Patents

Literature

31results about How to "Remove border" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

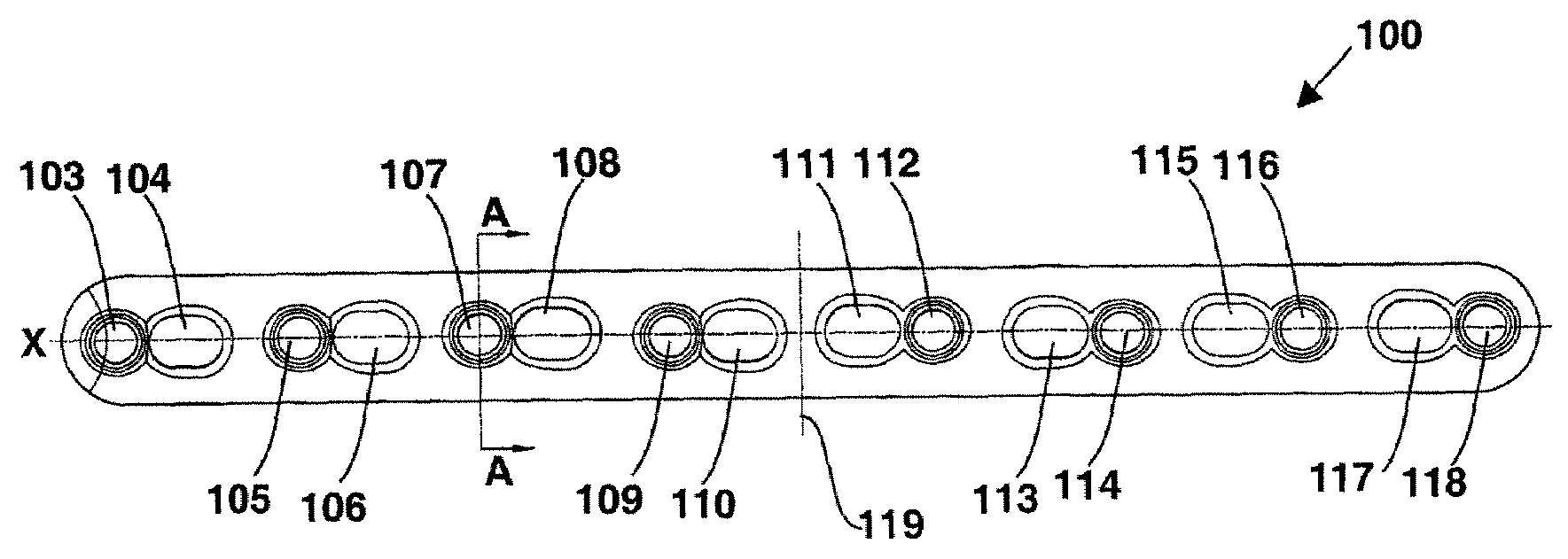

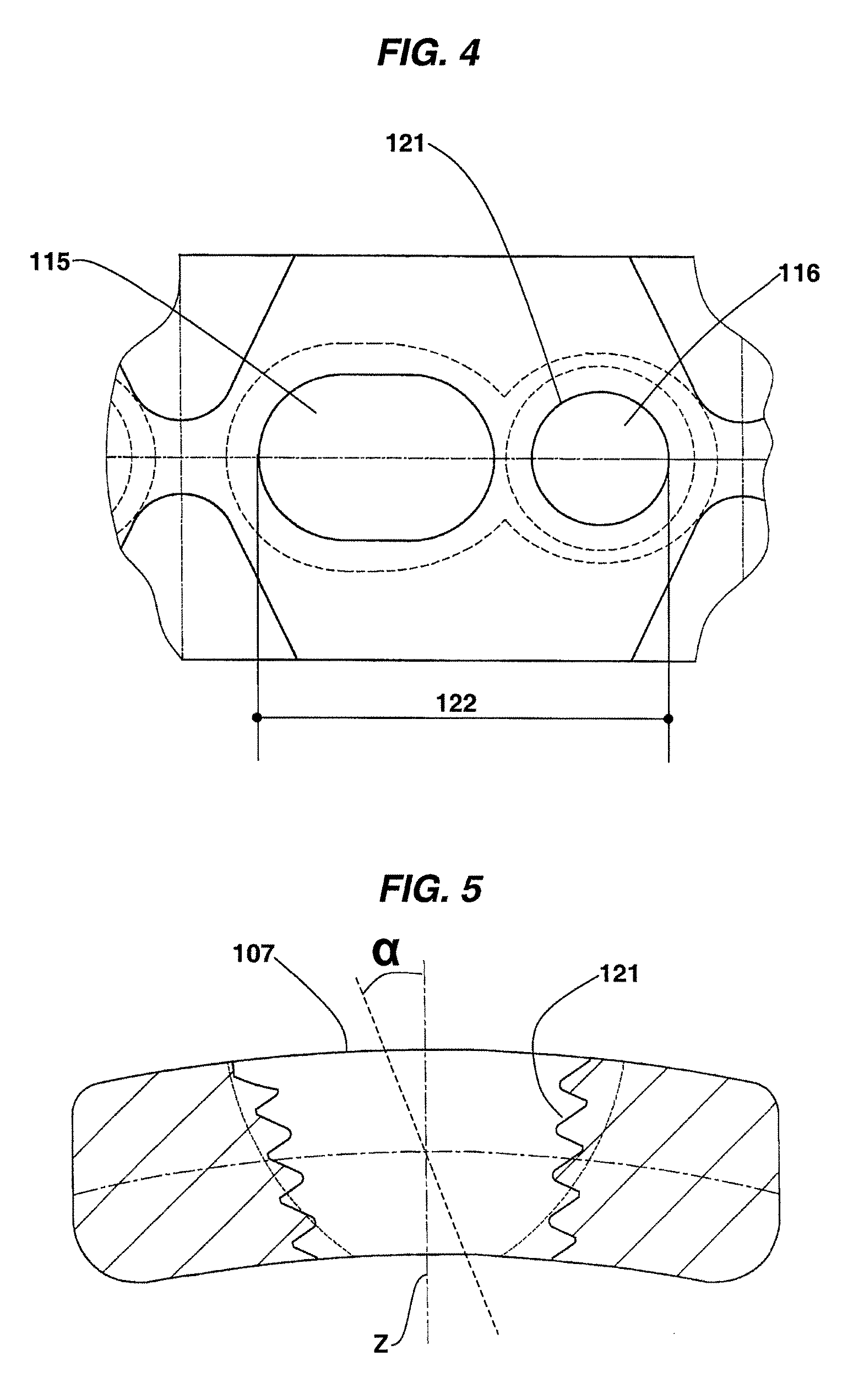

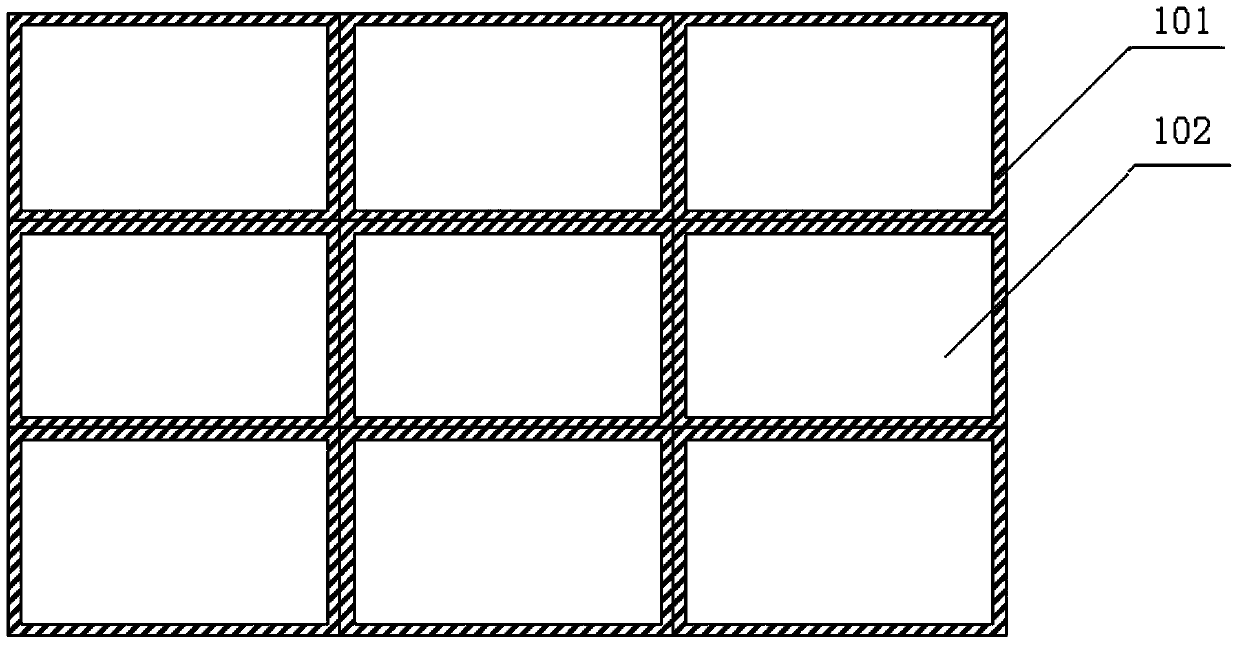

Bone Plate

InactiveUS20090024173A1Easy to anchorAvoiding that the bone splitsInternal osteosythesisBone platesOsteosynthesisFractured bone

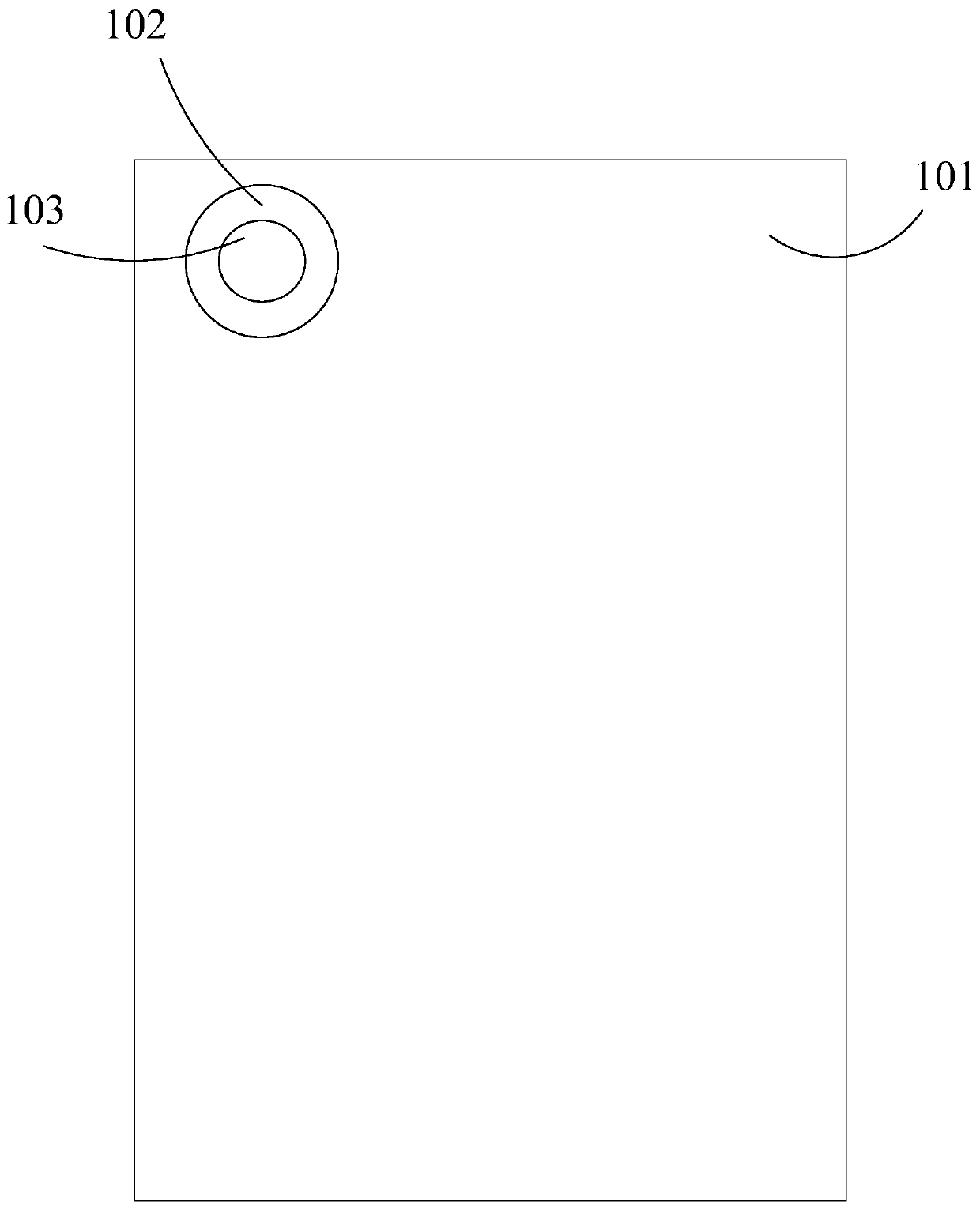

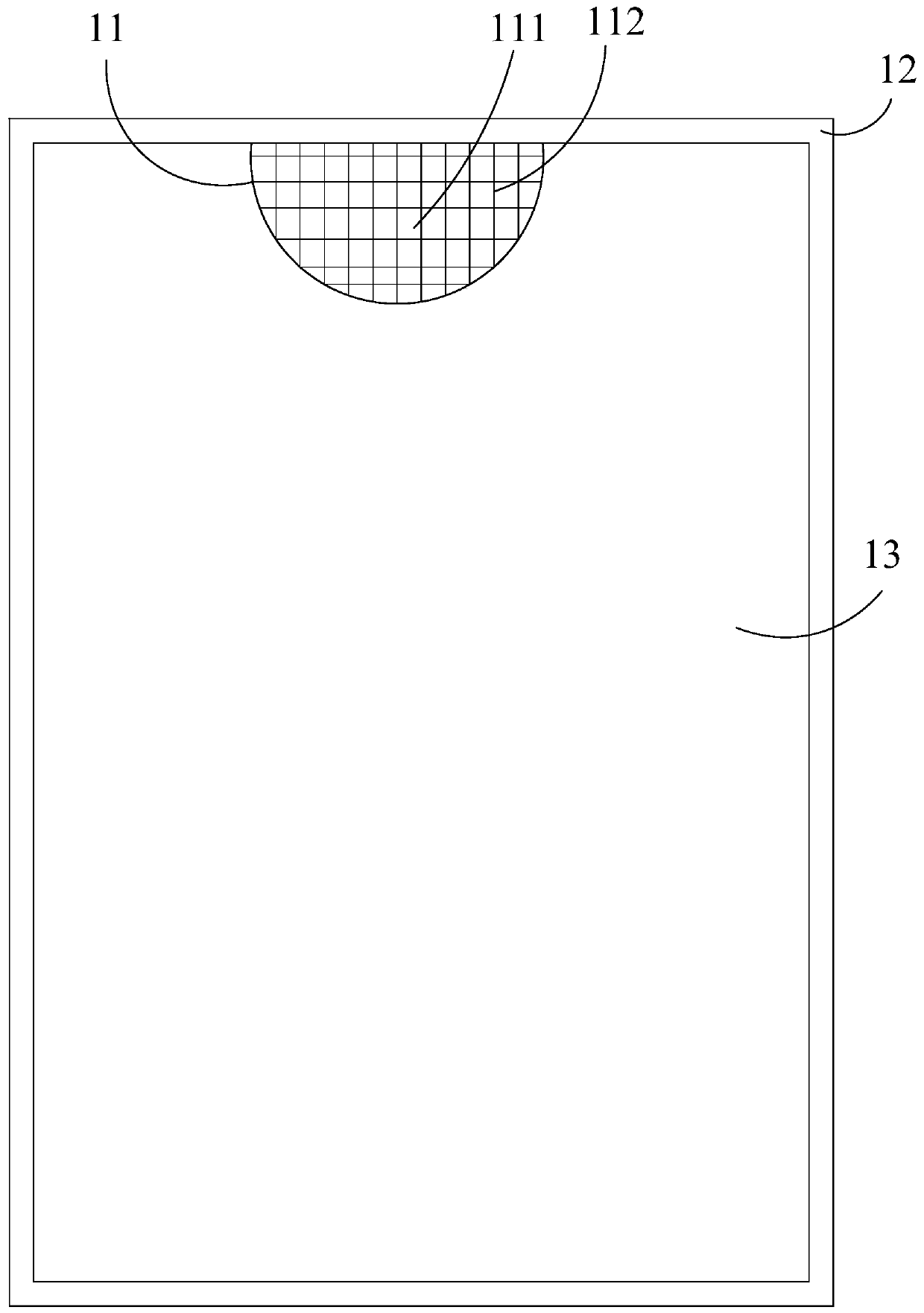

The present invention refers to a bone plate for the osteosynthesis of a fractured bone. According to an embodiment of the present invention, the bone plate comprises an upper side (101), intended to receive at least one bone screw and at least one fixation screw, and a lower side (102), intended to support itself on the bone, wherein said plate further comprises at least one pair (122) of holes (115, 116) distributed along a plane of the plate, and given that said pairs of holes (115, 116) consist of a first hole (115) intended to receive at least one bone screw, and a second hole (116) that has a thread, intended to receive at least one plate fixation screw, wherein said holes that comprise the pair (122) are tangent to each other and separated between their centers at a distance at least equal to the sum of the radiuses of said holes.

