Steel, iron wheel balancing device and manufacturing method thereof

A balancing device and wheel technology, applied in the direction of wheel counterweight, etc., can solve the problems of high temperature and difficult wheel balance weights, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

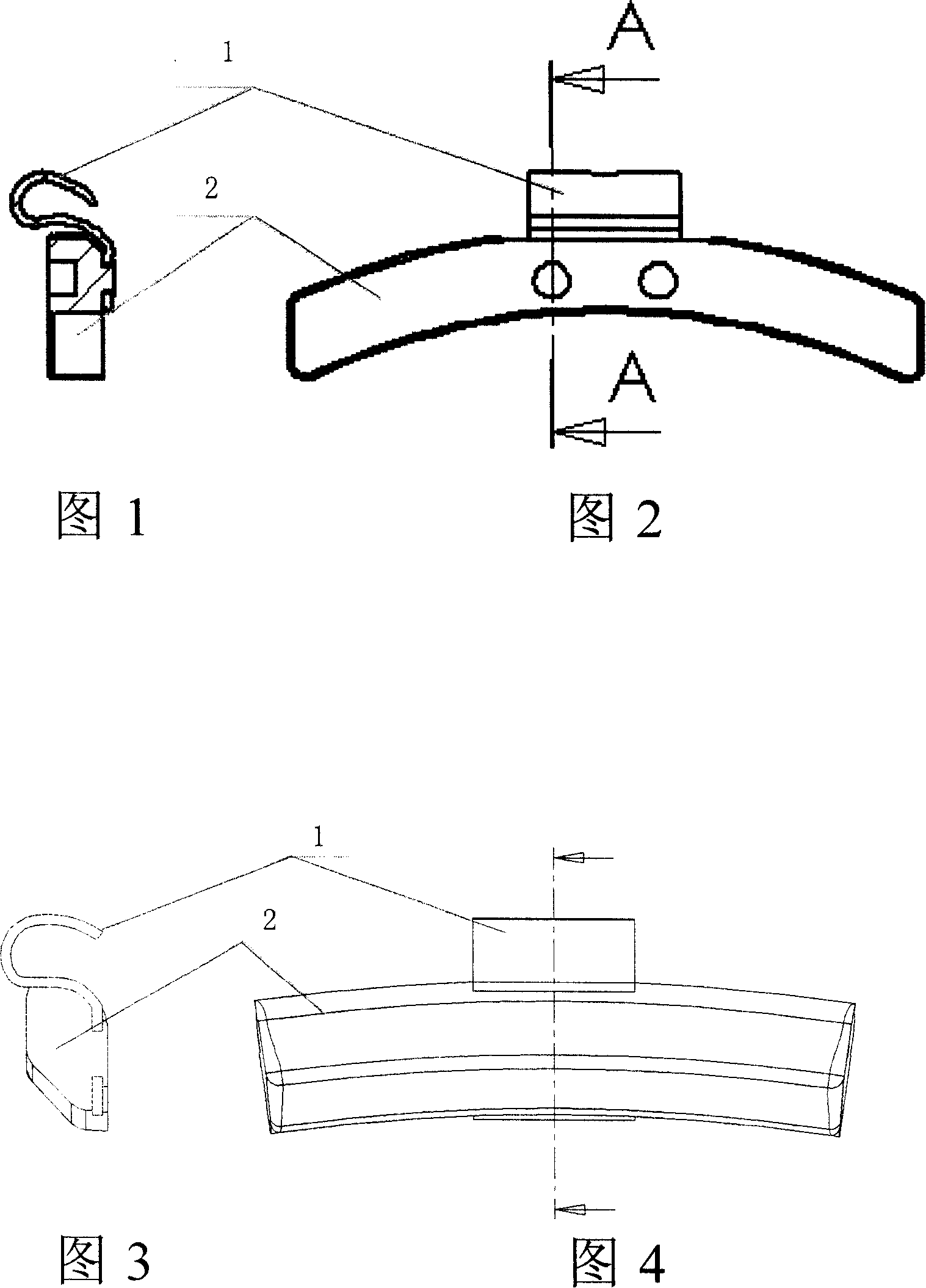

[0069] As shown in Figures 1 and 2, the hook is formed by stamping and heat treatment of SK5 steel strip, and its quenching hardness is HRC40-48. The surface of the hook is treated with white zinc plating.

[0070] The balance weight is formed by stamping 6mm thick Q235 low carbon steel plate, and the surface is plated with white zinc. The obtained balance weight has a specific gravity of 7.8 and a tensile strength of 375-500 MPa. After the hook and the balance weight are riveted, according to the different wheels, the surface is sprayed with silver-gray epoxy resin, and the average thickness of the coating is about 0.08mm.

