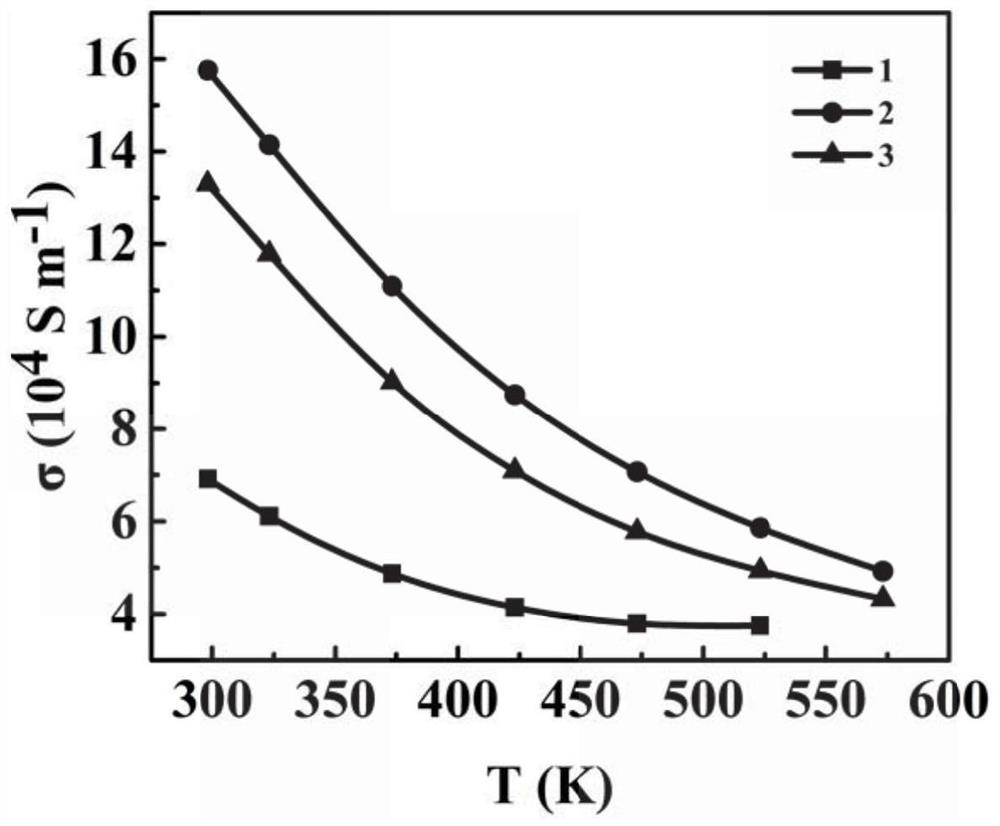

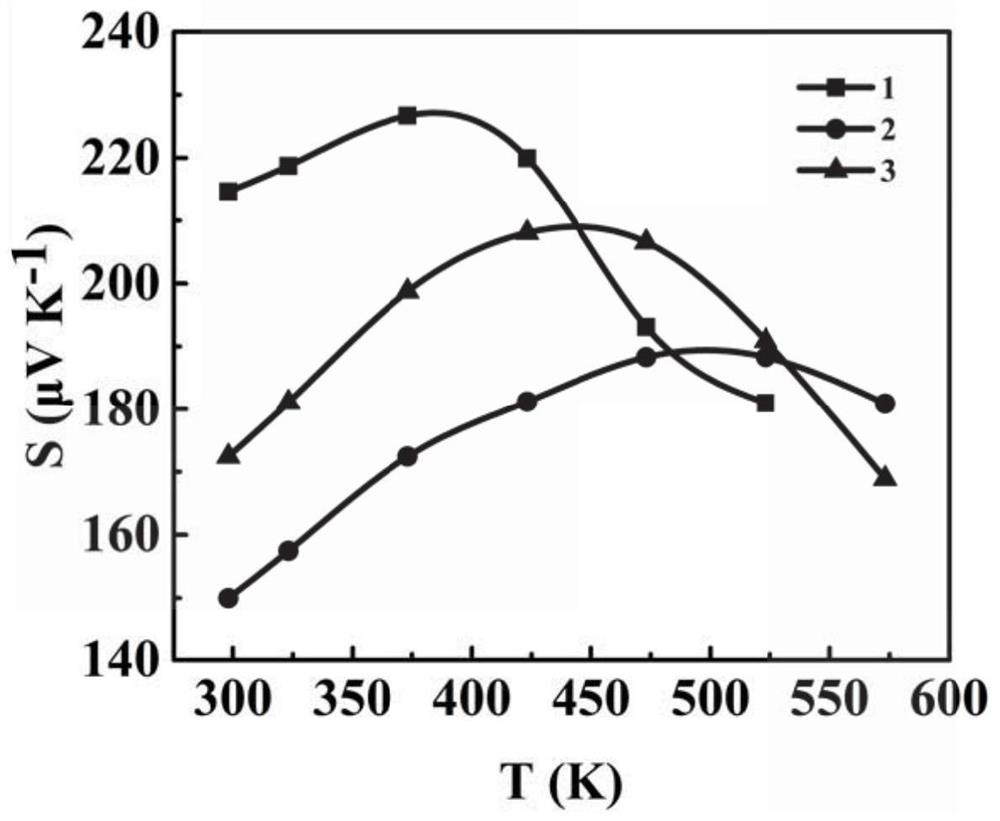

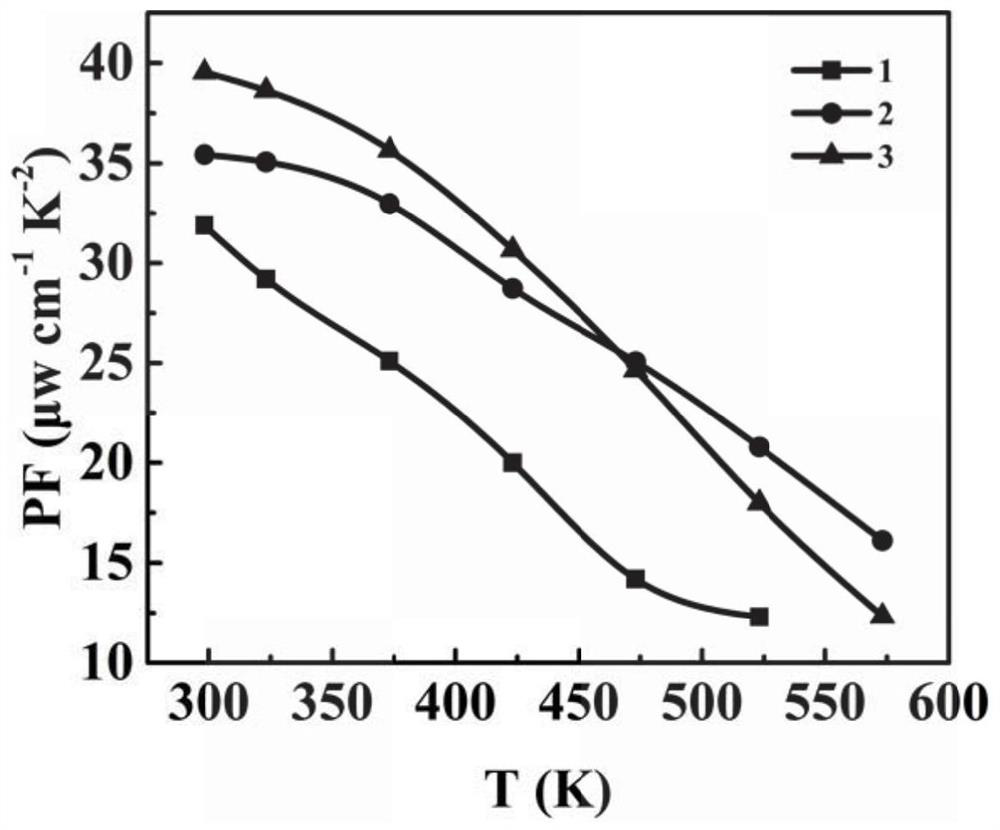

High-performance BiTe-based composite thermoelectric material and preparation method thereof

A composite material, thermoelectric technology, applied in the direction of thermoelectric device node lead-out materials, chemical instruments and methods, energy input, etc., can solve the problems of poor material repeatability, unstable material performance, complex preparation process, etc. , the effect of conductivity improvement, high thermoelectric figure of merit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] P-Bi 0.5 Sb 1.5 Te 3 The preparation method comprises the steps of:

[0048] 1) Ball milling and mixing: according to the general formula Bi x Sb 2-x Te 3-y Se y m z According to x=0.5, y=0, z=0, weigh the elemental powder of Bi, Sb, Te, Se, I, Br, Cu, Ag, Cd, Y, Yb, the total mass is 10g, and then put it into the ball mill jar Inside, filled with argon protection, under the condition of 260rpm, ball milled for 4h, then under the condition of 550rpm, ball milled for 12h.

[0049] 2) Cold pressing: Take it out under the protection of Ar gas, and then use a cold pressing machine to perform a cold pressing under the condition of 260MPa to form an alloy block for 2 hours.

[0050] 3) Solid sintering: Add a layer of carbon paper in the mold, then put the block material obtained by cold pressing directly into a graphite mold with an inner diameter of 12.7 mm, put it into an SPS device, and pressurize both ends of the mold, the pressure is 50MPa, vacuumize to 5Pa, the...