Owner:GM DOS REIS JR INDA E COMERCIO DE EQUIPAMENTOS MEDICOS

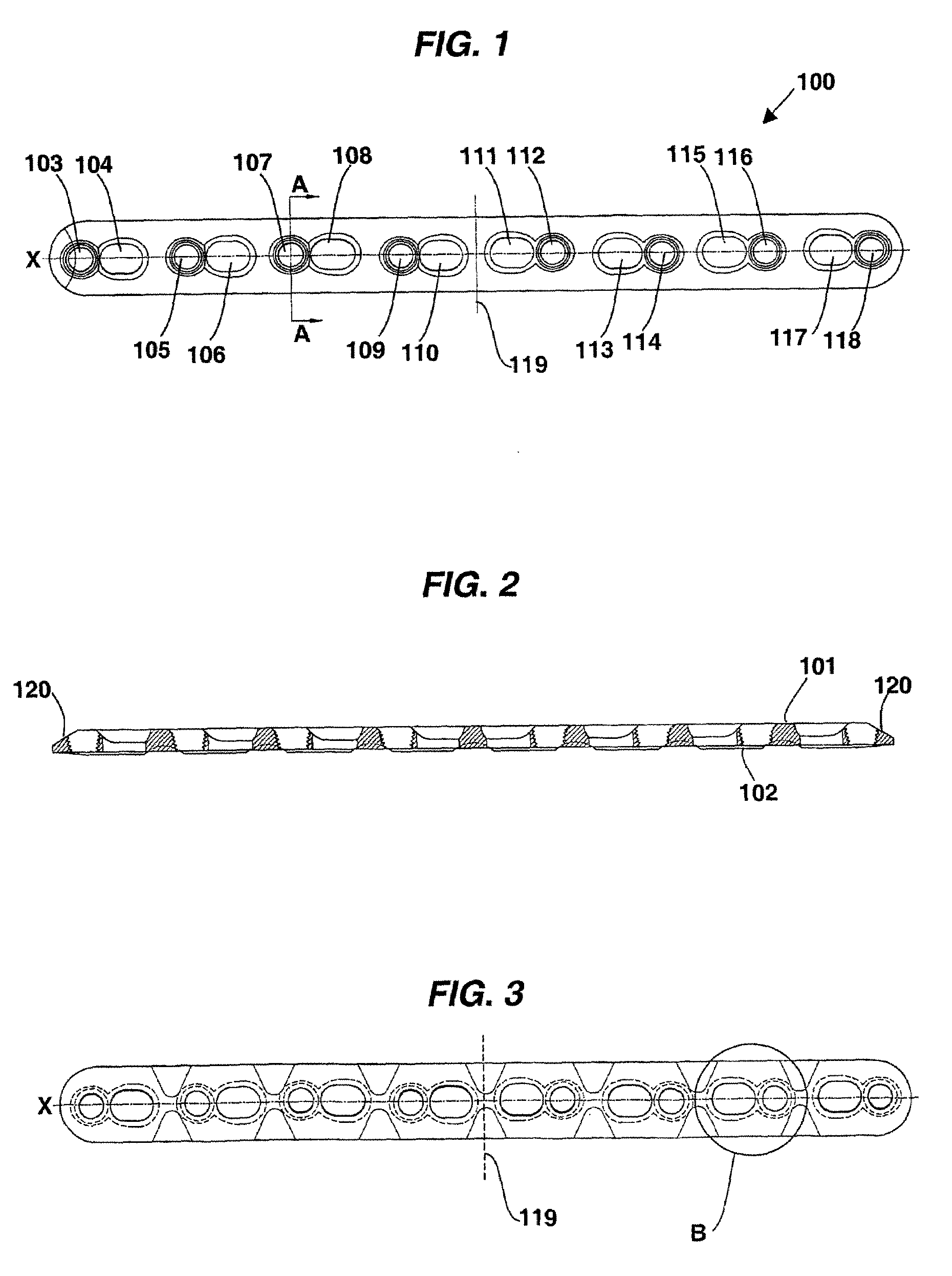

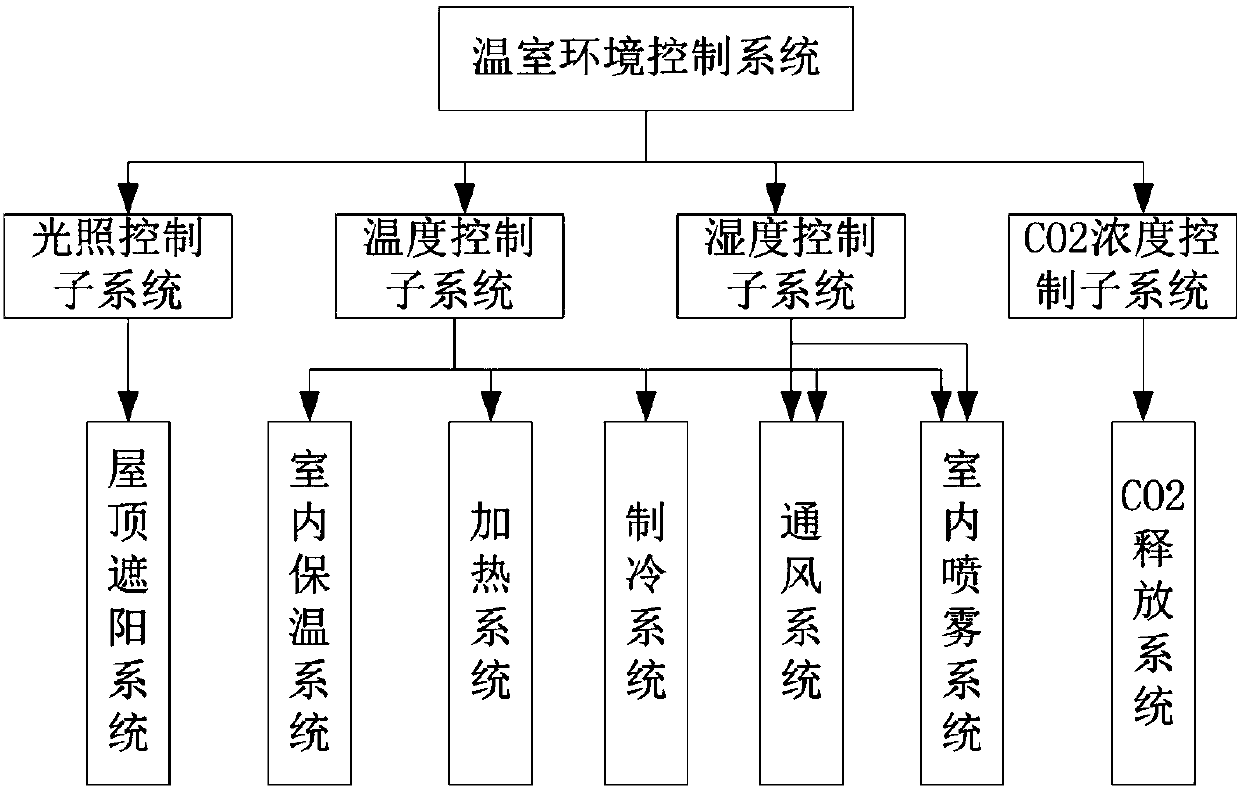

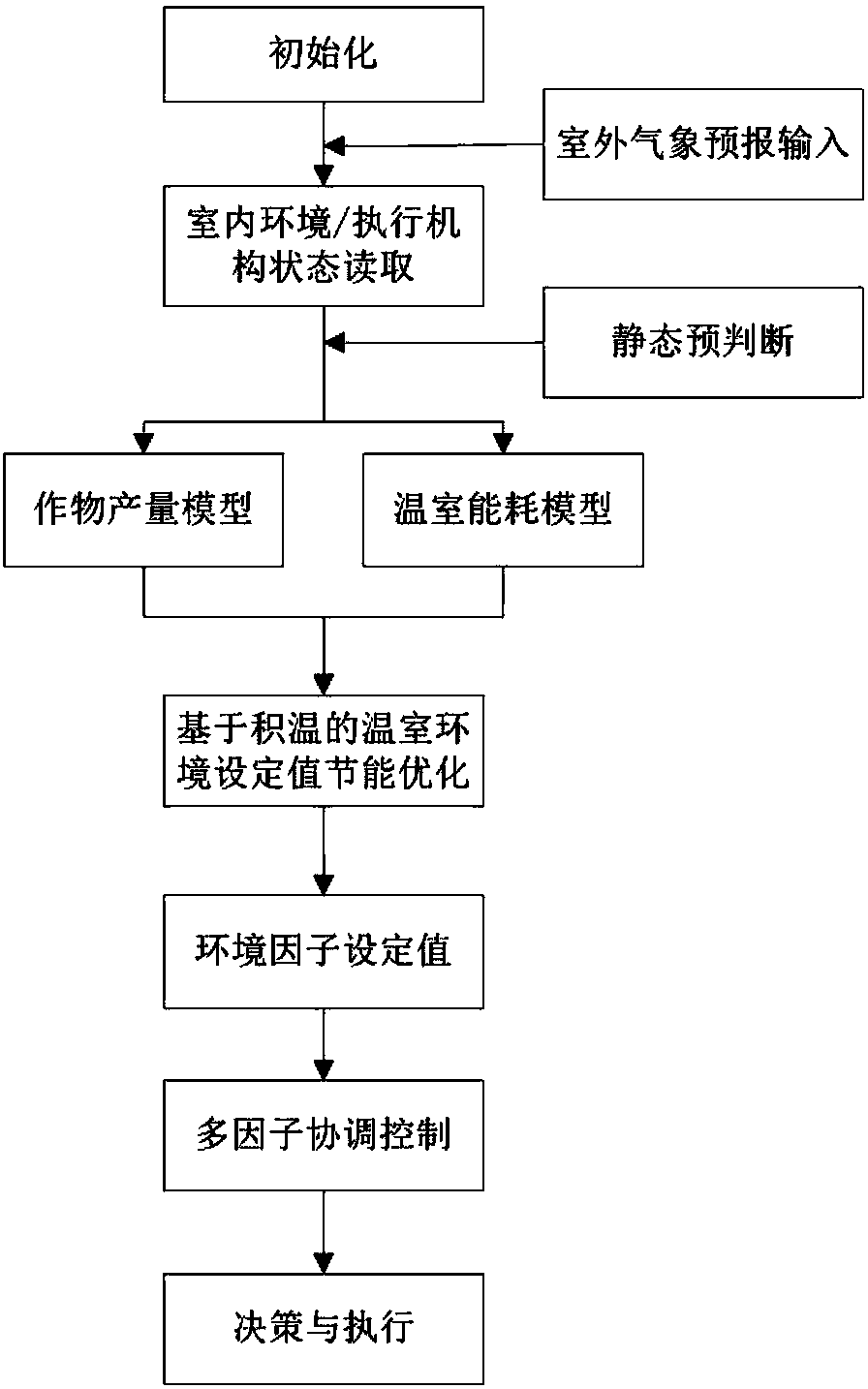

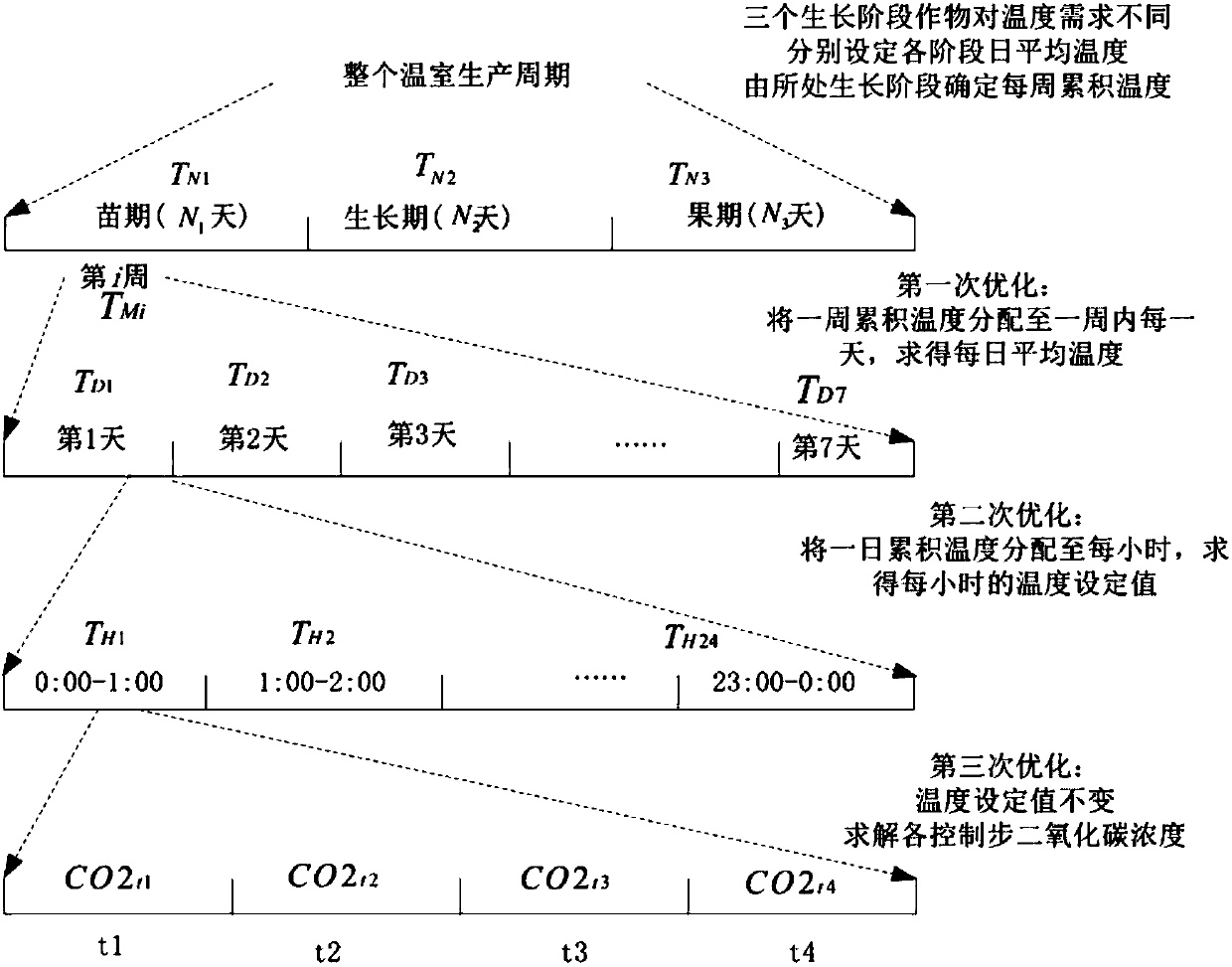

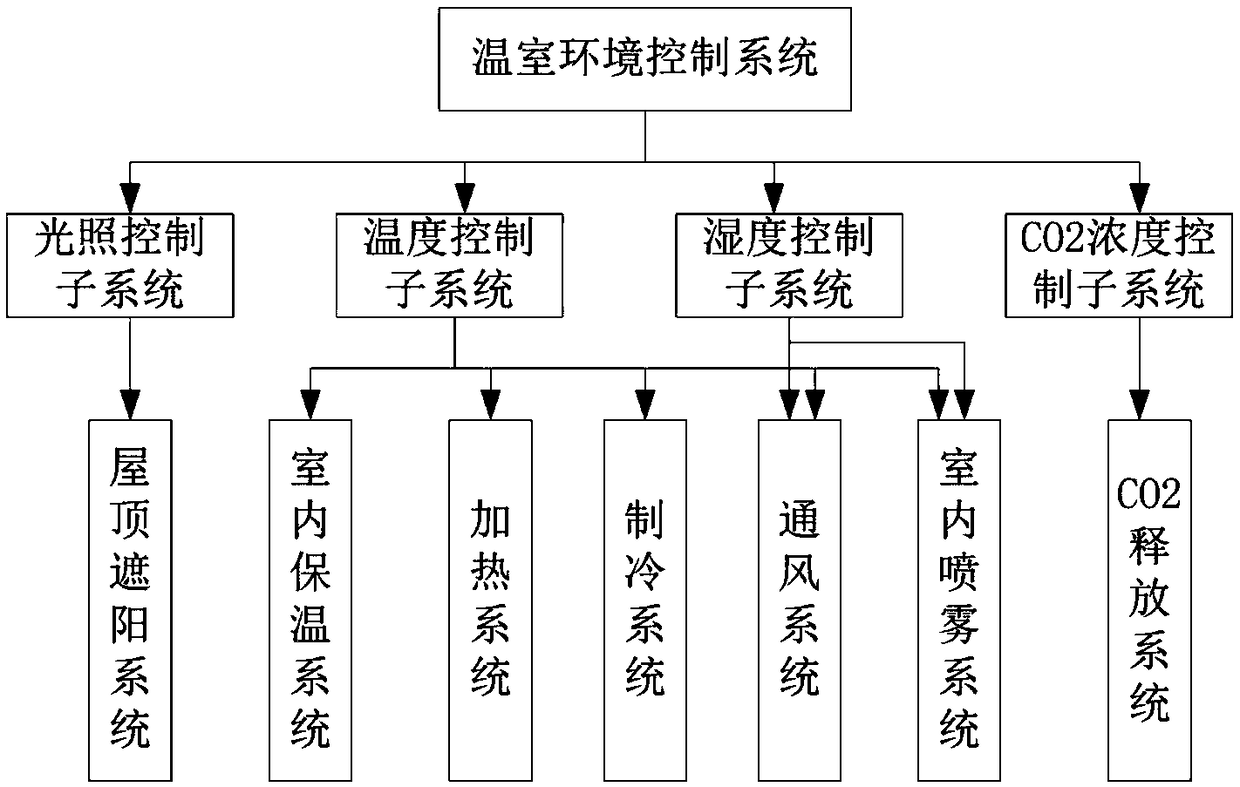

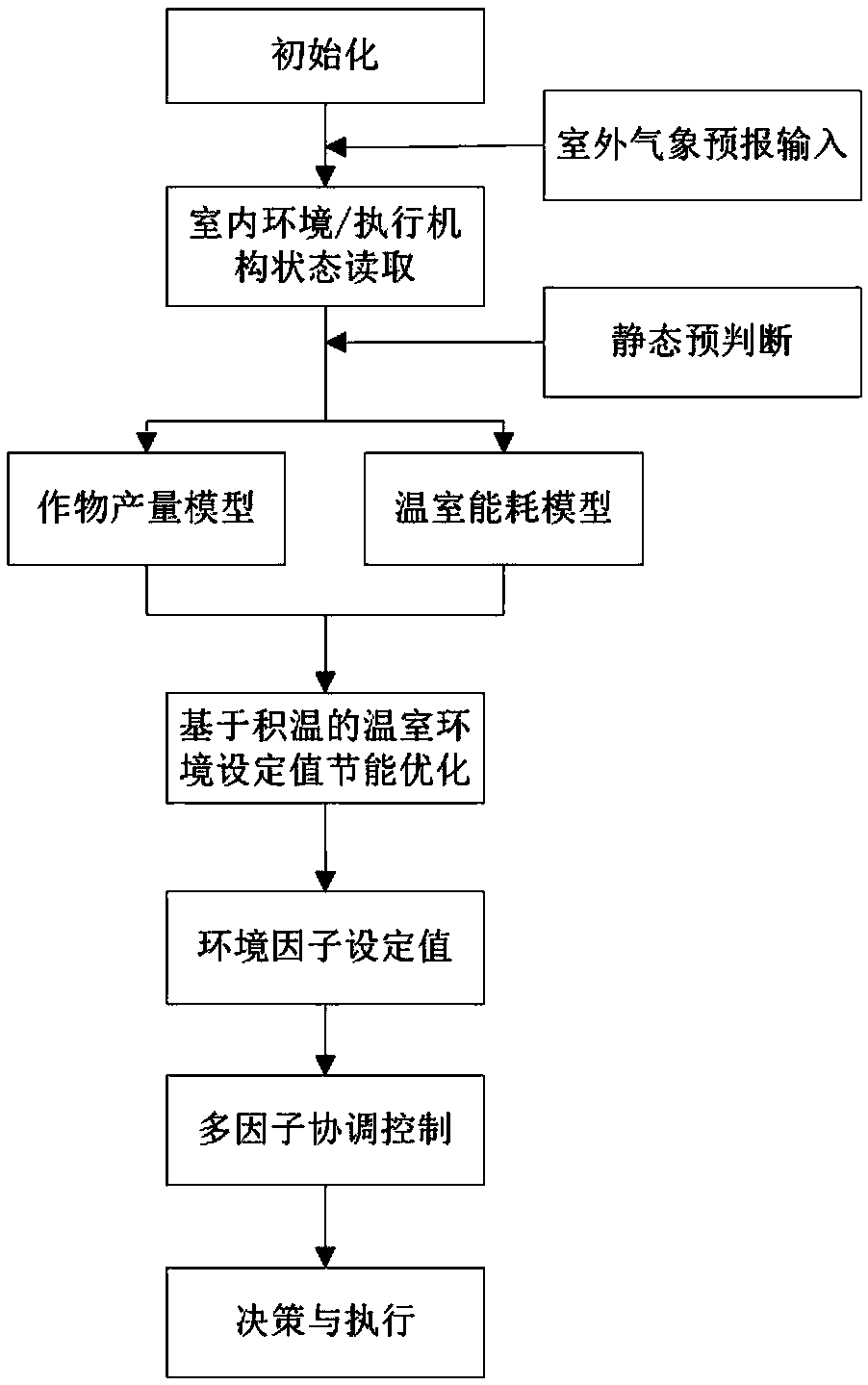

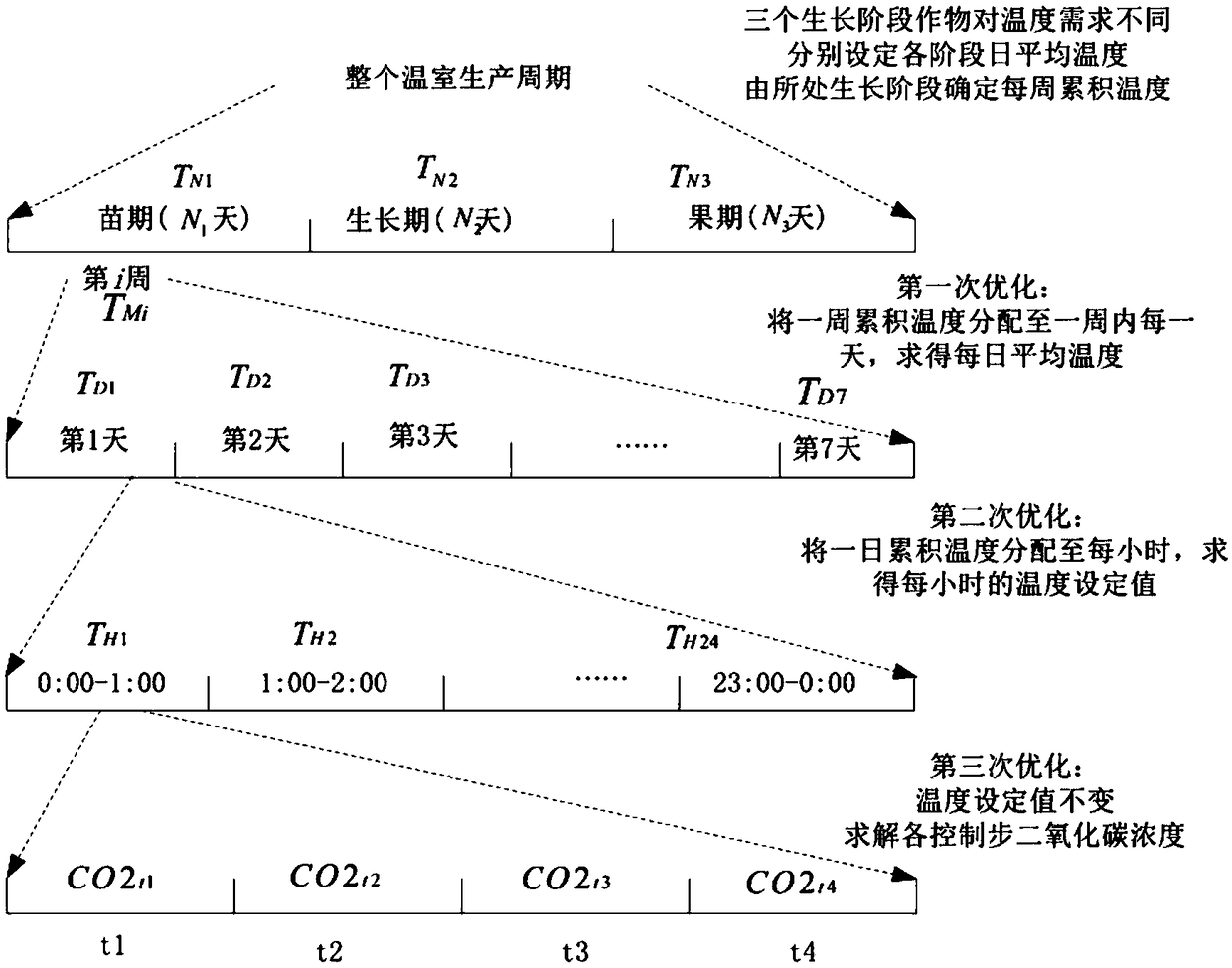

Multi-factor coordinated energy-saving optimization control method of greenhouse environment

ActiveCN107045367AReduce energy consumptionGuaranteed accumulated temperature requirementsSimultaneous control of multiple variablesEnvironmental factorCrop

The invention relates to a multi-factor coordinated energy-saving optimization control method of a greenhouse environment. The method comprises: (1), an expected daily average temperature of the crop in each growth period is set and weather forecast data of next seven days are obtained; (2), a greenhouse ventilation system state is estimated; (3), setting values of all environmental factors in the greenhouse are set by using a multi-factor coordination algorithm according to the steps (1) and (2), wherein the environmental factors include a temperature, humidity, a light radiation intensity and carbon dioxide concentration; and (4), real-time environmental factor values are obtained and corresponding executing mechanisms in the greenhouse are regulated according to the environmental factor setting values. Compared with the prior art, on the basis of crop physiological properties like temperature accumulation, the energy consumption of the greenhouse can be reduced effectively. With corresponding strategies, secondary greenhouse environment factors are coordinated to main temperature factors equivalently, thereby guaranteeing the precision and efficiency of greenhouse regulation, avoiding unnecessary energy wasting, saving the regulation cost, and ensuring the precise and effective controlling.

Owner:TONGJI UNIV

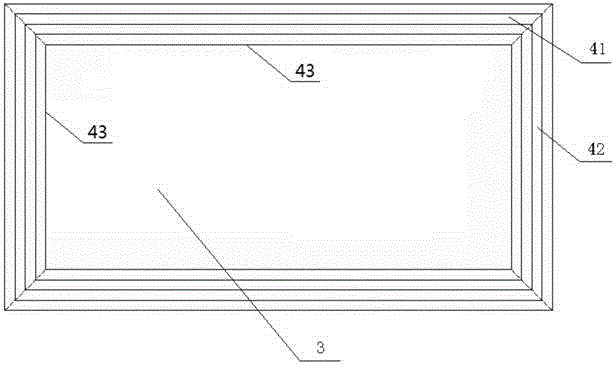

Frame-free display device and joint-free large-screen splicing display system

The invention discloses a frame-free display device and a joint-free large-screen splicing display system, and relates to the technical field of large-screen splicing display. The frame-free display device comprises a display screen with a frame, and the display area of the display screen includes a central area and fringe areas between the central area and the frame. An optical transparent panel covers in front of a central-area watching surface, and eccentric linear Fresnel lenses cover in the front of fringe-area watching surfaces. The Fresnel center line of each eccentric linear Fresnel lens is near to one side of the central area. The eccentric linear Fresnel lenses used for amplifying the fringe areas are arranged in front of the fringe areas of the display screen with the frame, and the amplified fringe areas are larger than or equal to the frame and completely cover the frame, so that the frame of the display device is eliminated visually.

Owner:OCRE TECH CO LTD

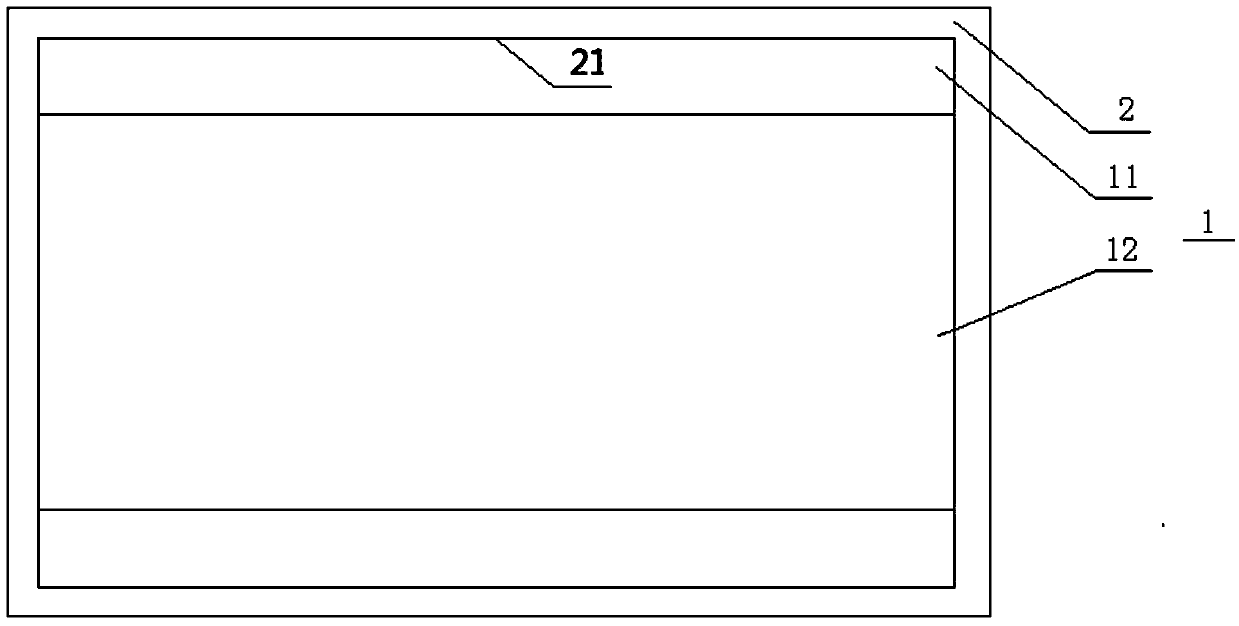

Display panel and display device

InactiveCN110853572ARemove borderSolve technical problems with large bordersStatic indicating devicesSemiconductor/solid-state device detailsLED displayDisplay device

The invention provides a display panel and a display device. According to the display panel, a driving circuit of a driving circuit layer is divided into a first part, a second part and a connecting part, the first part is positioned at one side of a substrate, the second part is positioned at the other side of the substrate, and the projection area of the second part on the substrate is positioned in the projection area of the first part on the substrate, so that the second part is located in a display area, an external lead connection area which cannot be displayed is eliminated, a frame ofthe display panel is eliminated, and the technical problem that the external lead area of an existing LED display screen is larger, so that the frame is bigger, is solved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

