Electrostatic spinning and spunlacing consolidation composite membrane-making device

A technology of electrospinning and spunlace consolidation, used in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as poor strength of non-woven membranes, and achieve the effect of improving strength and thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

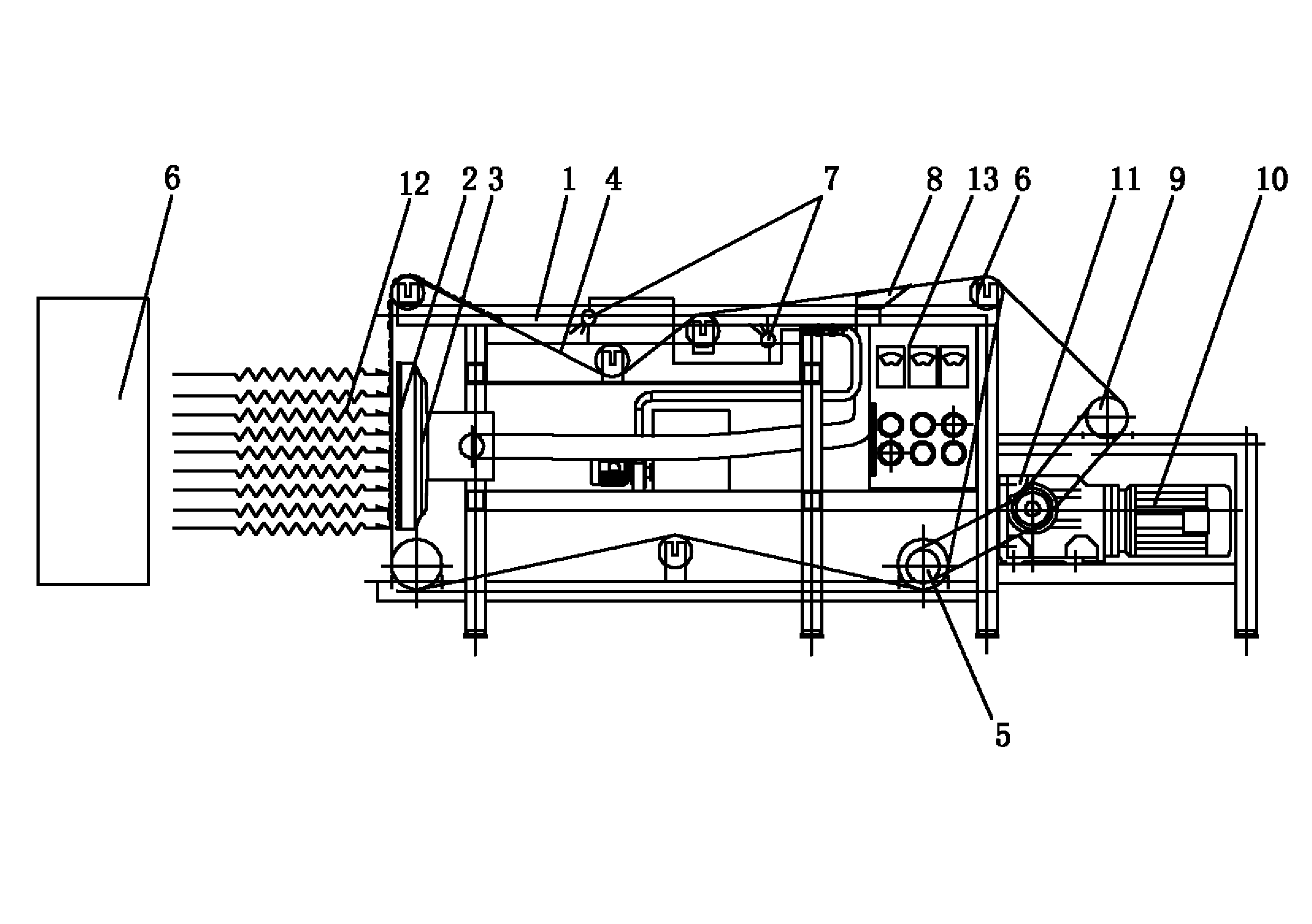

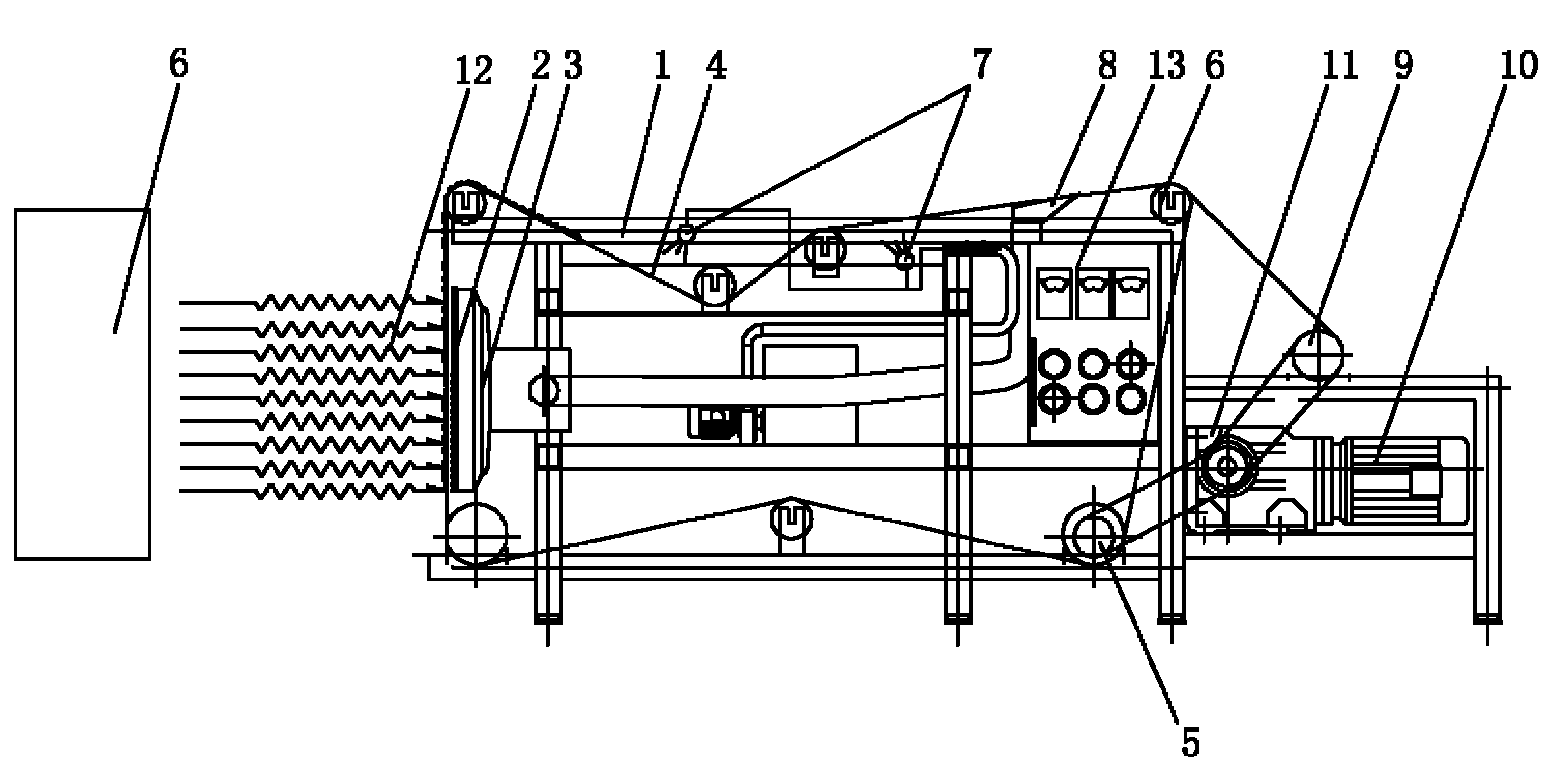

[0017] Embodiment 1 of electrospinning of the present invention and spunlace consolidation composite film-making device, such as figure 1 As shown, it consists of a frame 1, an electrospinning generating device 6 for jetting electrospinning liquid and combining with a receiving device to generate fiber filaments, a receiving device 2 for receiving fiber filaments, an airflow adsorption device 3, a holding net belt 4, A group of guide rollers 5, spunlace heads 7, airflow drying device 8, film winding reel 9, driving device 10 and speed regulating device 11 are composed. The frame 1 adopts a frame structure, the receiving device 2 is arranged on the front side of the frame 1, and the receiving device 2 adopts a mesh electrode, that is, a receiving electrode network; the electrospinning generating device 6 is correspondingly arranged on the front side of the receiving device 2; The supporting net belt 4 is ring-shaped, supported on the frame 1 by the guide roller 5 and can rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com