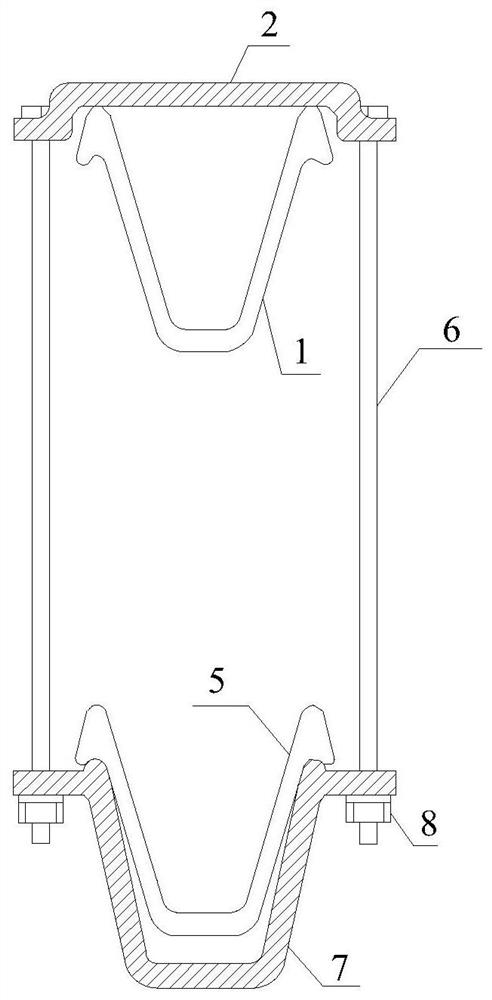

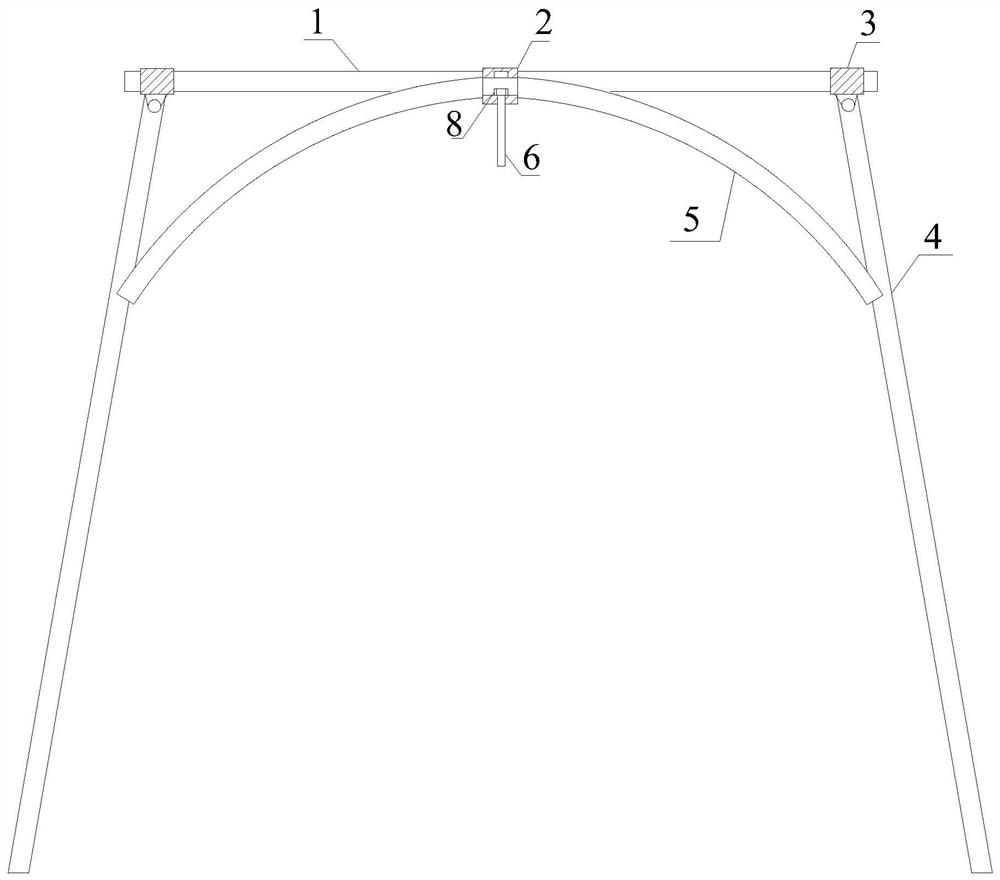

[0032] Such as Figure 1 to Figure 5 As shown, the present invention provides a U-shaped steel bracket, which includes a beam 1, two shed legs 4 arranged at both ends of the beam 1, an arc-shaped cross brace 5 made of U-shaped steel, an upper cable board 2, and a lower cable The plate 7 and two lengthened cross braces load the bolt rods 6; the upper end of the shed leg 4 is fixedly connected to the end of the beam 1 through the connector 3; the beam 1 and the shed leg 4 cannot be made of U-shaped steel;

[0033] The arc-shaped cross brace 5 is arranged at the lower part of the crossbeam 1, and its arc top is arranged close to the crossbeam 1, and its two ends are respectively buckled on the outside of the inner sides of the two shed legs 4, and are in sliding contact with the shed legs 4 Coordination; in actual support, the arc-shaped cross brace 5 is set close to the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com