Hot-rolled steel sheet, cold-olled steel sheet, and plated steel sheet each having exellent uniform ductility and local ductility in high-speed deformation

一种热轧钢板、冷轧钢板的技术,应用在热浸镀工艺、热处理炉、热处理设备等方向,达到局部韧性提升、改善碰撞安全性、有效效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

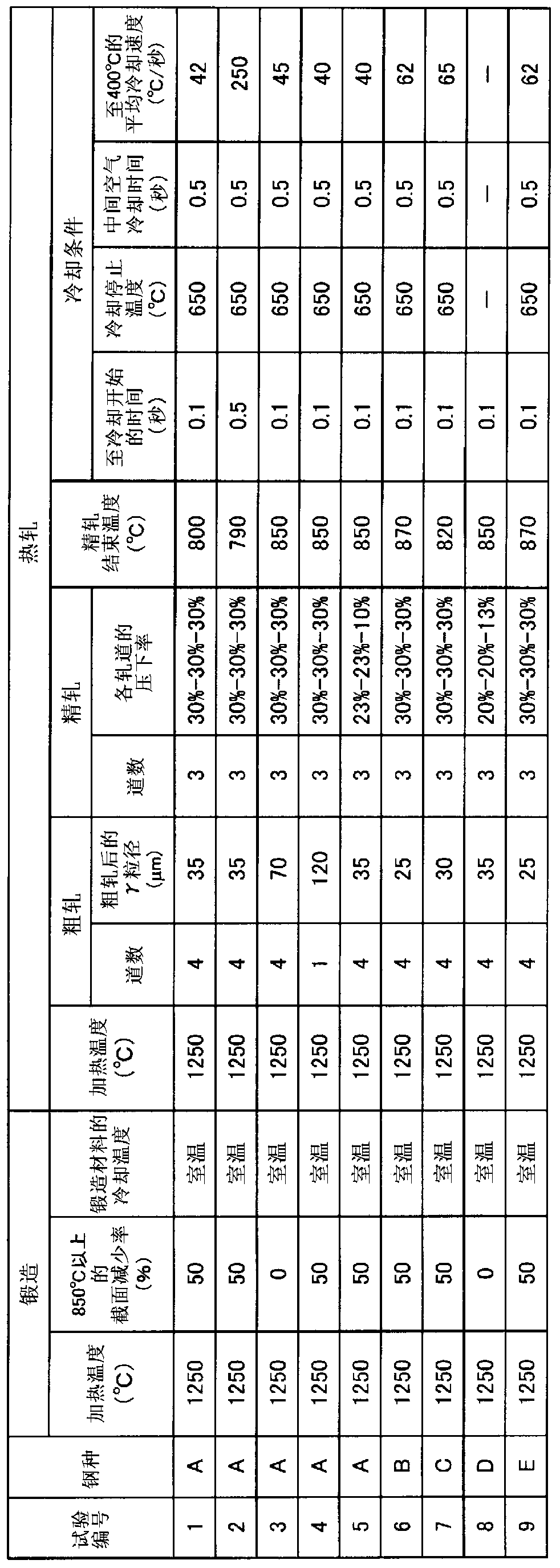

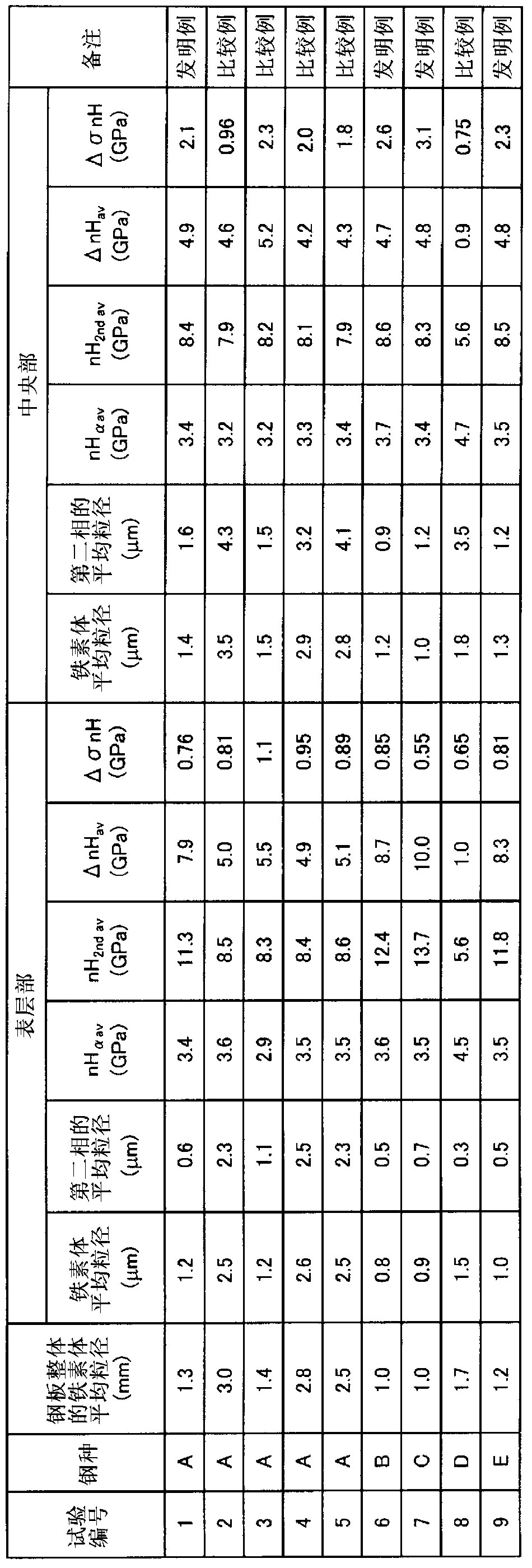

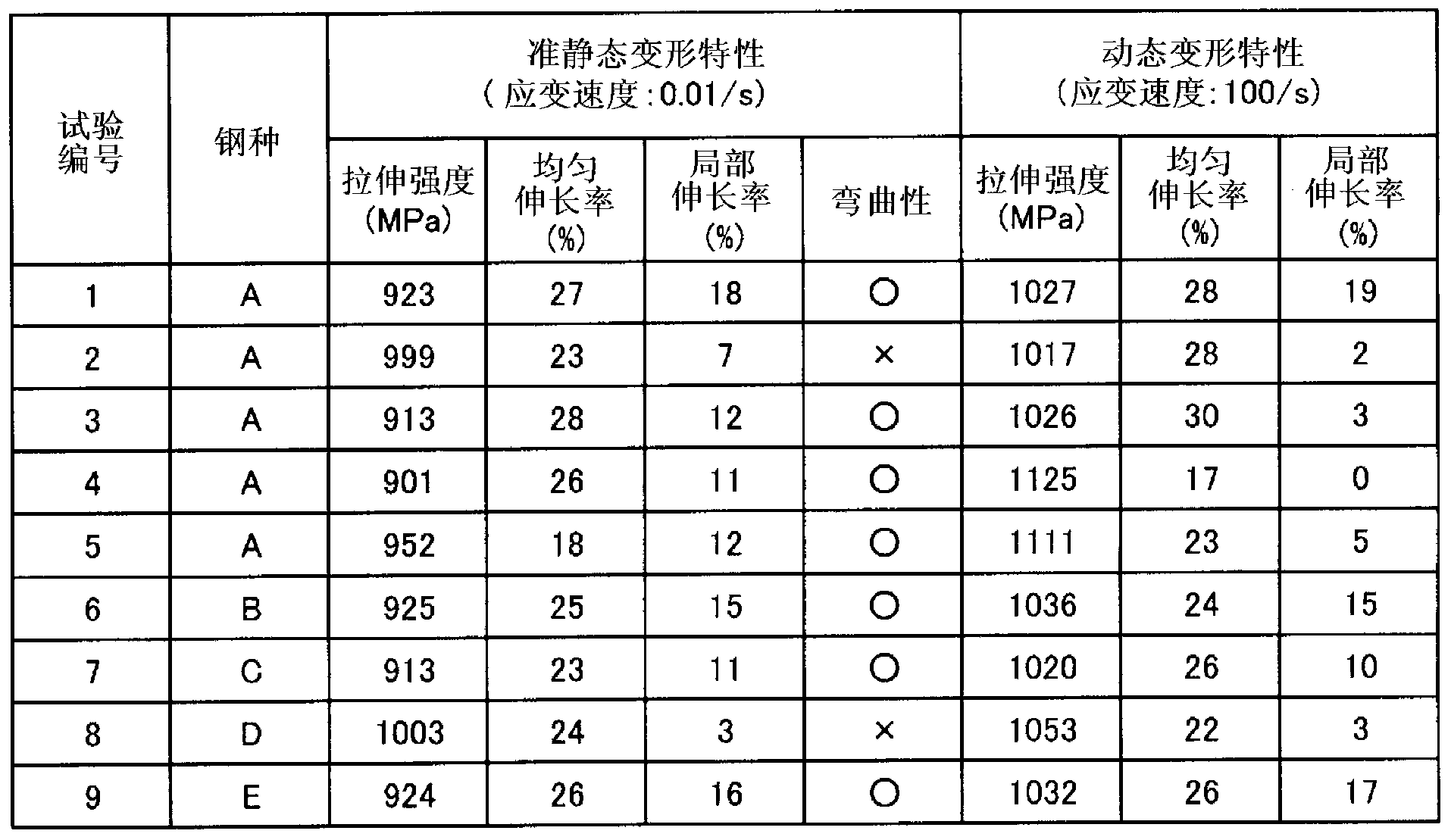

[0125] (hot rolled steel plate)

[0126] Experiments were conducted using slabs (35 mm in thickness, 160 to 250 mm in width, and 70 to 90 mm in length) formed of steel grades A, B, C, D, and E having chemical compositions shown in Table 1. Steel types A to C and E have chemical compositions within the range specified by the present invention, and steel D has a chemical composition other than that of the present invention.

[0127] [Table 1]

[0128] steel type

C

Si

mn

P

S

Cr

Ti

Nb

V

AI

N

Ae 3

A

0.15

0.54

2.02

0.001

0.002

0.25

0.010

-

-

0.035

0.0025

845

B

0.15

0.53

2.04

0.001

0.002

0.25

0.010

0.008

-

0.033

0.0021

841

C

0.15

0.52

2.01

0.002

0.002

0.25

0.010

-

0.05

0.033

0.0030

847

D

0.16

0.51

2.01

0.013

0.002

0.051

0.057

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com