Hydrophobic and lipophilic composite needle-punched nonwoven fabric and preparation method thereof

A technology of composite needles and non-woven fabrics, which is applied in non-woven fabrics, textiles and papermaking, and general water supply and conservation, and can solve problems such as poor absorption capacity, unsatisfactory oil absorption rate, and low oil-water separation efficiency, and achieve the effect of preventing water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

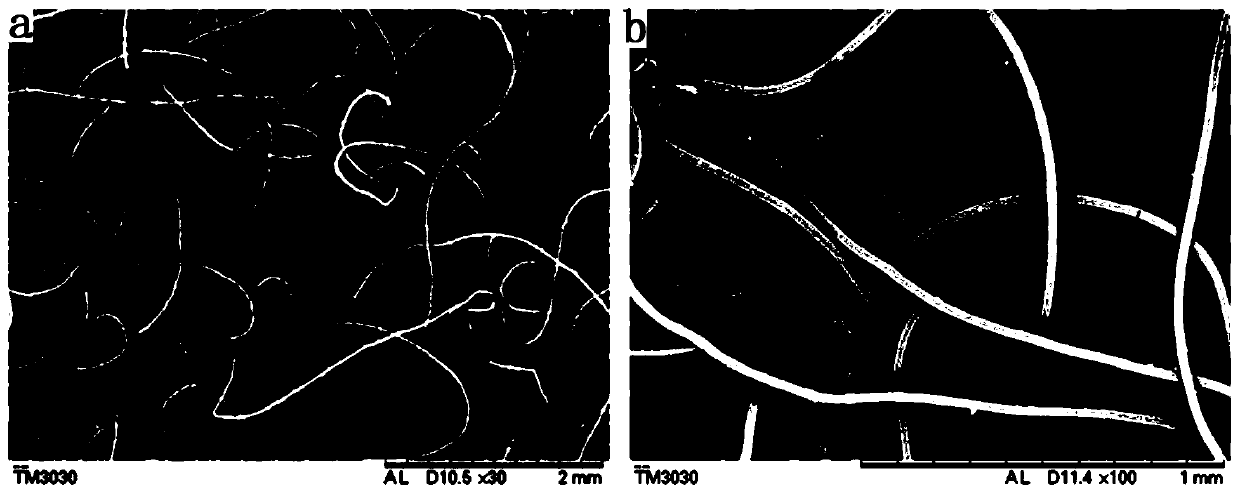

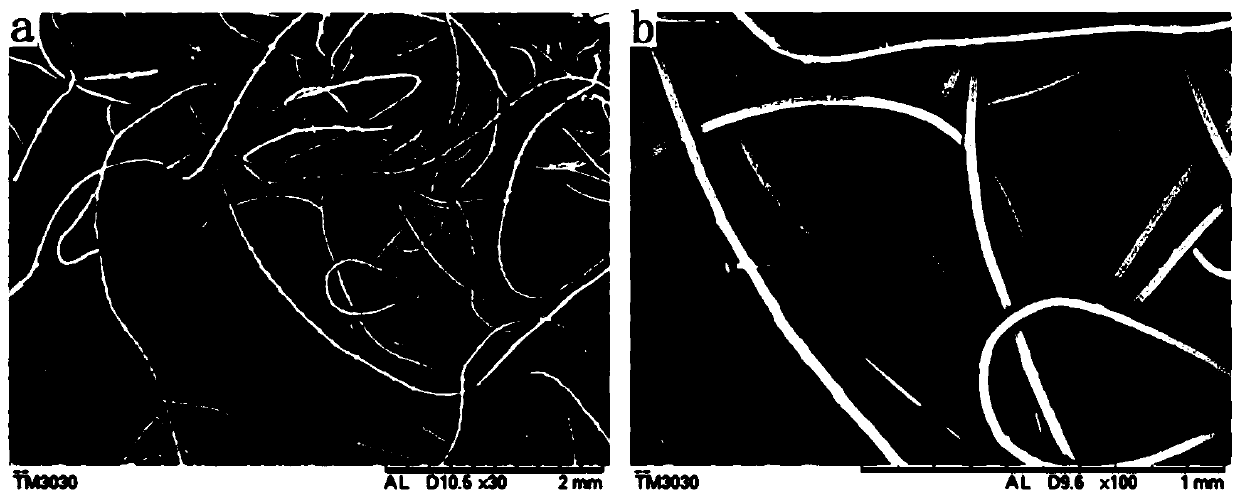

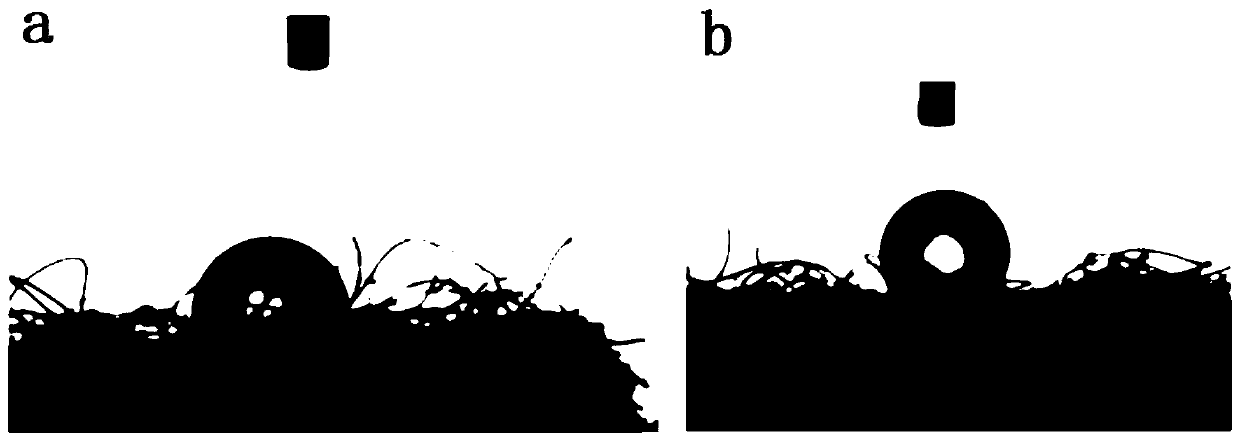

Image

Examples

Embodiment 1

[0044] (1) Preparation of PET / ES needle-punched non-woven fabric: fully mix PET fiber and ES fiber at a mass ratio of 3:1, and then process the blended fiber by needle punching process: PET / ES Opening and mixing → carding into web → lapper → pre-needling → main needling to obtain PET / ES needle-punched non-woven fabric. In order to increase the strength of the non-woven fabric, the pre-needled material was laminated for main needling, and the power frequency was set to 13Hz.

[0045] (2) Take part of the PET / ES needle-punched non-woven fabric prepared in step (1) for heat-drying treatment, put the sample into an oven, and heat-dry it for 60 minutes at a temperature of 120°C.

[0046] (3) Then use a fluorine-free water repellent aqueous solution with a concentration of 50mL / L to perform water-repellent treatment on the sample that has been heated and baked. The bath ratio of the fluorine-free water repellent aqueous solution to the sample is 10:1-20:1. Process flow: PET / ES need...

Embodiment 2

[0048] Hydrophobic and lipophilic composite needle-punched nonwoven fabrics were prepared according to the method of Example 1, except that in step (1), the mass ratio of PET fibers to ES fibers was 1:1.

Embodiment 3

[0050] Hydrophobic and lipophilic composite needle-punched nonwoven fabrics were prepared according to the method of Example 1, except that in step (1), the mass ratio of PET fibers to ES fibers was 1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com