High-strength heat-resistant conveying belt covering rubber material and preparation method thereof

A conveyor belt and covering rubber technology, which is applied in the field of transport conveyor belts, can solve the problems of affecting the service life of conveyor belts and reducing the performance of rubber conveyor belts, and achieve the effects of improving impact resistance, improving mechanical properties, and increasing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

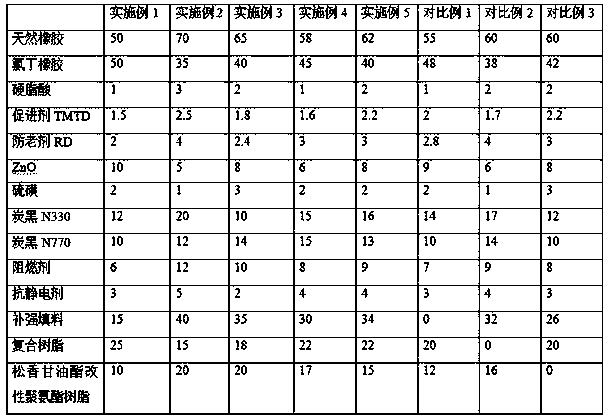

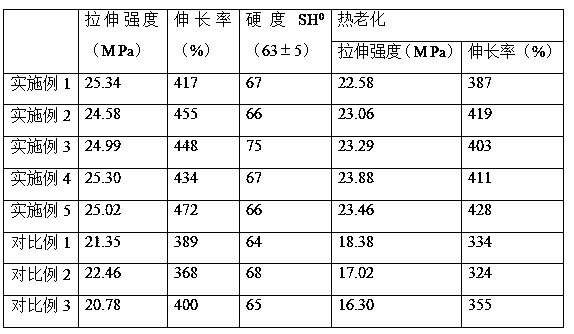

Embodiment 1

[0016] A preparation method of a high-strength heat-resistant conveyor belt covering rubber material, comprising the following steps:

[0017] S1. First add natural rubber and chloroprene rubber into the open mill and masticate, then add stearic acid, ZnO, accelerator TMTD, antioxidant RD, carbon black N330, carbon black N770, flame retardant (mass ratio m 阻燃剂TBC :m 三氧化二锑 =3:2), antistatic agent (mass ratio m 乙炔炭黑 :m 抗静电剂SN =1:1), then cut the knife 4 times, thin pass 3 times, so that the additives can be evenly dispersed;

[0018] S2. Then add reinforcing filler (mass ratio m 纳米二氧化硅复合材料 :m 硅烷偶联剂改性绢云母粉 =3:1), composite resin, rosin glyceride modified polyurethane resin, sulfur, cutting knife 3 times, and thinning 4 times, wherein, the preparation method of silica composite material is to mix ethyl orthosilicate, anhydrous After mixing ethanol, hydrochloric acid and silane coupling agent evenly, hydrolyze at 55°C for 6 hours to obtain a sol, then heat and evaporate to obta...

Embodiment 2

[0021] A preparation method of a high-strength heat-resistant conveyor belt covering rubber material, comprising the following steps:

[0022] S1. First add natural rubber and chloroprene rubber into the open mill and masticate, then add stearic acid, ZnO, accelerator TMTD, antioxidant RD, carbon black N330, carbon black N770, flame retardant (mass ratio m 阻燃剂TBC :m 氢氧化铝 =1:1), antistatic agent (mass ratio m 乙炔炭黑 :m 抗静电剂SN =1:2), then cut the knife 6 times, thin pass 3 times, so that the additives can be evenly dispersed;

[0023] S2. Then add reinforcing filler (mass ratio m 纳米二氧化硅复合材料 :m 硅烷偶联剂改性绢云母粉 =3:1), composite resin, rosin glyceride modified polyurethane resin, sulfur, cutting knife 3 times, and thinning 4 times, wherein, the preparation method of silica composite material is to mix ethyl orthosilicate, anhydrous After mixing ethanol, hydrochloric acid and silane coupling agent evenly, hydrolyze at 55°C for 6 hours to obtain a sol, then heat and evaporate to obtai...

Embodiment 3

[0026] A preparation method of a high-strength heat-resistant conveyor belt covering rubber material, comprising the following steps:

[0027] S1. First add natural rubber and chloroprene rubber into the open mill and masticate, then add stearic acid, ZnO, accelerator TMTD, antioxidant RD, carbon black N330, carbon black N770, flame retardant (mass ratio m 阻燃剂TBC :m 氢氧化铝 =3:1), antistatic agent (mass ratio m 乙炔炭黑 :m 抗静电剂SN =3:1), then cut the knife 5 times, thin pass 3 times, so that the additives can be evenly dispersed;

[0028] S2. Then add reinforcing filler (mass ratio m 纳米二氧化硅复合材料 :m 硅烷偶联剂改性绢云母粉 =2:5), composite resin, rosin glyceride modified polyurethane resin, sulfur, cutting knife 3 times, thin pass 3 times, wherein, the preparation method of silica composite material is to mix ethyl orthosilicate, anhydrous After mixing ethanol, hydrochloric acid and silane coupling agent evenly, hydrolyze at 55°C for 6 hours to obtain a sol, then heat and evaporate to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com