Method for controlling phase shifting stagger angle of doubly salient motor

A doubly salient motor, angle control technology, applied in the direction of electronic commutation motor control, control system, torque ripple control, etc., can solve the problems of motor torque ripple, etc., to achieve optimized operating performance, simple and fast switching angle, and guaranteed The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

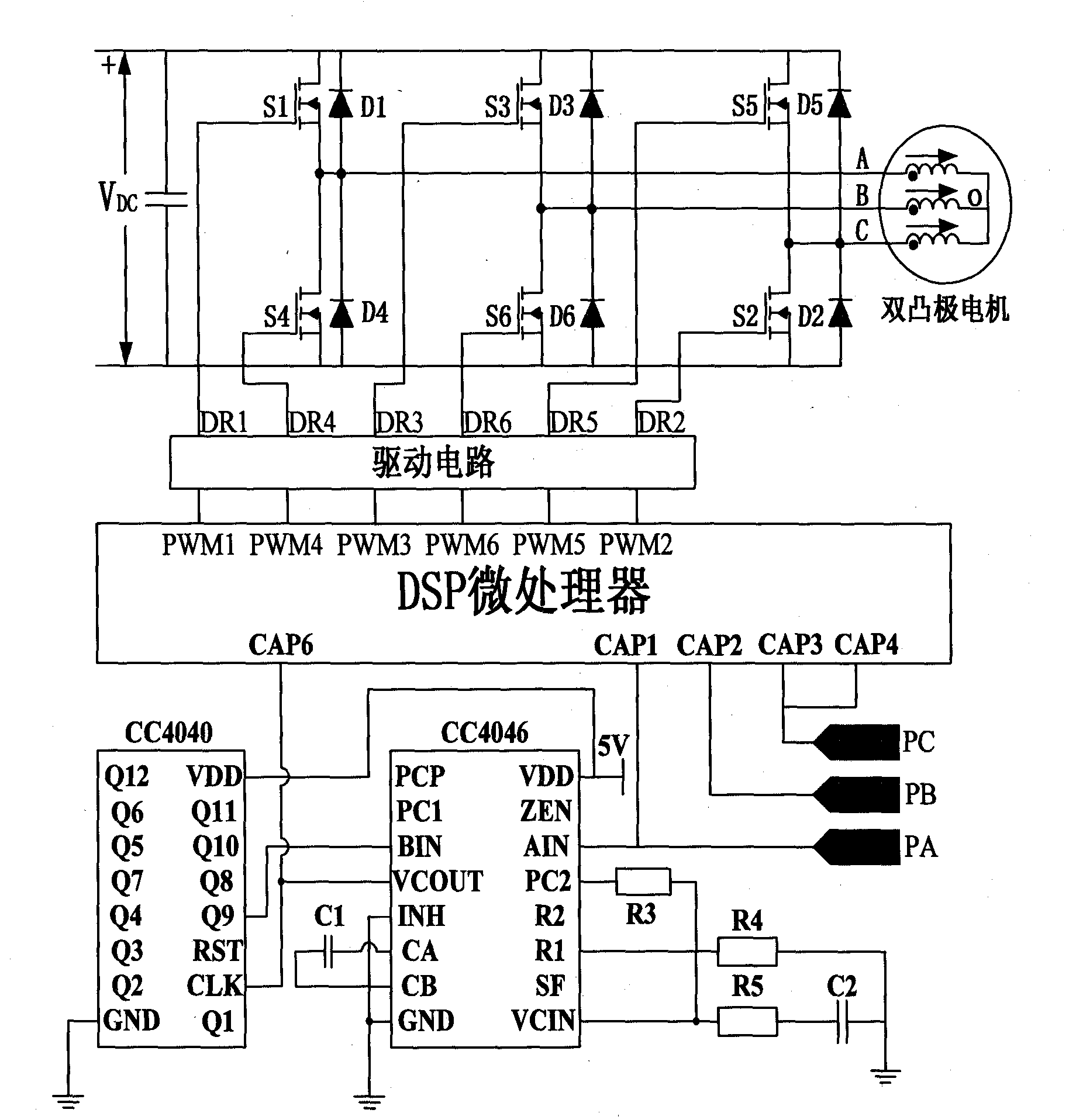

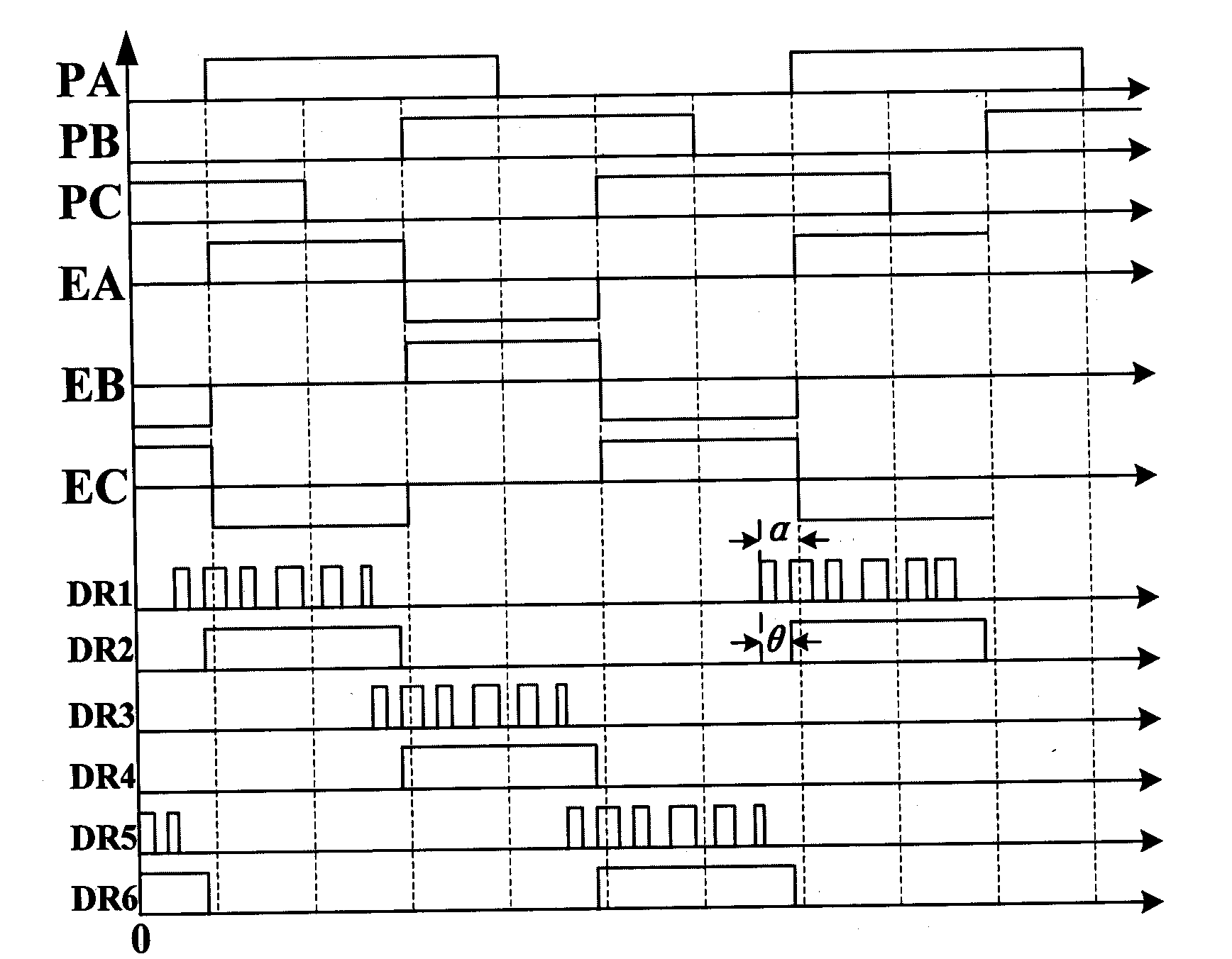

