Alkali etching and polishing method for monocrystalline silicon wafer

A monocrystalline silicon wafer, alkali etching technology, applied in the direction of polishing composition containing abrasives, chemical instruments and methods, preparation of organic compounds, etc., can solve the increasingly high requirements for silicon wafers of solar cells Problems such as reflectivity and etching and polishing loss need to be improved to achieve good etching and polishing effects, improved photoelectric conversion efficiency, and low thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

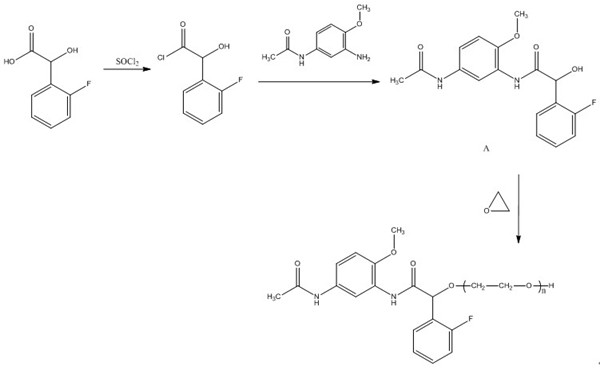

[0066] This embodiment provides a fluorine-containing nonionic surfactant, which is specifically prepared by the following method:

[0067] 1) Add 20.4 parts by weight of D-o-fluoromandelic acid to 60 parts by weight of dichloromethane, add 0.2 parts by weight of tetrabutylammonium halide, stir evenly, add 17.8 parts by weight of thionyl chloride, and stir at 115°C for reaction 8h, normal pressure distillation, obtain 21.2gD-o-fluoromandeloyl chloride, the molar yield is 93.9%;

[0068] 2) 18.1 parts by weight of 3-amino-4-methoxyacetanilide, the D-o-fluoromandelic acid chloride prepared in step 1) are added to 40 parts by weight of methylene chloride, and 0.08 parts by weight of 4-aminopyridine is added. Adjust the pH to 9.6 with sodium hydroxide solution, stir and react at room temperature for 12 hours, evaporate the solvent under reduced pressure, extract the residue with dichloromethane, wash with hydrochloric acid and deionized water in turn to obtain 30.5 g of product A,...

Embodiment 2

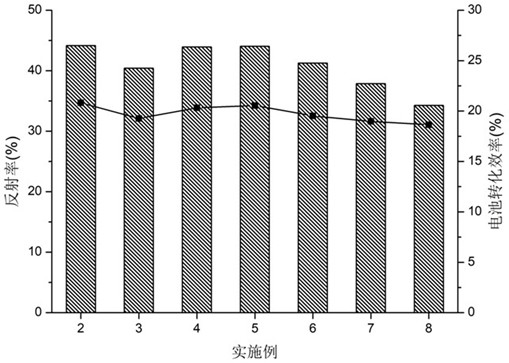

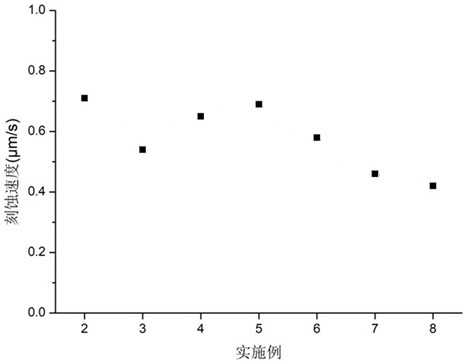

[0072] This embodiment provides an alkali etching and polishing method for a single crystal silicon wafer, comprising the following steps:

[0073] 1) Surface pretreatment: use 10wt% hydrofluoric acid solution to pretreat the monocrystalline silicon wafer to remove the phosphosilicate glass layer on the back;

[0074] 2) Surface etching and polishing: 8 parts by weight of lanthanum oxide (with a particle size of 50 nm, the same below), 0.6 parts by weight of glycerin, 0.3 parts by weight of sodium tartrate, 1 part by weight of 2-methylaminoethanol, and 0.4 parts by weight of the product prepared in Example 1 The obtained fluorine-containing nonionic surfactant and 89.7 parts by weight of deionized water were evenly mixed to obtain a polishing solution, and the back of the silicon chip was etched and polished at a temperature of 50° C. for 8 minutes. Microwave treatment was used to assist in the polishing process; microwave The processed power is 300W;

[0075] 3) Surface clea...

Embodiment 3

[0080] This embodiment provides another alkali etching and polishing method for a single crystal silicon wafer. The only difference from Example 2 is that the polishing liquid consists of 8 parts by weight of lanthanum oxide, 0.6 parts by weight of glycerin, 0.16 parts by weight of sodium tartrate, 1 It is prepared by mixing parts by weight of 2-methylaminoethanol, 0.4 parts by weight of the fluorine-containing nonionic surfactant prepared in Example 1, and 89.84 parts by weight of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com