Grain distribution controlled two-peak texture ZK21 magnesium alloy preparation method

A technology of ZK21 and magnesium alloy, which is applied in the direction of metal processing equipment, casting mold composition, manufacturing tools, etc., can solve the problem of low tissue repeatability and achieve consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The ZK21 magnesium alloy selected in this embodiment has a composition of Mg-2Zn-0.45Zr, and the length, width and height of the sample before processing are 35 mm, 35 mm, and 40 mm, respectively.

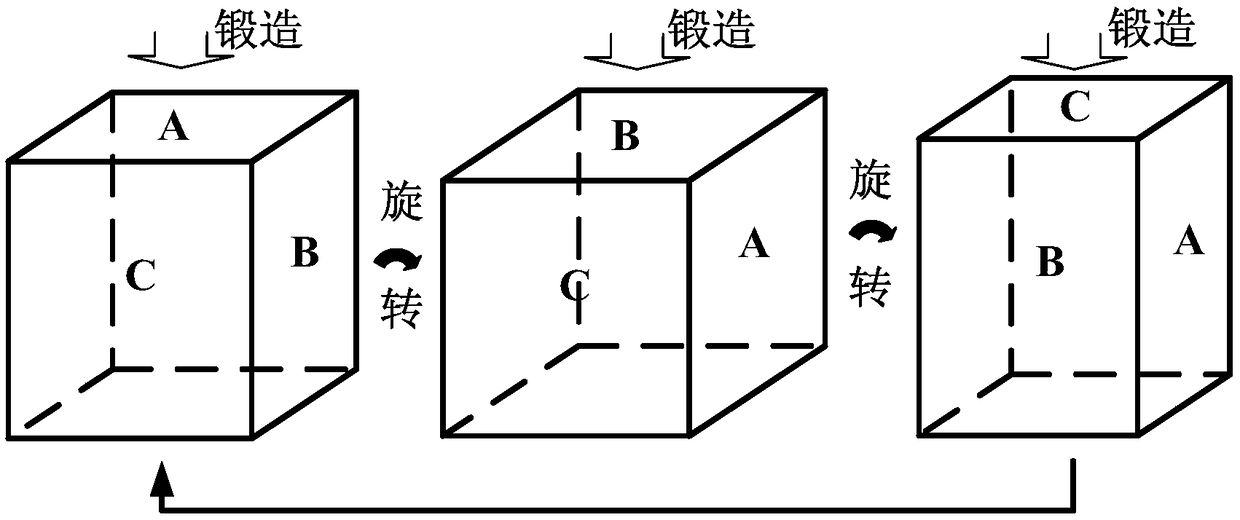

[0032] A method for preparing a bimodal structure ZK21 magnesium alloy with controllable grain distribution, comprising the following steps:

[0033] 1) Casting process: Prepare ZK21 magnesium alloy melt according to the magnesium alloy smelting method, pour the melt into a square water-cooled copper mold, the size of the copper mold is 150mm*150mm*150mm, the mold cooling water capacity is 300ml, and the cooling water flow rate is 3 liters per minute, during the pouring process, sulfur powder is sprinkled to prevent burning, and the ingot is taken out after cooling; under the action of the water-cooled copper mold, the solidification structure of the alloy is uniform equiaxed crystals, and there is no coarse second phase near the grain boundary, basically A single-phase soli...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 lies in that the size of the samples is different, and the length, width and height of the samples before processing are 70 mm, 70 mm, and 80 mm, respectively.

[0039] After thermal processing, the surface of the sample material is good, without obvious cracks, and without obvious macroscopic loss.

Embodiment 3

[0041] The difference between embodiment 3 and embodiment 1 and embodiment 2 lies in that the size of the samples is different, and the length, width and height of the samples before processing are 140 mm, 140 mm, and 140 mm, respectively.

[0042] The surface of the sample after thermal processing is good, with no obvious cracks and no obvious macro loss.

[0043] The microstructure and mechanical properties of the bimodal magnesium alloy obtained in Examples 1-3 are analyzed below in combination with the experimental data.

