Frictional anchorage device applied to fibre reinforced composite cables

A technology of fiber composite materials and composite materials, which is applied in the field of anchors for fiber-reinforced composite tendon cables, and can solve problems such as bending fatigue at the end of the bonded area and bending fatigue at the end of the stress uniformity boosting area. , to achieve the effect of simple installation, lower lateral pressure and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

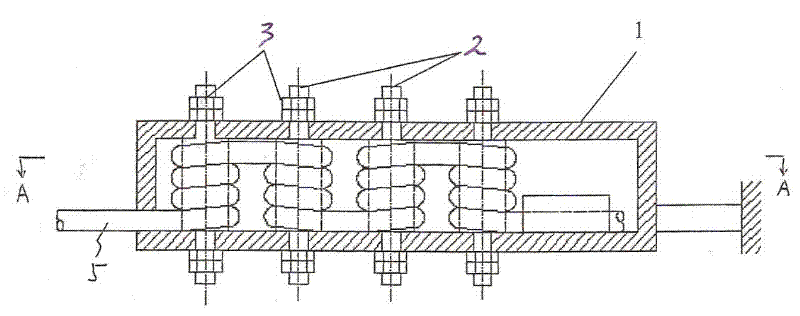

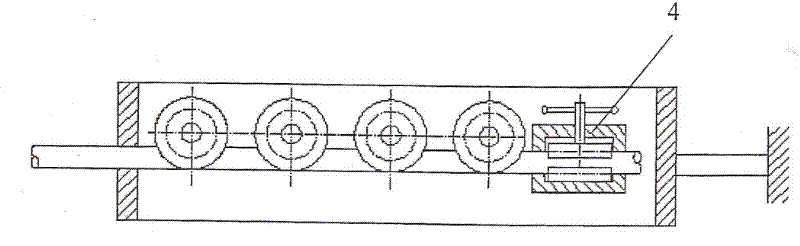

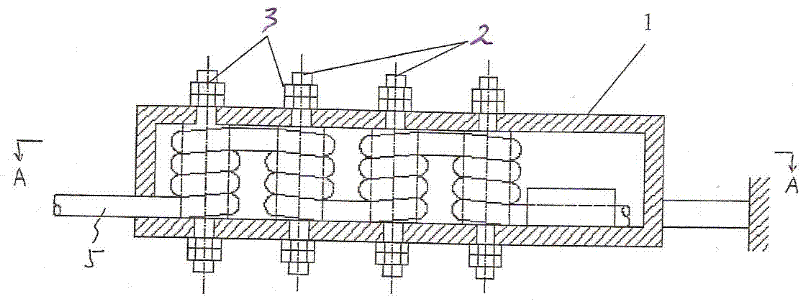

[0018] A friction anchor applied to fiber-reinforced composite tendon cables, comprising a frame 1 on which a plurality of fixed shafts (circular shafts) 2 wrapped around fiber composite tendon cables 5 are arranged, and the last The rear of the fixed shaft is provided with a helical pressure fastener 4 that compresses and fixes the end of the fiber composite tendon cable. The surface of the fixed shaft is in the form of a spiral groove matched with the fiber composite tendon cable, the width of the spiral groove is the same as the diameter of the fiber composite tendon cable, and the fiber composite tendon cable is wound in the spiral groove. Both ends of the fixed shaft are stepped. The screw pressure fastener is fixed on the frame. The two ends of the fixed shaft are fixed on the frame by fixing nuts 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com