Miniature stretching rheological device for in-situ structure detection of polymer film material, and experimental method thereof

A technology for polymer film and structure detection, applied in the direction of testing the ductility of materials, etc., can solve the problem of difficult in-situ rheological experimental devices to be combined, and achieve the effect of light weight, convenient installation and disassembly, and reducing thermal degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and examples.

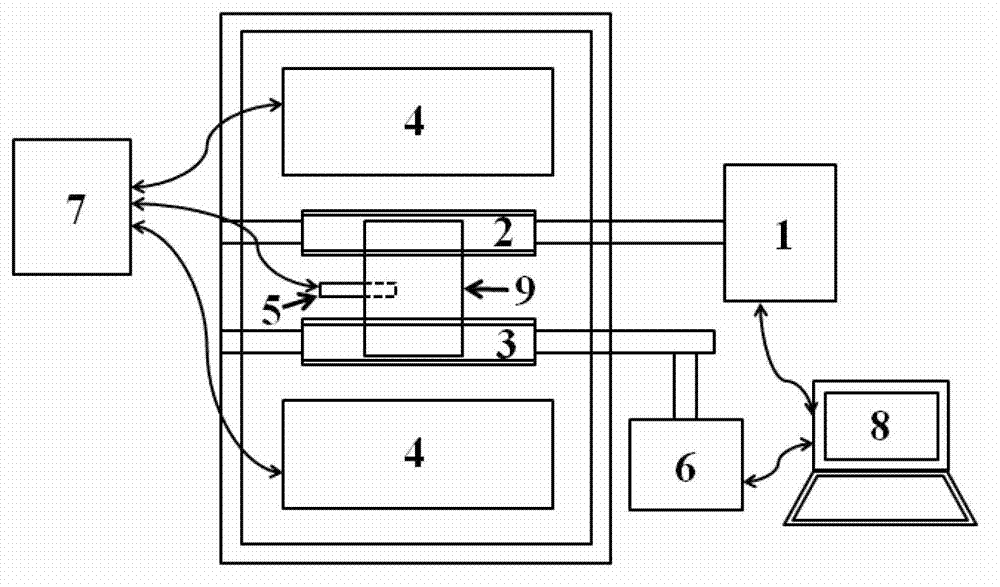

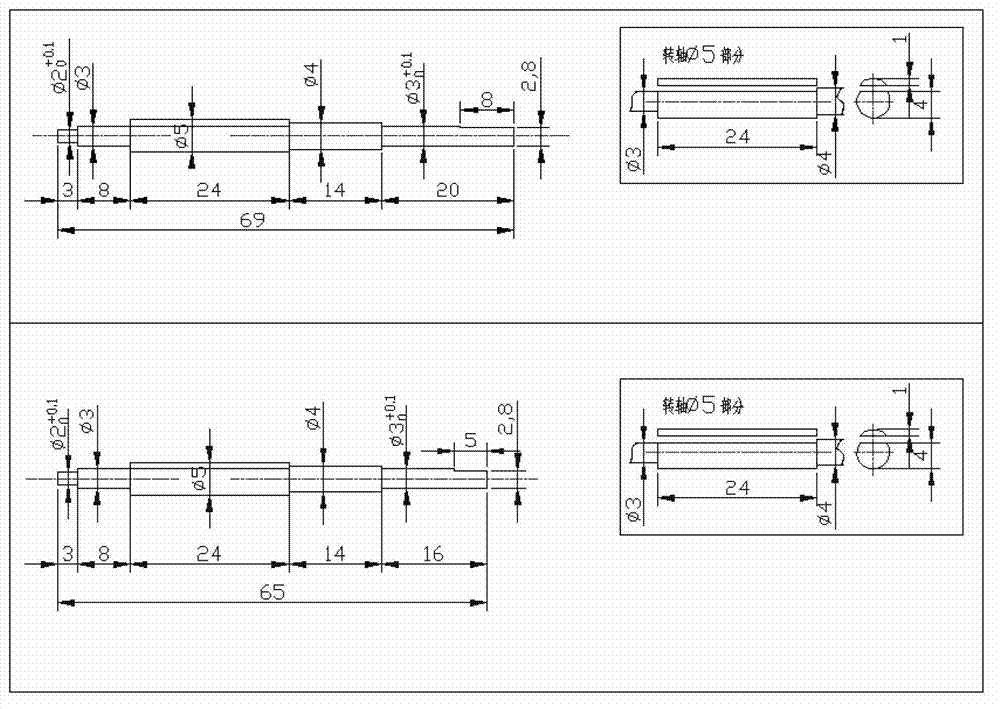

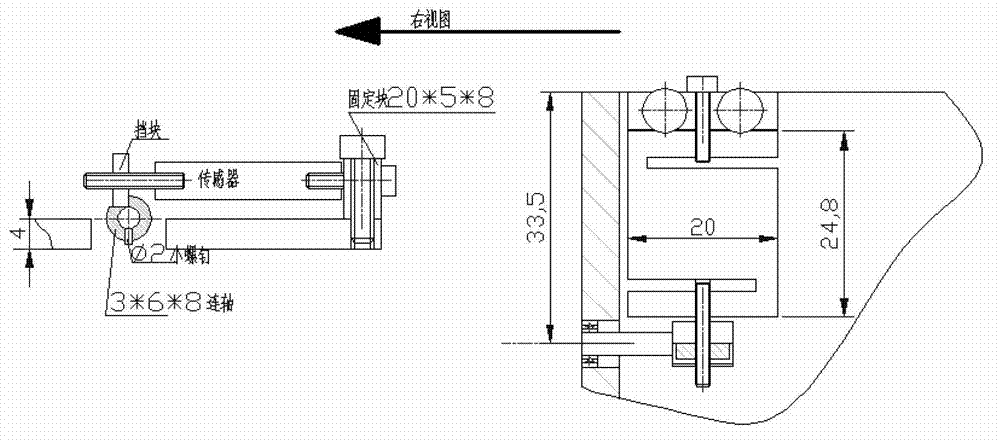

[0044] A miniature extensional rheological device for in-situ structure detection of polymer thin film materials, see attached figure 1 , the high-precision micro servo motor 1 is connected to the driving shaft 2 through a coupling, the polymer film sample 9 is clamped between the driving shaft 2 and the driven shaft 3, the driven shaft 3 is connected to the tension sensor 6, and the heating block 4 is distributed on both sides of the shaft. When stretching, the high-precision micro servo motor 1 drives the driving shaft 2 to rotate, the polymer film sample 9 stretches around the shaft, and the driven shaft 3 remains stationary. The control program of the high-precision servo motor written by Labview software is used to cooperate with the integrated Hall sensor and encoder on the motor to precisely control the displacement and speed of the motor rotation....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com