[0071] The processing process of steel stamping balance weight:

[0072]

Embodiment 2

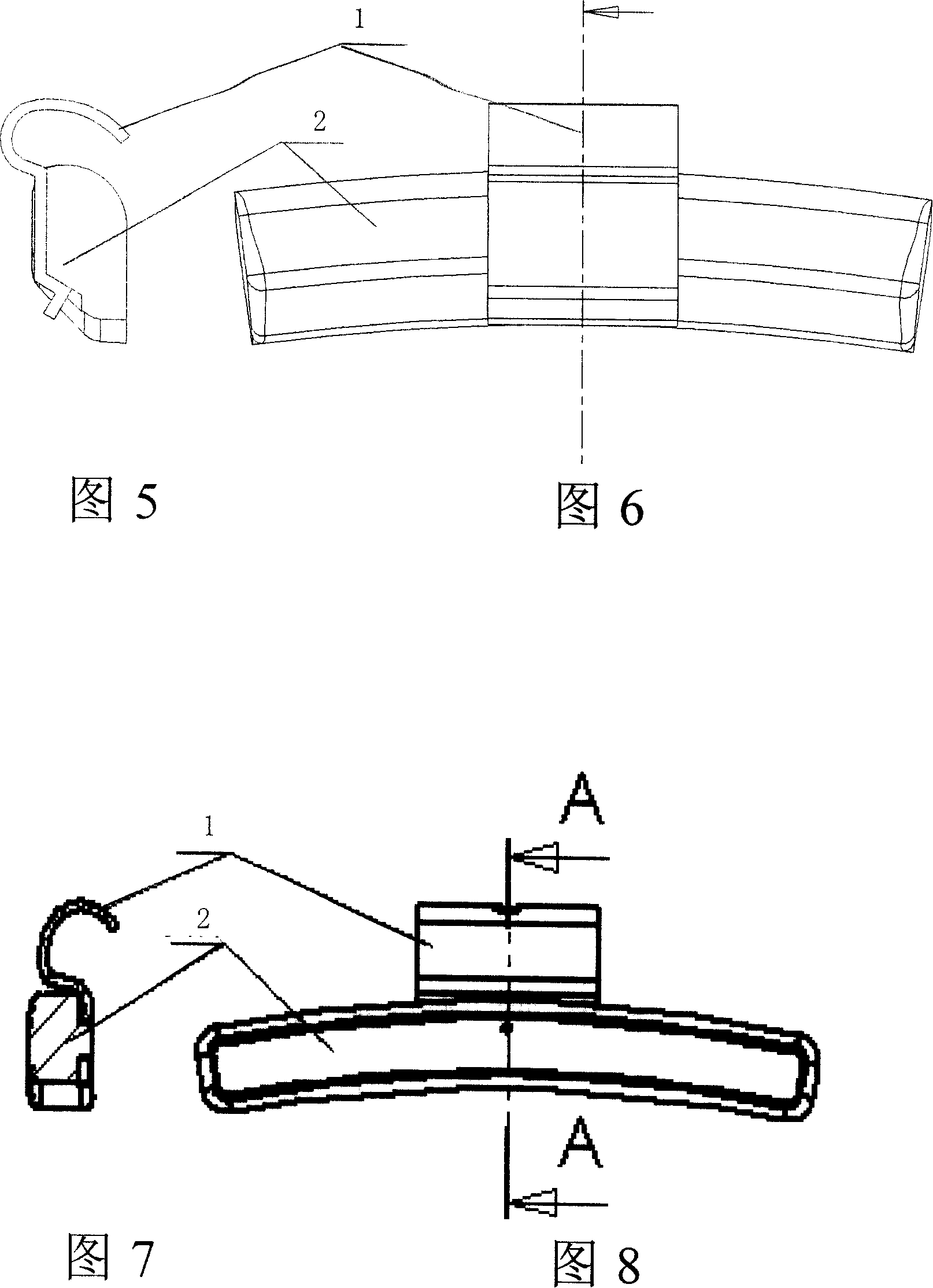

[0074] As shown in Figures 3 and 4, the hook is stamped and formed by 65Mn steel strip. After quenching and tempering, the hardness is HRC44~47, and then the surface is phosphating, and the coating thickness is 0.001mm.

[0075] The balance weight is made of ductile iron with an elongation rate of 15% through precision investment casting. After grinding to remove burrs, etc., the surface is phosphating. The specific gravity of the obtained balance weight is 7.3, and the tensile strength is greater than 400 MPa.

[0076] Then, the hook and the balance weight are riveted to form a riveted wheel balance device.

[0077] Spray silver-pink paint on the surface of the obtained riveted wheel balancer, and the average thickness of the coating is about 0.08mm.

[0078] Processing process of riveted balance weight:

[0079]

Embodiment 3

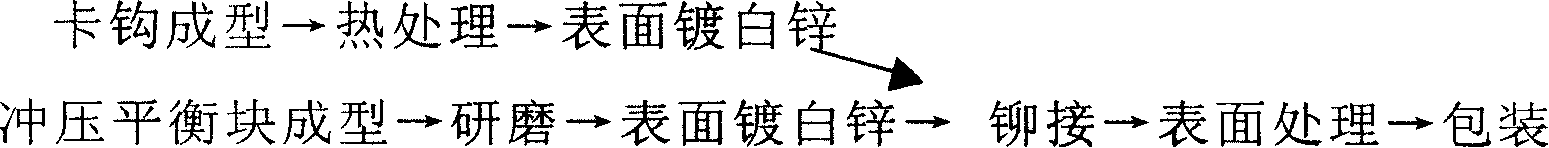

[0081] As shown in Figures 5 and 6, the hook is stamped from a 0.7-0.9mm 65Mn steel strip. After quenching and tempering, the hardness is HRC42-47, and then treated by Dacromet surface treatment.

[0082] The material of the balance weight is cast steel with a carbon content of 0.2%, and the balance weight body is formed by precision investment casting. Then spray epoxy resin paint on its surface, and the average thickness of the formed coating is about 0.08mm. The specific gravity of the obtained balance weight is 7.8, and the tensile strength is greater than 400 MPa.

[0083] When in use, the above-mentioned hook and the balance weight are assembled to the corresponding positions of the wheel rim.

[0084] The processing process of the assembled balance weight:

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com