Preparation method of ultra-fine grain AZ61 magnesium alloy bulk material

A technology of bulk material and magnesium alloy, applied in the field of ultra-fine grain AZ61 magnesium alloy bulk material preparation, can solve the problems of complicated operation process, unsuitable for processing large-sized bulk materials, unsuitable for industrialized production, etc., to ensure plastic forming ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The material selected in this embodiment is AZ61 magnesium alloy, the specific composition is Mg-3Al-1Zn, and the length, width and height of the sample before thermal processing are 35 mm, 35 mm and 40 mm, respectively.

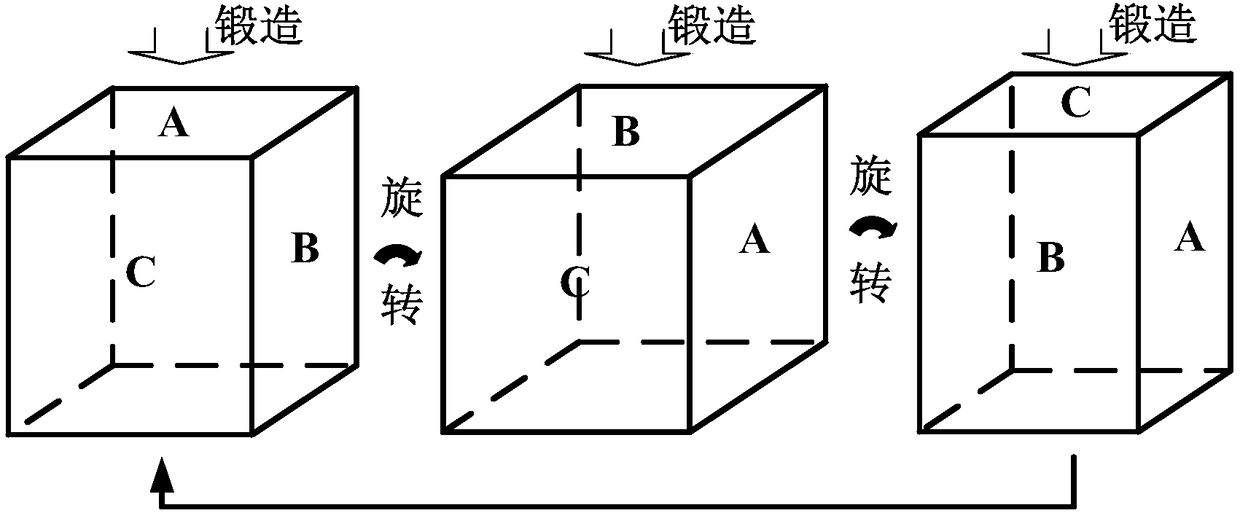

[0027] A method for preparing an ultrafine-grained AZ61 magnesium alloy bulk material, comprising the following steps:

[0028] 1) Heat treatment process: put the sample in an iron box and cover it with graphite-containing sand, put it in a heat treatment furnace for heating and heat preservation, set the heating temperature to 400°C, and keep it warm for 10 hours after reaching the set temperature, so that the continuous network distribution The second phase of the alloy basically dissolves into the matrix, and the sample is taken out and air-cooled, so that the second phase does not have time to precipitate, and a single-phase solid solution with basically uniform properties is obtained. The microstructure of the alloy before and after heat treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com