Zn-Al alloy having excellent high-speed deformation properties and its making method

An alloy and excellent technology, applied in the field of Zn-Al alloy and its manufacturing, can solve problems such as unstable deformation energy, and achieve the effect of excellent static deformation energy and dynamic deformation energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

[0087] [Manufacture of Zn-Al alloy]

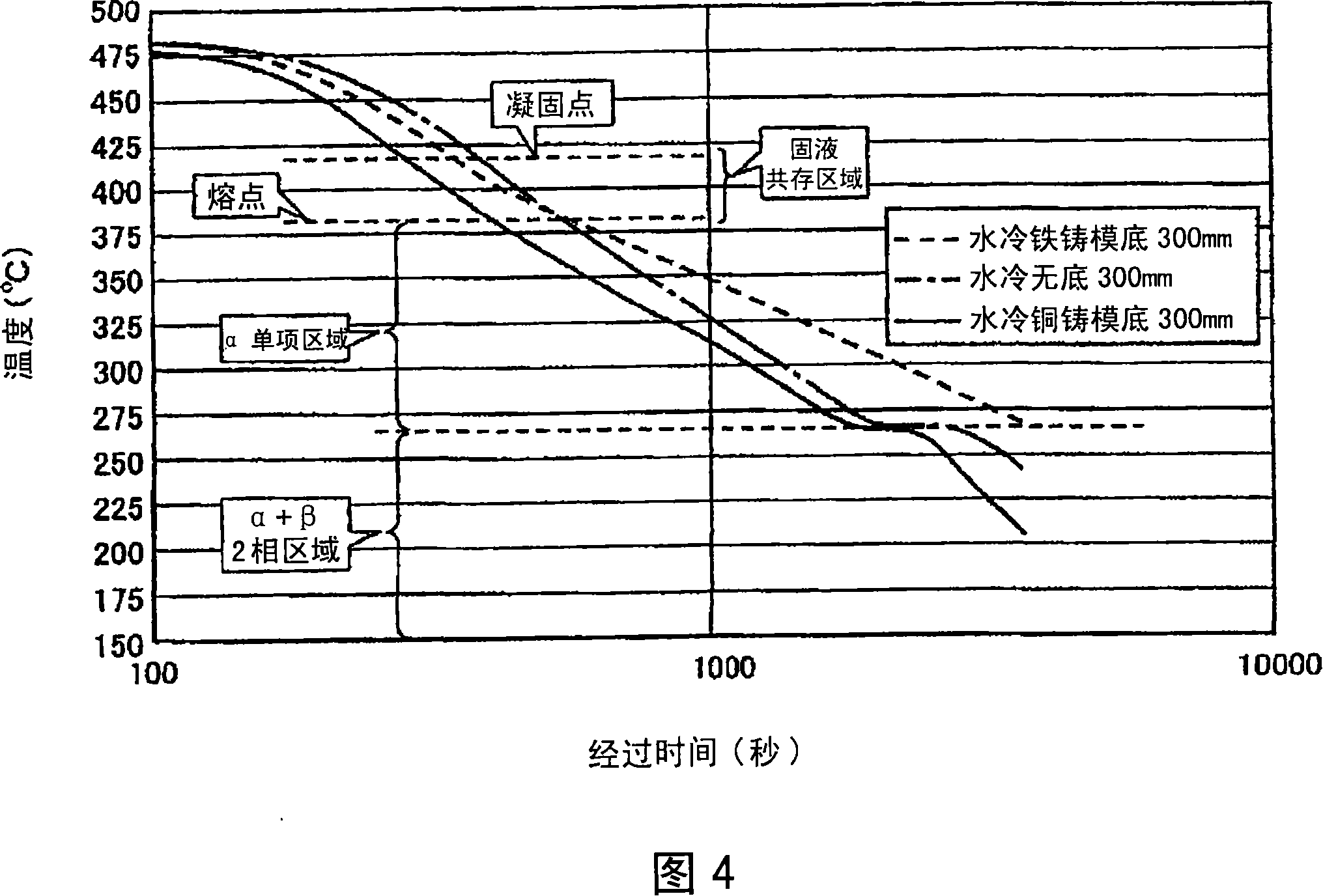

[0088] The Zn-22%Al alloy melt was casted using an iron mold or a copper mold with a cross-sectional shape of 200mm long×350mm wide, under both air-cooled or water-cooled conditions. In addition, a part (No. 12 of Table 1 described later) was continuously casted using a water-cooled copper mold with a cross-sectional shape of 200 mm. In this way, an ingot (ingot size: 180 kg) of Zn-22%Al (total impurity amount: 0.5% or less) in which alloy components tend to undergo macrosegregation was obtained.

[0089] In addition, the cooling behavior of the ingot was measured by installing a thermocouple at a position 300 mm from the bottom surface of each ingot (cross-sectional center position). An example of the temporal change (cooling curve) of the ingot internal temperature is shown in FIG. 4 . Based on the above cooling curve, the cooling rate (average cooling rate 1) in the solid-liquid two-phase domain (425-375°C) and the cooling rate (avera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com