Zn-Al alloy having excellent high-speed deformation properties and its making method

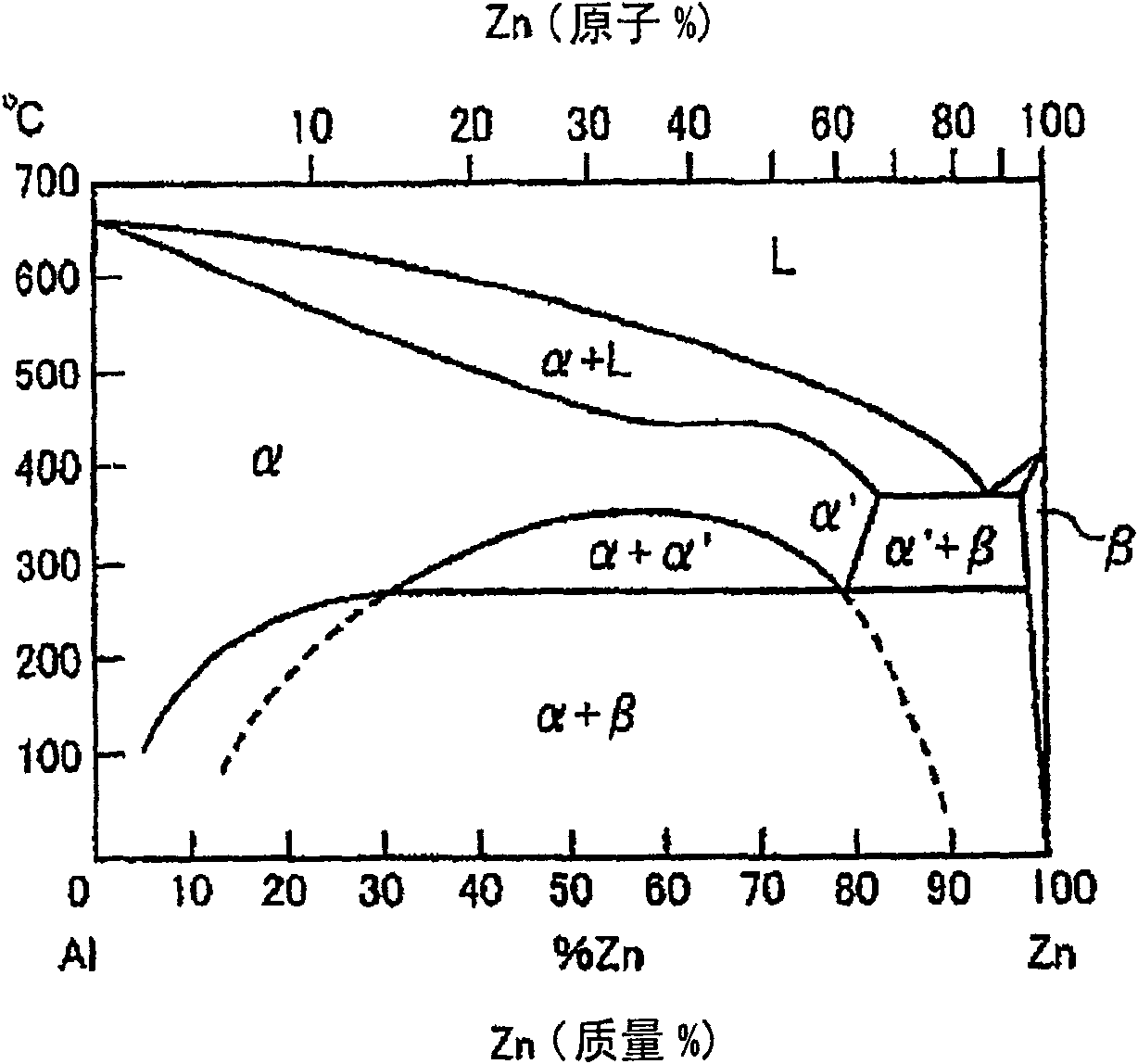

一种制造方法、合金的技术,应用在Zn-Al合金及其制造领域,能够解决变形能不稳定等问题,达到静态变形能优异、动态变形能优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

