Winding forming equipment and process based on mixed alpha winding technology

An alpha winding and forming equipment technology, applied in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve the problems of layering, cable winding, and low yield of wireless charging coil products. Long life, high precision, and the effect of meeting bending requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

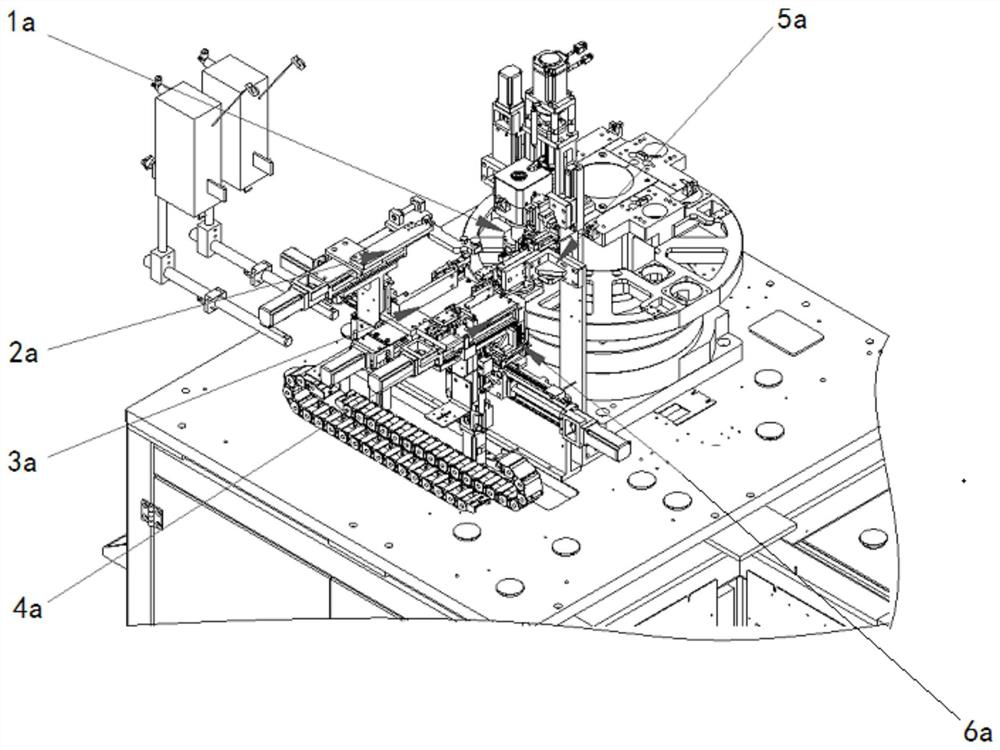

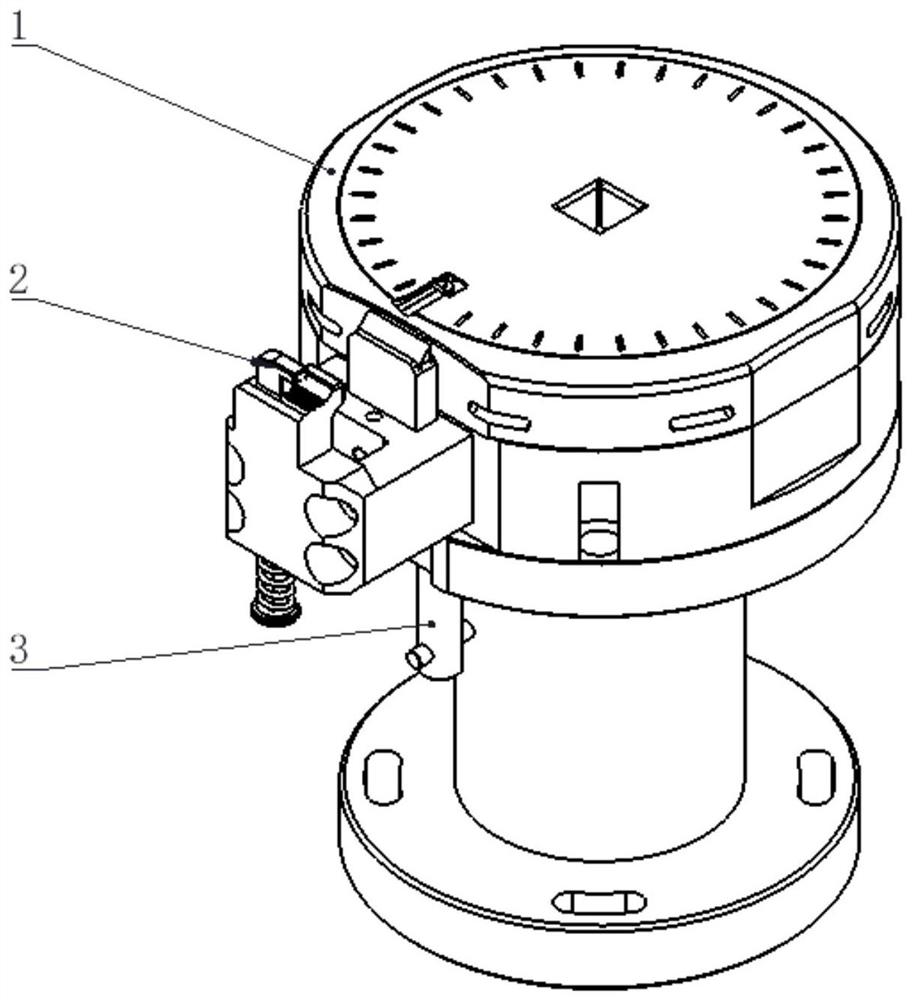

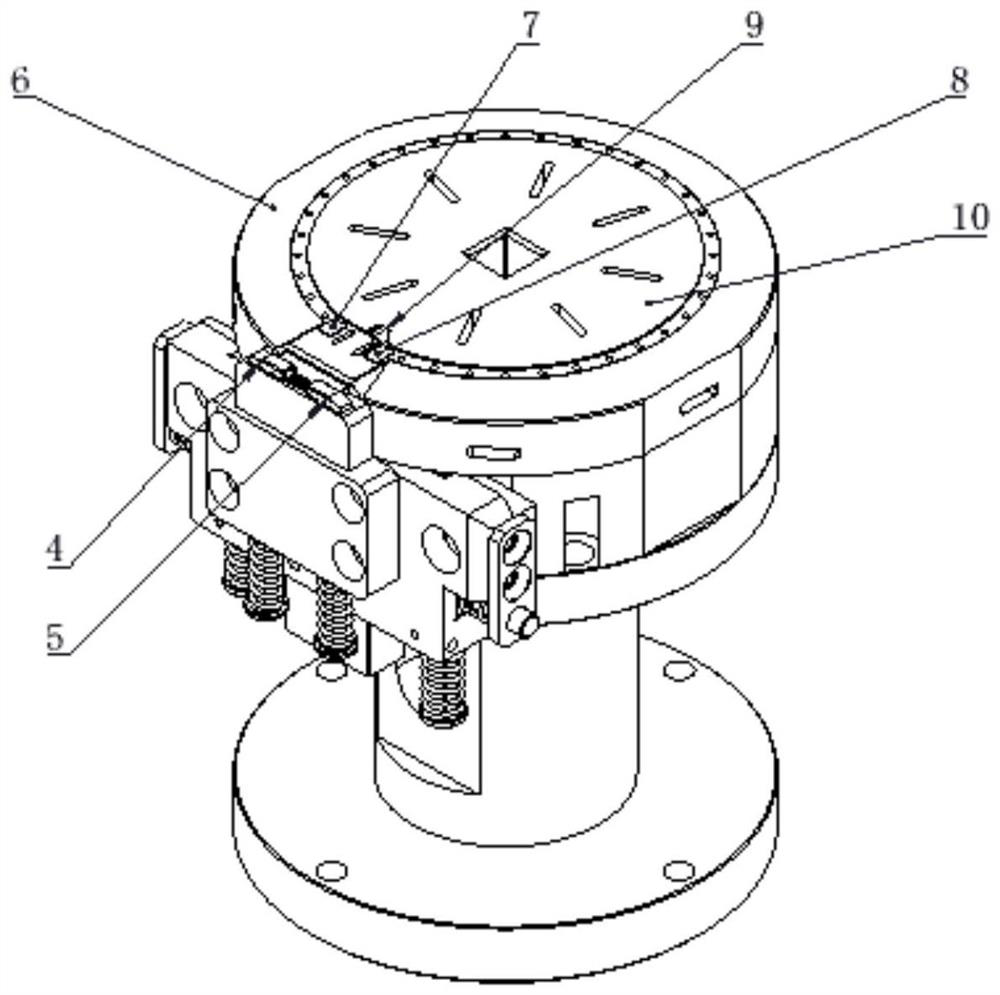

[0040] In the embodiment of the present invention, such as Figure 1-3 As shown, a winding forming equipment based on hybrid alpha winding technology includes an operation table; upper and lower mold groups 1a are installed on the operation table, and the upper and lower mold groups 1a are composed of an upper mold and a lower mold; and upper and lower molds Bending pins, wire clips and mold cores 10 are arranged on the group 1a, and one or more enameled wires are wound into a specified shape by using the bending pins, wire clips and mold cores 10, including cable bending;

[0041] A wire passing mechanism 2a and a wire clamping mechanism 3a are installed on the operating table on the side of the upper and lower mold groups 1a;

[0042] The sides of the upper and lower mold groups 1a are equipped with a straightening wire entry module 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com