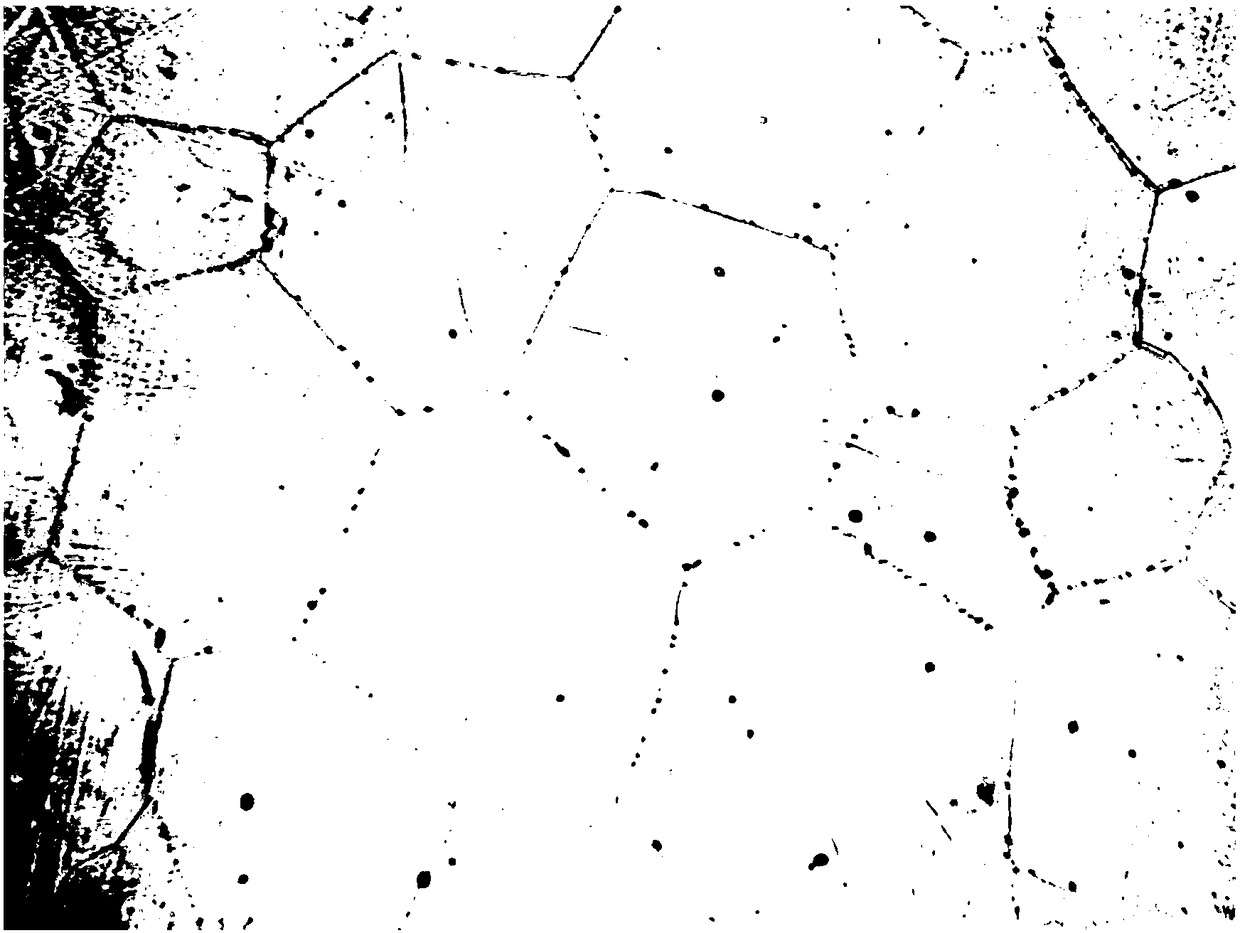

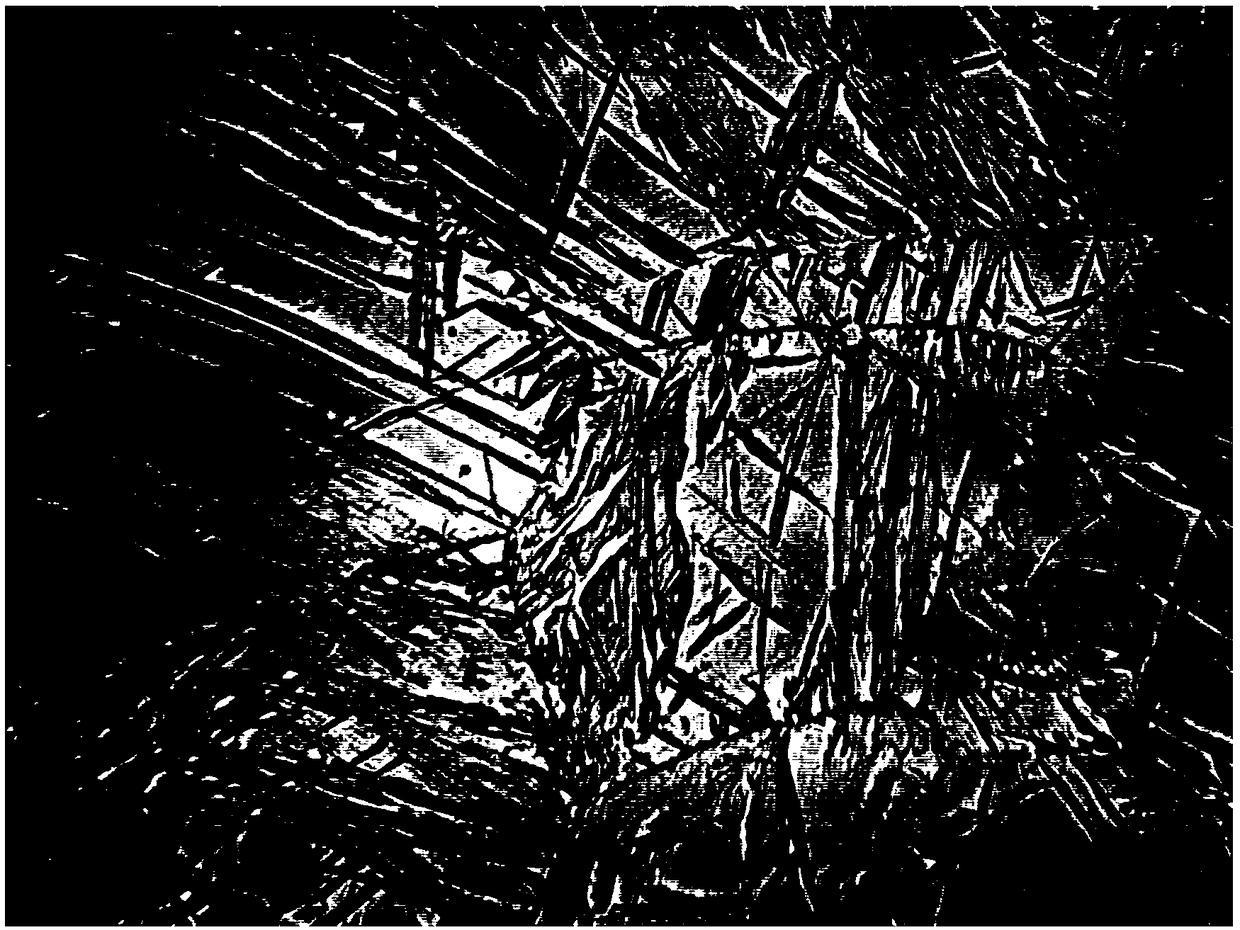

[0044] 1. Microstructure characterization: Select the core of the sample in Example 1-3 to prepare a microstructure observation sample. After mounting, pre-grinding, polishing, and corrosion, the MM6 horizontal metallographic microscope is used to observe the corroded sample. The plane of observation is vertical In the forging direction before sampling, the microstructure and morphology are as follows: Figure 3-Figure 6 and Figure 8-Figure 12 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com