Emergency safety device for car tire explosion

A safety device and tire blowout technology, applied in vehicle parts, tire parts, transportation and packaging, etc., can solve problems such as vehicle steering system and braking system out of control, vehicle skidding, major traffic accidents, etc., to ensure controllability and convenience Effect of replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

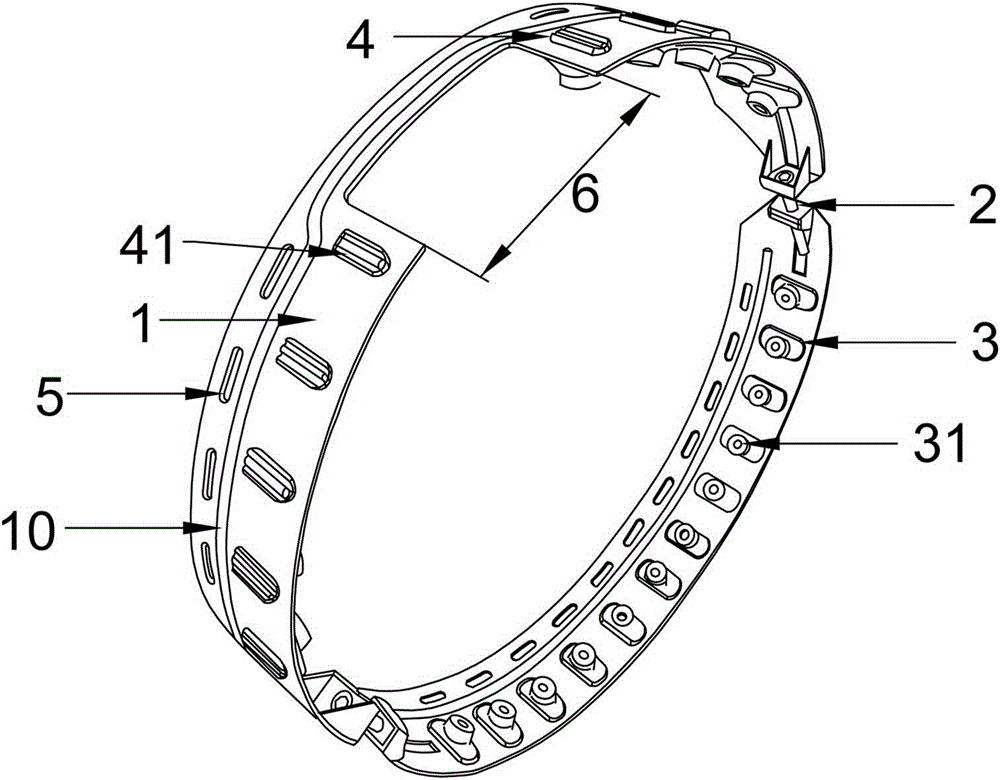

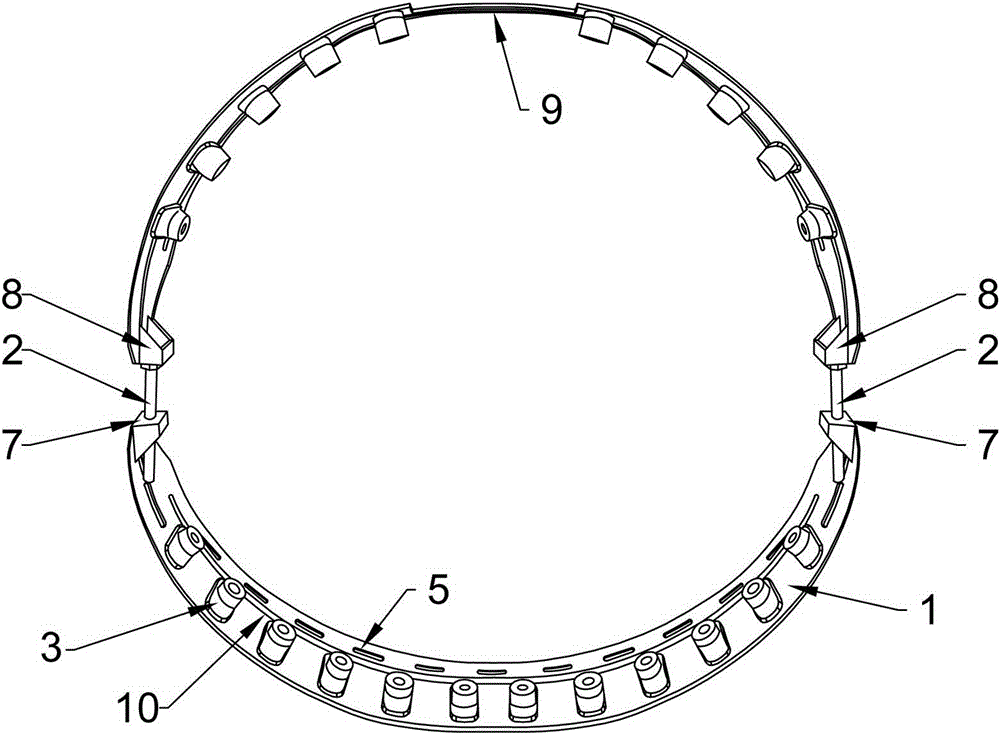

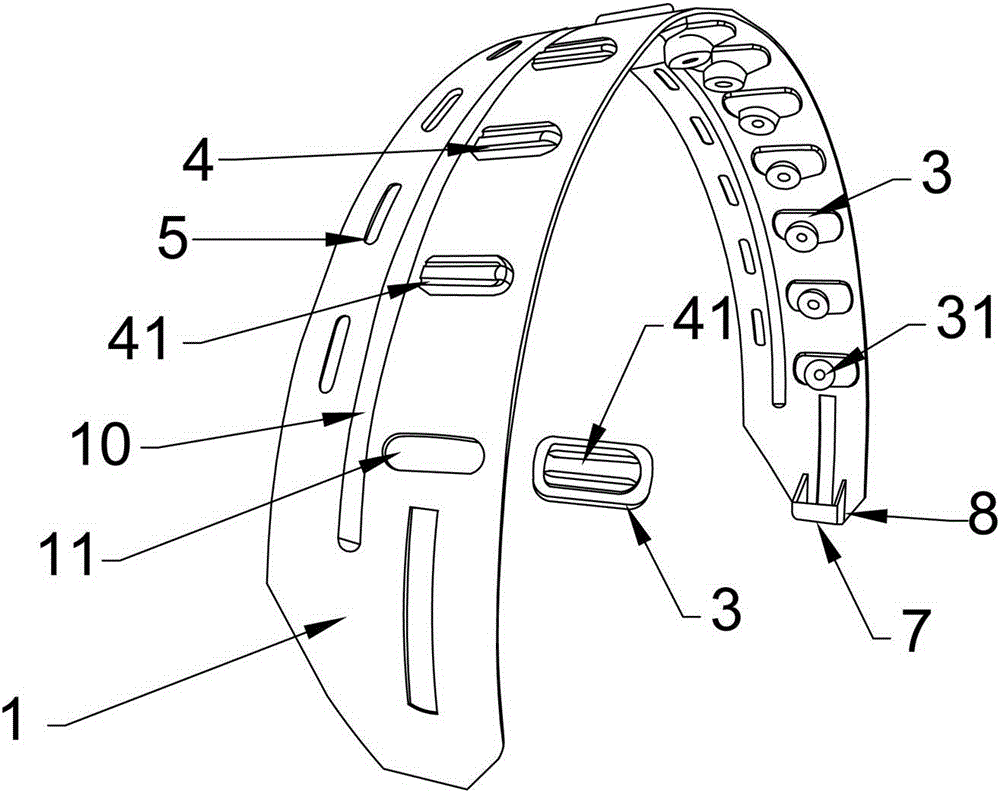

[0036] This embodiment provides an emergency safety device for automobile tire blowout, such as Figures 1 to 3 As shown, the safety device of this embodiment includes a ring composed of two annular support belts 1. The support belt 1 is made of high-strength rigid material, which has high strength and is not easily deformed, and plays a supporting role in the car when the car is blown out or running out of air. . Adjacent ends of two adjacent annular support belts 1 are connected by adjustable fasteners 2 .

[0037]Each support belt 1 is provided with a number of evenly distributed installation grooves 11 , the centers of each installation groove 11 are located on the same circumference of the lower half of the support belt 1 , and are used to install the support block 3 and the toothed engagement bar 4 . The support block 3 is arranged on the radially inner surface of the support belt 1 , and the toothed bite strips 4 and the bite teeth 41 are arranged on the radially outer...

Embodiment 2

[0047] like image 3 As shown, this embodiment is different from Embodiment 1 in that, in actual use, some vehicles are not equipped with a tire pressure monitoring device (TPMS). None of the tire pressure monitoring "concave" mounting positions 6 for the pressure monitoring device (TPMS) need to be provided.

Embodiment 3

[0049] like Figure 10 As shown, this embodiment differs from Embodiment 1 in that the widths of the wheel grooves 12 on the wheel rims 13 of different vehicles are different, so the width of the supporting belt 1 to be installed also changes with the change of the wheel grooves 12 . When the wheel groove 12 is narrow, the support belt 1 is correspondingly narrowed, so that the counterweight balance hole 5 and the "concave"-shaped installation position 6 cannot be opened on the support belt 1; therefore, the installation groove 11 in the length direction of the support belt 1 Position, a reinforcing rib 10 structure is provided on the left and right, which can also achieve the effect of strengthening the structure and the balance of the counterweight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com