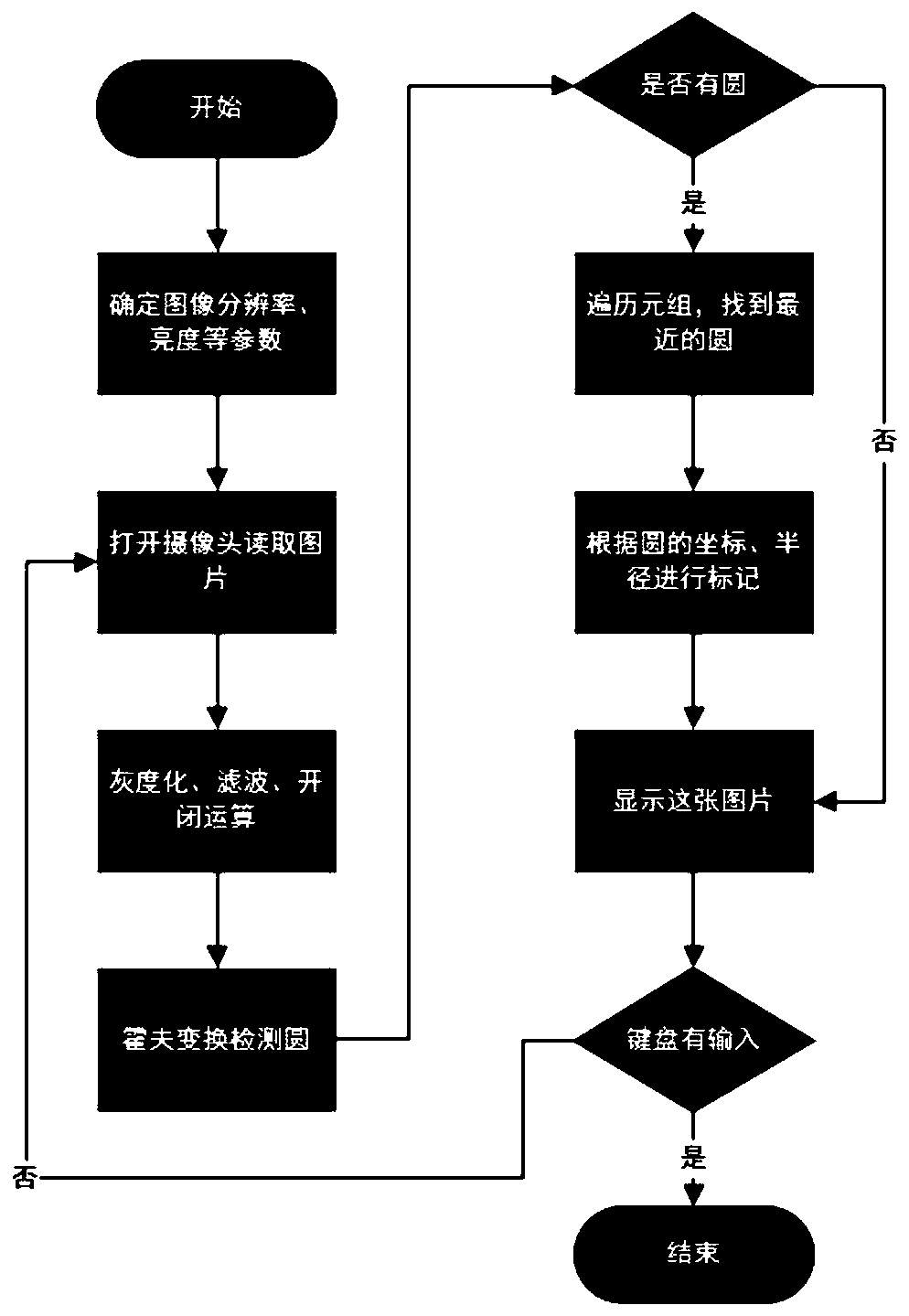

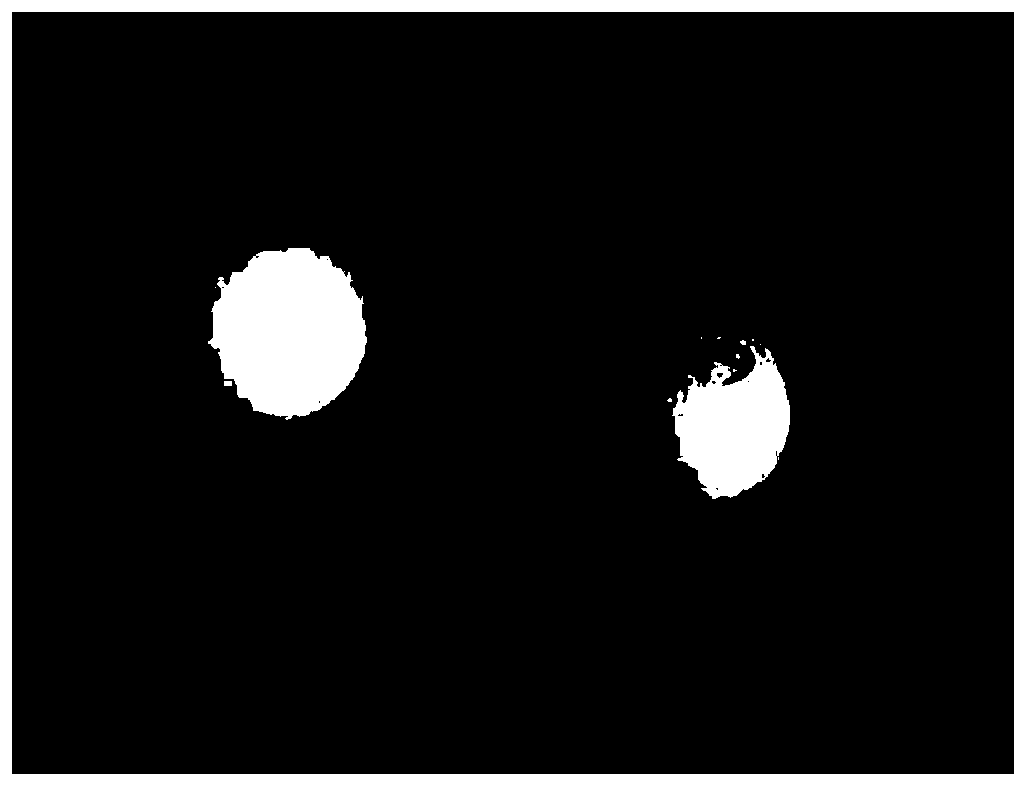

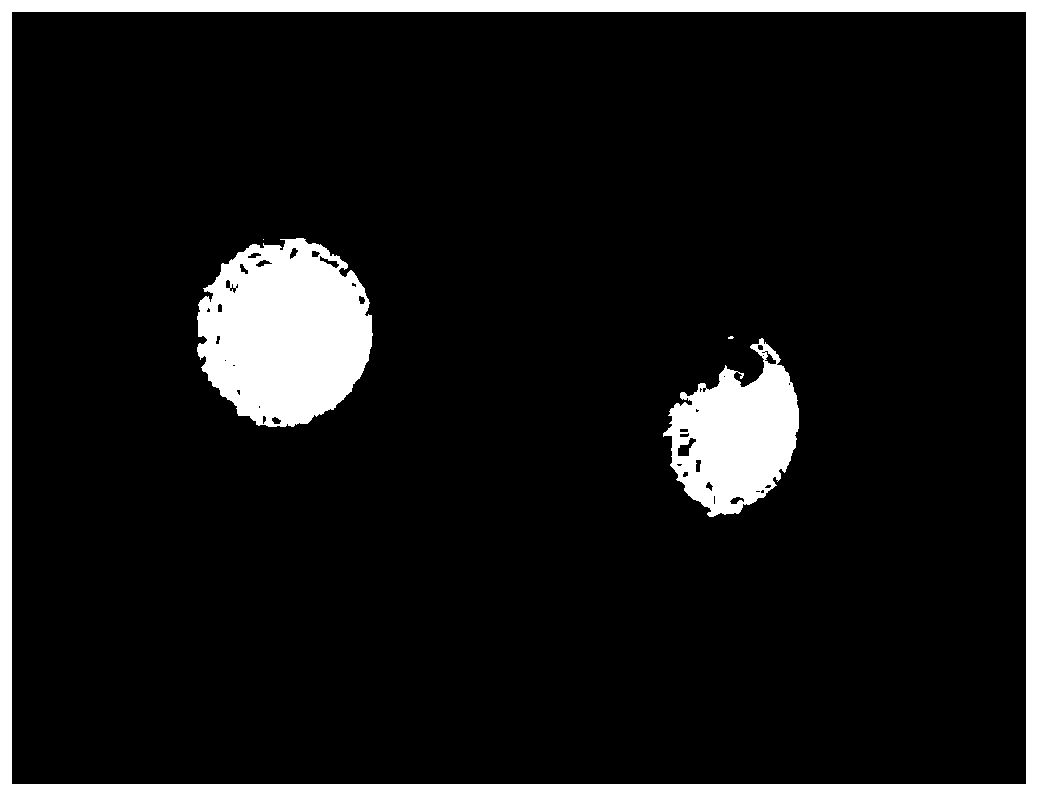

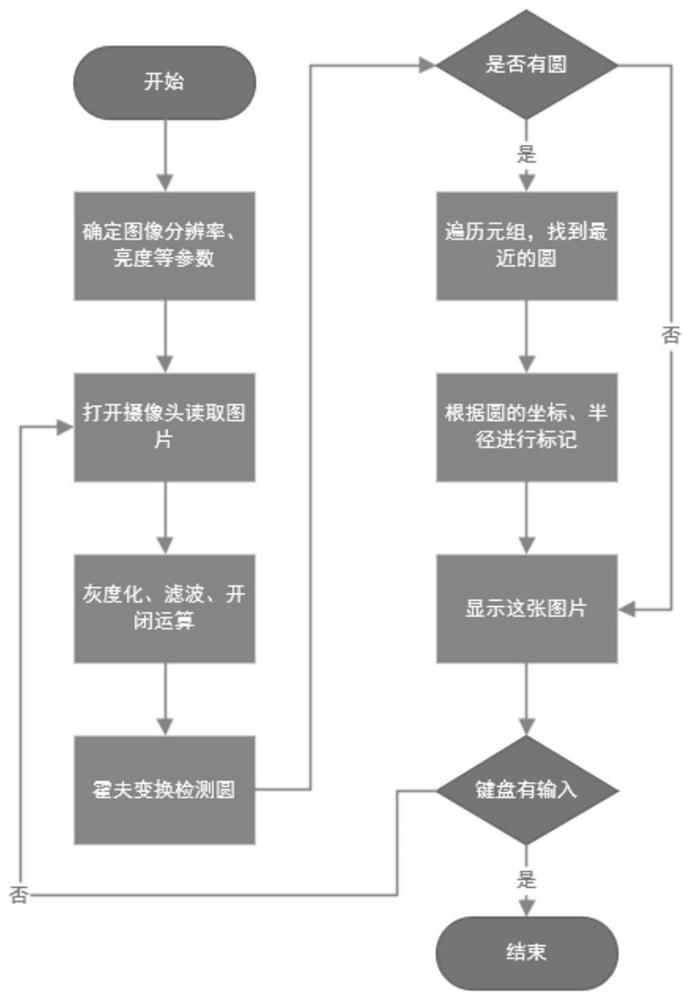

Table tennis ball recognition method based on Hough circle transformation technology

ActiveCN110866903ARemove borderImprove accuracyImage enhancementImage analysisPattern recognitionComputer graphics (images)

The invention discloses a table tennis ball recognition method based on a Hough circle transformation technology, for improving the recognition speed through a gradient Hough transformation method. The table tennis ball recognition method comprises the following steps: 1) image graying processing; 2) filtering processing; 3) edge extraction; 4) table tennis ball marking; and 5) special processingand related parameter setting for table tennis ball recognition. Compared with the prior art, the table tennis ball recognition method has the advantages that for the pictures read in the camera, thetable tennis balls contained in each frame of picture can be recognized in real time, and the table tennis balls can be accurately recognized under complex conditions.

Owner:BEIJING UNIV OF TECH

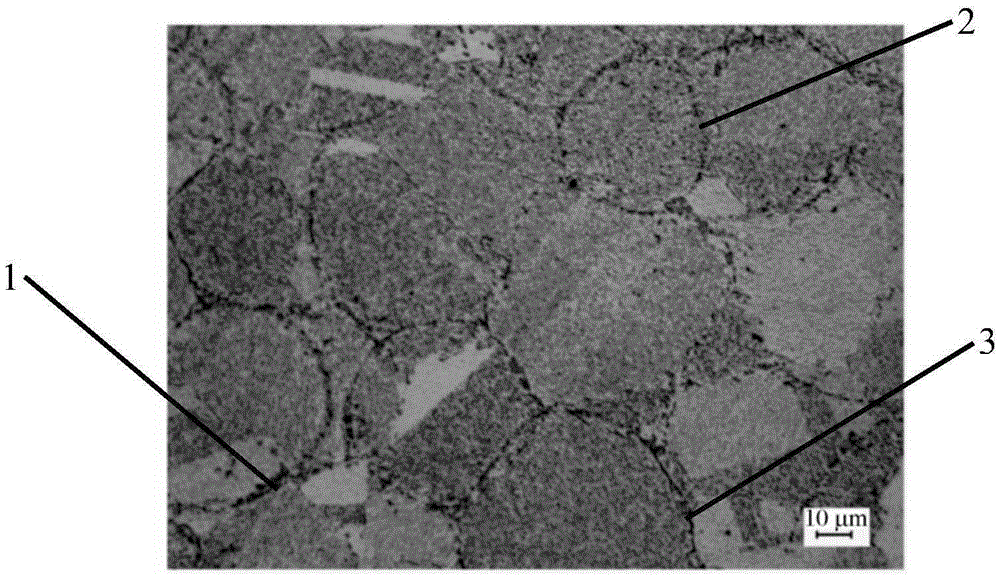

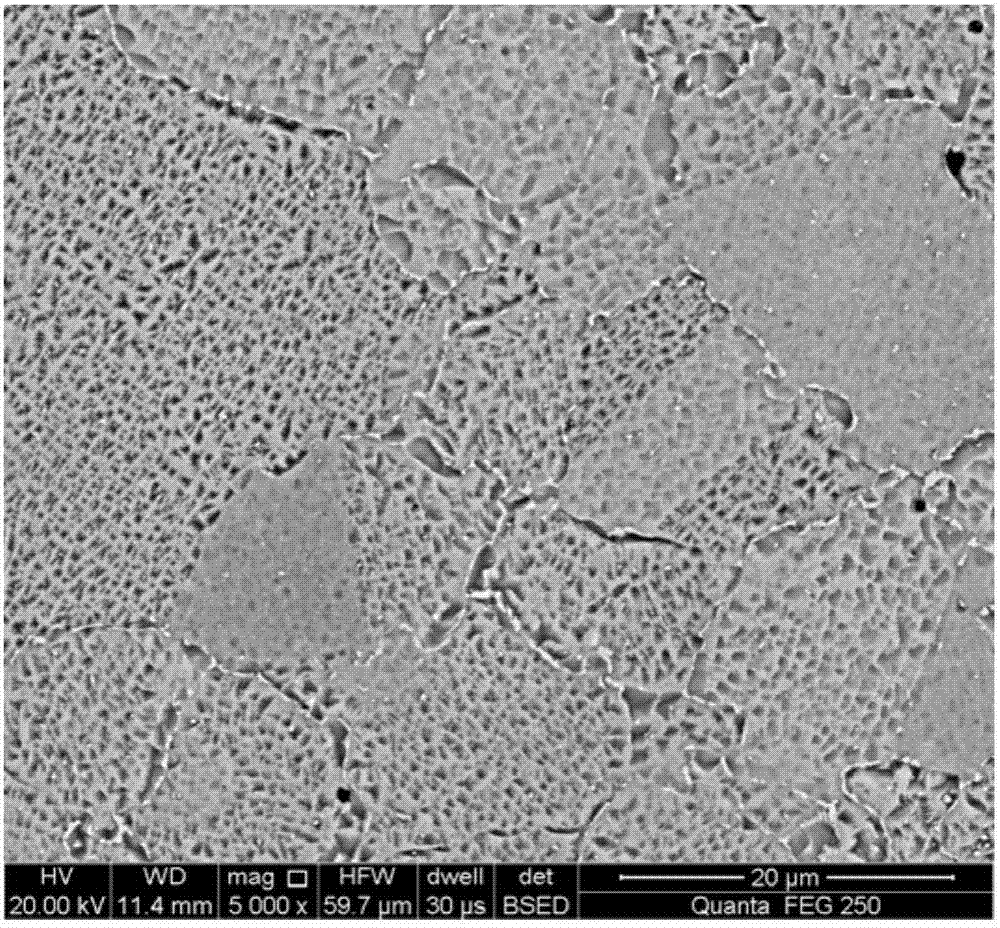

Method for preparing nickel-based powder superalloy through spark plasma sintering

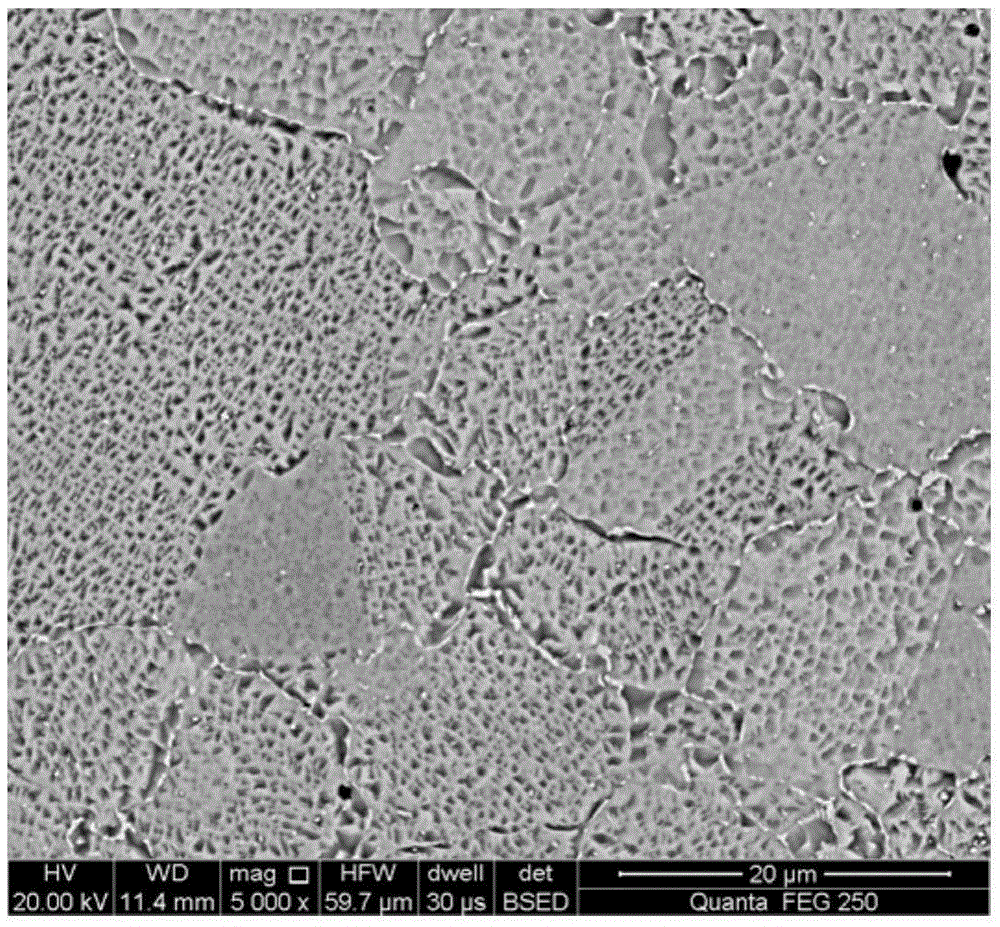

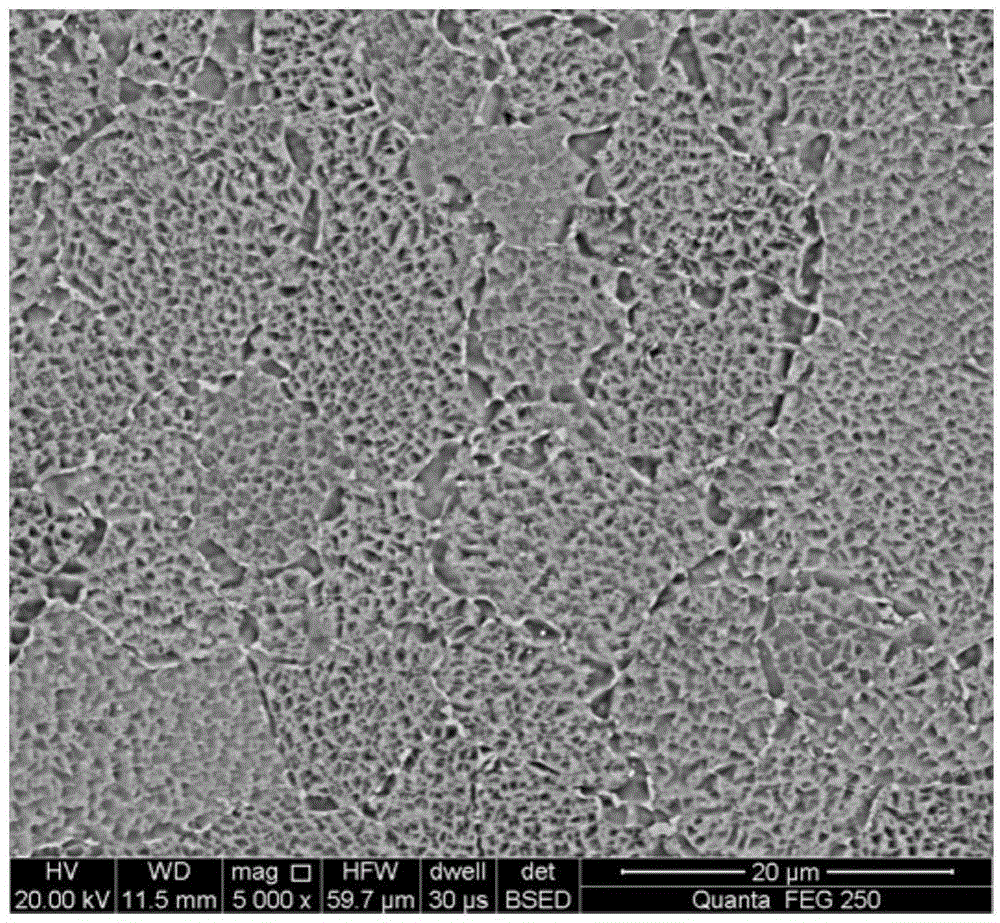

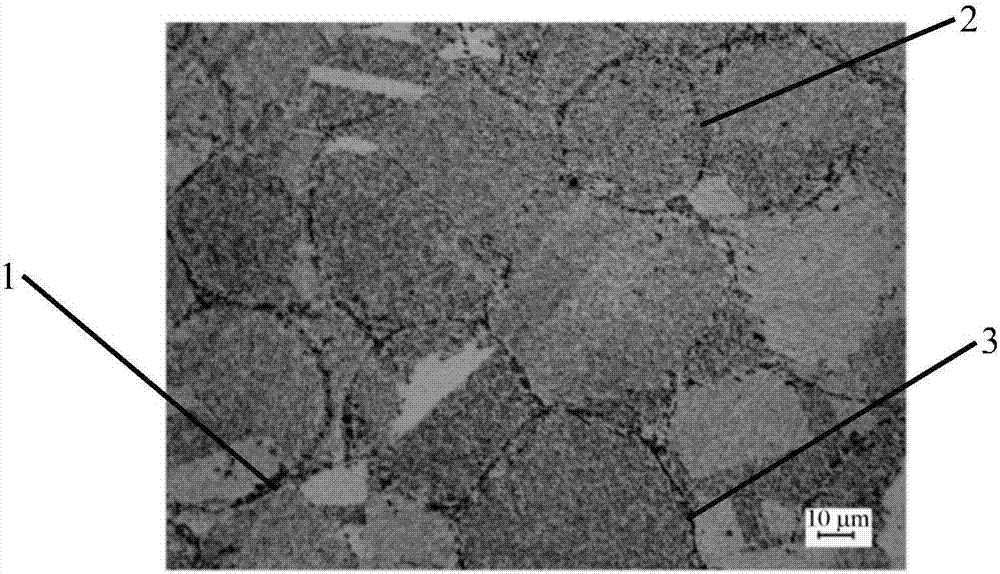

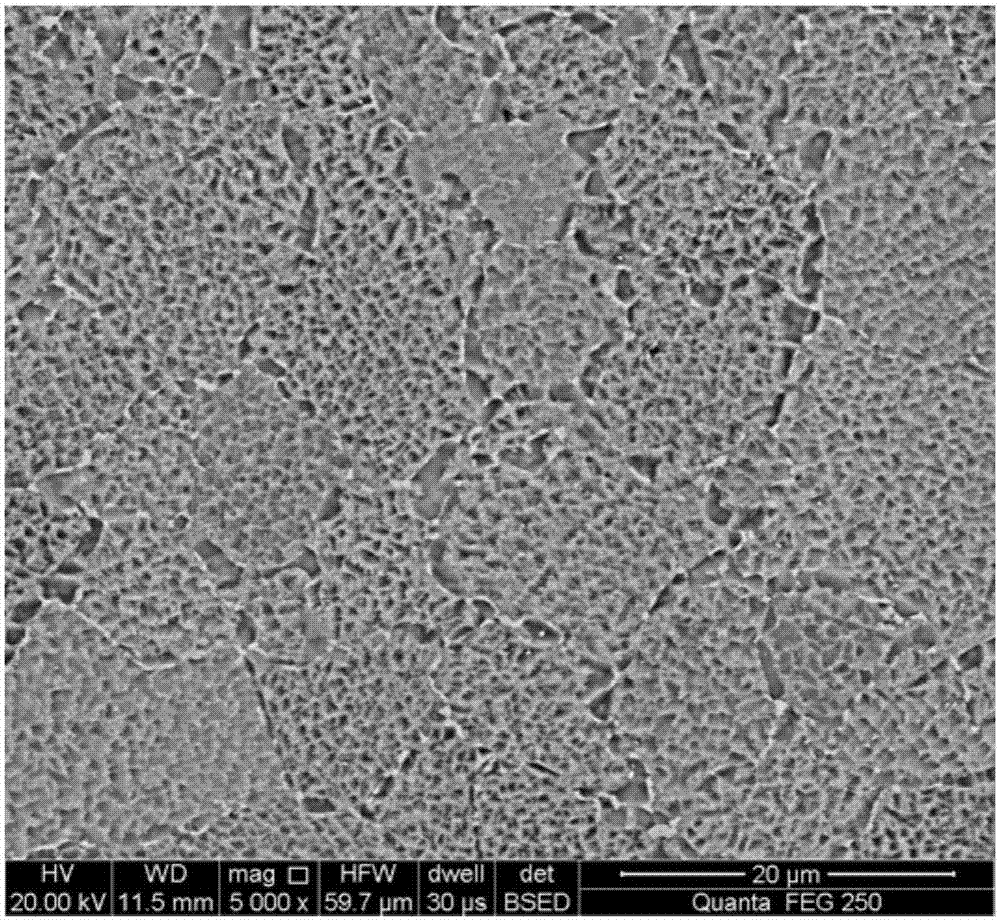

ActiveCN105397085ARapid sinteringFine equiaxed grain structureIncreasing energy efficiencyCarbideBiological activation

The invention discloses a method for preparing nickel-based powder superalloy through spark plasma sintering, and belongs to the field of powder metallurgy materials. The spark plasma sintering process is adopted for sintering forming of atomized nickel-based superalloy powder, and then solid solution treatment and aging treatment are carried out to obtain the nickel-based powder superalloy. The spark plasma sintering process is adopted for preparing the nickel-based powder superalloy, rapid sintering forming of the powder is achieved, growth of grains can be effectively restrained, and the prepared superalloy is provided with the fine and uniform equiaxial structure; through powder surface discharge activation and rapid diffusion bonding, formation of complex carbides and oxides on the boundaries of powder particles is restrained, and original particle boundaries are eliminated; the method is simple in process route, preparation time is short, the second phase is small in size and uniform in distribution, and the mechanical property is good.

