Vertical smelting furnace for continuously casting tungsten carbide

A vertical casting, tungsten carbide technology, applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of material oxidation, poor labor conditions, etc., to achieve a small degree of material oxidation, fast cooling, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

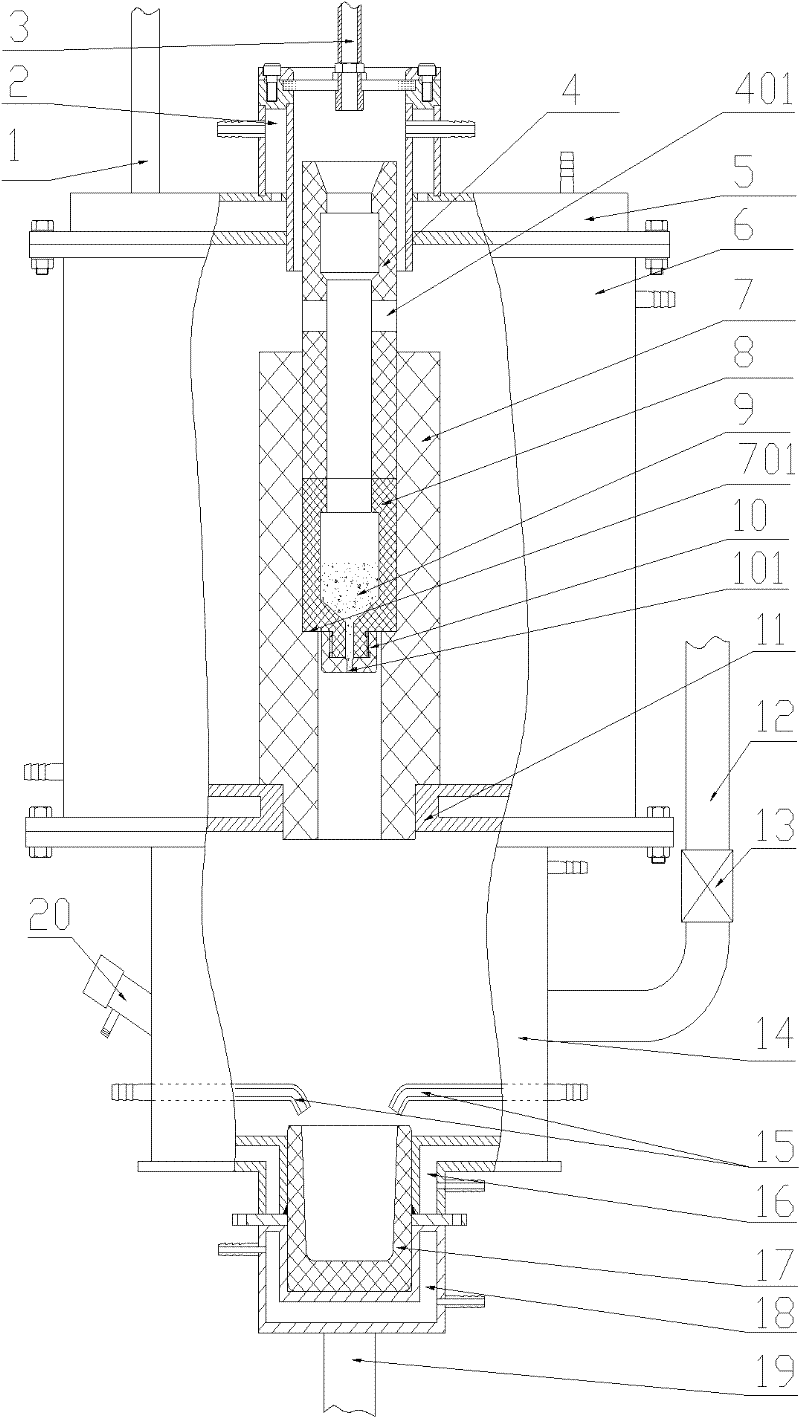

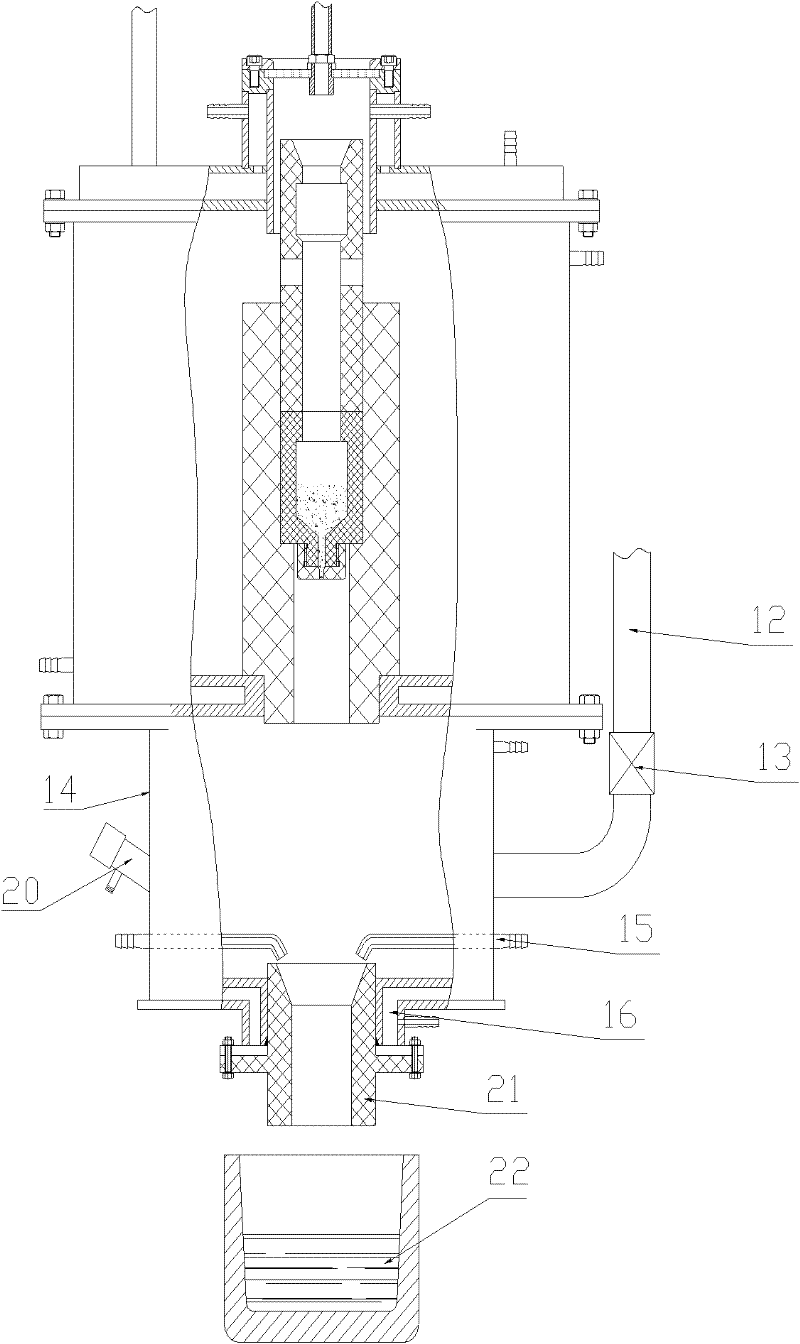

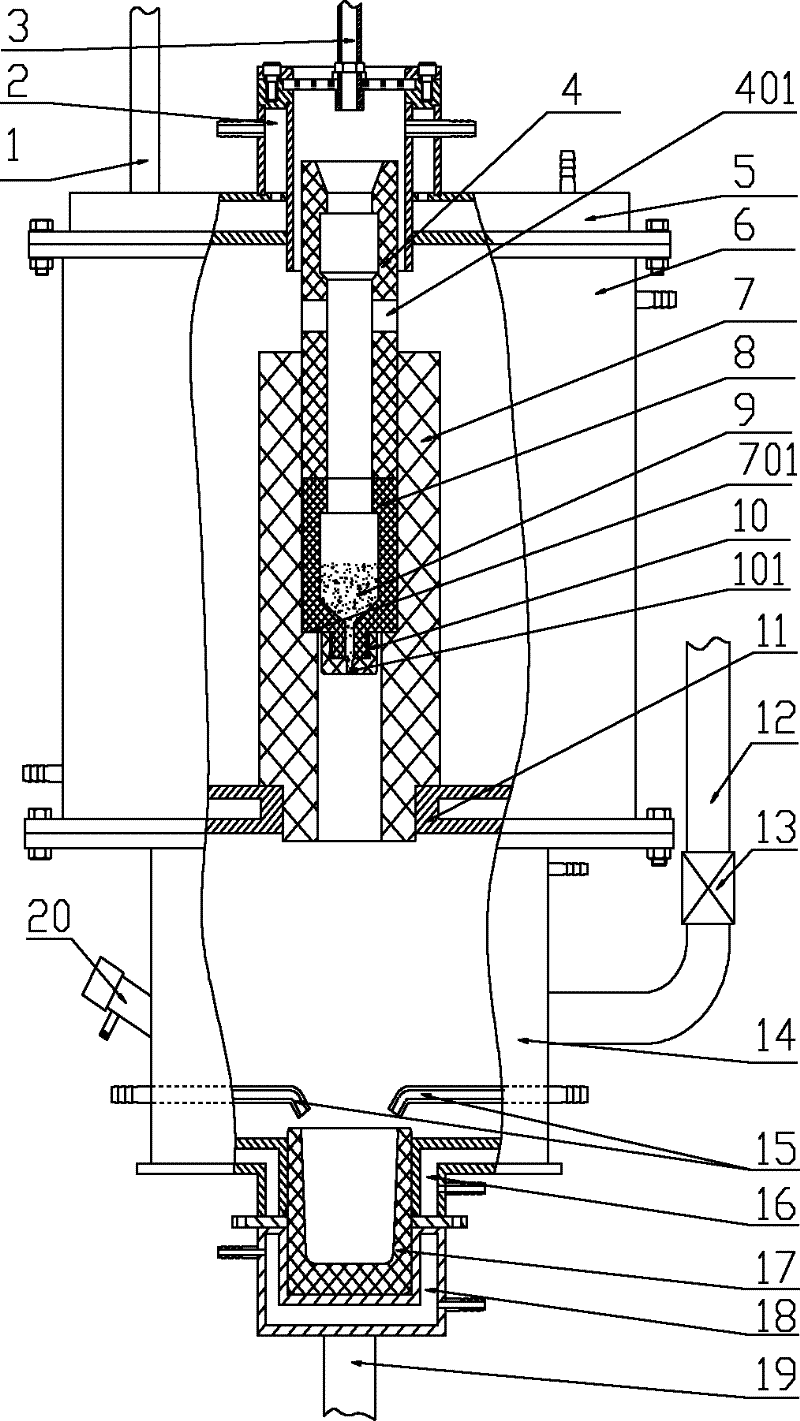

[0016] Referring to the above drawings, a vertical cast tungsten carbide continuous melting furnace includes an upper exhaust pipe 1, an upper furnace nozzle 2, a lower material pipe 3, a top cover 5, an upper cylinder body 6, a heating pipe 7, a funnel 8, and a nozzle 10. The inner support seat 11, the lower cylinder 14 and the cooling device are characterized in that the heating tube 7 in the upper cylinder 6 is provided with a circular graphite funnel 8, that is, the heating tube 7 is provided with an inner step 701 to form A heating channel with a large top and a small bottom. A circular graphite funnel 8 is set on the upper part of the step 701 in the heating channel. The upper part of the funnel 8 is provided with a bushing 4 that prevents the charge from splashing during the feeding and boiling process and has a vent hole 401 on the side wall. , the upper end of the bushing 4 extends into the upper furnace nozzle 2, and the bottom of the funnel 8 is provided with a detac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com