Method for preparing nickel-based powder superalloy through spark plasma sintering

A technology of discharge plasma and nickel-based powder, which is applied in the field of powder metallurgy materials, can solve the problems of the original grain boundary, reduce the mechanical properties of the alloy, and the easy growth of grains, so as to inhibit the growth of grains, realize metallurgical bonding, The effect of simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Plasma sintering of argon atomized nickel-based pre-alloyed powder (composition: Ni-20.6Co-13Cr-3.8Mo-2.1W-3.4Al-3.9Ti-2.4Ta-0.9Nb (wt%)) at 1150°C / 40MPa , heat preservation for 5 minutes, and prepare a billet; then perform solution treatment: 1180°C / 1h, aging treatment: 815°C / 8h, to obtain a nickel-based superalloy.

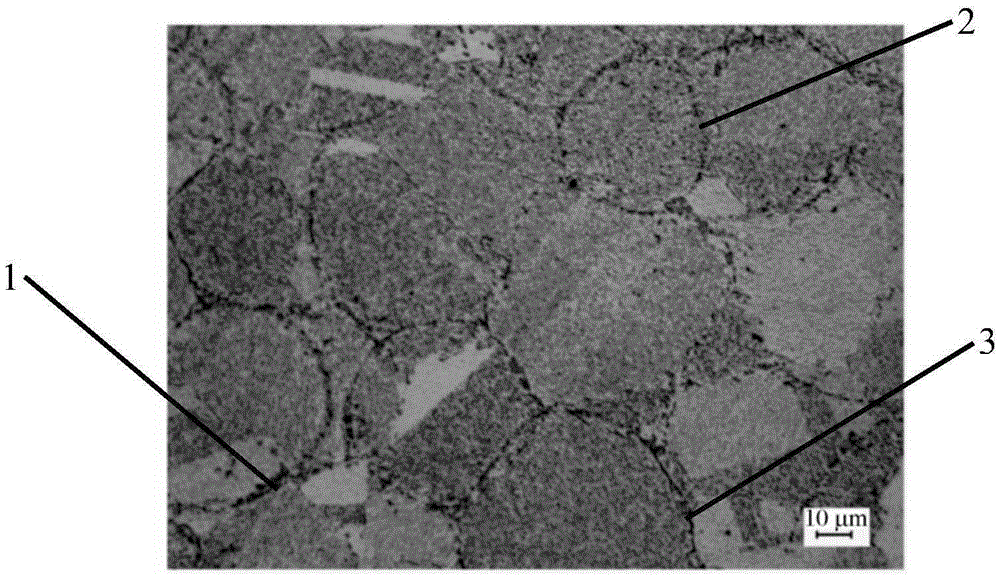

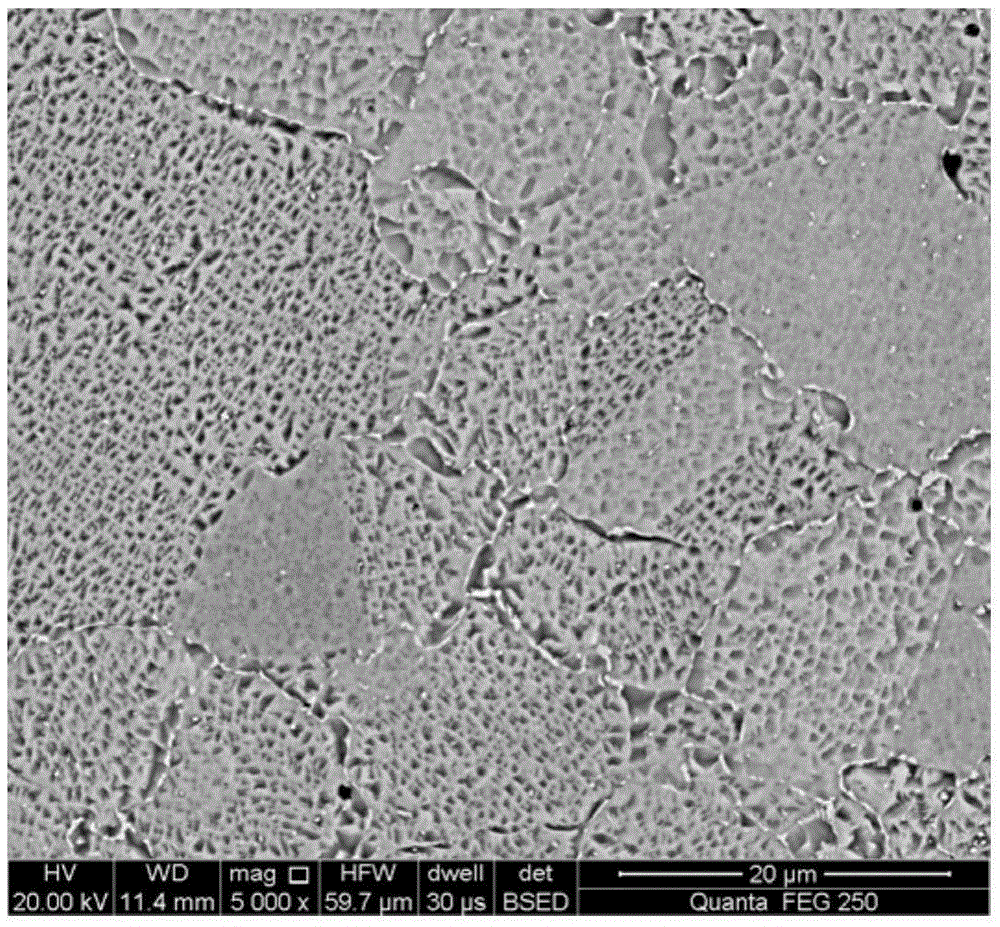

[0040] The mechanical properties of the alloy at room temperature are: breaking strength 1273MPa; yield strength 906MPa; elongation 10.65%; density 8.1735g / cm 3 . The microstructure of the alloy is shown in the appendix image 3 , 4 , the grain size level is ASTM10 level, and the original grain boundary is basically eliminated.

Embodiment 2

[0042]Plasma sintering of argon atomized nickel-based pre-alloyed powder (composition: Ni-20.6Co-13Cr-3.8Mo-2.1W-3.4Al-3.9Ti-2.4Ta-0.9Nb (wt%)) at 1100°C / 60MPa , heat preservation for 10min, and prepare a billet; then perform solution treatment: 1115°C / 1h+1170°C / 3h, aging treatment: 845°C / 8h+760°C / 8h, to obtain a nickel-based superalloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com