Owner:CENT SOUTH UNIV

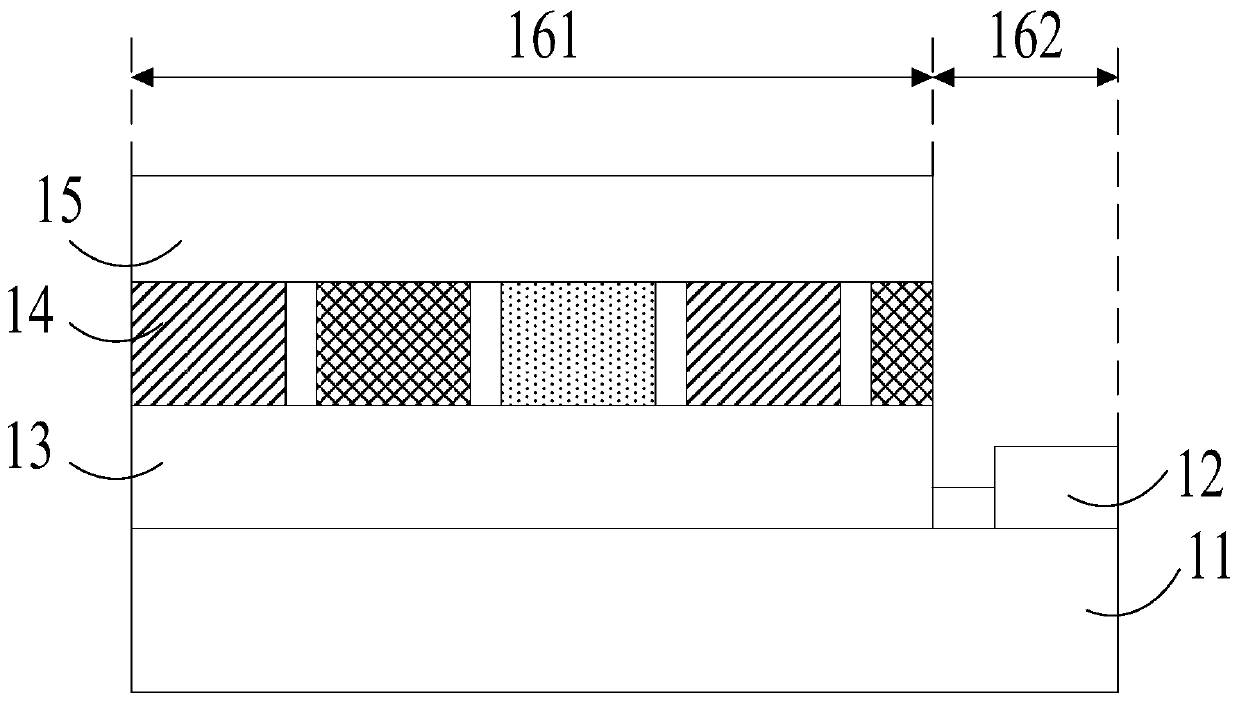

LDC panel and preparation method thereof

InactiveCN110221472ARemove borderIncrease the proportionSubstation equipmentNon-linear opticsEngineeringElectronic component

The present invention provides an LCD display and a preparation method thereof. The LCD panel comprises an electronic component setting region corresponding to an electronic component setting position, wherein the electronic component setting region is provided with a polymer dispersed liquid crystal, and the polymer dispersed liquid crystal of the electronic component setting region is processedto form retaining walls and a liquid crystal, with the liquid crystal located between the retaining walls. By disposing the polymer dispersed liquid crystal in the electronic component setting regionand processing the polymer dispersed liquid crystal of the electronic component setting region to form the retaining walls and the liquid crystal, the electronic component setting region is caused tobe spaced from a display region through the retaining walls, instead of being spaced with a bezel, thereby removing the bezel between the electronic component setting region and the display region andincreasing the ratio of a screen. Furthermore, the liquid crystal and the retaining walls are transparent, such that the electronic component setting region is photic normally, thereby solving the technical problem of the bezel existing in a junction area between an Alien region and the display region for the current display screen of a mobile phone.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

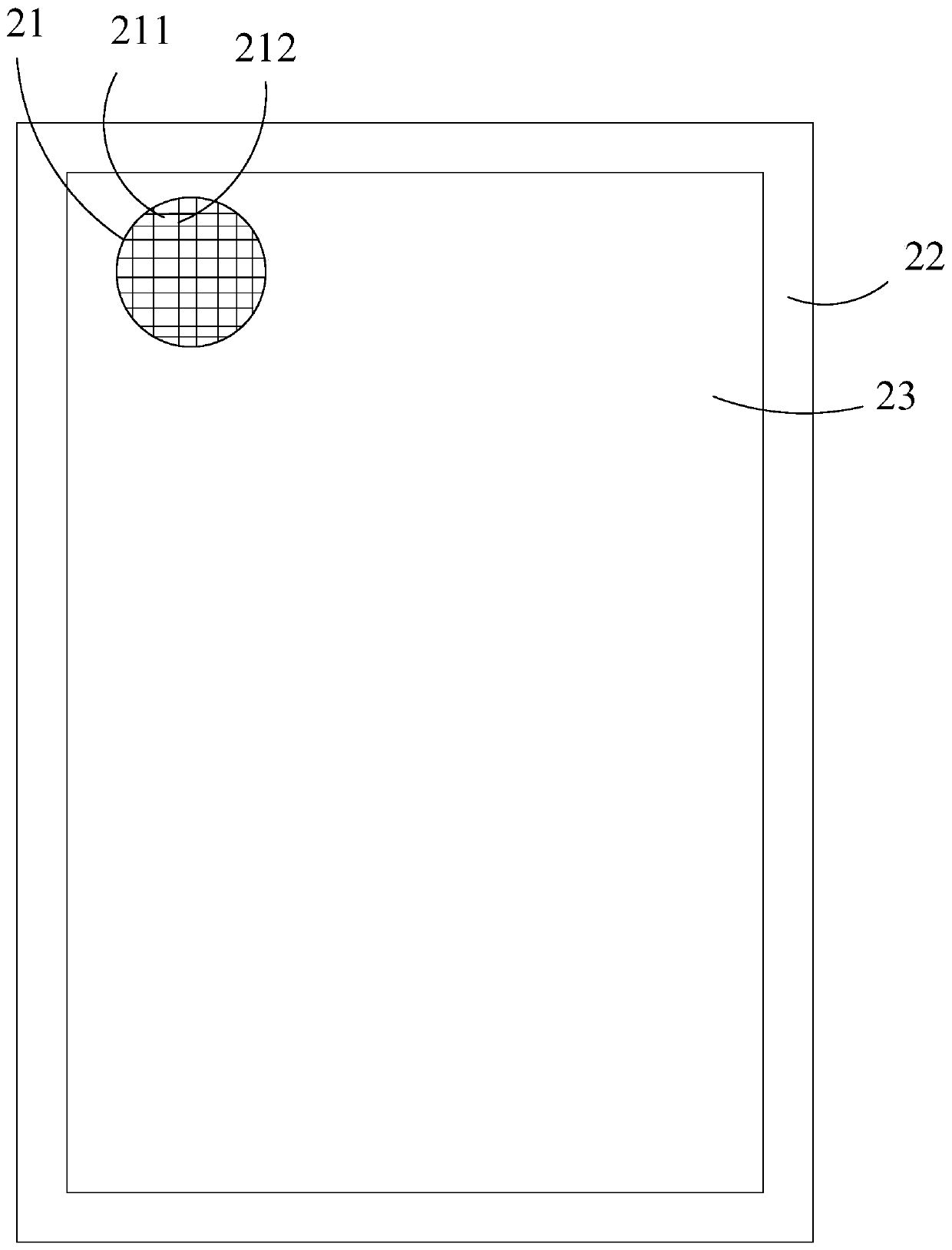

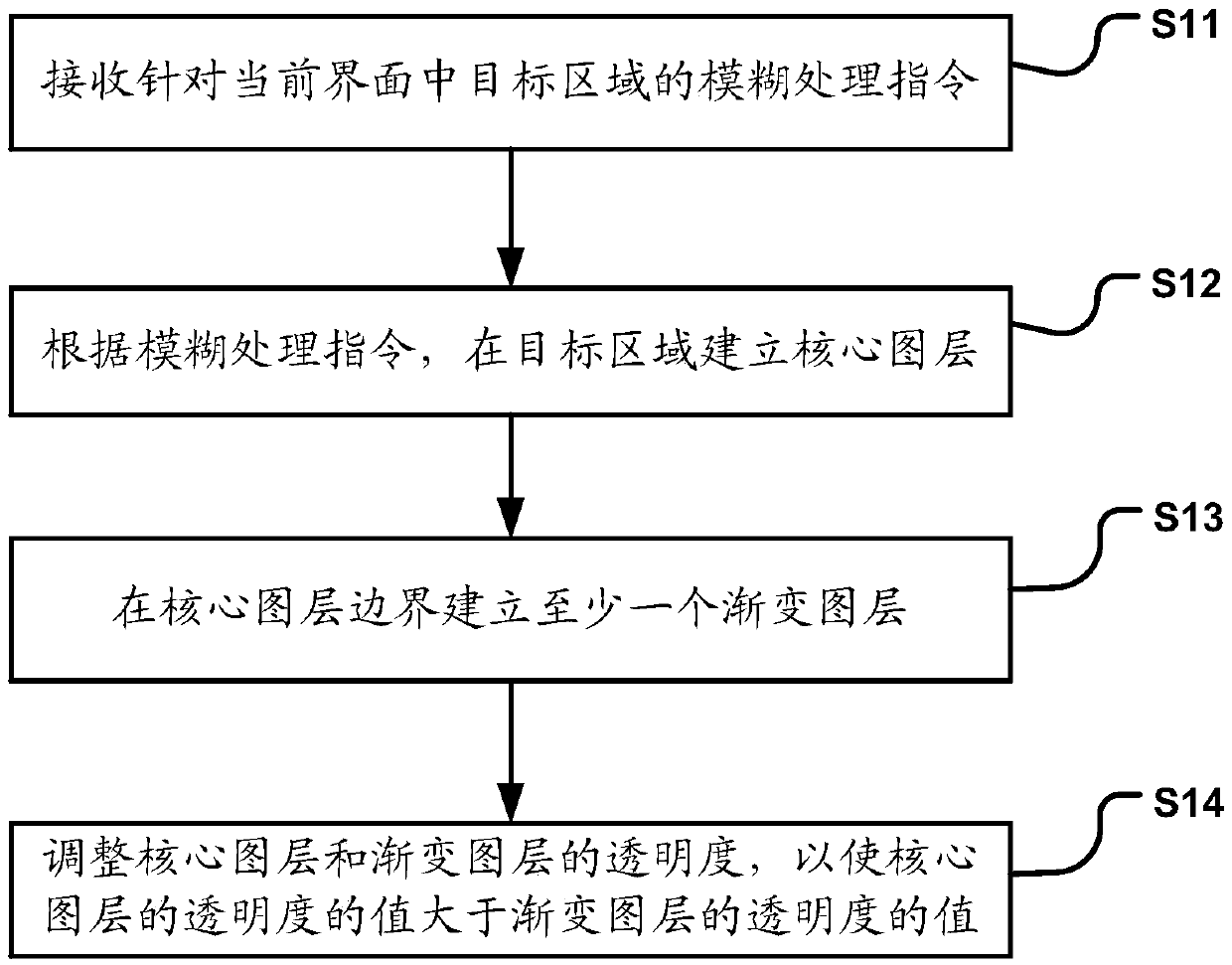

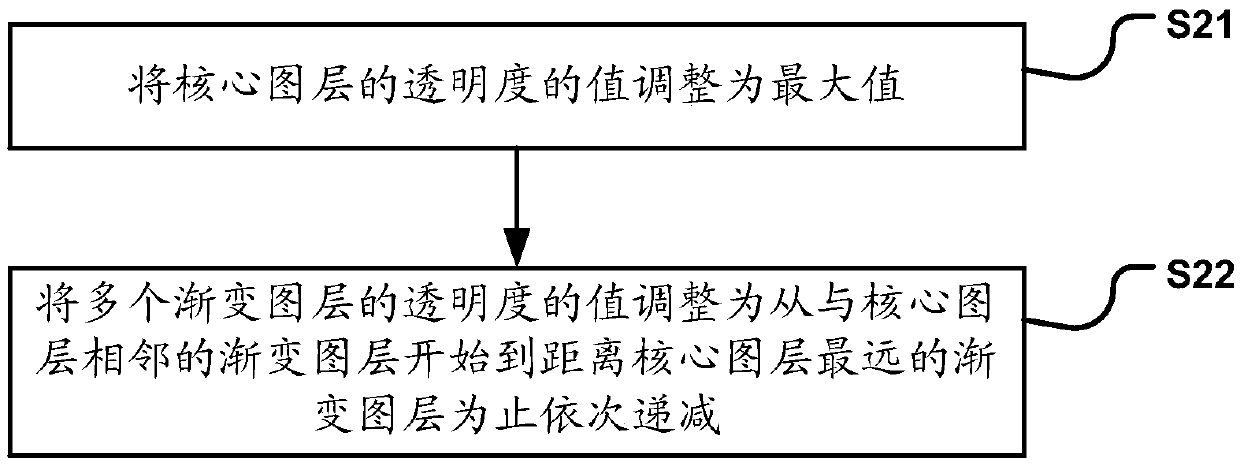

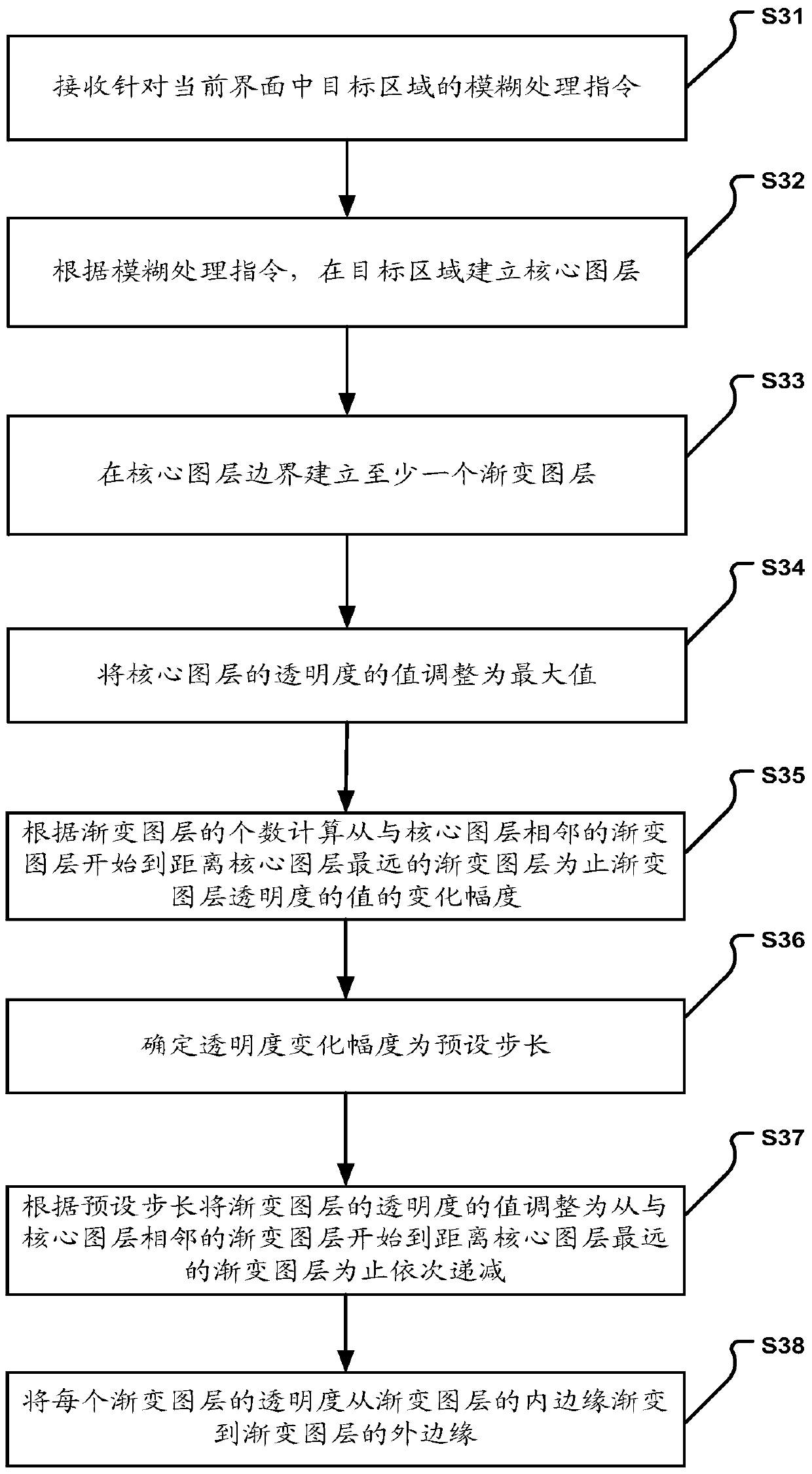

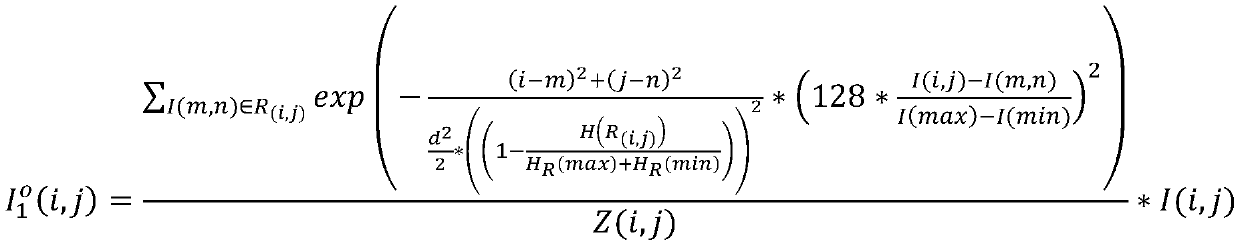

Fuzzy processing method and device

InactiveCN105513027AFade borderValue to increase transparencyImage enhancementImage analysisProcessing InstructionControl theory

The invention discloses a fuzzy processing method and device, realizing the gradual change effect between a fuzzy area and a non-fuzzy area, so as to weaken the boundary between the fuzzy area and the non-fuzzy area. The method comprises: receiving a fuzzy processing instruction specific to the object area in a current interface; according to the fuzzy processing instruction, creating a core layer in the object area; establishing at least one gradual change layer on the boundary of the core layer; and adjusting the transparency between the core layer and the gradual change layer, allowing the transparency value of the core layer to be greater than the transparency value of the gradual change layer, wherein transparency values and transparency form an inverse relation. According to the invention, one or more than one layer of gradual change layer having the transparency smaller than the transparency of the core layer is / are arranged between the fuzzy area and the non-fuzzy area, realizing the gradual change effect between the fuzzy area and the non-fuzzy area, and weakening the boundary between the fuzzy area and the non-fuzzy area.

