Oil-water separator for numerically-controlled machine tool

A technology of oil-water separator and numerically controlled machine tools, which is applied in the field of numerically controlled machine tools, and can solve problems such as blockage of the connection end face of the oil-water separator and the discharge port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

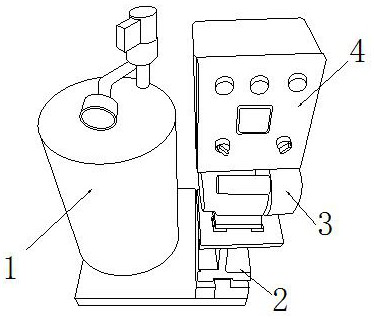

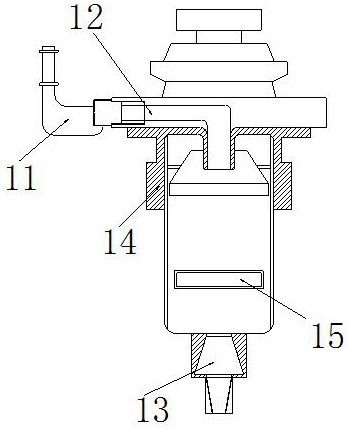

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The invention provides an oil-water separator for a numerically controlled machine tool, the structure of which includes a separation mechanism 1, a fixed base 2, a motor 3, and a control center 4. The separation mechanism 1 is embedded and installed directly above the fixed base 2, and the fixed base 2 is provided with a motor 3, the motor 3 is located on the right side of the separation mechanism 1, and the control center 4 is installed and fixed directly above the motor 3 by welding; the separation mechanism 1 includes a connecting pipe 11, a flow pipe 12. Confluence port 13, filter element housing 14, separation port 15, the connecting pipe 11 is nested and installed on the left side of the flow pipe 12, the flow pipe 12 is inlaid directly above the filter element shell 14, the confluence port 13 is embedded and installed directly below the separation port 15, and the filter element housing 14 is fixed on th...

Embodiment 2

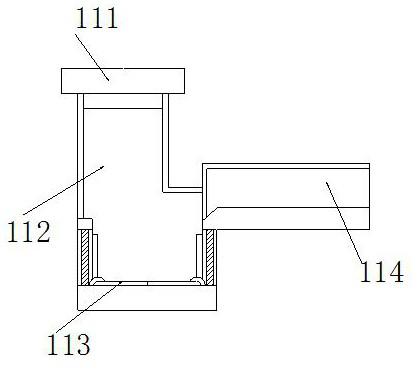

[0033] as attached Figure 6 To attach Figure 7 As shown: the separation pipe 114 includes a flow gap 141, a screening device 142, an embedded plate 143, and a flow pipe 144. The flow gap 141 is inlaid on the inner end surface of the separation pipe 114, and the screening device 142 is movably engaged and installed. Right above the embedded plate 143, the lower end of the embedded plate 143 is attached to the inner lower end surface of the separation pipe 114, the flow tube 144 is connected in series with the sedimentation tube 112, and the outer contour of the upper end of the embedded plate 143 is set It is in the shape of an obtuse triangle, so that the left end surface of the separation pipe 114 expands in a wide-angle manner, and can effectively accommodate the flowing coolant and debris during the flow.

[0034] Wherein, the screening device 142 includes a collection box 421, a handle 422, a filter screen 423, and an inlaid shell 424. The upper end surface of the collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com