Fastening device applicable to remote-control maintenance

A technology for fastening devices and remote control maintenance, which is applied in the direction of fixing devices, mechanical equipment, etc. It can solve the problems of rigid impact, disassembly and assembly of fastening devices, poor fastening safety, and inflexible movements, so as to ensure disassembly and fastening. The effect of solid security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe the technical content and structural features of the present invention in detail, the following will further explain in conjunction with the embodiments and the accompanying drawings.

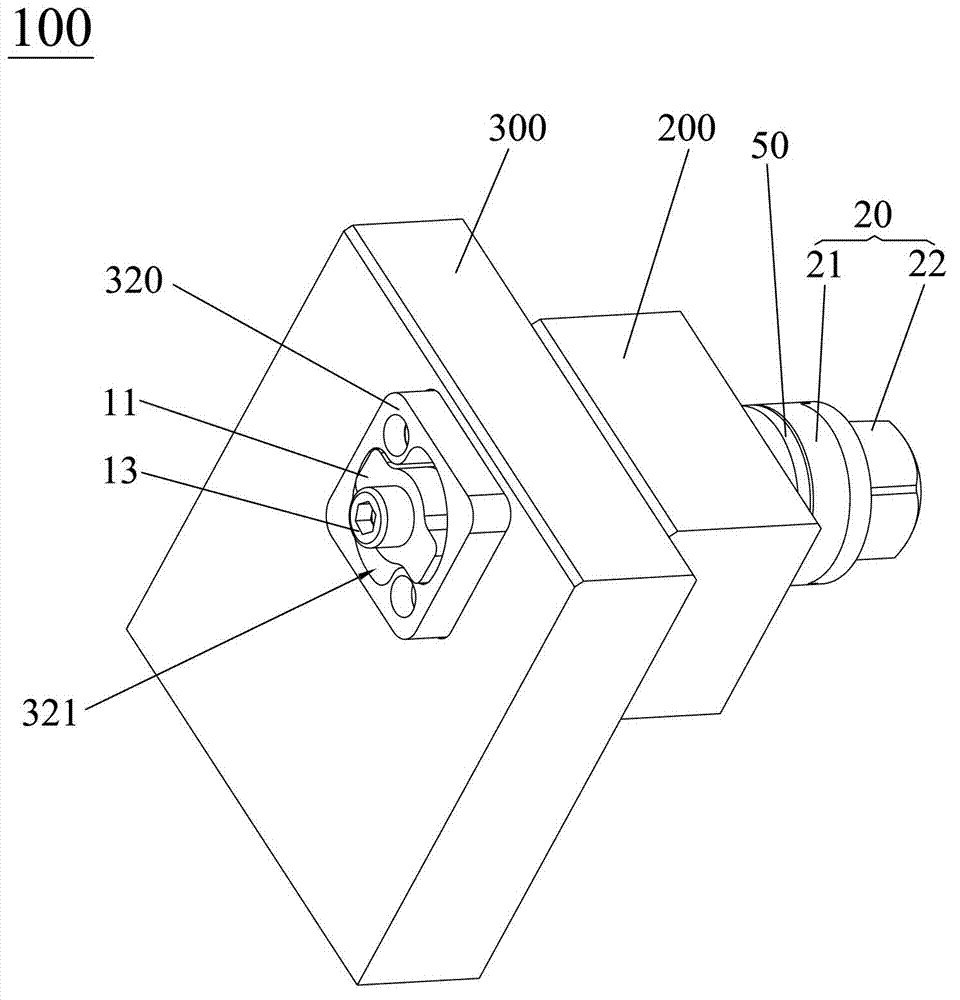

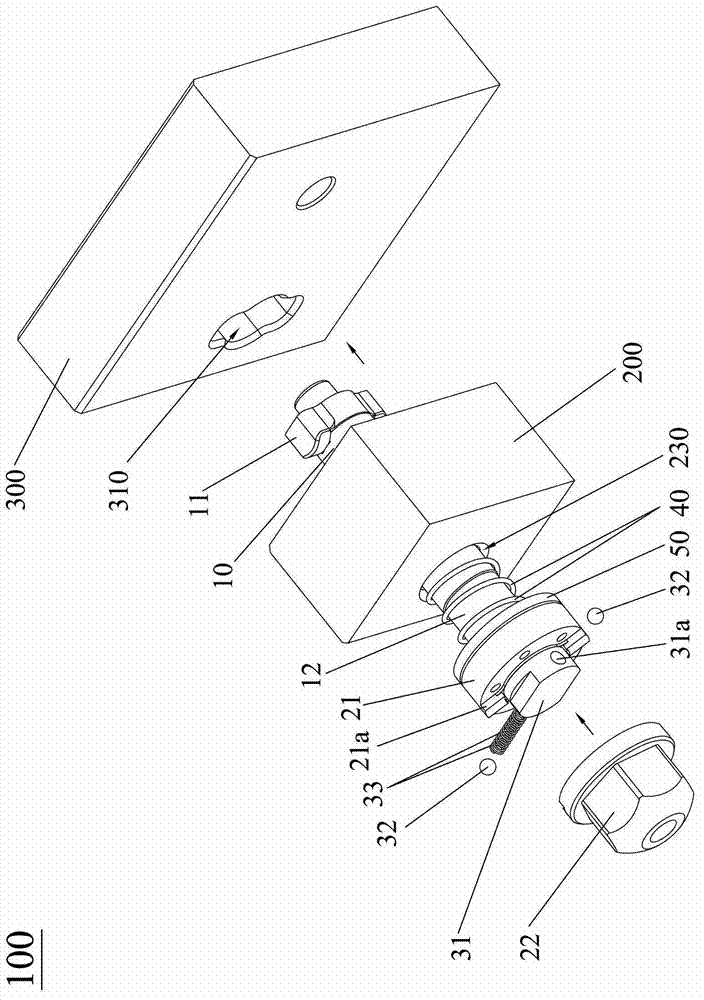

[0027] See Figure 1 to Figure 7 The fastening device 100 that can be used in remote maintenance of the present invention is used to fix the workpiece 200 on the support 300, wherein the fastening device 100 that can be used in remote maintenance of the present invention includes a screw 10, a nut structure 20, and a stop 出Component 30. The rear end of the screw 10 has a rotating block 11. Specifically, in this embodiment, the rotating block 11 is fixed to the rear end of the screw 10 by a screw 13 so that the rotating block 11 is on the screw 10 The installation of the screw 10 and the installation of the screw 10 on the workpiece 200; and the front end of the screw 10 passes through the workpiece 200. Specifically, the workpiece 200 is provided with a through hole 210 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com