Owner:TVM BEIJING TECH

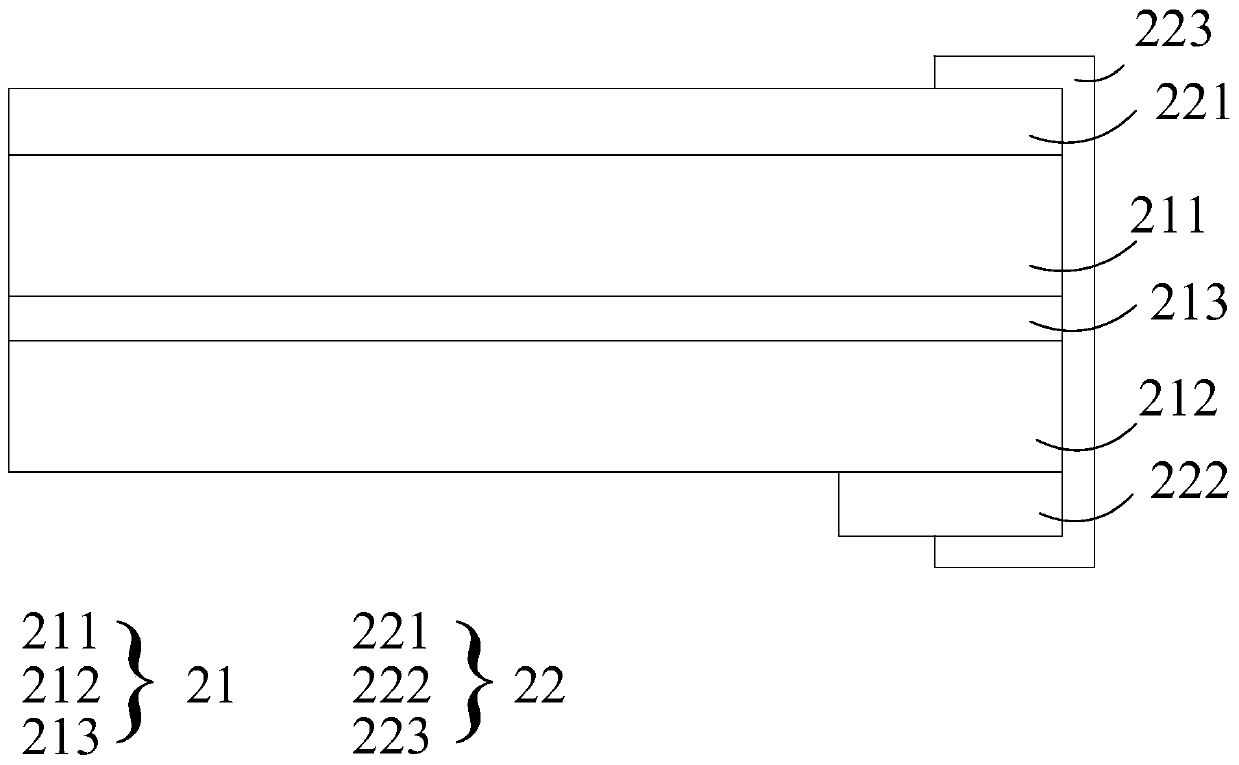

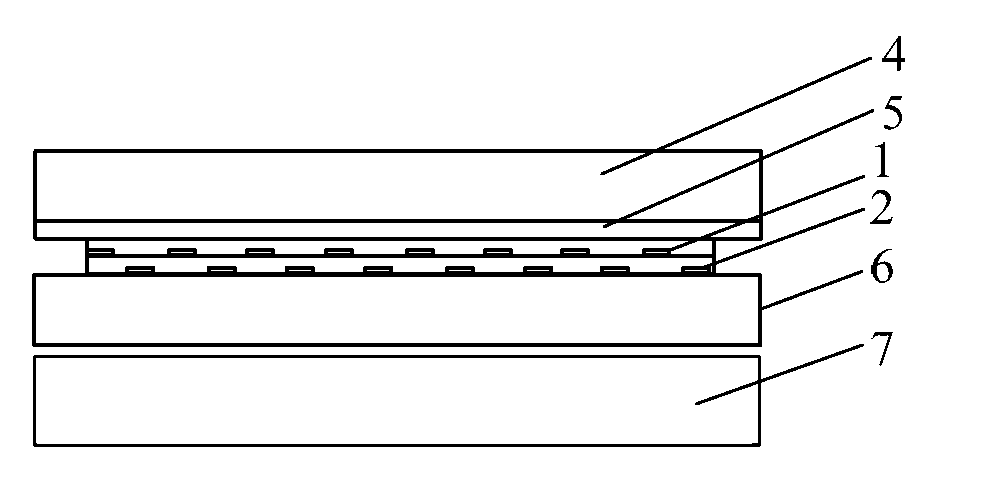

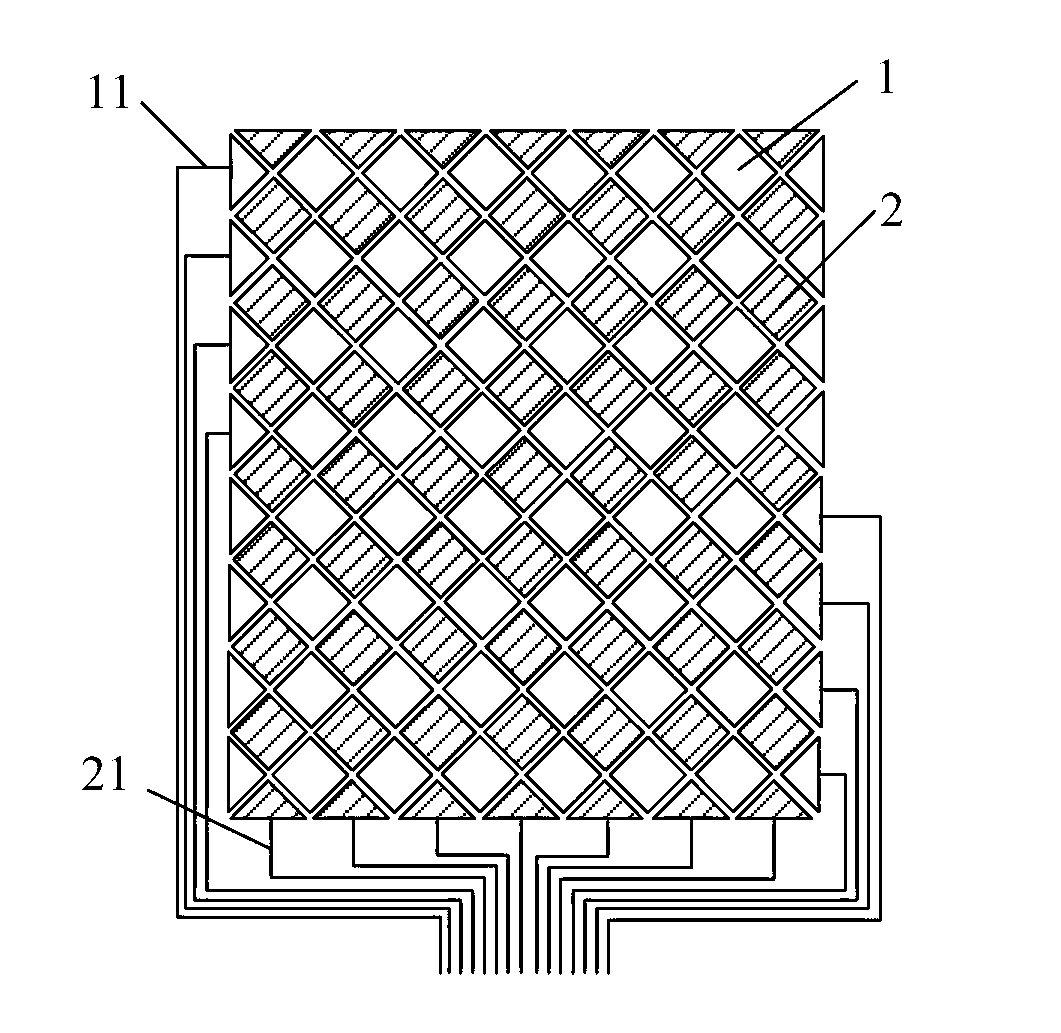

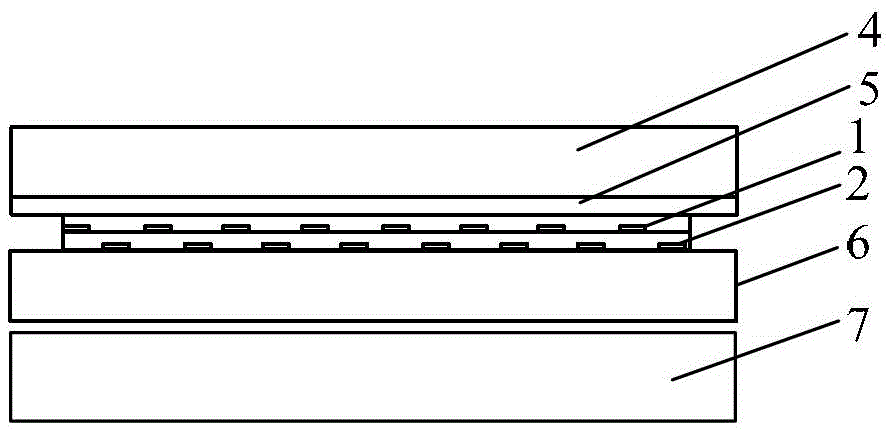

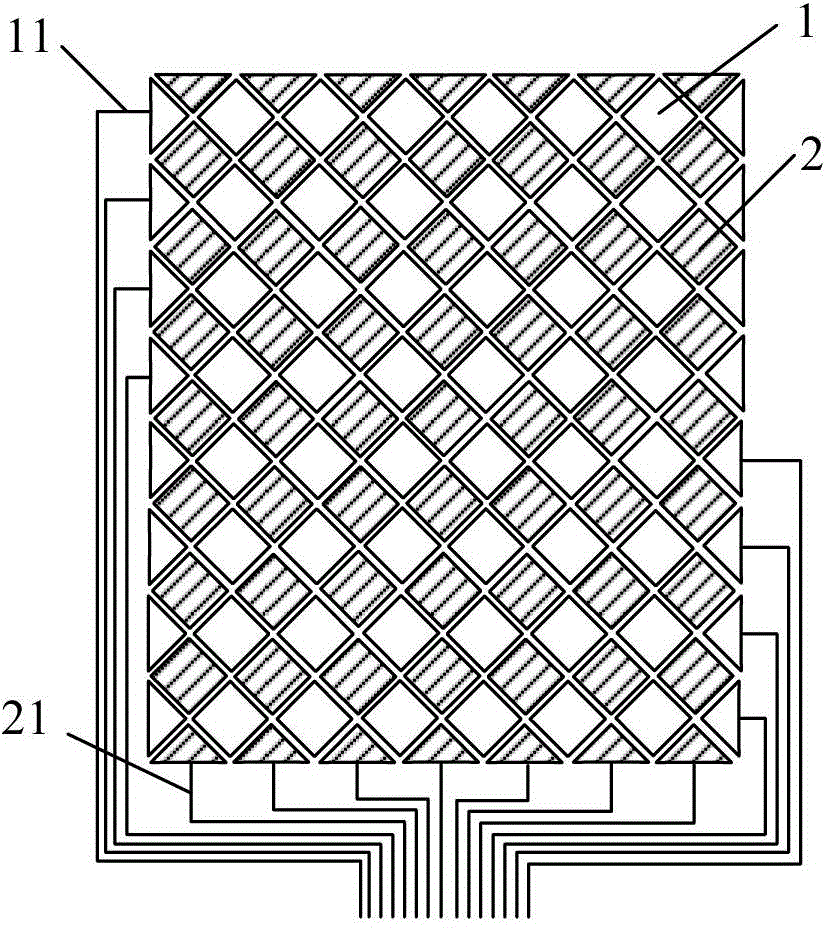

Capacitive touch screen and terminal

ActiveCN102707856AReduce widthRemove borderDigital data processing detailsInput/output processes for data processingVertical projectionEngineering

The embodiment of the invention discloses a capacitive touch screen and a terminal, which have the capability of reducing and even removing the width of a side frame of the terminal. The capacitive touch screen comprises base plates of a first surface and a second surface, a first graph, and a first outlet line, wherein the first graph and the first outlet line are formed on the first surface of the base plate; some area on the first surface of the base plate is covered by the first graph; the first outlet line is formed within the area on the first surface of the base plate out of first graph; the capacitive touch screen further comprises a second graph and a second outlet line which are formed on the second surface of the base plate, wherein some area of the second surface of the base plate is covered by the second graph; and the second outlet line is formed on the area on the second surface of the base plate out of the second graph, wherein the first surface and the second surface are two opposite surfaces of the base plate, and the vertical projection of the second graph on the first surface at least covers the area on the first surface out of the first graph.

Owner:HONOR DEVICE CO LTD

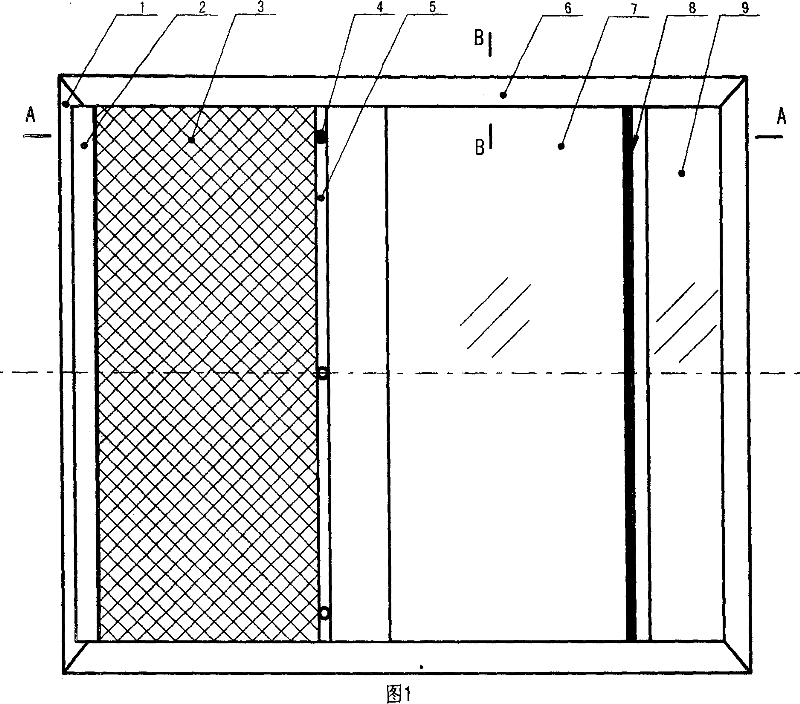

Window of frameless window linked with frameless mesh window

InactiveCN101042039AIncrease the lighting areaImprove breathabilityInsect protectionSealing arrangementsGlass windowEngineering

It relates to a frameless glass wire gauze window. A seal strip is fixed inside between two frameless glass window and the fixed connecting strip of the inside of the frameless glass window connects with the fixed connecting strip of the fixed connecting strip at the end of the wire gauze in embedment. It is simple, novel in design, convenient and practical, high in working efficiency, reduced in cost, improved in lighting efficiency and ventilation effect, a substitute of existing glass windows.

Owner:李自力

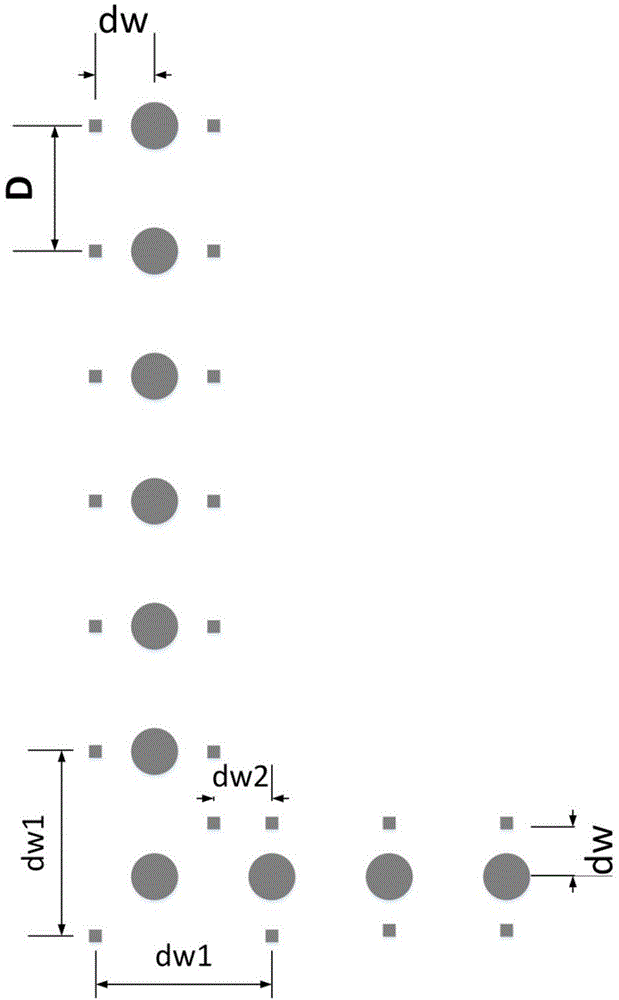

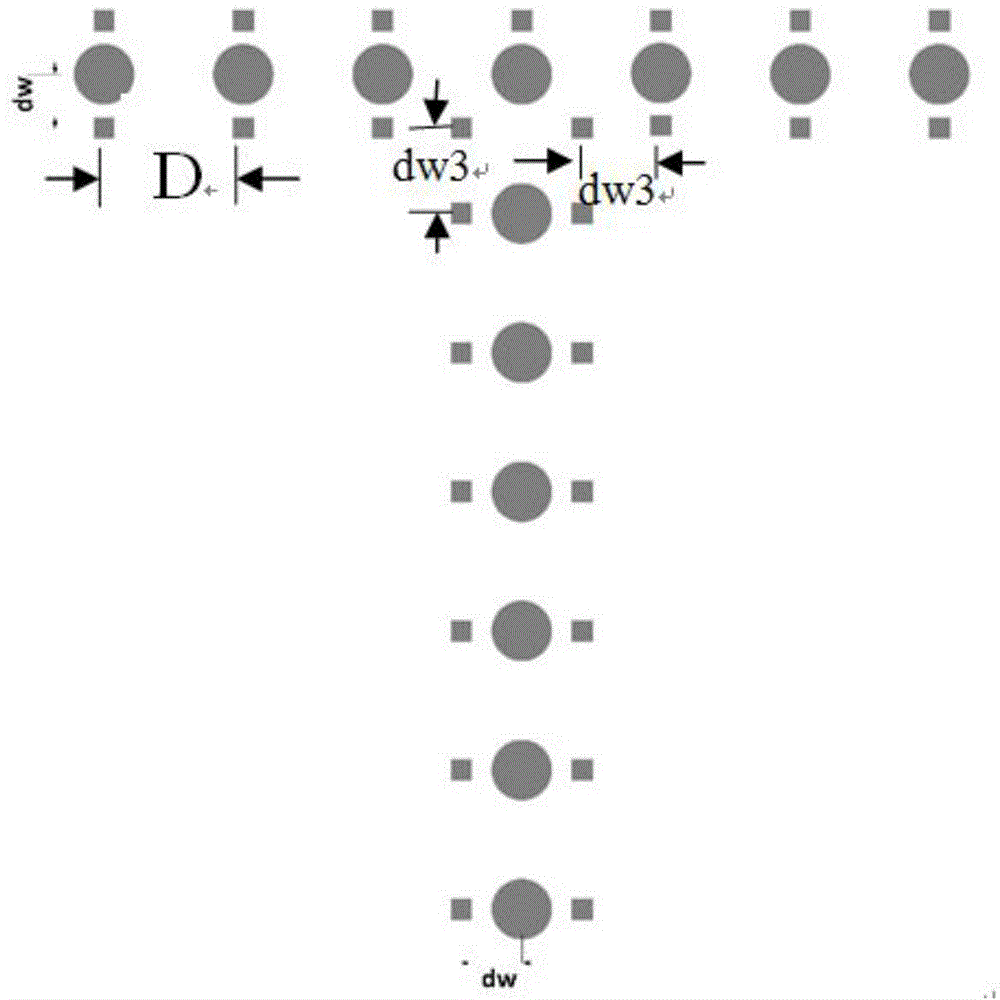

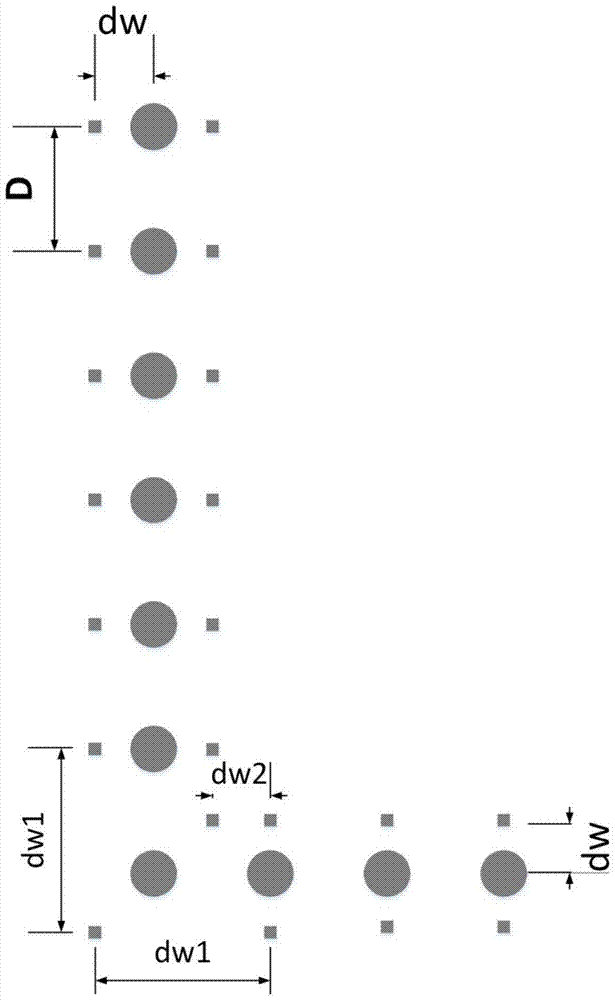

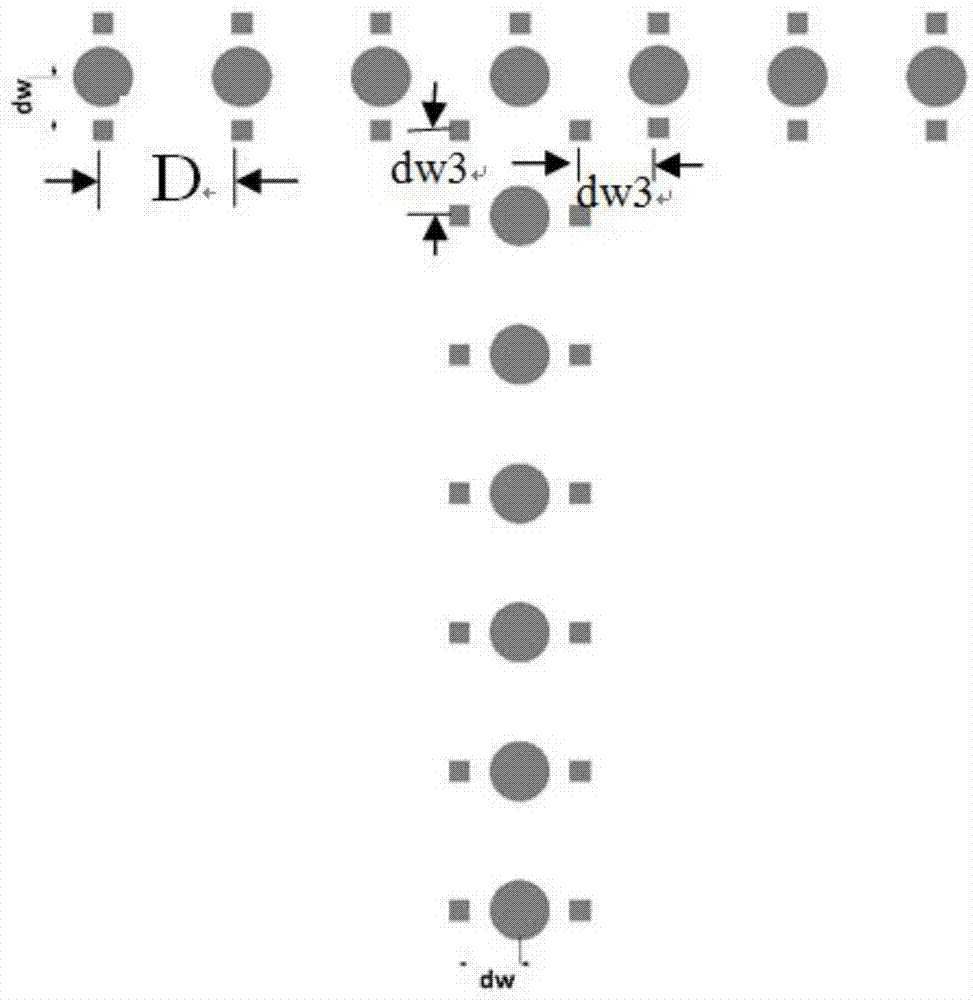

Method for constructing shaping field source based on metal scattering body assisting

InactiveCN104809282AEliminate side lobesRemove borderSpecial data processing applicationsComposite mediaSide lobe

The invention provides a method for constructing a shaping field source based on metal scattering body assisting, and belongs to the technical field of electromagnetic wave space propagation and control. The method is different from the method which uses the simple space discrete array for building the shaping field source. The novel method for constructing the shaping field source by adding a simple metal scattering body around the space discrete array or outside the shaping field area is provided on the basis of the electromagnetic scattering wave random phase cancelling principle in a composite medium space, and is used for sharpening an edge field of the shaping field and reducing the problem of excessive and overhigh side lobes outside the area. The method has the advantages that the geometric boundary of the shaping field can be sharpened, the problem of the side lobes outside the shaping field area can be effectively solved, the operation and implementing are simple and convenient, the complicated and time-wasted space field calculation and number optimizing are not needed, and the constructing difficulty of the high-quality shaping field source is greatly simplified.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

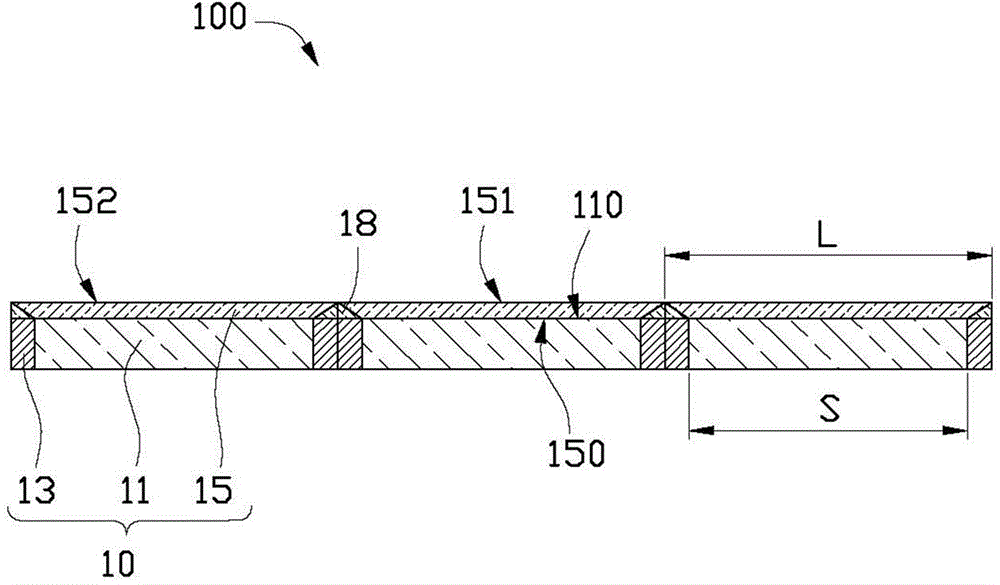

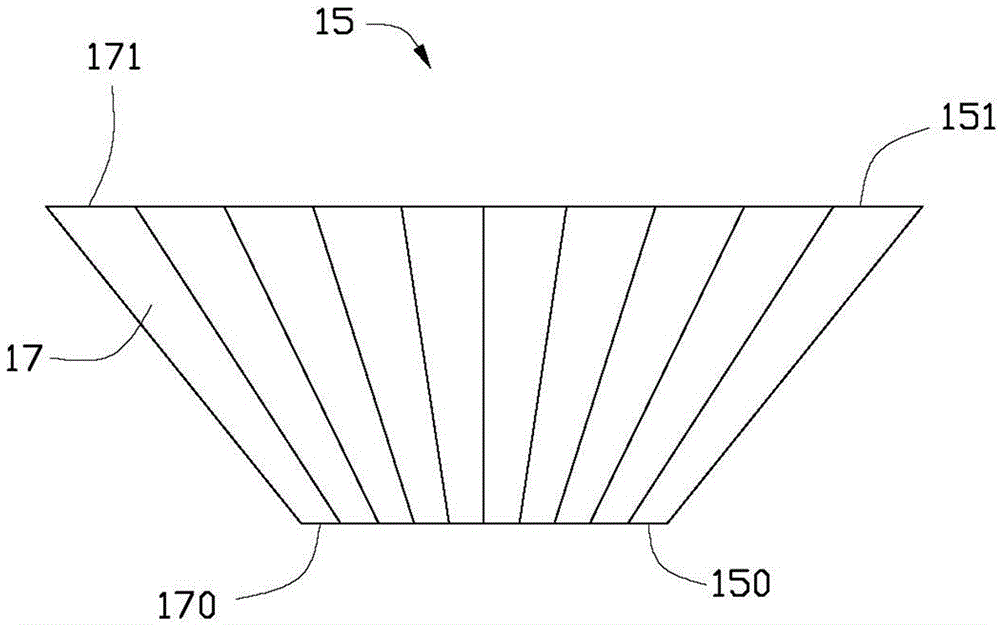

Display and television wall

InactiveCN104424864AImprove the display effectRemove borderPlanar/plate-like light guidesIdentification meansLight guideDisplay device

The invention provides a display which comprises a display panel, a frame and a light guide plate. The display panel comprises a display surface for displaying an image, the frame is positioned at the edge of the display surface, the light guide plate comprises a light entering surface and a light exiting surface which are opposite to each other, the light entering surface is positioned on the display surface, the light exiting surface covers the frame in a direction perpendicular to the display surface, the light guide plate comprises a plurality of arrayed optical fibers, each optical fiber comprises a light entering end and a light exiting end, the light entering ends are positioned on the light entering surface, the light exiting ends are positioned on the light exiting surface, the light entering ends of the optical fibers form the light entering surface, and the light exiting ends of the optical fibers form the light exiting surface. The invention further provides a television wall comprising a plurality of displays.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

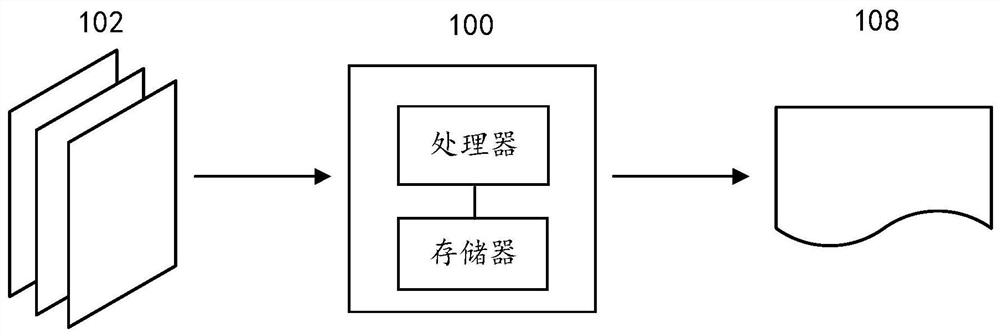

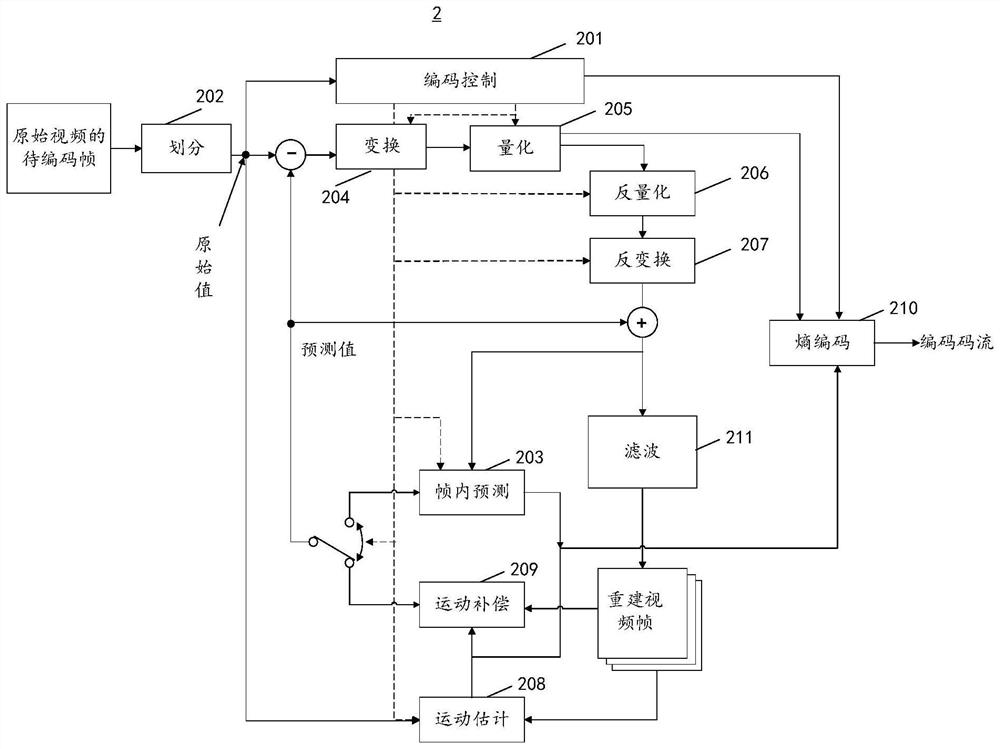

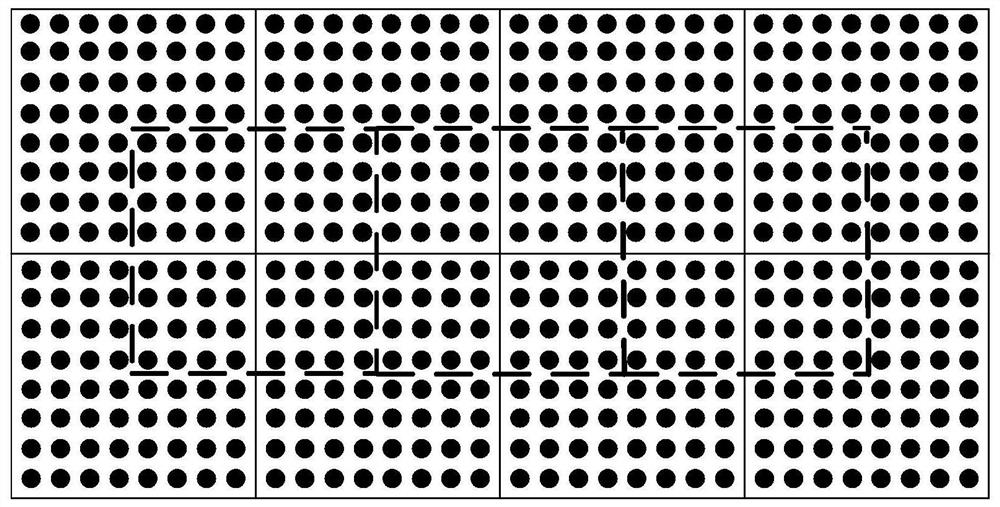

Video encoding method and apparatus

ActiveCN112514390AGuaranteed coding qualitySimplify Design ComplexityDigital video signal modificationPattern recognitionComputer graphics (images)

The invention provides a video encoding method and apparatus, comprising: receiving, with a first processor, first encoding parameter information and first reconstructed pixels of a first boundary image block in an image to be encoded, the first boundary image block being encoded by a second processor; receiving, by the first processor, second encoding parameter information and second reconstructed pixels of a second boundary image block in the image to be encoded, the second boundary image block being encoded by a third processor, the image to be encoded comprising a first image and a secondimage adjacent to each other, wherein the first boundary image block is a boundary image block in the first image, the second boundary image block is a boundary image block in the second image, and the second boundary image block is adjacent to the first boundary image block; and filtering, using the first processor, adjacent boundaries between the first image and the second image based on the first encoding parameter information, the second encoding parameter information, the first reconstructed pixel and the second reconstructed pixel.