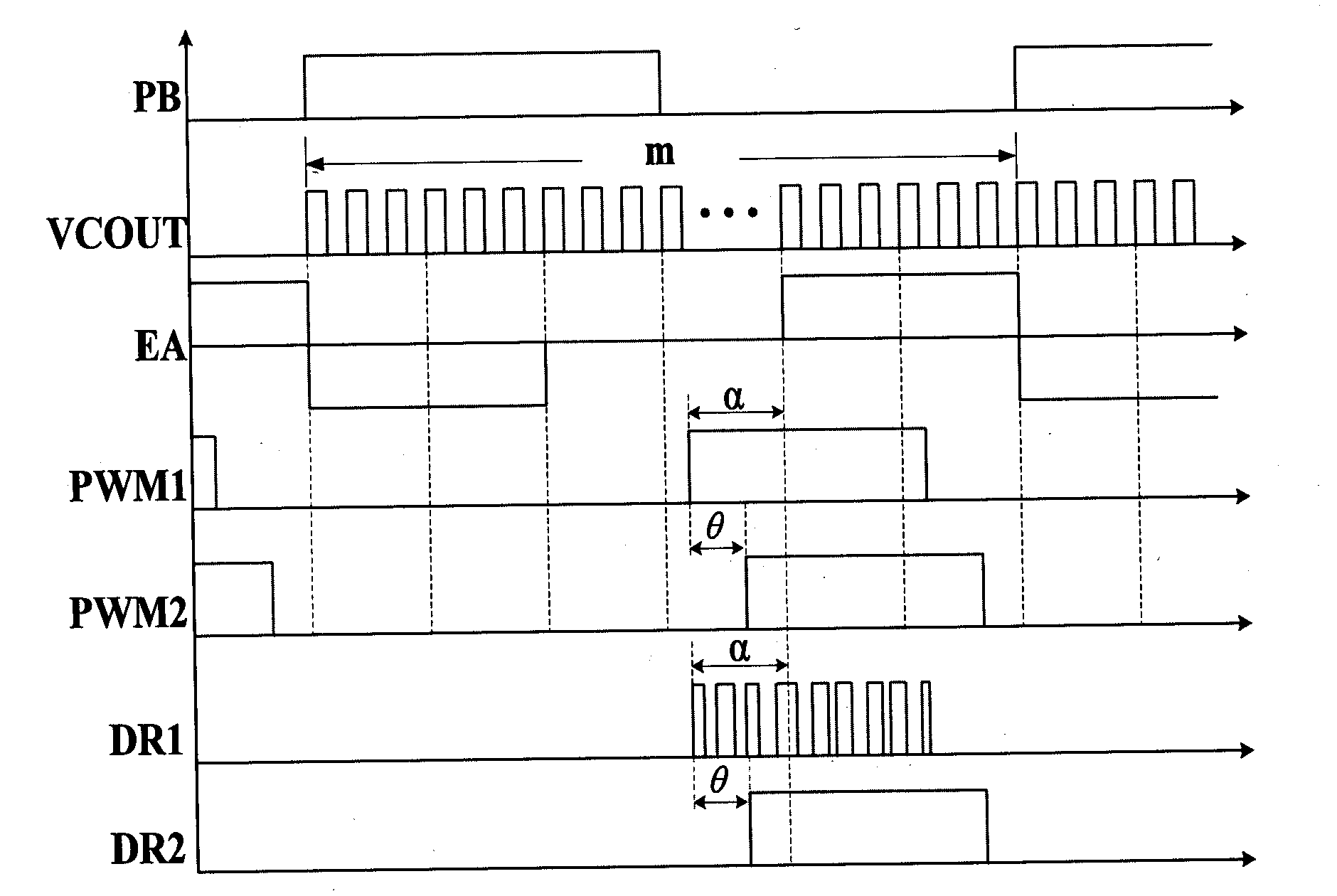

[0017] Such as figure 1 , The phase-shifting interleaving angle control of double salient motor is formed by the combination of software and hardware. The hardware part includes a phase-locked frequency multiplication circuit composed of a twelve binary counter CC4040 and a logic phase-locked loop chip CC4046. Any phase position signal of the three-phase position signal of the double salient motor is processed by the phase-locked frequency multiplication circuit for m multiplication to obtain a multiplier. frequency signal; connect the three-phase position signal and multiplied frequency signal to the capture port of the DSP processor for acquisition and processing. The specific method is: the power switch tubes S1-S6 constitute a three-phase bridge drive circuit, the power switch tubes S1 and S4, the power switch tubes S3 and S6, and the power switch tubes S5 and S2 are connected in series as the A-phase, Phase B and Phase C drive the bridge arm. The midpoint of each phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com