Embodiment 2

[0052] P type (Bi 0.5 Sb 1.5 Te 3 )Cu 0.005 A method for preparing a thermoelectric composite material, comprising the steps of

[0053] 1) Doping and mixing: Cu powder is doped into the Bi of Example 1 0.5 Sb 1.5 Te 3 Among them, according to the general formula (Bi 0.5 Sb 1.5 Te 3 )Cu n Weigh with n=0.005, and the total mass is 10g, then put it into a ball mill jar, fill it with argon protection, ball mill at 260rpm for 4h, and then at 550rpm for 12h.

[0054] 2) The remaining steps are the same as Step 2 and Step 3 of Embodiment 1.

Embodiment 3

[0056] P type (Bi 0.5 Sb 1.5 Te 3 ) (AgSbTe 2 )n (n=0.004) the preparation method of thermoelectric composite material, comprises the steps:

[0057] 1) Ball milling: first according to the general formula AgSbTe 2 The molar ratio of Ag, Sb, Te elemental powder was weighed, the total mass was 10g, and then put into a ball mill jar, filled with argon protection, ball milled at 260rpm for 4h, and then at 550rpm for 12h.

[0058] 2) Doping and mixing: the AgSbTe obtained in step 1 2 Powder is doped to embodiment one Bi 0.5 Sb 1.5 Te 3 In powder, according to the general formula (Bi 0.5 Sb 1.5 Te 3 ) (AgSbTe 2 )n in n = 0.004 to weigh, the total mass is 10g, then put into the ball mill jar, filled with argon protection, at 260rpm, ball mill for 4h, then at 550rpm, ball mill for 12h.

[0059] 3) The remaining steps are the same as Step 2 and Step 3 of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com