Owner:SZ DJI TECH CO LTD

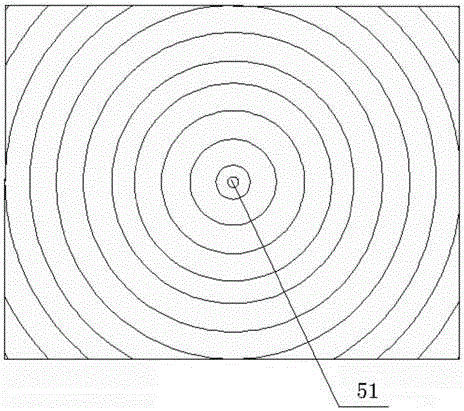

Borderless display device and large-screen splicing display system that eliminates stitching

The invention discloses a frame-free display device and a joint-free large-screen splicing display system, and relates to the technical field of large-screen splicing display. The frame-free display device comprises a display screen with a frame, and the display area of the display screen includes a central area and fringe areas between the central area and the frame. An optical transparent panel covers in front of a central-area watching surface, and eccentric linear Fresnel lenses cover in the front of fringe-area watching surfaces. The Fresnel center line of each eccentric linear Fresnel lens is near to one side of the central area. The eccentric linear Fresnel lenses used for amplifying the fringe areas are arranged in front of the fringe areas of the display screen with the frame, and the amplified fringe areas are larger than or equal to the frame and completely cover the frame, so that the frame of the display device is eliminated visually.

Owner:OCRE TECH CO LTD

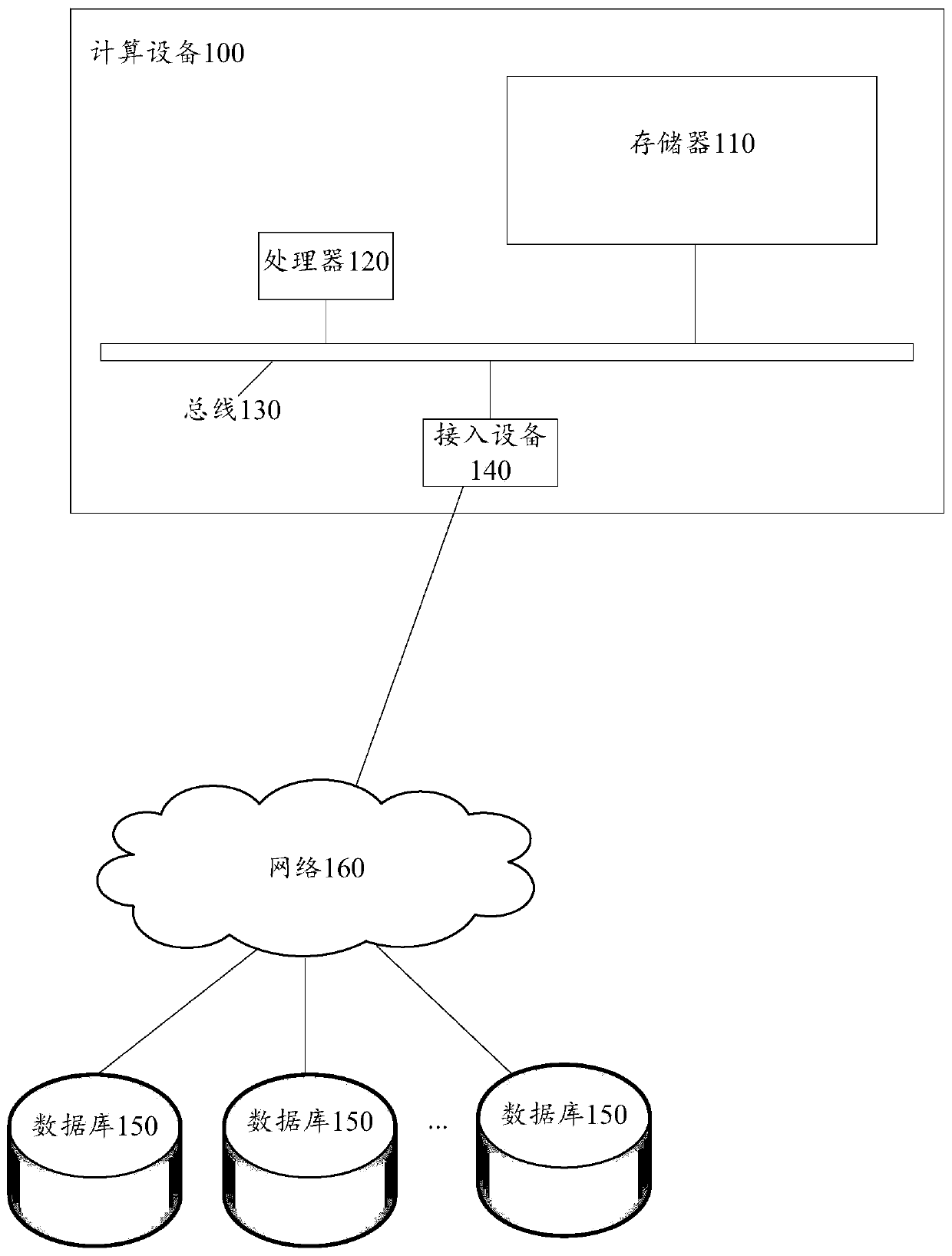

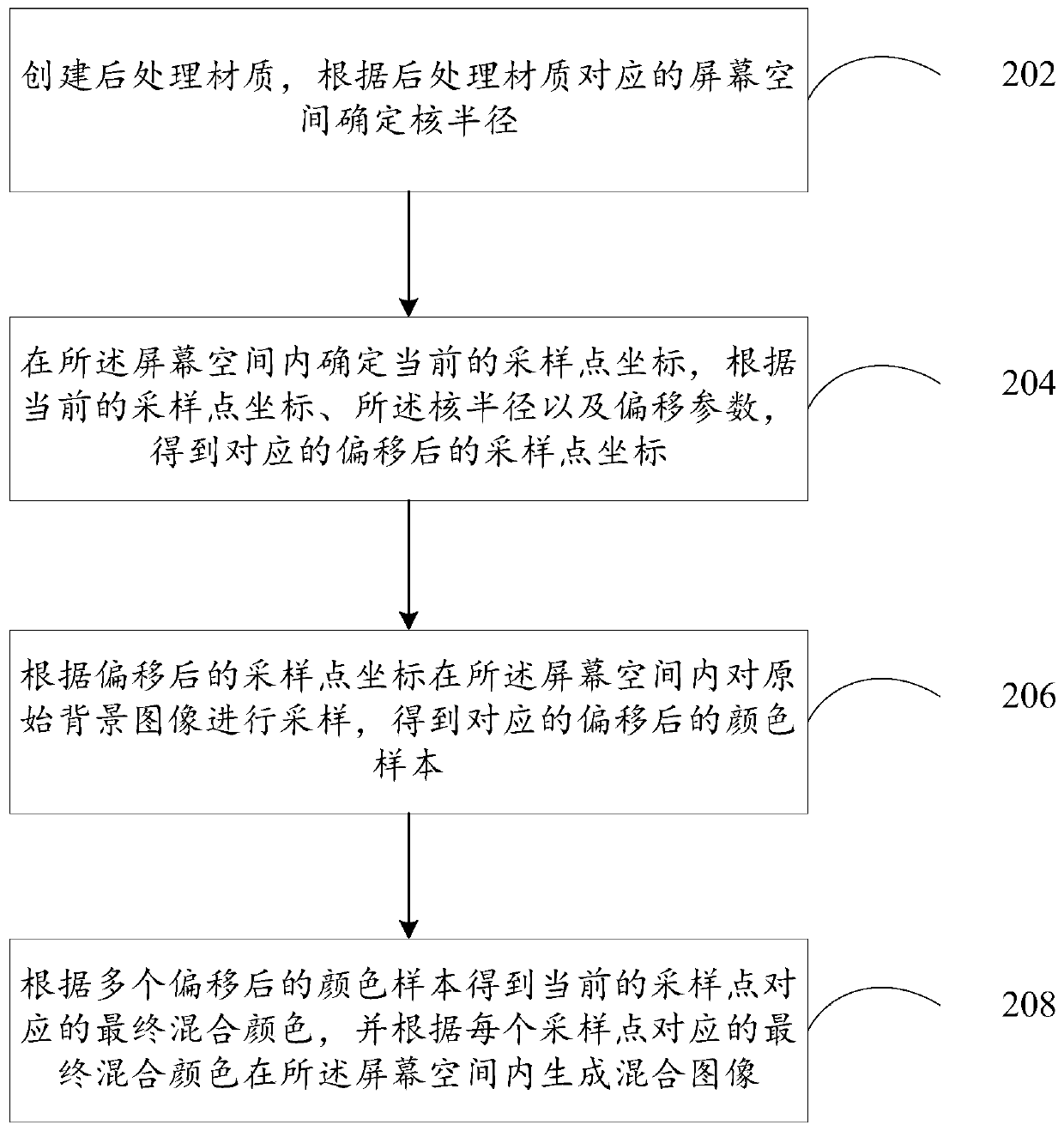

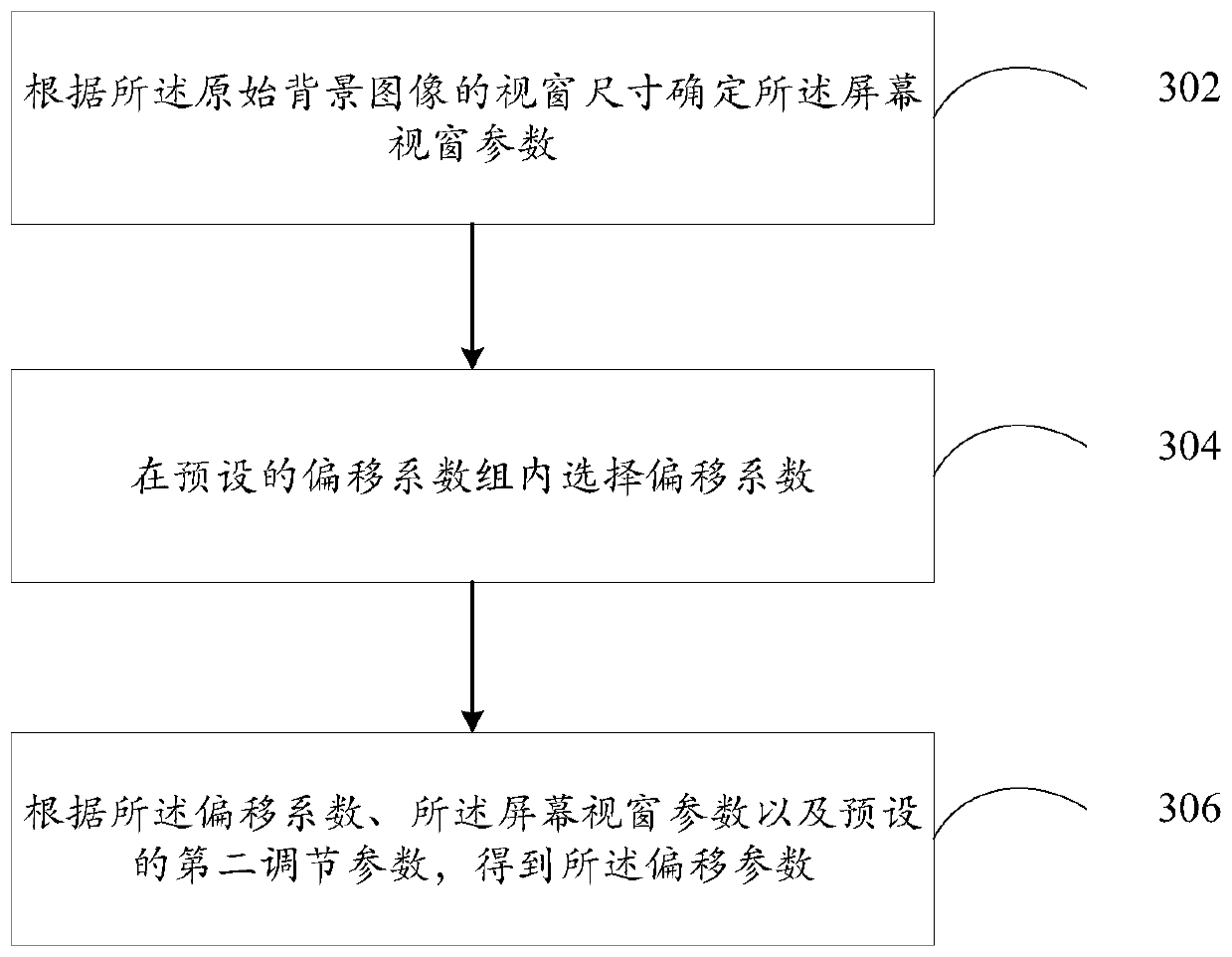

Hybrid image generation method and device

ActiveCN110363733AContinuityRemove borderImage enhancementImage analysisBackground imageScreen space

The invention provides a hybrid image generation method and device, and the method comprises the steps: building a post-processing material, and determining a core radius according to a screen space corresponding to the post-processing material; determining a current sampling point coordinate in the screen space, and obtaining a corresponding deviated sampling point coordinate according to the current sampling point coordinate, the kernel radius and a deviation parameter; sampling the original background image in the screen space according to the deviated sampling point coordinates to obtain acorresponding deviated color sample; and obtaining a final mixed color corresponding to the current sampling point according to the plurality of deviated color samples, and generating a mixed image in the screen space according to the final mixed color corresponding to each sampling point. The final mixed color corresponding to each sampling point is generated by fusing a plurality of shifted color samples, so that the mixed color in the finally generated mixed image has continuity, and an obvious boundary can be eliminated.

Owner:ADVANCED NEW TECH CO LTD

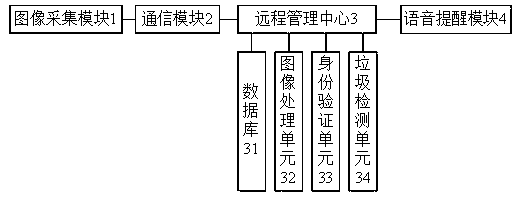

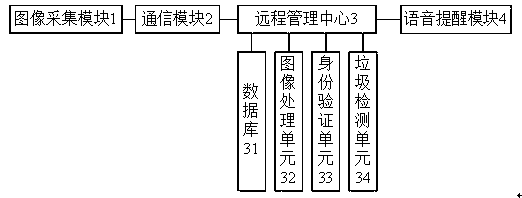

Intelligent management system for garbage classified discharge

ActiveCN110647854ARealize intelligenceImprove the level ofData processing applicationsCharacter and pattern recognitionImaging processingIntelligent management

The invention discloses an intelligent management system for garbage classified discharge. The system comprises an image acquisition module, a communication module, a remote management center and a voice reminding module, wherein the image acquisition module is used for acquiring a facial image of a current garbage throwing person and a thrown garbage image; the acquired images are transmitted toa remote management center through a communication module; the remote management center is used for verifying the identity of the garbage throwing person, judging whether the garbage throwing person throws the garbage into the correct garbage can or not, if yes, rewarding the credits, and if not, reducing the credits and enabling the voice reminding module to remind the garbage throwing person ofthe throwing error. The beneficial effects of the invention are as follows: the invention is suitable for large-scale production; an image processing method is adopted to verify the identity of a garbage throwing person and judge whether garbage is correctly thrown or not, intelligentization of garbage classified discharging management is achieved, an integral system is adopted, the integral of residents is increased or decreased according to whether garbage throwing is correct or not, and the residents are promoted to conduct correct garbage classified throwing.