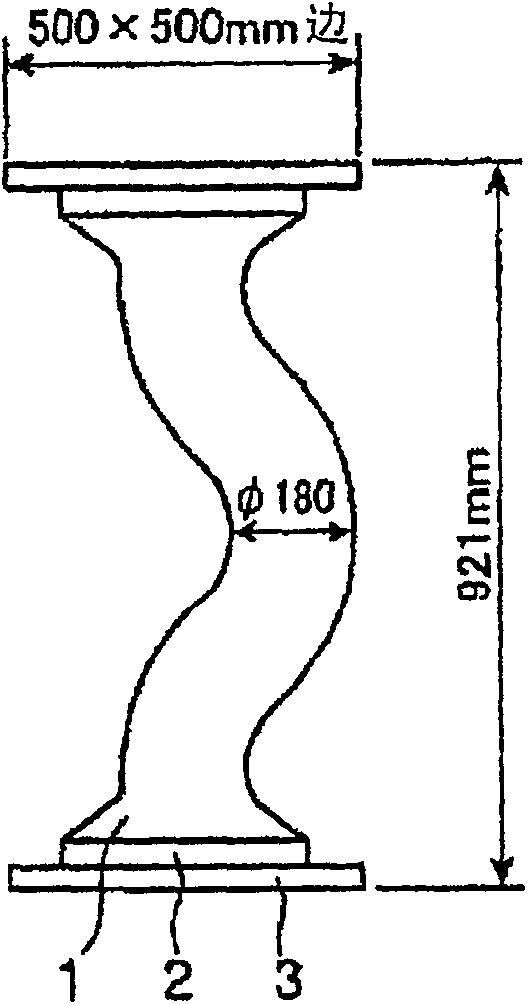

[0087] [Manufacture of Zn-Al alloy]

[0088] The Zn-22%Al alloy melt is cast using an iron or copper mold with a cross-sectional shape of 200mm in length×350mm in width, under both air-cooling and water-cooling conditions. In addition, a part (No. 12 of Table 1 described later) was continuously cast using a water-cooled copper mold with a cross-sectional shape of 200 mm angle. In this way, an ingot (ingot size: 180 kg) of Zn-22% Al (total impurities: 0.5% or less) in which alloy components are prone to macrosegregation is obtained.

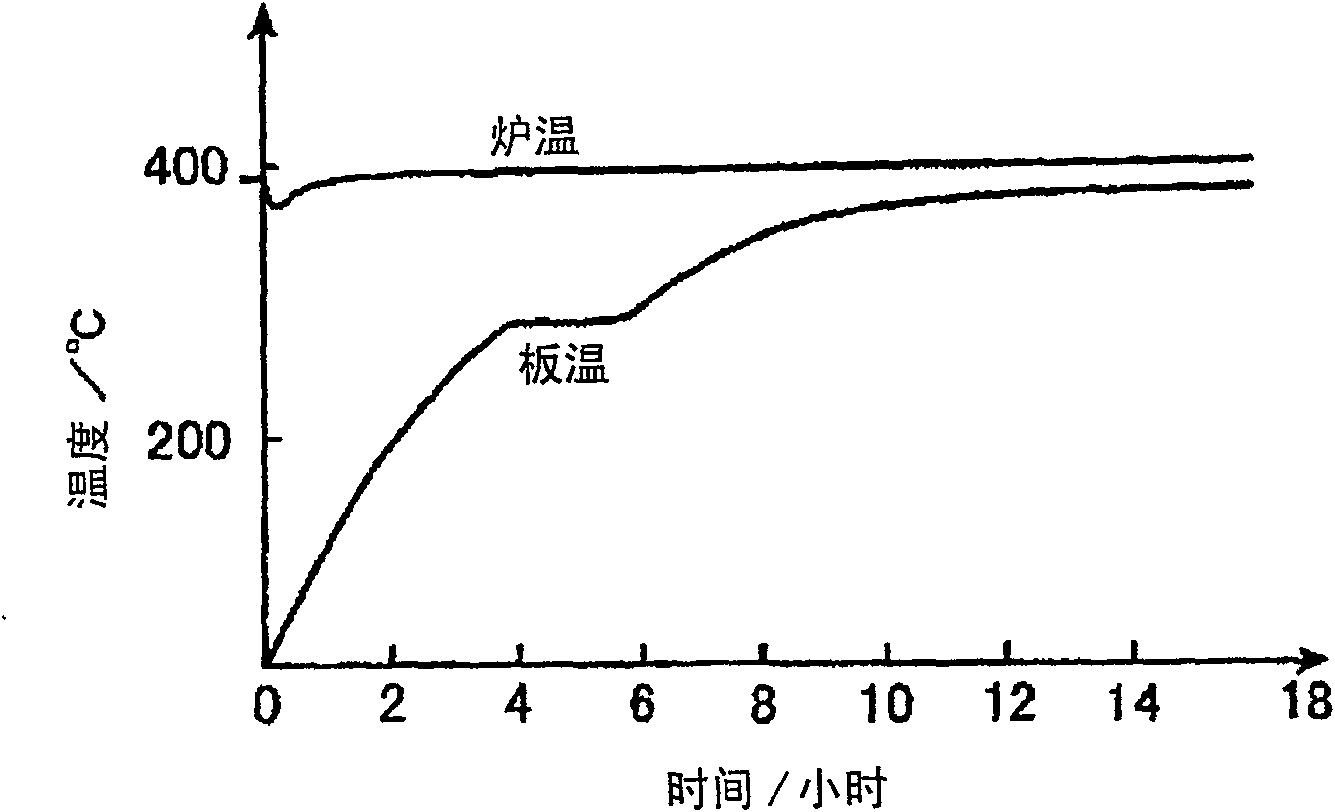

[0089] In addition, the cooling behavior of the ingot was measured by installing a thermocouple at a position (the center position of the cross section) 300 mm from the bottom surface of each ingot. Figure 4 An example of the change over time (cooling curve) of the internal temperature of the ingot is shown in. Based on the above cooling curve, the cooling rate (average cooling rate 1) of the solid-liquid two-phase region (425 to 375°C) and the cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com