Owner:华清永安(北京)科技发展有限责任公司

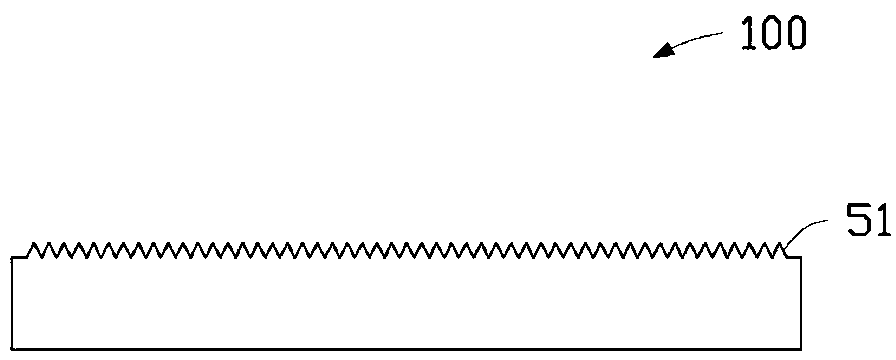

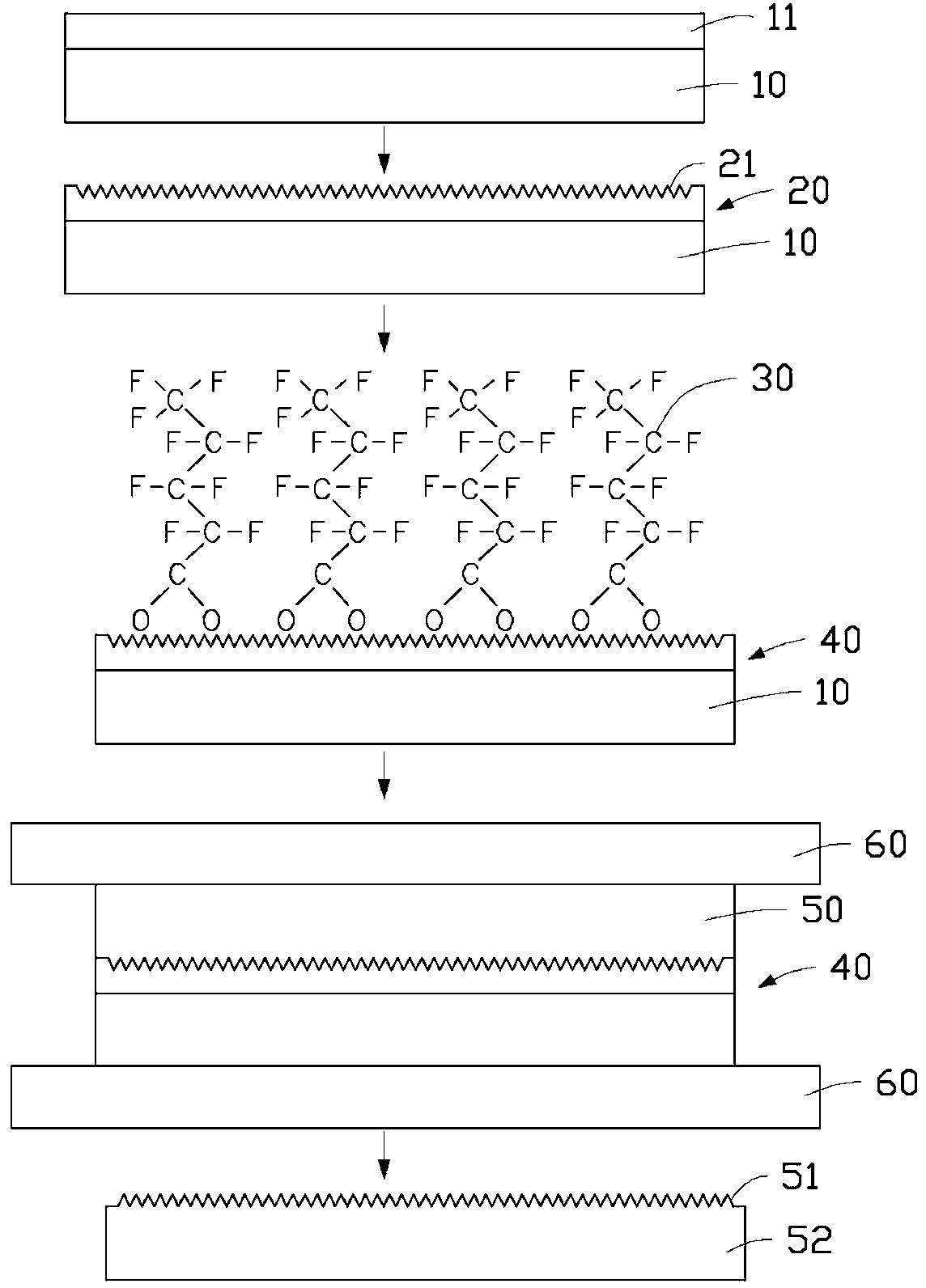

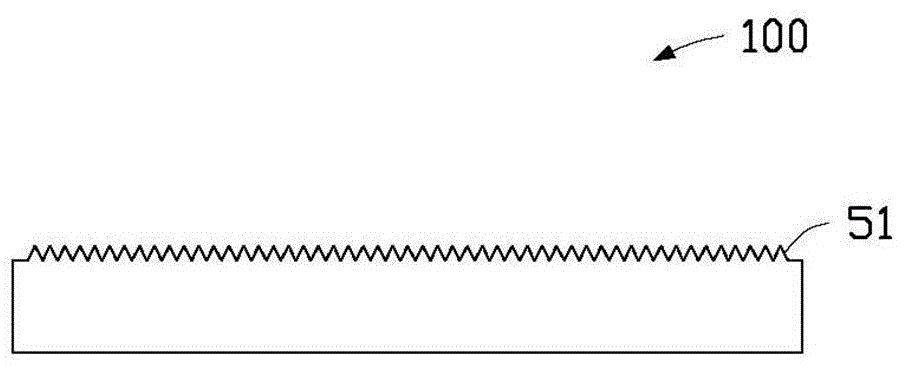

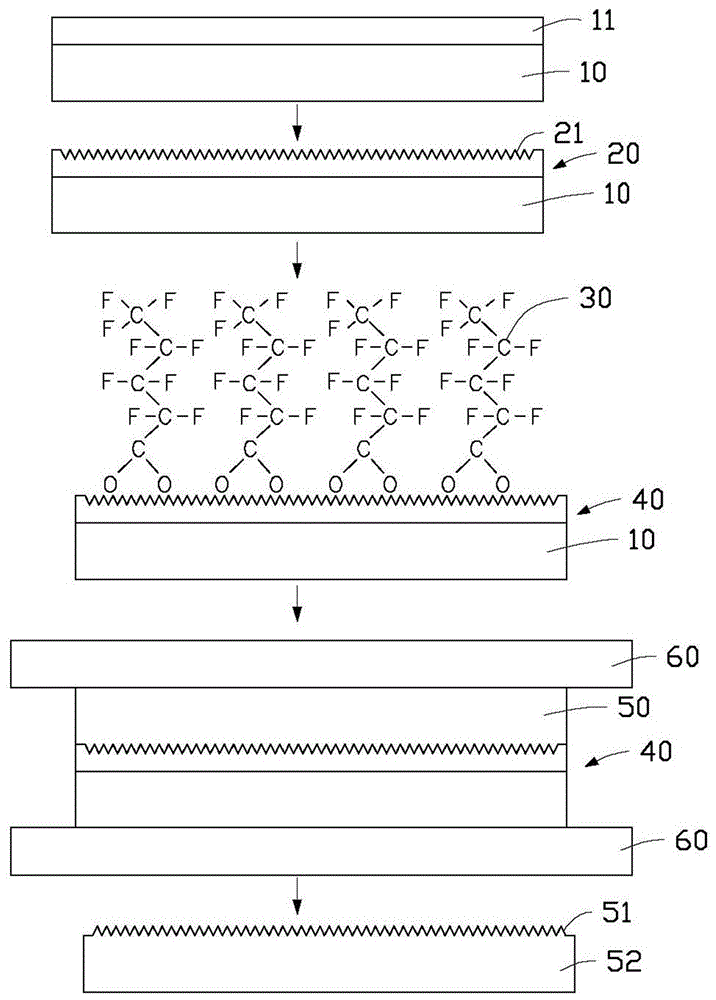

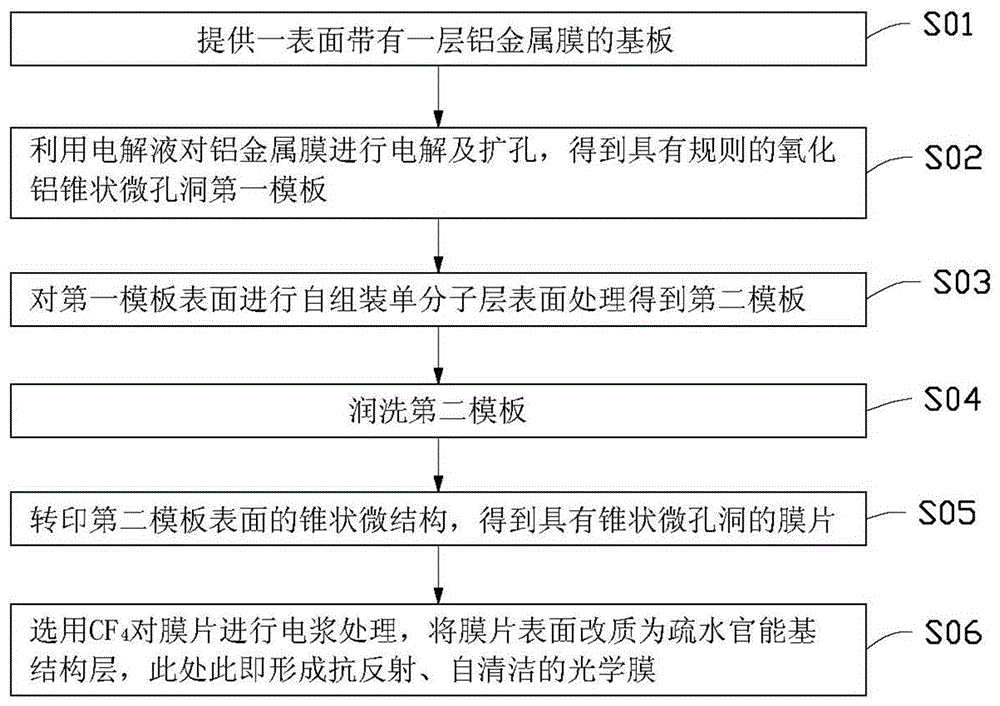

Optical film and manufacturing method thereof

The invention relates to an optical film and a manufacturing method of the optical film. The optical film has an anti-reflection self-cleaning function. The manufacturing method of the optical film comprises the following steps of preparing a secondary wavelength microstructure on the surface of a transparent polymeric film to form an anti-reflection optical surface, modifying the surface of the polymeric film by utilizing CF4 plasma to form a hydrophobic functional group structure; obtaining the optical film with the anti-reflection self-cleaning function. The manufacturing method of the optical film disclosed by the invention has the advantages of simple process, repeatability, low cost and capability of meeting requirements of market on anti-reflection self-cleaning products.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

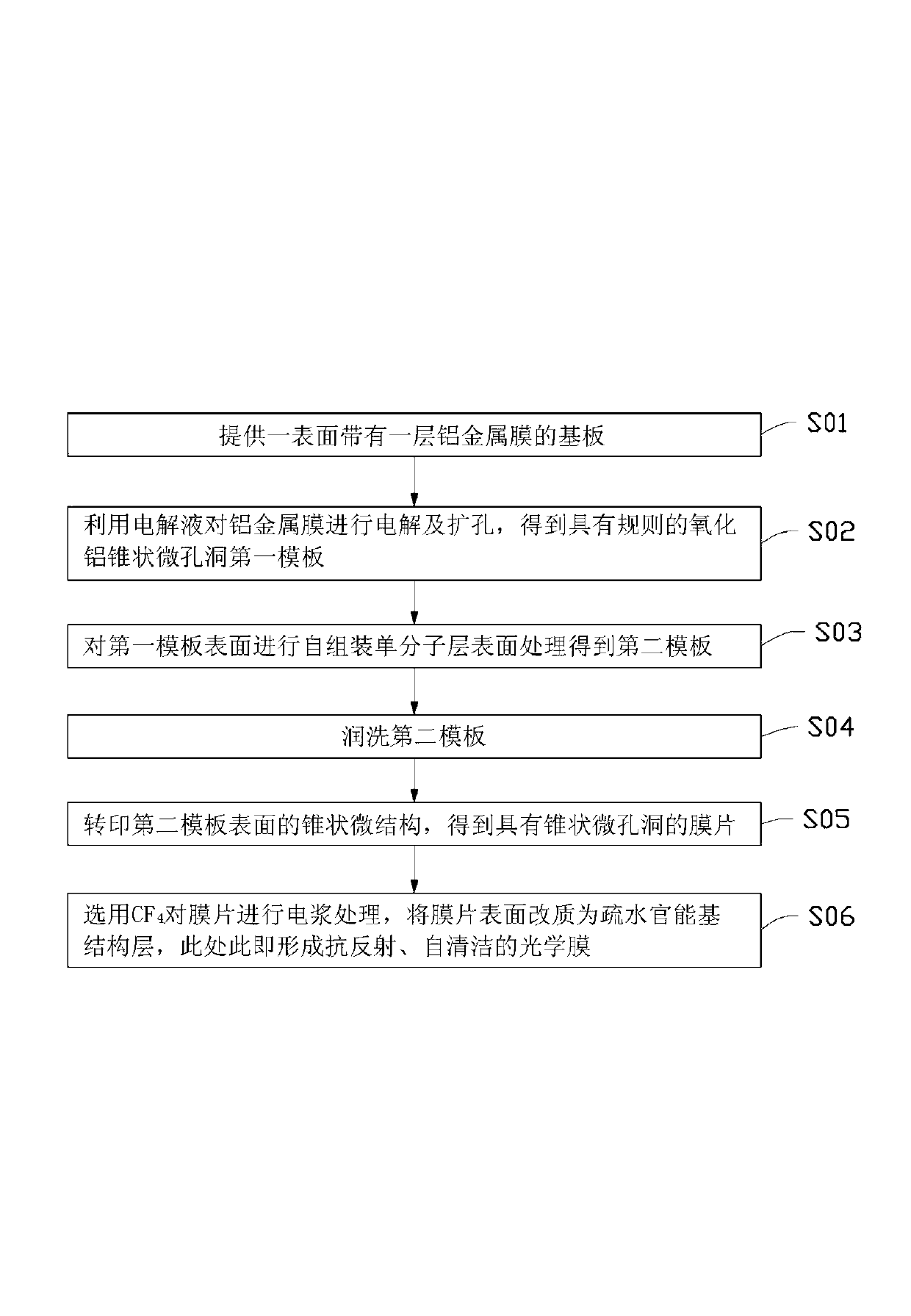

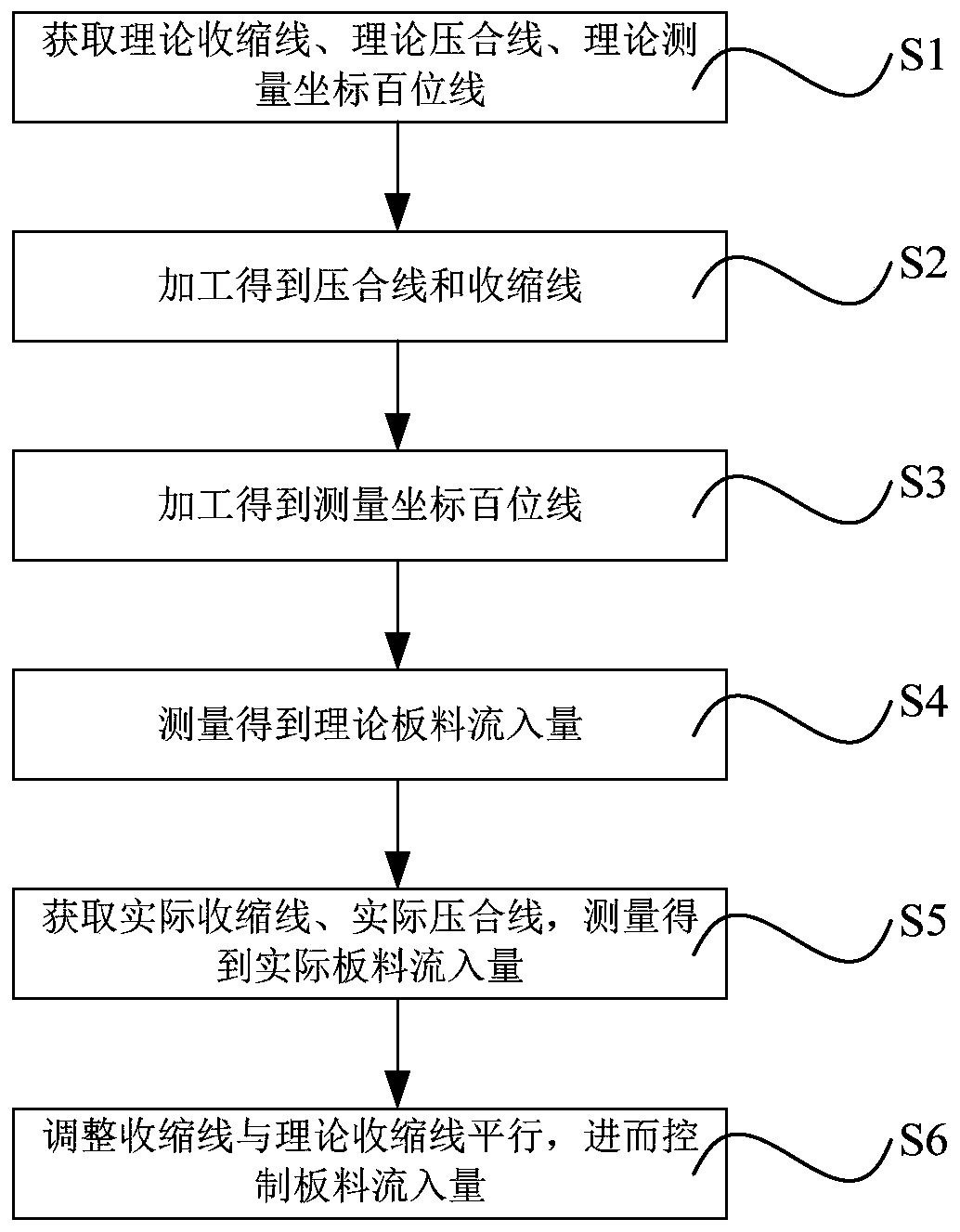

Method for controlling plate inflow volumes for drawing dies for sound-insulation double-layer plates of automobiles

ActiveCN105983608ARemove borderSmall sizeShaping toolsSpecial data processing applicationsTheoretical plateEngineering

The invention provides a method for controlling plate inflow volumes for drawing dies for sound-insulation double-layer plates of automobiles. The method includes steps of acquiring theoretical shrinkage lines, theoretical press-fit lines and theoretical measurement coordinate hundred-bit lines; acquiring press-fit lines and shrinkage lines and measuring coordinate hundred-bit lines; measuring the distances from the press-fit lines to the shrinkage lines corresponding to points of each measurement coordinate hundred-bit line to obtain theoretical plate inflow volumes of the points; acquiring actual shrinkage lines and actual press-fit lines and measuring actual plate inflow volumes; adjusting angles R of drawing ribs and drawing grooves. The angles R of the drawing ribs and the drawing grooves are adjusted, so that the actual shrinkage lines can be parallel to the theoretical shrinkage lines, the difference between numerical values of the actual plate inflow volumes of the various points on the measurement coordinate hundred-bit lines and numerical values of the theoretical plate inflow volumes can be guaranteed against being higher than 3%. The method has the advantages that theoretical analysis results can be clearly and accurately reflected into the actual dies and accurately and clearly contrast with actual component debugging plate shrinkage, and accordingly plate boundary forming and component resilience sizes can be controlled.

Owner:上海赛科利汽车模具技术应用有限公司

A method for preparing nickel-based powder superalloy by spark plasma sintering

ActiveCN105397085BRapid sinteringFine equiaxed grain structureIncreasing energy efficiencyCarbideBiological activation

The invention discloses a method for preparing nickel-based powder superalloy through spark plasma sintering, and belongs to the field of powder metallurgy materials. The spark plasma sintering process is adopted for sintering forming of atomized nickel-based superalloy powder, and then solid solution treatment and aging treatment are carried out to obtain the nickel-based powder superalloy. The spark plasma sintering process is adopted for preparing the nickel-based powder superalloy, rapid sintering forming of the powder is achieved, growth of grains can be effectively restrained, and the prepared superalloy is provided with the fine and uniform equiaxial structure; through powder surface discharge activation and rapid diffusion bonding, formation of complex carbides and oxides on the boundaries of powder particles is restrained, and original particle boundaries are eliminated; the method is simple in process route, preparation time is short, the second phase is small in size and uniform in distribution, and the mechanical property is good.

Owner:CENT SOUTH UNIV

Capacitive touch screen and terminal

ActiveCN102707856BReduce widthRemove borderDigital data processing detailsInput/output processes for data processingEngineeringTouchscreen

Owner:HONOR DEVICE CO LTD

Optical film and its preparation method

InactiveCN103308960BMeet needsContinuously changing refractive indexCoatingsOptical elementsOptical thin filmLength wave

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

An intelligent management system for waste sorting and discharge

ActiveCN110647854BRealize intelligenceImprove the level ofData processing applicationsCharacter and pattern recognitionImaging processingIntelligent management

An intelligent management system for waste sorting and discharge, comprising an image acquisition module, a communication module, a remote management center and a voice reminder module, the image acquisition module is used to collect the facial images of the current garbage throwers and the images of the garbage thrown, and the collected The image is transmitted to the remote management center through the communication module, and the remote management center is used to verify the identity of the garbage thrower, and judge whether the garbage thrower puts the garbage into the correct garbage bin. If the delivery is wrong, the points will be reduced, and the voice reminder module will be reminded of the delivery error. The beneficial effects of the present invention are: using the image processing method to verify the identity of the garbage dumper and judging whether the garbage is put in correctly, realizing the intelligent management of garbage sorting and discharge, adopting the point system, according to whether the garbage is put in correctly or not Points are increased or decreased to promote residents to correctly sort garbage.

Owner:华清永安(北京)科技发展有限责任公司

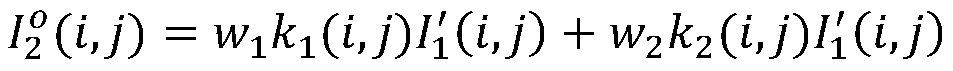

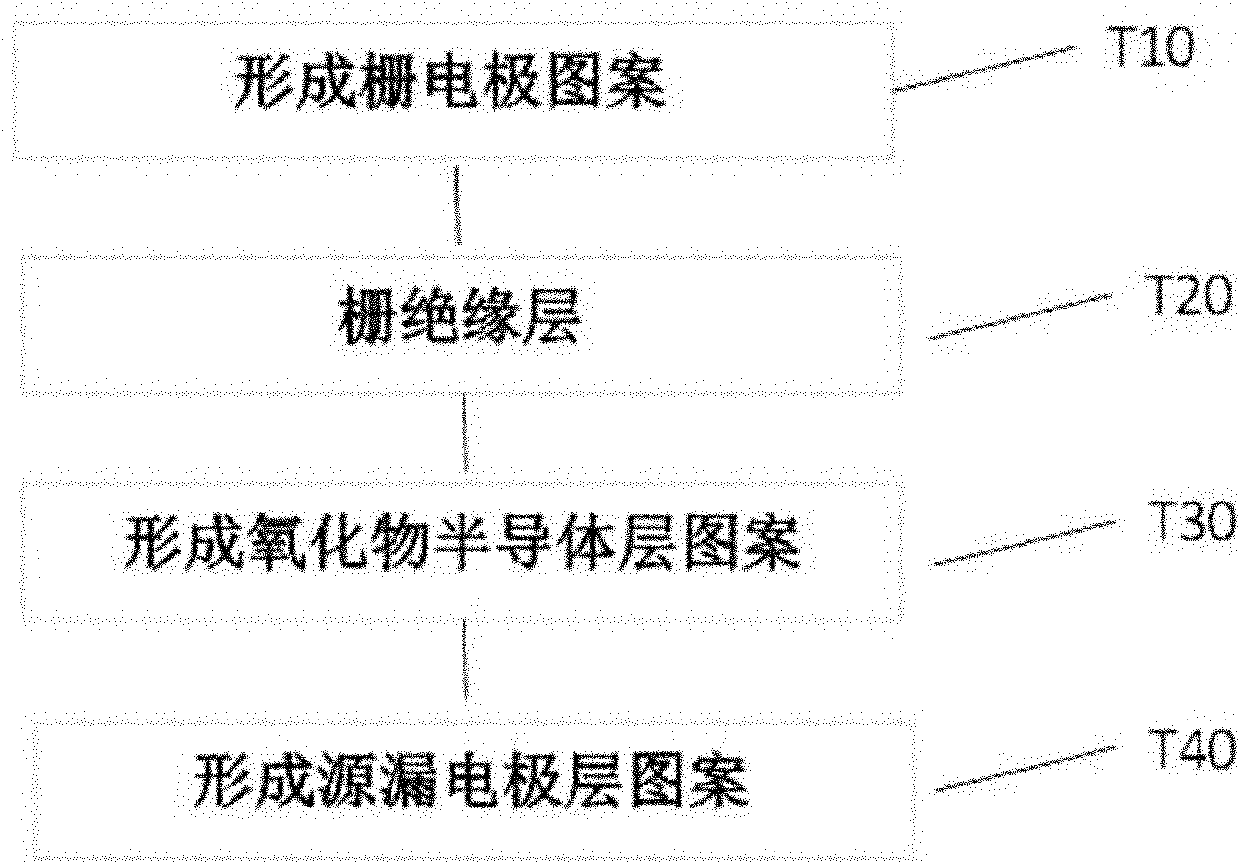

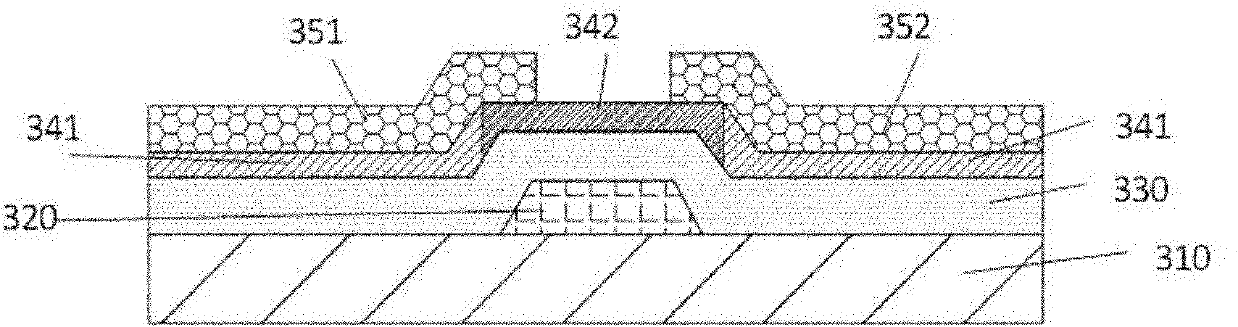

Method for manufacturing bottom gate metal oxide thin film transistor

ActiveCN102157562BRemove borderReduce stress concentrationTransistorSemiconductor/solid-state device manufacturingResistBottom gate

The invention relates to a method for manufacturing a bottom gate metal oxide thin film transistor in the technical field of semiconductor manufacturing. The method comprises the following steps: sequentially manufacturing a gate electrode and a metal oxide material; then coating an optical resist on the surface of the metal oxide material and the optical resist, and carrying out planarization treatment on the optical resist by adopting chemical machinery polishing; carrying out annealing treatment or plasma treatment on the metal oxide which is not masked by the optical resist; and finally stripping the optical resist, then carrying out magnetron sputtering and deposition on the source electrode and the drain electrode materials, and forming the source electrode and the drain electrode through photoetching and wet process etching. According to the invention, the characteristic that the metal oxide material can be converted from an insulator into a semiconductor after special treatment is utilized, the metal oxide thin film transistor with an active layer of a special structure is manufactured, and the occurrence of the crack phenomenon of the source electrode and the drain electrode can be prevented effectively.

Owner:广东芯聚能半导体有限公司

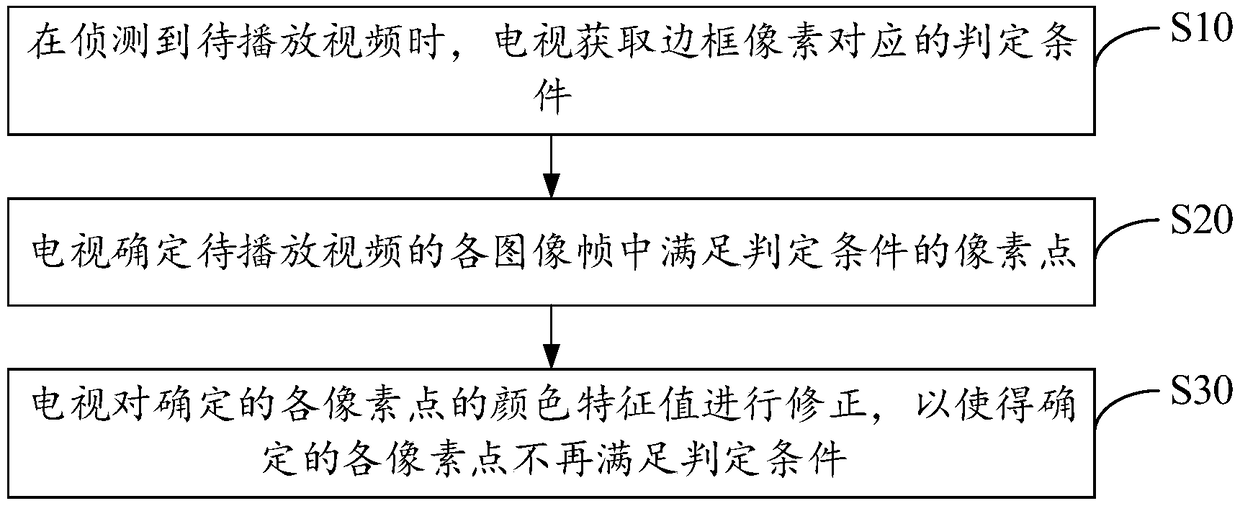

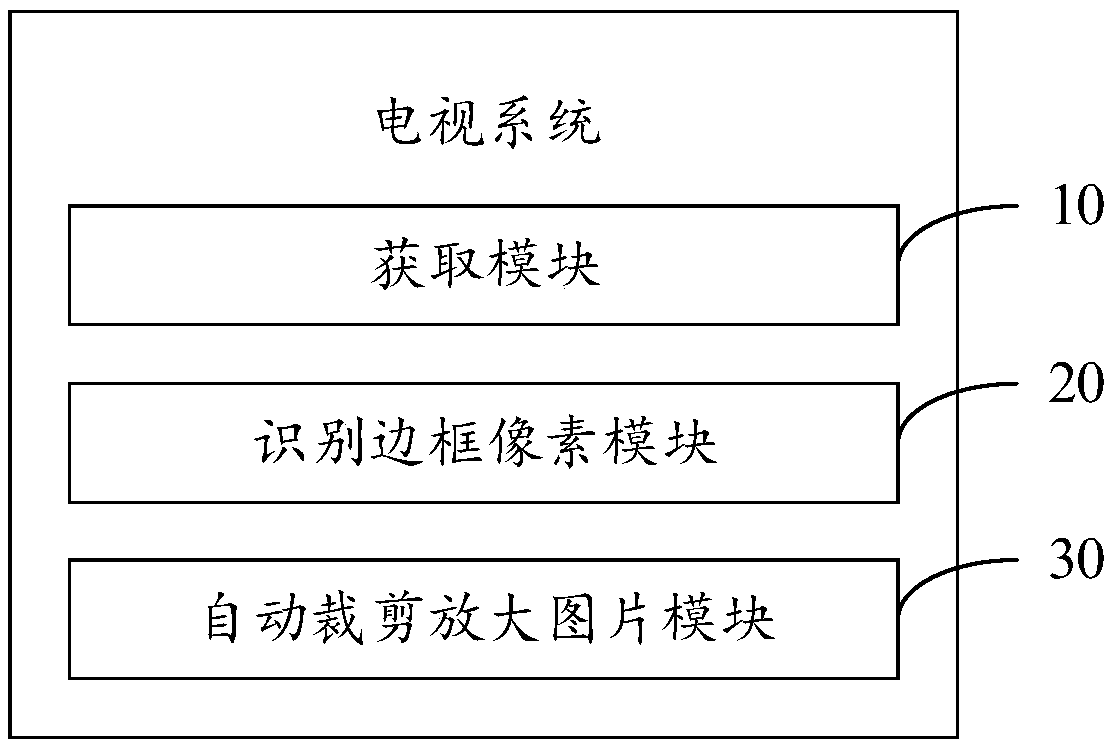

Video processing method and TV system

ActiveCN106231278BImprove playbackRemove borderColor signal processing circuitsTelevision systemComputer graphics (images)

The invention discloses a video processing method. The video processing method comprises the following steps: when a video to be played is detected, a television obtains a judging condition corresponding to border pixels; the television determines pixel points satisfying the judging condition in various image frames of the video to be played; the television corrects colour characteristic values of various determined pixel points, so that the various determined pixel points do not satisfy the judging condition, wherein the judging condition comprises: the difference value of the pixel point and a pre-set colour component value of another pixel point symmetrical to the centre of the line, where the pixel point is, is in a pre-set difference value period. The invention further discloses a television system. By means of the video processing method and the television system disclosed by the invention, the video playing effect of the television can be improved.

Owner:SHENZHEN TCL DIGITAL TECH CO LTD

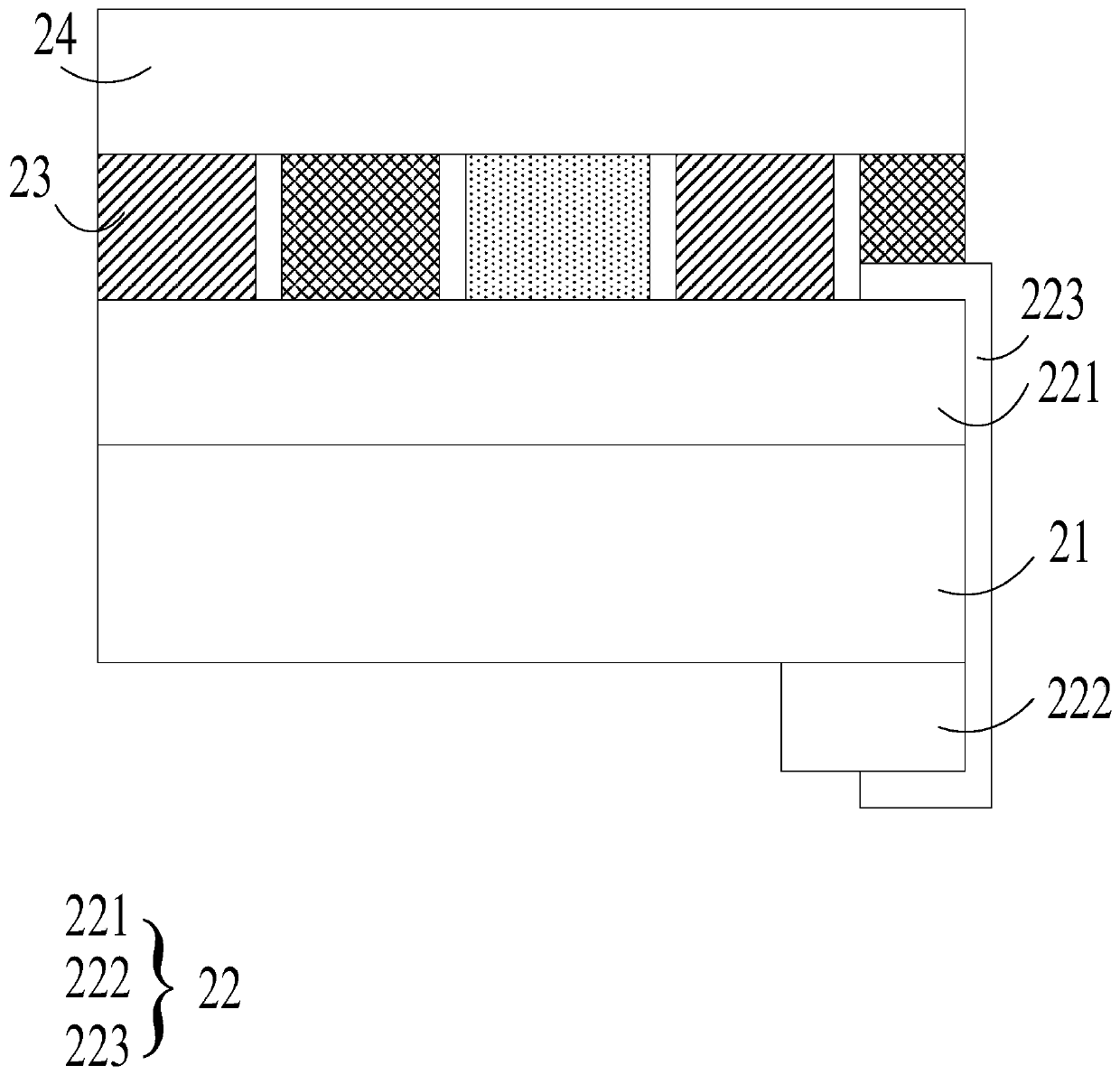

Process for producing flexible OLED screens and flexible OLED screens

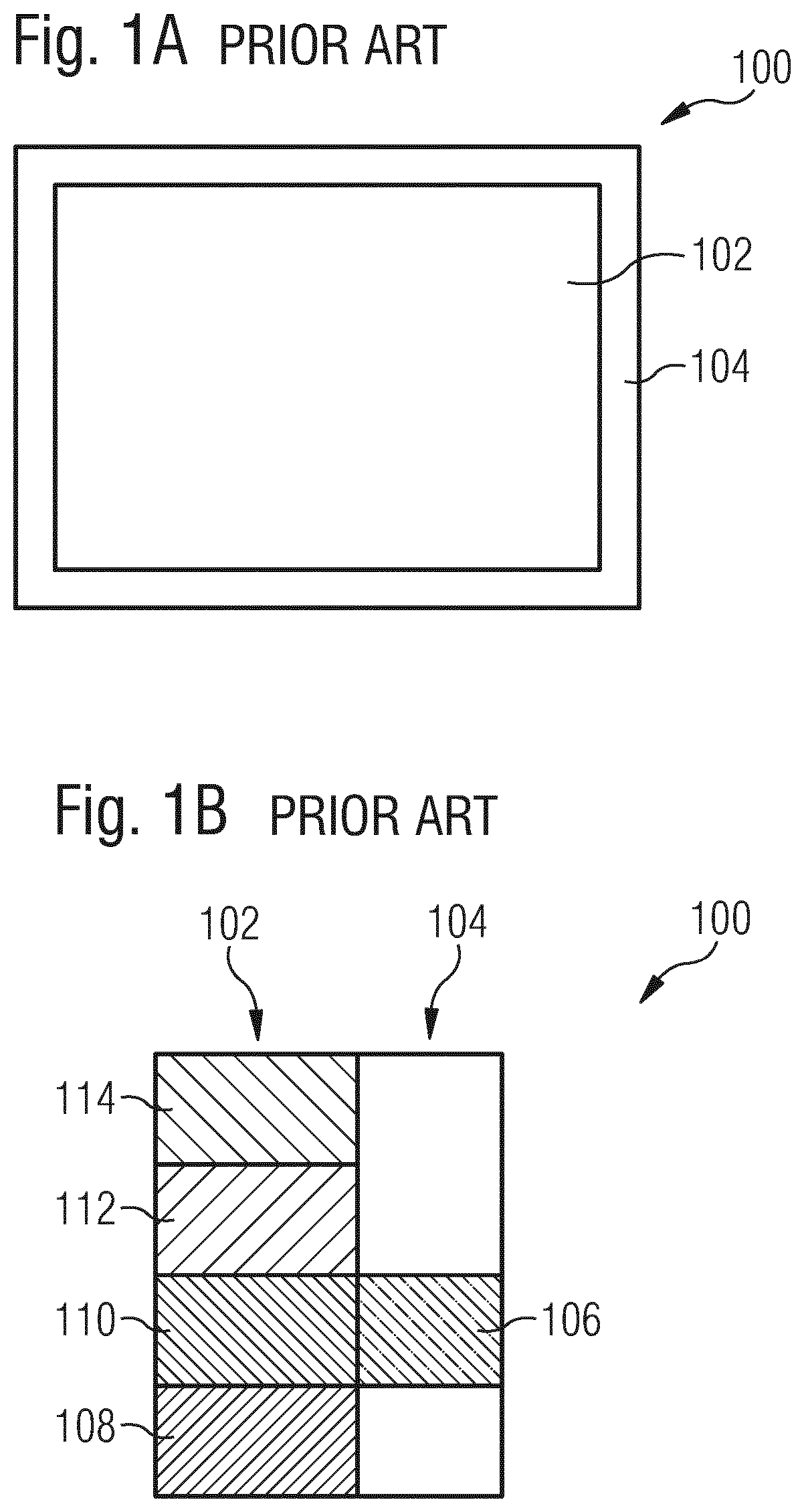

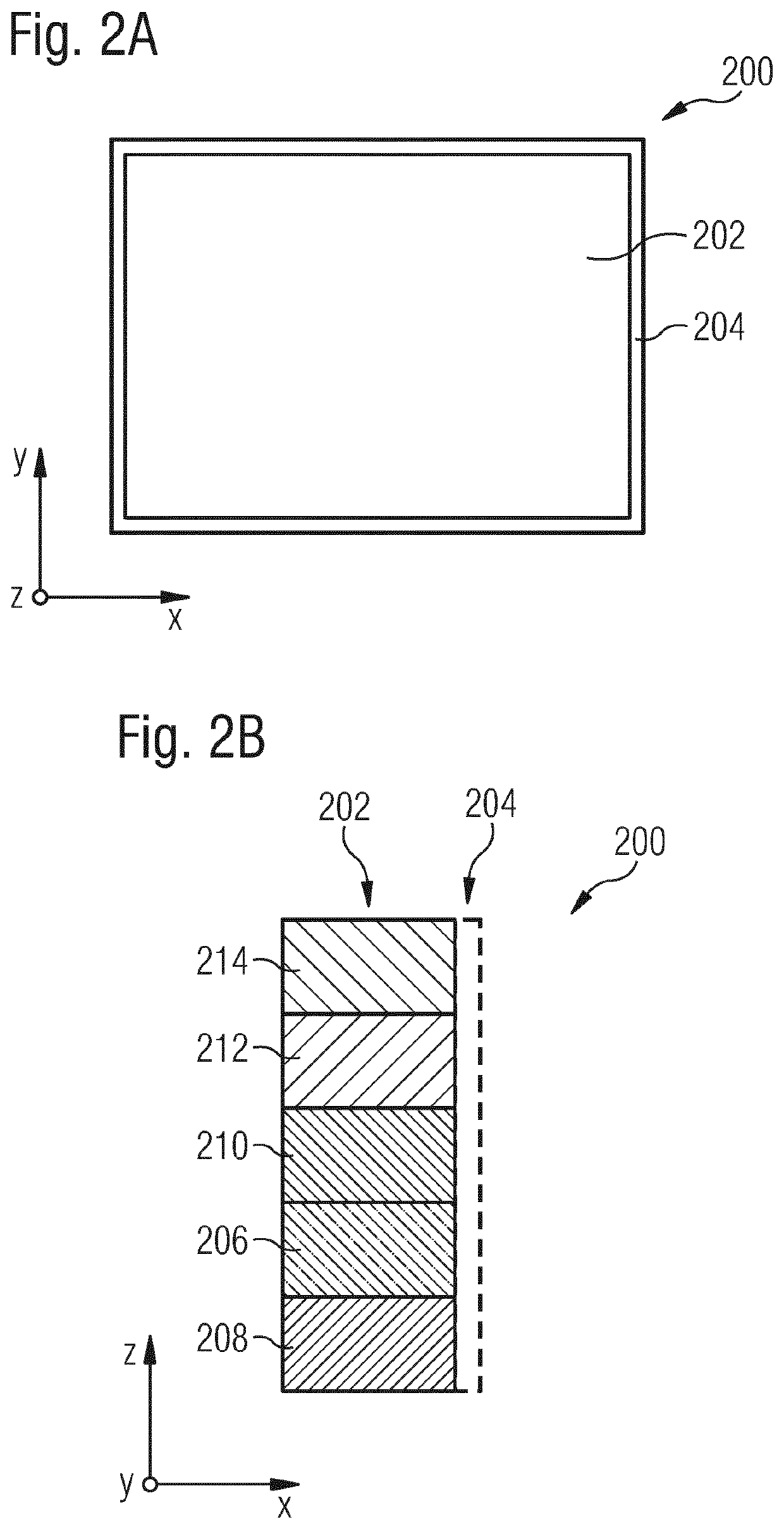

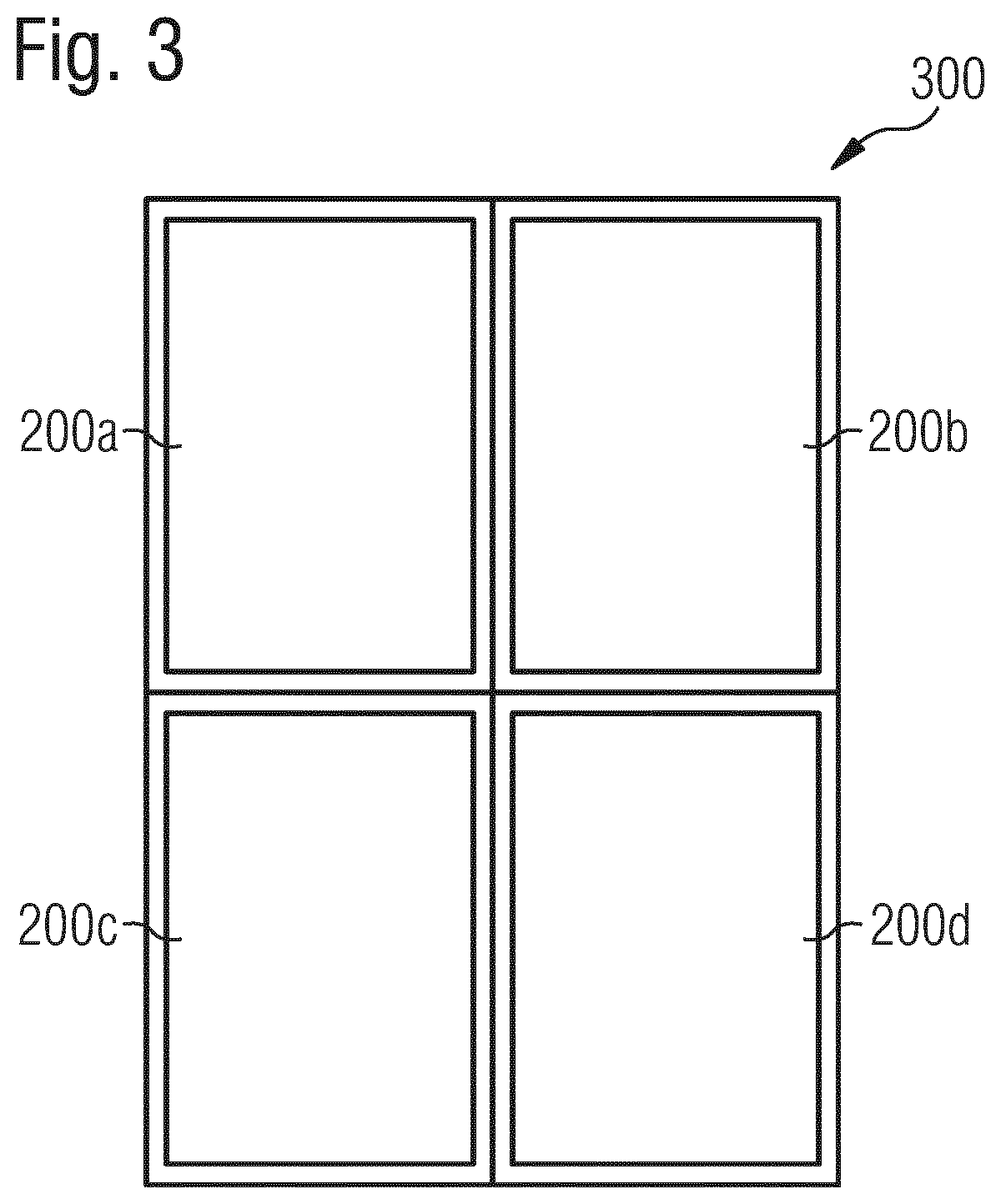

PendingUS20220320476A1Remove borderSmall bezelSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceHemt circuits

Processes for producing an OLED screen with a reduced, minimized, or eliminated bezel section surrounding the display are. The circuitry (206) of the display screen is moved to beneath the OLED (212) and transistor layers (210). The screens with the reduced sized may be installed in an aircraft, and, two or more of the OLED screens with reduced sized may be positioned adjacent to each other so as to form an array.

Owner:AIRBUS OPERATIONS GMBH

Ping-pong Ball Recognition Method Based on Hough Circle Transform Technology

ActiveCN110866903BRemove borderImprove accuracyImage enhancementImage analysisPattern recognitionComputer graphics (images)

The invention discloses a table tennis ball recognition method based on the Hough circle transform technology, which uses the gradient Hough transform method to improve the recognition speed. The method includes the following steps: 1) image grayscale processing; 2) filtering processing; 3) edge extraction; 4) table tennis marking; 5) special processing for table tennis recognition and setting of related parameters. Compared with the prior art, the present invention can realize real-time identification of the table tennis balls contained in each frame of pictures for the pictures read in by the camera, and can accurately identify the table tennis balls in complex situations.

Owner:BEIJING UNIV OF TECH

A multi-factor coordinated energy-saving optimization control method for greenhouse environment

ActiveCN107045367BReduce energy consumptionGuaranteed accumulated temperature requirementsSimultaneous control of multiple variablesEnvironmental factorCrop

The invention relates to a multi-factor coordinated energy-saving optimization control method of a greenhouse environment. The method comprises: (1), an expected daily average temperature of the crop in each growth period is set and weather forecast data of next seven days are obtained; (2), a greenhouse ventilation system state is estimated; (3), setting values of all environmental factors in the greenhouse are set by using a multi-factor coordination algorithm according to the steps (1) and (2), wherein the environmental factors include a temperature, humidity, a light radiation intensity and carbon dioxide concentration; and (4), real-time environmental factor values are obtained and corresponding executing mechanisms in the greenhouse are regulated according to the environmental factor setting values. Compared with the prior art, on the basis of crop physiological properties like temperature accumulation, the energy consumption of the greenhouse can be reduced effectively. With corresponding strategies, secondary greenhouse environment factors are coordinated to main temperature factors equivalently, thereby guaranteeing the precision and efficiency of greenhouse regulation, avoiding unnecessary energy wasting, saving the regulation cost, and ensuring the precise and effective controlling.

Owner:TONGJI UNIV

Control method of sheet material inflow in drawing die of automobile sound-proof double-layer sheet

ActiveCN105983608BRemove borderSmall sizeShaping toolsSpecial data processing applicationsTheoretical plateMeasurement point

The invention provides a method for controlling the inflow of sheet material into a drawing die of a sound-insulating double-layer sheet for an automobile, comprising the following steps: obtaining a theoretical shrinkage line, a theoretical lamination line, and a hundredth line of theoretical measurement coordinates; obtaining the lamination line and the shrinkage line , measure the coordinate hundred line; measure the distance between the press line and the shrinkage line corresponding to each point of the measurement coordinate hundred line, and obtain the theoretical sheet material inflow at this point; obtain the actual shrinkage line and the actual press line, Measure the actual sheet inflow; adjust the R angle of the drawbead and the drawing groove so that the actual shrinkage line is parallel to the theoretical shrinkage line, and ensure that the actual sheet inflow value and the theoretical sheet inflow value of each point on the measurement coordinate hundred-digit line The difference does not exceed 3%. The invention clearly and accurately reflects the theoretical analysis results into the actual mold, and forms an accurate and clear comparison with the shrinkage amount of the adjusted sheet metal of the actual parts, thereby controlling the boundary forming of the sheet material and the rebound size of the parts.

Owner:上海赛科利汽车模具技术应用有限公司

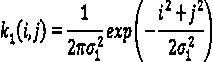

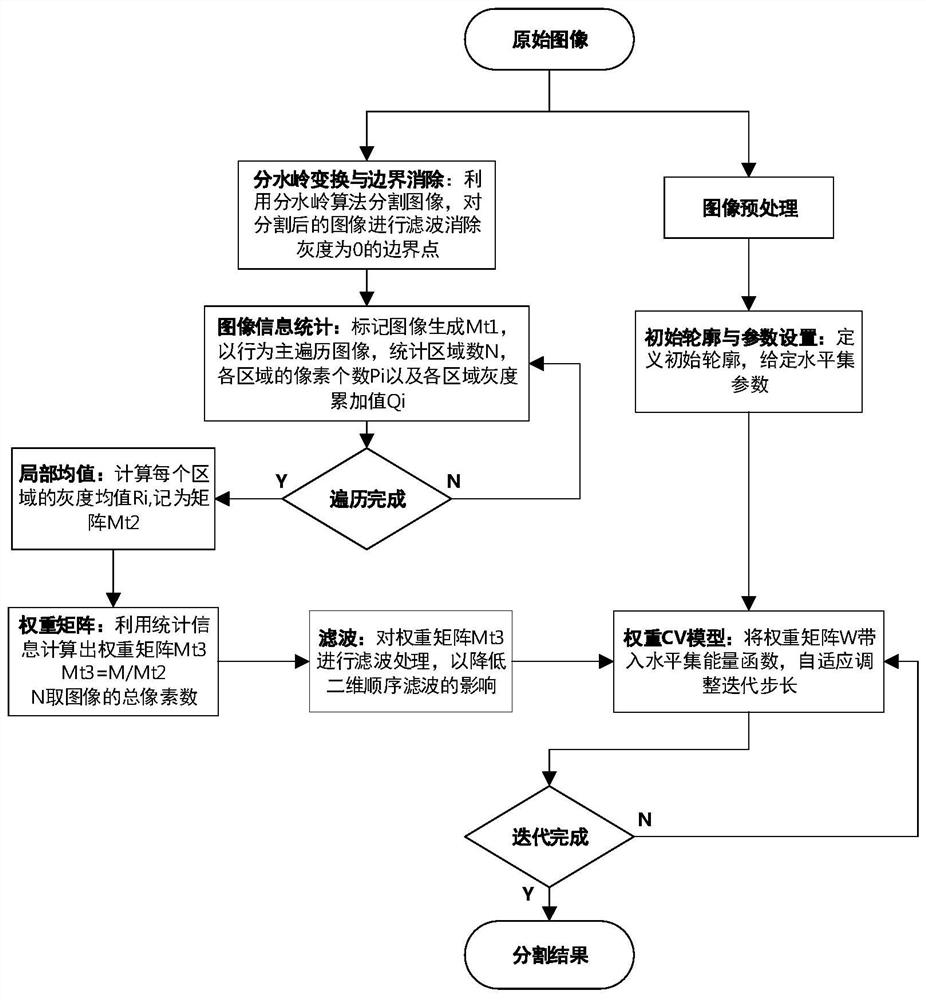

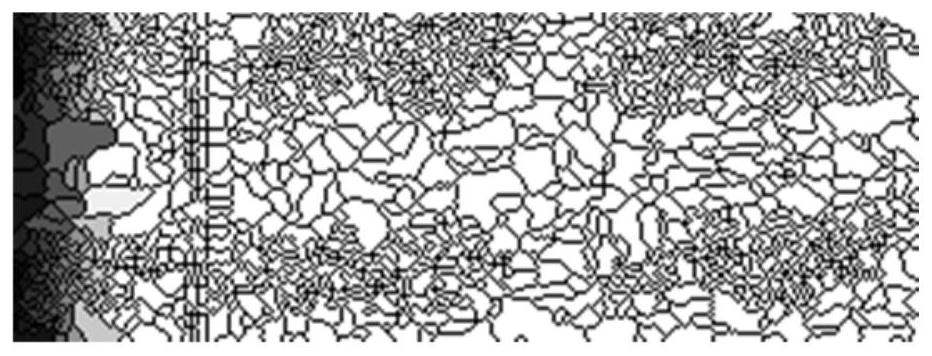

Ultrasonic phased array ndt image segmentation method based on watershed and cv model

ActiveCN108648199BImprove segmentation efficiencyImprove Segmentation AccuracyImage enhancementImage analysisPattern recognitionEngineering

The invention relates to an ultrasonic phased array NDT image segmentation method based on a watershed and a CV model. The method includes: performing watershed transformation on an image to be segmented based on a watershed algorithm, obtaining a watershed image, counting pixel information of the watershed image, and obtaining a weight matrix Perform filtering and denoising processing on the image to be segmented to obtain a pre-processed image, and set the initial parameters of the CV model based on the pre-processed image; Introduce the weight matrix into the CV model to establish a weight CV model; Based on the weight CV The model performs level set function iteration to obtain the final segmentation result. Compared with the prior art, the present invention has the advantages of high segmentation efficiency and high segmentation accuracy of the ultrasonic phased array NDT image.

Owner:SHANGHAI UNIV OF ENG SCI

Constructing method of shaped field source based on metal scatterers

InactiveCN104809282BEliminate side lobesRemove borderSpecial data processing applicationsComposite mediaSide lobe

The invention provides a method for constructing a shaped field source based on the assistance of a metal scatterer, and belongs to the technical field of electromagnetic wave space propagation and control. Different from using a simple spatially discrete array to construct a shaped field source, in order to sharpen the edge field of the shaped field and reduce the problem of too many and too high side lobes outside the region, the present invention based on the random phase of the electromagnetic scattered wave in the complex medium space Based on the elimination principle, a method for constructing a shaped field source is proposed by adding a simple metal scatterer around the spatially discrete array or outside the shaped field area. This method can not only sharpen the geometric boundary of the shaped field, but also effectively solve the sidelobe problem outside the shaped field area. Difficulty in constructing high-quality shaped field sources.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com